Best Single Chamber Vacuum Packaging Machine For You

- Safety Quadruple Protection Design

- Support Single Sealing Function

- Large Suction Cavity

Single Chamber Vacuum Packaging

Allpack single chamber vacuum packaging machine takes advantages of compact design, modern appearance, high degree of automation, low maintenance and easy to operate, it is suitable for multiple occasions,any bags.As long as you press the vacuum case’s lid, the machine will automatically complete the orderly assumed processes of vacuum extraction or aerate the orderly assumed processes of vacuum extraction or aerate the inner gas,sealing, printing, cooling and aeration. The packed products can be prevented from oxidation, going mould, insects or getting damp, thus can be kept fresh in a prolonged storage period. Allpack can make machine base on your requirement. It is widely used in a variety of food and non-food industries.

Single Chamber Vacuum Packaging

DZ-400/T Compact Designed Single Chamber Vacuum Packaging Machine

The function of Allpack DZ-400/T compact designed single chamber vacuum packaging machine is to extract the air inside the package of product, let it under a low-oxygen condition, to keep it fresh and extend its shelf time. This type of vacuum packaging machine is designed small and beautiful, it can be used in desktop, which can save much space. The chamber of this machine is deep so that it can accommodate larger products, as a result, it has wider range of application.

Easy To Use

Transparent Organic Glass Lid

Food Grade Safety

DZ-4002E Floor Type Single Chamber Vacuum Packaging Machine

Allpack DZ-4002E floor type single chamber vacuum packaging machine is a vertical form vacuum packaging machine, it has large cavity so that it can pack all kinds of products. The single chamber vacuum packaging machine is made of food grade stainless steel, which makes it durable and hard, it extends the machine’s service life in a certain degree. It has high efficiency, simple operation, easy maintenance, also, it is compact and moveable. It is widely used in food, pharmaceutical, agriculture, beverage, chemical industries, etc.

ISO9001 Certification

Increase Vacuum Pump

Dry&Wet Dual-use

DZ-500-T Tabletop Single Chamber Vacuum Packaging Machine

Allpack DZ-500-T tabletop single chamber vacuum packaging machine is made of AISI304 stainless steel, it has a compact and beautiful design, it is equipped with front sealing bar, which can guarantee the sealing effect of the products, to avoid gas leakage. This machine has transparent chamber lid, clear control panel and vacuum gauge, which make the vacuum process more convenient and visual. This single chamber vacuum packaging machine will consume little power energy during its working process, it is very suitable for family use and supermarkets.

Gas Injection System

Simple&Compact Structure

Thickened Plexiglass Cover

DZ-500/2ES Floor Type Single Chamber Vacuum Packaging Machine

Allpack DZ-500/2ES floor type single chamber vacuum packaging machine is widely applied in food, commodity, chemical, medical, beverage industries, etc, it has strong suction, can quickly extract the air inside products. This single chamber vacuum packaging machine is made of thick stainless steel so that it is quite durable, it has low power consumption and wide range of application, is very trendy on the market. The single chamber vacuum packaging machine can seal pouches firmly, there will be no air leakage of products after being packed by this machine.

Intelligent Computer Broad Control

Instantaneous Vacuum Process

Industrial&House Use

DZ-600S Vertical Single Chamber Vacuum Packaging Machine

The DZ-600S vertical single chamber vacuum packaging machine of Allpack is made of AISI304 stainless steel, it is equipped with high level digital control panel and volumetric electronic sensor. This single chamber vacuum packaging machine can complete the whole procedures such as air extraction, sealing and cooling automatically and quickly, which can largely increase production efficiency. It is suitable for packing all kinds of products, especially food products.

Long Sealing Length

Sealing Time Adjustment

Moveable Wheels

DZ-8002L Large Volume Single Chamber Vacuum Packaging Machine

Allpack DZ-8002L large volume single chamber vacuum packaging machine possesses large sized chamber, meanwhile, it has high production speed, therefore, it is suitable for large scale production. This single chamber vacuum packaging machine is equipped with 2 pieces of sealing bars which form a L-form to meet demands of packaging different sized pouches. It has hard, durable and sanitary stainless steel frame, thus it is more suitable for packing food products.

