Induction Sealing Machine: The Complete Buying Guide in 2024

Induction Sealing Machine: The Complete Buying Guide in 2024

Sealing of multiple bottles and vials through a contactless process is becoming more convenient these days for production security and safety.

And to perform this kind of task, Induction sealing machine is used which is a modern equipment with latest technology installed inside for proper working.

So, to learn and explore more about how induction sealing machine is becoming popular across different industries and also how beneficial it is for your business line along with its working procedure you have to read this helpful guide.

1.What is induction sealing machine?

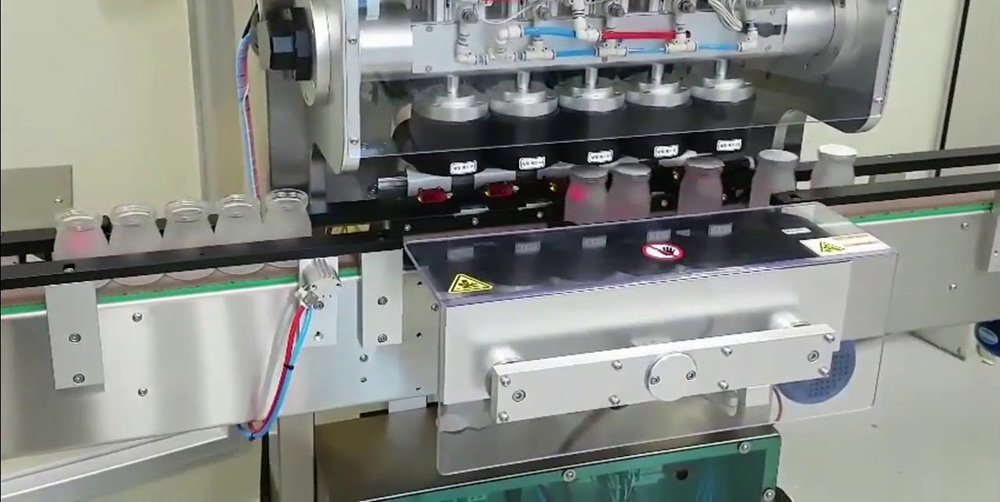

Induction Sealing Machine

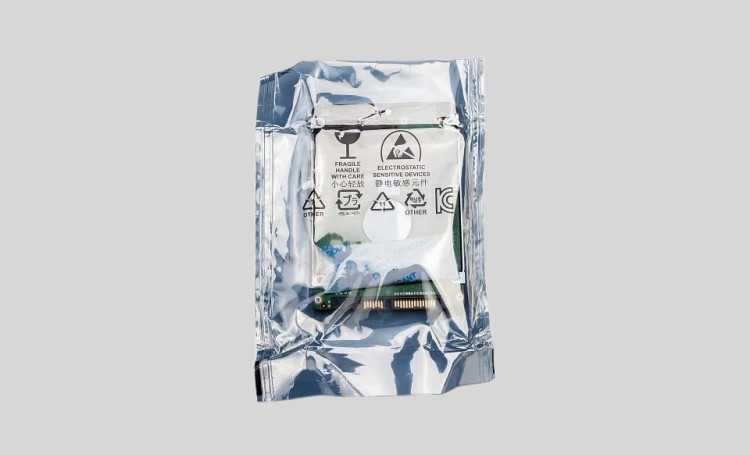

Induction sealing machines are a vital part of any business that needs to package products in containers. These machines create an airtight seal that keeps products fresh and prevents them from leaking.

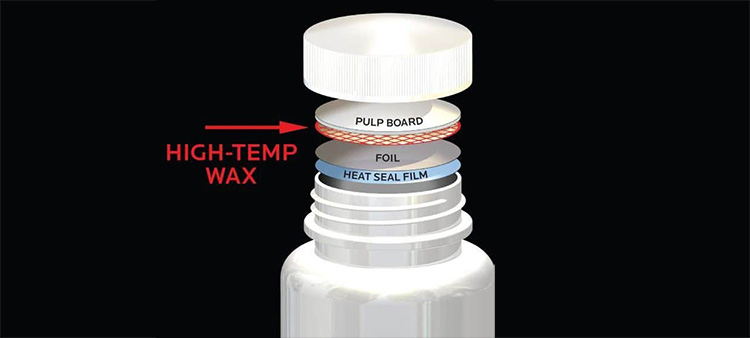

An induction sealing machine is a device that uses induction sealing to hermetically seal the lids of containers. The machine works by using an electromagnetic field to generate heat, which melts the inner liner of the lid and creates a seal.