Hygienic Design

Heating Emission Hole

Emergency Stop Function

DZ-900-T High Suction Single Chamber Vacuum Packaging Machine

Allpack DZ-900-T high suction single chamber vacuum packaging machine is a mid-sized vacuum packaging machine, it is equipped with heavy duty rotary vacuum pump, single bar wide sealing system and modified atmosphere gas injection system, with these advanced component, the machine is suitable for industrial applications.

Intelligent Computer Control System

Durable Working Table Surface

Delicate Vacuum Packaging Effect

HVC-210T1D Table Top Single Chamber Vacuum Packaging Machine

The HVC-210T1D table top single chamber vacuum packaging machine of Allpack is designed compact, it will occupy little space during working, so it is suitable for family use, small shops and supermarkets. The purpose of this machine is to keep products fresh and extend their shelf time. This single chamber vacuum packaging machine is equipped with smart PLC touch screen which can be easily operated, it can extract air inside the products quickly, let the products quickly reach low oxygen conditions.

Soft Air Extraction Function

Transparent Plexiglass Cover

High Suction Vacuum Pump

HVC-300T/1A Desktop Single Chamber Vacuum Packaging Machine

Allpack HVC-300T/1A desktop single chamber vacuum packaging machine is used to pack food and nonfood small sachet products, it is small and lightweight, it has a hygiene vacuum chamber and high suction vacuum pump, which can guarantee quick vacuum process. This single chamber vacuum packaging machine is always used in family, supermarkets, butcher shops, delicatessens and restaurants since they are small, convenient to place and use. This machine consists of high grade components and it is made of stainless steel so that it is very durable.

Compact & Ergonomic Structure

Easy To Clean

Long Service Life

HVC-410F/2A Floor Type Single Chamber Vacuum Packaging Machine

Allpack HVC-410F/2A fllor type single chamber vacuum packaging machine is a grounded device which is equipped with moveable wheels, it is suitable for both wet and dry products. The frame of the machine is made of hard stainless steel, and the chamber lid is made of transparent acrylic so that the operator can observe the whole working process of the machine. This single chamber vacuum packaging machine has perfect packaging effect, the products which are packed by it all have beautiful appearances.

All Clear Acrylic Chamber Lid

Rugged All Stainless Steel Chassis

High Quality Vacuum Gauge

HVC-410T/2A Desktop Single Chamber Vacuum Packaging Machine

Allpack HVC-410T/2A desktop single chamber vacuum packaging machine is equipped with smart control panel and vacuum gauge, which make it easy to operate, and operator can monitor the vacuum index inside the vacuum chamber timely. This machine is a table top type vacuum packaging machine, it is small but it has high production capacity, can pack products quickly and continuously. Therefore, this single chamber vacuum packaging machine is widely used in industries such as food, beverage, medical, chemical, PET food and so on.

High Transparency Chamber Cover

Low Power Consumption

Space Saving Design

The Buyer's Guide

Single Chamber Vacuum Packaging Machine:The Complete Buying Guide In 2025

Vacuum packaging is used for proper sealing of food and other products. A single chamber vacuum packaging machine likewise preserves the product in vacuumed plastic bags for longer period. By this, the product remains safe from all microbial attacks.

This buying guide will assist you in getting all information regarding single chamber vacuum packaging machines and its applications. How they perform and what benefits can be gained using these machines. So, take most of it before buying a vacuum chamber packaging machine.

1.What Is A Single Chamber Vacuum Packaging Machine?

Single chamber vacuum packaging machines are globally used to produce low volume, hygienic and greater shelf-life products. The product is packed in a thin plastic bag or film and placed in the chamber. The chamber sucks all the air and shrinks it to a low volume, air-tight product. Also, a hot seal is applied in the end to avoid entrance of air in future which could cause contamination.

Single chamber vacuum packaging machines are essential in all food, packaging, and chemical industries because they remove all the atmospheric oxygen and prevent any bacterial or fungal growth inside the product. It also reduces the size of product which results in easy packaging and travelling. Single chambered machines are more preferred in packaging of small items like seafood, electronic parts, medical instruments, medicines, fresh meat, spices, hardware products, herbs etc.

2.What Are The Types Of Single Chamber Vacuum Packaging Machine?

Depending upon the structure of a single chamber vacuum packaging machine, they are classified in two types

Table Type Vacuum Packaging Machine

A table type vacuum chamber machine is mostly used in pharmaceutical, chemical, electronics, and food industries. This type of machine is preferred for production setups that is designed within flat or table surfaced. From small and large manufacturing firms, every sector is using these machines to fulfill their manufacturing needs. The best thing is that the machine is human friendly, and its operation is much easy as compared to others. Products at a rate of 1-4 products/ minutes can be achieved by table type vacuum machine.

Vacuum Type Vacuum Packaging Machine

A vertical type of single vacuum chamber packaging machine is used for packaging of bulk material like grain, wheat, rice, beans, herbs, chemicals etc. The construction of these machines is mostly of stainless steel which makes it highly durable and efficient. It has an ability to keep the product fresh and ensure long shelf life. The structure is in vertical shape and occupies less space too.

3.What Are The Applications Of A Single Chamber Vacuum Packaging Machine?

Single chamber vacuum packaging machines are mainly used in

Food Industry

Food industry mainly uses these machines as they must make their product last for a longer period and to avoid any fungal or bacterial attack. This type of packaging is important for all eating materials like meat, fruits, vegetables etc. This secures the product for a longer period and remains its freshness.

Cosmetic and Chemical Industry

Cosmetic items are applied on human skin. It is important to secure them because they can cause a lot of damage to skin if catches microorganism like bacteria. Chemical items on the other hand also follow the same principle and gets contaminates easily when kept open. These industries also use single chamber vacuum packaging machine to secure their products from such damages and contamination.

Household Industry

Small scale household items like food, rice, vegetables, or leftovers can be packed in films using a single chamber vacuum packaging machine. The food can be reused easily when needed with same taste and quality.

A single chamber vacuum packaging machine also has an ability to pack eatables that are in liquid form. Such types of materials are easily reused for a longer period and are free from contamination.

Electronic Hardware Industry

Globally export of electronic hardware’s is a very large industry. It is important to ensure safe travelling of these boards and hardware components. Therefore, single chamber vacuum packaging machine are used in electronic industry for safe packaging of items so that no moisture enters in it.

Medical Instrument Packaging

Preservation of medicines and medical instrument from environmental influence is an essential benefit which medical industry gets from single chamber vacuum packaging machines. They allow medicine to have a safe packaging and used when needed.

Fabric Industry

Sealing and vacuum packaging is one of the key factors that a fabric industry requires. It mainly reduced the size of fabric to and also avoids from any contamination of fabric material.

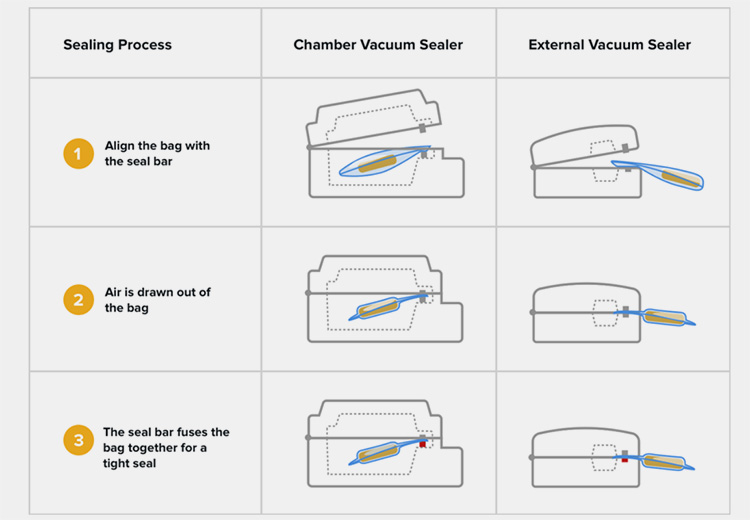

4.What Are The Working Principle Of A Single Chamber Vacuum Packaging Machine?