Induction sealing is a process in which an induction coil generates heat that melts a metal disk (called an inner seal) inside a closure. The molten metal forms a bond with the container and closure, creating a hermetic seal. These seal the contents of the container from outside contaminants and extend the shelf life of the product.

2.How induction sealing machine provide different benefits?

Induction sealing machine provides many benefits the industries. The benefits of an induction sealing machine are as follows:

Improved Shelf Life

Induction seals create an airtight barrier that protects contents from oxygen and moisture contamination. This can help to extend the shelf life of products.

Prevents Leakage

Induction seals can help to prevent leaks by creating a tight seal around the container opening. So, by doing this the product will not be leaked easily.

Tamper Evidence

Tamper proof

Induction seals provide a visual tamper-evident seal that lets consumers know if a product has been opened before they purchase it.

Protects from Counterfeiting

Induction seals can be customized with logos or other security features to help protect against counterfeiting.

Remains Fresh for a Longer Period of Time

The induction seal products can remain fresh for a longer period of time. So, you can preserve them for long.

3.What is the working procedure of induction sealing machine?

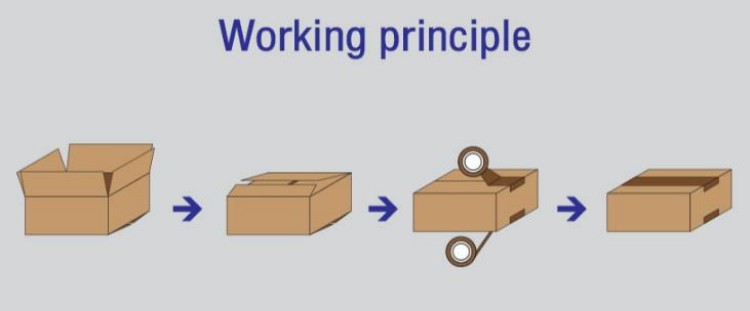

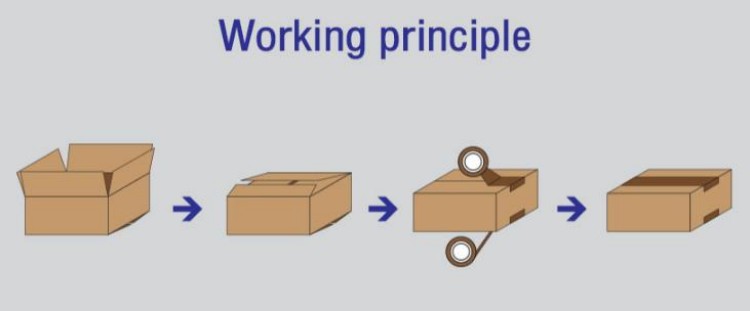

The working of the induction sealing machine is very simple. As we know that the machine uses the electromagnetic induction to seal the products.

There is an operator that is present there. So, the operator places the cap on the container. After that, the container is than placed on the conveyor belt of the induction sealing machine.

So, by doing this an electric field is created by the induction coil that is present in induction sealing machine. That helps in heating of the linear material that is present in the cap.

By providing the heat, the linear material melts. And after melting, the seal is then created by it between the container and the cap.

After doing the above procedure, the container is then cooled, and the seal is set. Now your product is ready to go.

This all the procedure of working of induction sealing machine.

4.What are the main parts of induction sealing machine?

The induction sealing machines are widely designed in different size and shapes. Therefore, every machine has different components.

But there are some components that are common in every machine. These components are considered the main parts of induction sealing machine.

Now in this section, you will come to know the important parts of induction sealing machine. These main parts are as follows:

The induction sealing machine has three main parts

- The Power Supply

- The Sealing Head

- The Conveyor Blet

The explanation of these parts include:

The Power Supply

The very first main part of induction sealing machine is the power supply. The power supply provides the high frequency electromagnetic field that is required for induction sealing. It typically consists of a transformer, rectifier, capacitor, and coil.