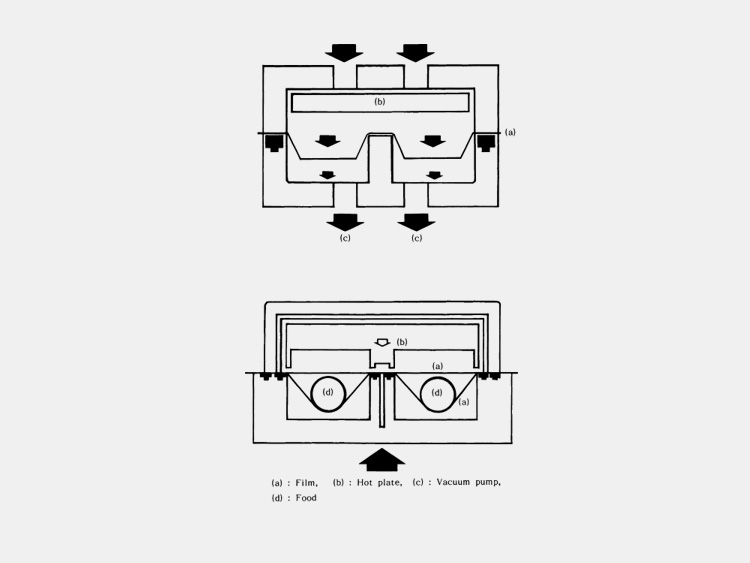

As the name explains, a single chamber vacuum packaging machine consists of a single chamber and is preferable for small scale industries. The steps involved in the process of a single chamber vacuum packaging machine are

- Initially all the external parameters like temperature, speed, duration, sealing quantity and vacuum level are set according to the packaging material used.

- Then the product is packed in a thin film in which its packaging is to be done.

- The product is then placed inside a vacuum room of a single chamber vacuum packaging machine in a way that the side on which the sealing will apply is kept under the sealing frame.

- Then operation of machine starts. All the atmospheric oxygen is removed from the product and film through vacuum pump and after that sealer is applied on the edges of it so that no cross-contamination may be carried out in future.

- As the vacuum room completes its operation the door of room is opened and the product is carried out.

- Efficient and similar sealing is done on each product which makes the quality of a single chamber vacuum packaging machine stand out.

5.What Are The Main Components Of A Single Chamber Vacuum Packaging Machine?

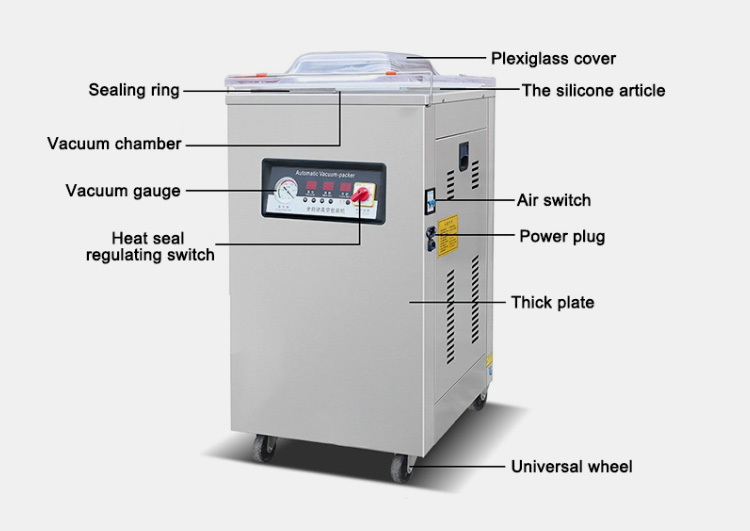

Components in a Table Type Single Chamber Vacuum Packaging Machine

Plexiglas Vacuum Cover

Transparent plexiglass vacuum cover provides clear vision of product process. The covers keep the product rust free for a longer time. It is present on the upper side of a single chamber vacuum packaging machine and helps the operator see whether the packaging is performed in proper manner. As the vacuum cover is closed it creates an air tight atmosphere in the bank which reduces the chances of any microorganism in the said product.

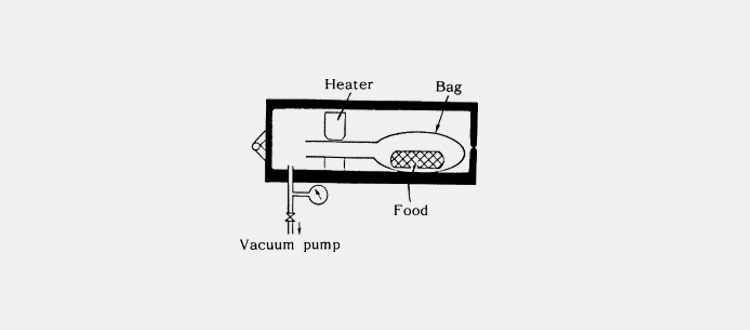

Vacuum Pump

High power vacuum pumps are there to maximum productivity and increase the efficiency of packaging process. This is the most essential part of a single chamber vacuum packaging machine because it creates the vacuum state within the machine. Product with less weight or few products can use low powered vacuum pumps.

Transformer

For stable supply of power, high quality transformers are there in a table type single chamber vacuum packaging machine. A single chamber vacuum packaging machine usually uses a step-down transformer as it operates on 110V or 220V.

Battery operated single chamber vacuum packaging machine do not carry any type of transformer because of 24V in the system.

Power Switch

Power switch assembles the power plug to ensure proper safety and normal operation. The power switch can be shifted to desire voltage according to the requirement of user. Smooth and reliable atmosphere is there for the operator due to power switches.

Controlling Switches

Vacuum gauge, air switches, regulating switches and all other controlling devices are present in the controlling switches panel. This panel is present mostly on the front side of a single chamber vacuum packaging machine where the operator can easily monitor and control things within the time limitation.

Components in a Vertical Type Single Chamber Vacuum Packaging Machine

The main components of a vertical type single chamber vacuum packaging machine are

Control Panel

The parameters of a vertical type single chamber vacuum packaging machine are controlled through this control panel. Controls of temperature, humidity, sealing width, power and others are present on the control panel. A control panel is used as the display monitor where all the control of these parameters is present. The operator can easily observe all the working parameters from this control panel.

Main Frame/ Body

The main frame of vertical type single chamber vacuum packaging machine is made up of pure stainless steel which makes it much durable. A 350-grading stainless steel is best preferred for main frame of a single chamber vacuum packaging machine as it lasts for a longer period of time and reduces purchase cost with the passage of time.

Power Supply

External power of 110-220V is required to run a vertical type single chamber vacuum packaging machine in a smooth manner. Power supply units are there to make sure smooth supply of power and avoid any electric surge. As the power increases or decreases to the given limits it cuts the operation of a single chamber vacuum packaging machine.

Vacuum Pump

Vacuum pump is the most important part of a single chamber vacuum packaging machine. It is the main source of sucking atmospheric oxygen and providing vacuumed packaging. All the gases and moisture are removed when a vacuum pump start its operation.

Vacuum Room

This is the area where the packaging is done. The product is place inside a vacuum room and then closed completely. The packet then undergoes suction process and recollected from same vacuum room. It is covered by vacuum cover. This room does not contain any type of microorganisms or bacteria which is much beneficial for packaging process.

Sealer Frame

When the vacuum process gets complete, sealing is applied on the frame for further prevention to entrance of any microorganism. A heated sealing bar is applied on the product to seal the thin film which carries the product.

6.What Are The Difference Between A Table Top Type And Vertical Type Single Chamber Vacuum Packaging Machine?

Pump Capacity

A table top single chamber vacuum packaging machines are ideal for production places that are flat in nature. Therefore, a low pump capacity between 8 to 10 m3/h is required.

In a vertical type of single chamber vacuum packaging machine 40 to 100 m3/h pump capacity is required because of large packaging products and smooth packaging.

Machine Cycle

Due to low production rates, a tabletop single chamber vacuum packaging machine has an operating cycle of 20 to 40 seconds.

A running time of 10 to 15 second is mandatory for a vertical type single chamber vacuum packaging machine to meet the production requirements.

Machine Power

Table type machine works on 220V and 1 KW that is easily available in every part of world. Whereas 415V, 3 phase and 3 KW operating power is required for proper working of a vertical type single chamber vacuum packaging machine.

Machine Controlling

Liquid controlling system is present in both type of machines whereas digital and sensor controls are easily present in a vertical type single chamber vacuum packaging machine.

Application

All type of industrial, food, wholesale and export products are packed easily using both type of vacuum chamber packaging machine. This keeps the product contamination free for a much longer time.

7.What Packaging Material Is Used In Single Chamber Vacuum Packaging Machine?

Following materials are used as packaging wrap in a single chamber vacuum packaging machine

Polyvinylidenchloride (PVDC)

The best material that prevents air, water, and oxygen to enter into products is PVDC. Single chamber vacuum packaging machines prefers PVDC because of its strong chemical composition and good wrapping qualities.

PVDC is a bit expensive material as compared to the other packaging materials, but its internal strength and quality packaging makes it stand out.