This cable simply provides the electric power from the socket to the machine invertor. After that, the invertor then makes this power used for a machine that helps in sealing the products.

The important point to be noted is that you should always confirm the power rating of your machine. Power rating becomes important as by the reading you can come to know the suitability of your induction sealing machine.

The Sealing Head

Sealing head of induction sealing machine

Another main component of an induction sealing machine is the sealing head. The sealing head is where the container and cap are placed during the sealing process. It contains the primary and secondary coils that create the electromagnetic field.

The size of the sealing head is different according to the needs of the products to be sealed. It may be small or vast.

Also, the sealing coil that is present in the sealing head is considered to be a great metallic conductor.

Moreover, the coil has two main designs that are present in the market. These two are named flat coils and tunnel coils.

The flat coils are used for the inner sealing of products. The diameter of the products to be sealed is almost 20 to 120 millimeters.

On the other hand, tunnel coils are used for the caps like spouted ad flip-top. Also, this type of capping is not good for sealing solid products.

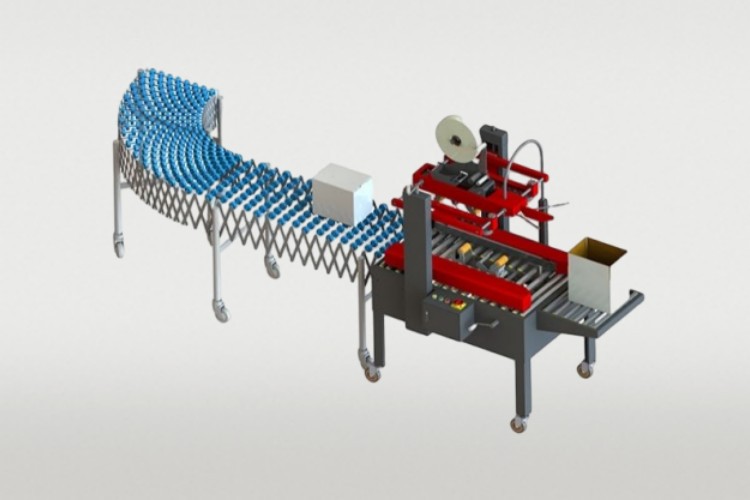

The Conveyor Belt

Conveyor Belt

The last crucial part of the induction sealing machine is the conveyor. The conveyor moves the containers through the sealing head. It is typically a belt conveyor with variable speed control.

You can adjust the speed of the conveyor belt according to your requirements. You just have to place the container on the conveyor belt. Then it will move automatically.

All these are essential parts of an induction sealing machine. Without these parts the machine is incomplete.

5.In which industries induction sealing machine is used?

The industries that use induction sealing machines are as follows:

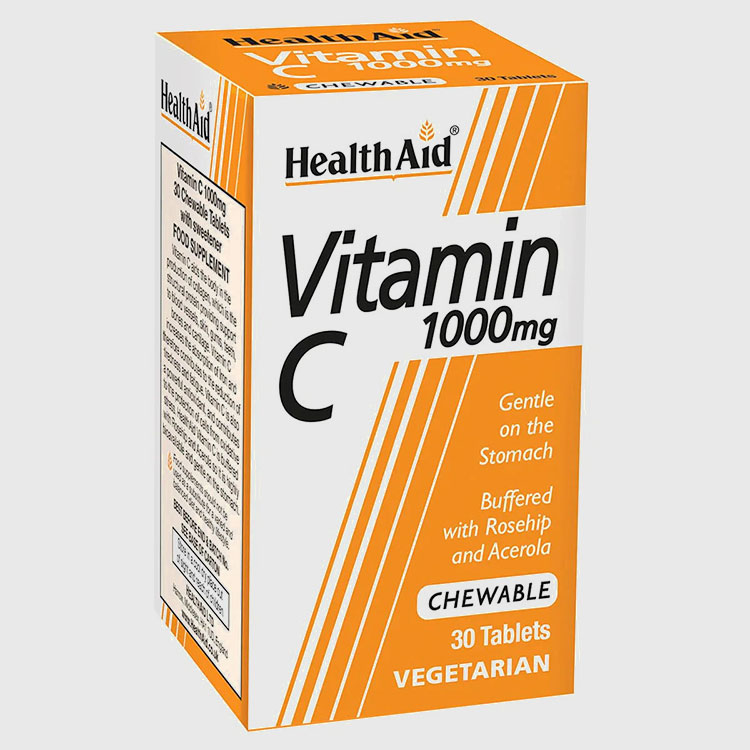

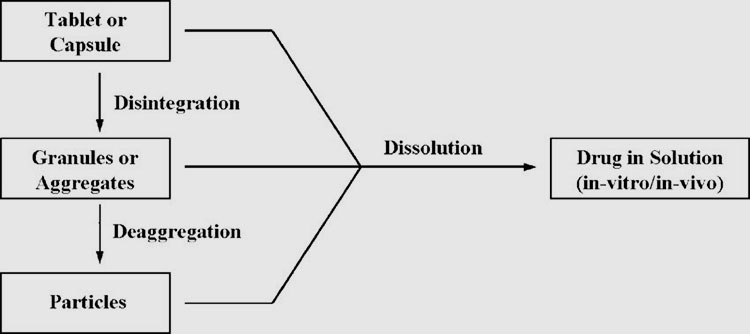

Pharmaceutical Industries

Pharma line Credits

Induction sealing machines are commonly used in pharmaceutical industries. The machine provides safety and protection to pharmaceutical products.

You can seal pharmaceutical drugs, syrups, capsules, tablets, ointments, and many other pharmaceutical products with the help of an induction sealing machine.

Chemical Industry

Induction sealing machines are widely used in chemical industries. The delivery of chemical products with full safety now becomes easy with induction sealing machines.

The chemical products cannot be harmed by the environment as the machine uses a biological and ecological system of protection.

You can seal the different types of lubricants, fuel additives, pesticides, and enzymes from induction sealing machines in the chemical industry.

Cosmetic Industries

Cosmetic industries also use induction sealing machines for sealing different types of cosmetic products. The products are sealed airtight. So, you do not need to worry about entering something into the product.

The products that are sealed by the induction sealing machine are shampoo, different types of lotions, body washes and, oils.

Beverage Industries

The induction sealing machines are very essential in preserving the food products that are packed in beverage industries. The products are protected from any type of leakage. And also. It makes the product remain usable for a longer period of time.

The inner seal of the products helps in packing the products more tightly and firmly. It makes the products fresh and secure.

You can seal organic food in the beverage industry very easily with the help of an induction sealing machine.

The products you can pack in the beverage industries are different types of spices, ketchup, juices, cheese and, dry food items.

Dairy Industries

The dairy industries also use induction sealing machines to seal dairy products. This machine is very widely used in the dairy sector. Everyone gives great importance to it in the dairy industry.

In the past, only glass bottles are used to seal the milk. But nowadays you can pack the milk in plastic bottles also. This makes the milk fresh and safe.

The other products that can be sealed in the dairy industries by using induction sealing are tea, yogurt, butter, milk powders, and ghee.

6.What are the different types of induction sealing machine?

Induction sealing machines are available in different types. These types are as follows:

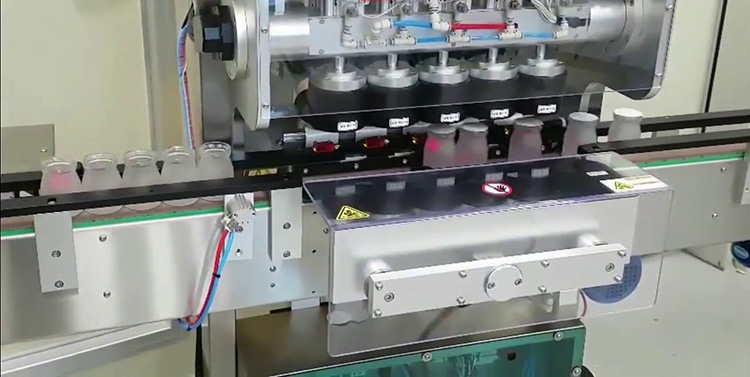

Continuous Induction Sealing Machine

The very first type of induction sealing machine is the continuous induction sealing machine. This type of machine is specifically used in medium and large-scale industries.

The machine is very suitable to pack nonmetallic bottlenecks products. Also, the machine works nonstop. Due to this, the machine gives very large input and output.

The machine is capable of handling the vast products to be sealed. It seals very fast and smoothly. This type of machine is available in different designs in the market. You can get the best machine according to your requirement.

Working

Continuous machines have a conveyor belt that moves the containers through the machine. The working principle of a typical continuous induction sealing machine follows these steps. At the very first, the containers to be sealed are placed on the conveyor belt of the machine. Then, an electromagnetic coil in the machine produces a high-frequency electromagnetic field.

Moreover, when the containers pass through this electromagnetic field, an electric current is induced in the metal foil or film liner of the container. These current heats up the liner, causing it to melt and adhere to the container. At last, the sealed containers are then cooled down and discharged from the machine.

Advantages

- The main advantage of using an induction sealing machine is that it is a very efficient to seal the containers.

- It is also cost-effective

- Additionally, it is a versatile technology that can be used for a wide variety of container sizes and shapes.

Disadvantages

- The main advantage of continuous induction sealing machine is that during sealing the metal cap remain hot for longer period of time. Due to this you can face some safety issue.

- Also, when you are sealing the plastic containers, you can face the problem of melting of threads.

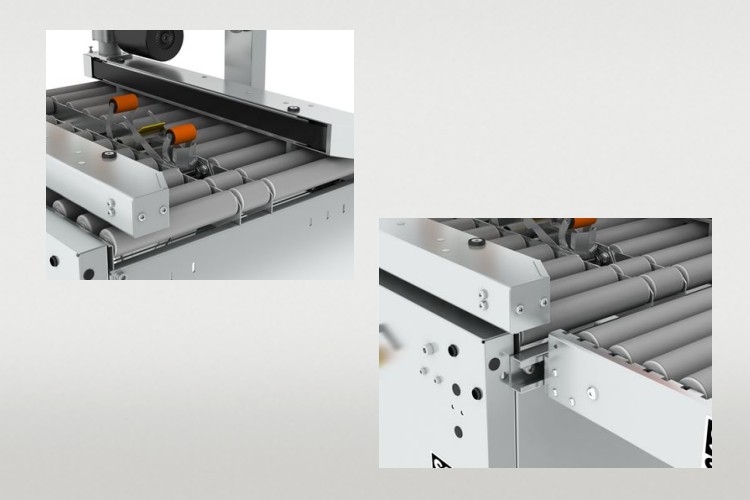

Parts

- Conveyor belt

- Induction head

- The wheels

- The air regulator

- The control panel

Manual Induction Sealing Machine

The next type is a manual induction sealing machine. It works fully manually. The machine is preferred to use in small-scale industries. This machine is not very fast as compared to the first one.

It gives low output. The machine is much cheaper than other types. But you cannot do extensive manufacturing by using this equipment.

It has a moderate consumption of power. It can also be ideal for different industries. You cannot seal or cap the metallic products from manual induction sealing machine.

Working

The machine works by holding the container in place and then passing an electromagnetic coil around the neck of the container. This coil creates a magnetic field that induces an electric current in the liner material. This current heats up the liner material, which melts and forms a seal around the edge of the container.

Advantages

- The price of manual induction sealing machine is comparatively low from others.

- The machine is ideal for small-scale industry.

- It uses moderate power consumption

Disadvantages

- The machine does not support extensive manufacturing

- The range of sealing bottles is very limited

- You can not seal the metal caps

Parts

- Heating plate

- Power cable

- Down timer

Semi-Induction Sealing Machines

This type of sealing equipment is considered similar to the continuous sealing machine. The machine is very much capable of packing the bottles with a seamless workflow.

Moreover, this type of sealing is not good for a longer period of time. The machine is also very quick. It is very simple to use. Maintenance is not as high as others.

It has a PLC control system. Also, there is a power cut memory that helps in regulating the power supply.

Working

The working of the semi-automatic induction sealing machine is somehow the same as the others. But in this machine, you have to do some manual work as the level of automation is semi as compared to a fully automatic one.

Advantages

- This type of induction sealing machine is faster

- It is capable of giving large outputs

- Simple to use

Disadvantages

- It does not work for longer periods of time

- The equipment is not suitable for capping the metal caps

Parts

- Power control

- Induction head

- Digital control panel

Capless Induction Sealing Machine

The other famous type is the capless induction sealing machine. This machine seals the product airtight. The equipment is directly punching the seal material onto the bottle in capless induction sealing machine.

This type of process is considered a little bit complicated as compared to the others. You can do the full visual inspection with this equipment.

Working

The working of capless induction is just like all. The induction generator produces an electromagnetic field that inductively heats the inner sealant material. The power supply provides the electricity needed to operate the induction generator. The sealing head holds the container in place and contains the heating element that comes into contact with the container lid.

Advantages

- The equipment saves the expense of the buyer

- Seals properly

- Make it very easier to take charge of the sealing

Disadvantages

- Heavily reliant one

Parts

- The reel holders

- The generators

- The foil feeds

Fully Automatic Induction Sealing Machine

The last type of induction sealing machine is a fully automatic induction sealing machine. The machine works automatically. This is the fastest version of the induction sealing machine.

In addition, the equipment is highly efficient as compared to the other types. The latest technology is used in automatic sealing machines.

It also has a PLC-driven system. The machine is very much easy to use and also it saves energy as it does not waste power.

Gives you a very high output. The machine is usable in large-scale industries. There is no need for any manual work while working on the automatic sealing machine.

Working

The working of the automatic induction sealing machine is somehow different from others. This is due to its automated function. As the machine is fully automatic and works automatically. You just have to switch on the equipment before using it.

Advantages

- The machine is very highly efficient

- Uses in large-scale industries

- The equipment is adjustable

Disadvantages

- The price of the machine is very high as compared to the manual ones

Parts

- The digital touch screens

- Power control

- The cooling fans

working on the automatic sealing machine.

7.What kind of products you can seal with induction sealing machine?

Pharma bottles sealing using Induction Sealer

There are a wide variety of products that can be sealed with an induction sealing machine. The products that you can seal by induction sealing machine are as follows:

Food Products

Induction sealing machines are used to seal food products. You can easily seal the food products with this equipment. The food products that can be sealed are butter, cheese, milk, energy drinks and, many others.

Pharmaceutical Products

The pharmaceutical products that be sealed by the induction sealing machine. In pharmaceutical industries, you can seal the different types of syrups, medicines, ointments, and many other pharma products.

Cosmetic Products

In cosmetic industries, different types of cosmetic products are used to pack by induction sealing machines. Cosmetic products like shampoo, oils, body wash, and many other items can be sealed by this machine.

Chemical Products

In chemical industries, induction sealing machines play a key role in sealing chemical products. You can seal different types of enzymes, pesticides, and other chemical materials with the help of this equipment.

8.How to choose suitable induction sealing machine for your business?

When it comes to choosing an induction sealing machine for your business, there are a few factors you need to take into account in order to make the best decision.

Type of Business

The first is the type of business you have. If you have a large production line, then you’ll need a machine that can handle higher volumes. On the other hand, if you have a small business with lower production levels, then a smaller machine may suffice.

The Material You Want to Seal

The next factor to consider is the material you’ll be using for your seals. Some machines are designed for specific materials, so it’s important to choose one that can work with the type of sealant you plan on using.

Size of Machine

You’ll also need to take into account the size of the seals you’ll be making. Some machines can only accommodate certain sizes, so be sure to check this before making your purchase.

The Price of the Induction Sealing Machine

Finally, think about your budget. Induction sealing machines can range in price from several hundred dollars to several thousand, so it’s important to set a realistic budget before beginning your search.

By taking all of these factors into consideration, you can be sure to choose the best induction sealing machine for your needs.

9.Tips to operate induction sealing machine?

There are various tips that can help one in operating an induction sealing machine and some of them are as follows:

Read the User Manual

Firstly, it is essential to read the user manual properly in order to understand the working of the machine.

Test the Induction Sealing Machine

Secondly, one should always test the machine on a scrap piece of material before using it on the actual product.

Awareness of Various Settings

Thirdly, the operator should be aware of the various settings of the machine so that he can adjust it according to the requirement.

Keep Checking on Power Supply

Fourthly, it is necessary to keep a check on the power supply while operating the machine.

Use Proper Safety Measures

Fifthly, one should always use proper safety gear while operating the machine.

Conclusion

Induction sealing machines are becoming increasingly popular as a means of tamper-proofing products. They offer a quick and easy way to seal packages, bottles, and other containers, preventing them from being opened until they reach their final destination. Allpack induction sealing machines are the best machines in the market. If you are thinking of investing in an induction sealing machine for your business, we hope that this article has given you some food for thought. If you have any questions regarding this article, you can contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Induction Sealing Machine: The Complete Buying Guide in 2024 Read More »

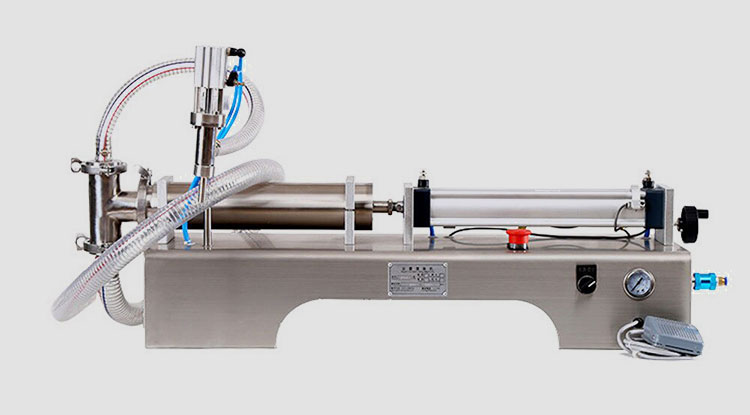

Adaptability -photo credits: askingletterresume

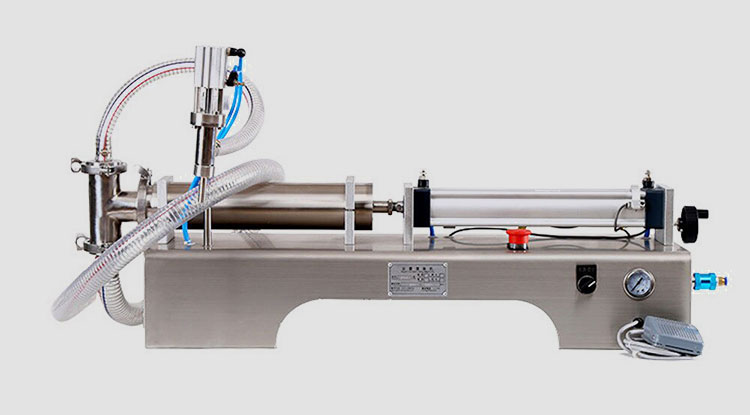

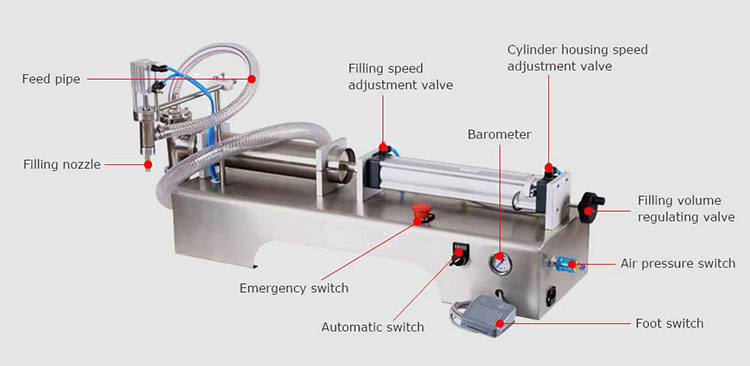

Adaptability -photo credits: askingletterresume Oil Filling Machine -photo credits: vkpak

Oil Filling Machine -photo credits: vkpak

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Cling Film package

Cling Film package