Polypropylene

Polypropylene is a rigid and tough thermoplastic material that is used for plastic wrapping in most of the industries. Polypropylene is recommended due to its safer composition and cancer free property.

Polyethylene

Polyethylene material is a type of thermoplastic polymer that is vastly applicable for packaging of food and medical products. Tons of millions of polyethylene material is used for packaging industries worldwide.

Polyvinylchloride (PVC)

PVC is the mostly used packaging material globally. This type of material is not recommended for strong packaging methods because it has weak chemical composition as compared to PVDC and Polyethylene.

8.What Are The Salient Features Of A Single Chamber Vacuum Packaging Machine?

Some of the salient features of a single chamber vacuum packaging machines are

Adjustable Plate Sizes

A single chamber vacuum packaging machine can easily be adjusted and allows vacuum packaging of products ranging between 250mm to 400mm. Further numbers of machines are present which a manufacturer can select according to its production requirement.

The size of packaging material is also selected according to the size of vacuum chamber plate and its compatibility.

Compatibility

A single chamber vacuum packaging machine is compatible with all type of industries and can be used for packaging of variety of products. The machine is made up of complete stainless that also makes it more durable.

Spare Parts

The best part of a single chamber vacuum packaging machine is that no unique part is present in it. All spare parts are easily available globally and it reduces machines stoppage time to a distinct level.

The manufacturer nowadays also supports the buyer in purchasing spares of machine which is one of the most significant features of a single chamber vacuum packaging machine.

Operational Procedures

Operation of a single chamber vacuum packaging machine is easy to understand for any unknown person. No such expertise is required to run the machine. Table type construction in such machines allows the operator to easily handle things without having any restrictions of space.

9.What Are The Difference Between A Single And Double Chamber Vacuum Packaging Machine?

Number of Chambers

A single chamber vacuum packaging machines are single chambered and have only a single vacuum room for its operation whereas two chambers are there in a double chamber vacuum packaging machine.

A single chamber machines involves human intervention but due to present of two different chambers, the working procedure can be done automatically.

Operational Procedure

Product must be placed in the vacuum room and the rest is performed by the machine itself. The operator places the product in the vacuum room and then the packaging process is carried out.

Double chamber vacuum packaging machine also follows the same process and produces packaging with vacuum chambers

Size

A certain size of products can be sealed in these machines, and it limits the size of bag to be placed in the room. Room adjustment can be done but only for low and medium scale industry.

More capacity and greater size limit products can be sealed in a double chamber vacuum packaging machine.

Sealing Capacity

Single chamber vacuum packaging machines are more suitable for low and medium packaging volume.

Medium and high-volume packaging procedures uses double chamber vacuum packaging machine.

Type of Lids

Manual lids are present in a single chamber vacuum packaging machine. Lid usually slide from one chamber to another and accelerates the system as compare to a single chamber vacuum packaging machine.

Product

Small quantity of liquids and solids can be efficiently packed in single chamber vacuum packaging machine.

A double chamber vacuum packaging machine prefers packaging of vacuum sealed liquids in greater quantity. Products of greater size are packed in these machines.

Packaging Material

Single chamber vacuum packaging machines are applicable for packaging of Liquids, chemicals, medical instrument, and vegetables.

Meat, Dairy products, can and confectionary items can be packed using a double chamber vacuum packaging machine.

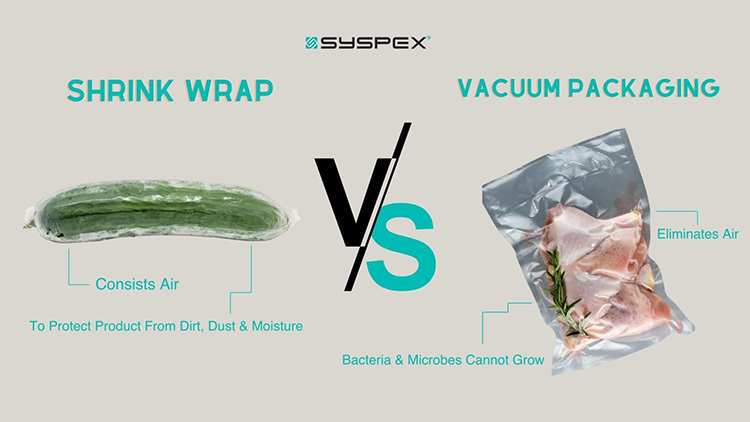

10.What Are The Difference Between Vacuum Packaged Products And Shrink Packaged Products?

Thickness

Thick packaging materials are used in a vacuum chamber packaging machine as compared to shrink wrapping. Around three to four time’s thicker material is used for packaging in vacuum packaging machines.

Absence of Oxygen

Every type of compressed air is removed from the products in a vacuum packaging machine. This is necessary to keep the product secure for a longer period

Heating in a shrink packaging traps the air and oxygen within the product during its operation. Small pours are present in products for removal of air in shrink packaging machine.

Machinery

Heating complete package is done to seal the entire product in a shrink-packaging machine

The sealing parts requires heating only in a vacuum packaging. Heating of entire product is not essential

Packaging

Both the machines production packages that re transparent in nature. Plastic and clear bags allow the customer to clearly monitor the product quality and freshness

11.What Supporting Equipment Are Associated With A Single Chamber Vacuum Packaging Machine?

Some of the other equipment that are incorporated with single chamber vacuum packaging to smooth its production are

Strapping Machine

Some of the single chamber vacuum packaging machines use strapping machines to strap products like fabric, clothes, vegetables etc. This already reduces the size of product and then supports the packaging machine to get wrapped easily. A strapping machine is mostly used in small scale industries along with single chamber vacuum packaging machine as the size of product is small.

Laser Inkjet

While having a vacuum packaging of product, it is always necessary to have a maker or product identity on it. These laser Inkjets provide high quality graphical representation to product which attracts the customer towards it. Bar code and QR codes are also given to products by these supporting devices.

Scrap Collecting Unit

Some of the single chamber vacuum packaging machines also contain scrap collecting units. Here all the scrap of wrapping foils and its wastage is collected so that no residual may left in the system. If any of the cutting part stays in the system it directly causes material, quality, and economic loss

Boiling Unit

Products like foods, vegetables, fruit, eatables and etc. are boiled to a certain level after getting packed because it kills all the bacteria present in them and makes them fresh for a longer period. Packaging leakages can also be observed while boiling products to a certain temperature.

Collecting Pallets

Pallets or cartons are present at the end of single chamber vacuum packaging machines where the packed products are collected and placed accordingly. These pallets are then transported globally to all parts of world.

12.How Long Does Food Last Packed Using A Vacuum Packaging Machine?

Before buying a vacuum packaging machine it is always a concern that how long any food can remain fresh and pure. The research shows that when air is removed from the product it ensures absence of bacteria. This directly lasts the food item for a longer period as compared to other packaging solutions. Some product life according to research are

| S. No | Product | Life |

| At Room Temperature | ||

| 1 | Flour | 1-2 years |

| 2 | Nuts | 2 years |

| 3 | Cereal | 6-12 months |

| 4 | Bread | 7-8 days |

| Freeze or In Refrigerator | ||

| 5 | Hard cheese | 40-60 days |

| 6 | Vegetables | 2-3 years |

| 7 | Meat | 2-3 years |

| 8 | Fish | 2-3 years |

| 9 | Fruit | 2-3 years |

| 10 | Roasted meat | 8-12 days |

13.What Are The Steps Taken To Maintain A Single Chamber Vacuum Packaging Machine?

A single chamber vacuum packaging machine can be maintained in following ways

- Proper checking of internal and external parameters of machine including electric connections, vacuum pressure, and machine equipment.

- Before operating the machine, guidance provided by the manufacturer should be read accordingly. This will help the operator to easily understand all the procedures of single chamber vacuum packaging machine.

- Schedule maintenance of equipment, oiling of vacuum pump and greasing of gears can ensure proper working of machine.

- After every processing cycle, the bed of vacuum chamber should be clean. Cleaning gives efficient, neat and defect free packaging of products.

- Regular monitoring and checking of sealing areas and power condition can guarantee best quality packaging.

- Preparing a schedule preventive and predictive maintenance chart can keep the process smooth for a longer period.

Conclusion

Usage of single chamber vacuum packaging machines is drastically increasing in small and medium scale industries. It applies innovative packaging solutions to protect products. Allpack China provides you complete solutions of single chamber vacuum packaging machines and are always there to assist you 24/7. Feel free to contact us anytime or visit our website http://www.allpackchina.com.pk/.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours