Liquid Paste Filling Machine: A Complete Buying Guide In 2025

Since the manufacturing industry is growing and producing more and more products, there are a lot of filling materials to be finished at the industrial level. If you have a liquid paste filling machine, you can speed up your filling efficiency and time.

This buying guide can provide you everything that you need to know about choosing the right liquid paste filling machine. Let’s have a look together!

1.What Is The Liquid Paste Filling Machine?

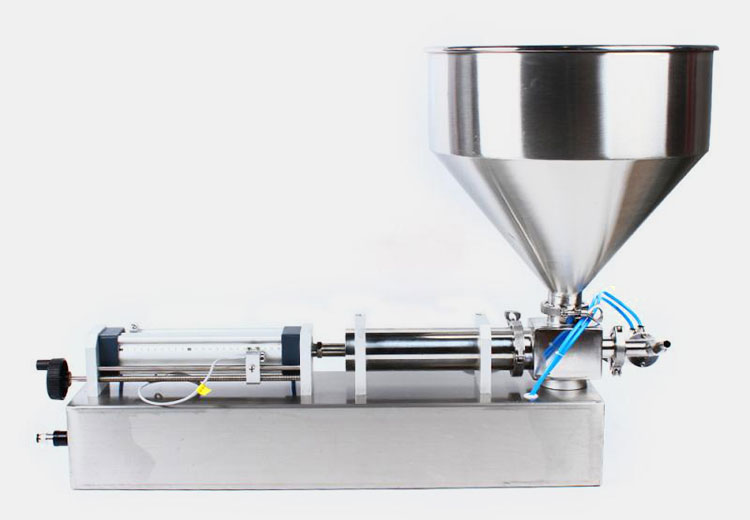

Horizontal Liquid Paste Filling Machine

Liquid paste filling machine uses compressed air as power, and is composed of precision pneumatic components to form an automatic filling system. Liquid paste filling machine is simple in structure, sensitive and reliable in action, easy to adjust, suitable for filling various liquids, viscous fluids and pastes.

Vertical Liquid Paste Filling Machine

Liquid paste filling machine is also suitable for canning in flammable and explosive environments, and it is the most ideal filling equipment for pharmaceutical, chemical, food, cosmetic and other industries.

2.What Industries Are Liquid Paste Filling Machines Mostly Applied?

Liquid paste filling machines are mainly applied in various industries which include food industry, pharmaceutical industry, chemical industry, cosmetics industry and other industries.

Food Industry

Filling Machine for Food Industry

In food industry it has great uses to fill different products in different shapes and sizes like Snack food, snacks, health products, canned food, instant food, seasoning, jam, fruit juice, wine, beverage, purified water, nutrition, egg products, meat products, pickled products, etc.

It is capable of handling a variety of liquid pastes, including body lotions, variety of creams and cosmetics. Even food products like sauces, cooking oil, soup, and salad dressing can be packaged with them.

Pharmaceutical Industry

Filling Machine for Pharmaceutical Industry

Liquid paste filling machine for pharmaceutical industries are in the most common applications. For example, it can be used to fill prescription drugs, chemical liquids, and many other products. It ensures the quality of the raw materials with high efficiency and save more working time.

Chemical Industry

Liquid paste filling machine mechanical equipment is also widely used in the chemical industry. Liquid paste filling machine can be used to fill chemical products, such as inorganic chemical products, organic chemical products, biochemical products and fine chemical products, etc. Subdivided products include coal chemical and petrochemical products, such as ethane, formaldehyde, acetaldehyde, etc.

Biochemical products include starch sugar, amino acid food additives derived from fermentation, antibiotic pharmaceutical products, etc. Fine chemical products include dyes, pigments, spices, rubber additives, plastic additives, printing and dyeing textile paper-making additives, water treatment agents, oilfield and mining additives, etc.

Cosmetics Industry

In terms of daily cosmetics, liquid paste filling machine mechanical equipment is also widely used. Liquid paste filling machine can be used to fill daily chemical products, such as facial cleanser, shampoo, facial cleansing foam, facial mask, shampoo, toilet water, talcum powder, air freshener, prickly heat remover, foot powder, nail remover, cologne .

3.How Many Types Of Liquid Paste Filling Machines Are There?

From the point of view of operation, there are 3 types of liquid paste filling machines, which are manual liquid paste filling machine, semi-automatic liquid paste filling machine, fully automatic liquid paste filling machine.

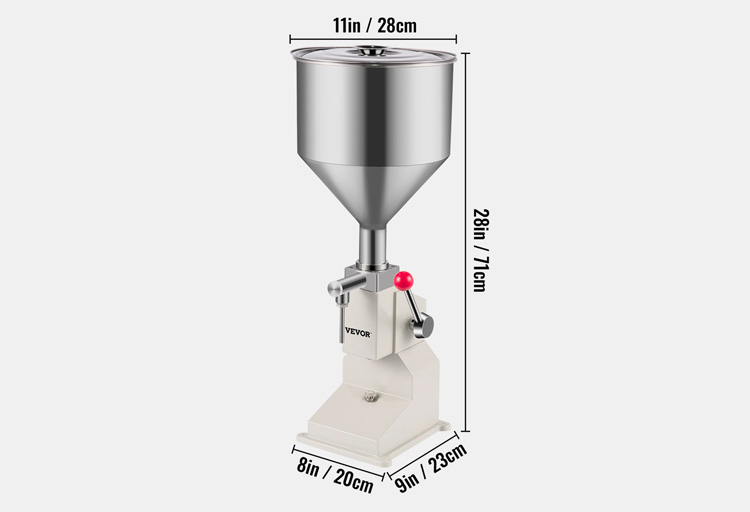

Manual Liquid Paste Filling Machine

Manual Liquid Paste Filling Machine

Manual liquid paste filling machine can fill paste and liquid substances such as liquid medicine, fluid food, lubricating oil, shampoo, shampoo cream, etc., and has the function of an all-in-one paste and liquid filling. The structure of manual liquid paste filling machine is simple and reasonable, and manual operation is convenient.

Manual liquid paste filling machine is a semi-automatic piston paste filling machine with reasonable design, small size and convenient operation. Material contact parts are made of 304L stainless steel. The filling volume and filling speed can be adjusted arbitrarily, the canning precision is high, and the filling head adopts anti-drip and upgraded filling device.

Semi-automatic Liquid Paste Filling Machine

Semi-automatic Liquid Paste Filling Machine

Semi-automatic liquid paste filling machine (horizontal) is a semi-automatic quantitative filling machine for paste and liquid. The series of filling machine has widely used in the fields such as pharmaceutical, cosmetic, food and special industries with the different range. For liquid and high viscosity fluid and paste, the kind of machine is the best choice.

Driven by a cylinder and piston made from materials with one-way valves control the flow of materials and also magnetic reed switch control cylinder itinerary can control the filling volume.

Fully Automatic Liquid Paste Filling Machine

Fully Automatic Liquid Paste Filling Machine

Fully automatic liquid paste filling machine is suitable for filling viscous, inviscid, and corrosive liquid. It’s widely applied in plant oil, chemical liquid, and the daily chemical industry.

It adopts linear type filling, electromechanical & instrucmental integration controlling. It’s simple and rapid for changing the varieties with unique design and superior capability. Its appearance accords with the international machinery concept.

From the point of view of filling, there are 3 types of liquid paste filling machines, which are single head vertical liquid paste filling machine, double head horizontal filling machine, stirring liquid paste filling machine.

4.What Are The Structures Of Liquid Paste Filling Machines?

Different types of liquid paste filling machines have different structures. The structures of manual type and semi-automatic types are simple, but the fully automatic types are comparatively complicated. And there are the details below.

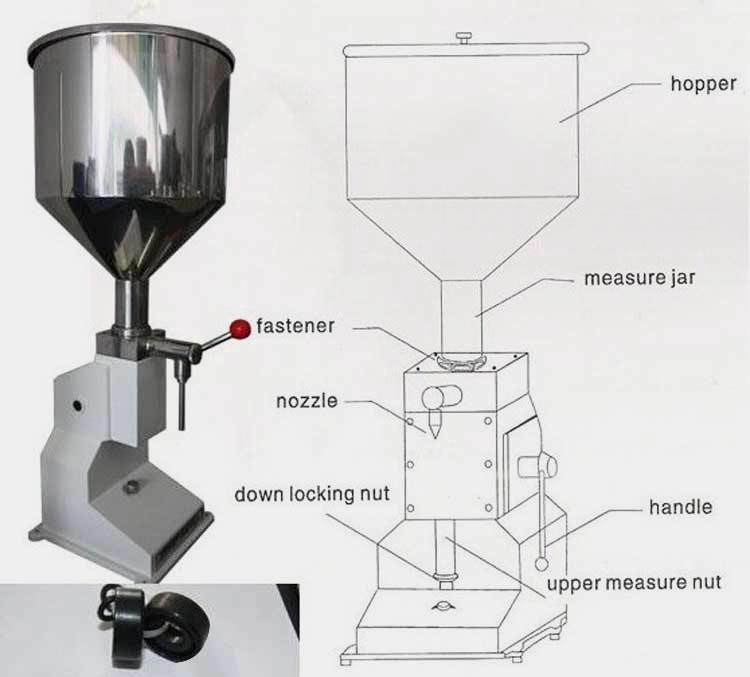

Structures of Manual Liquid Paste Filling Machines

Structures of Manual Liquid Paste Filling Machine

There are total 7 parts of the manual liquid paste filling machine including hopper, fastener, measure jar, nozzle, down locking nut, handle, upper measure nut.

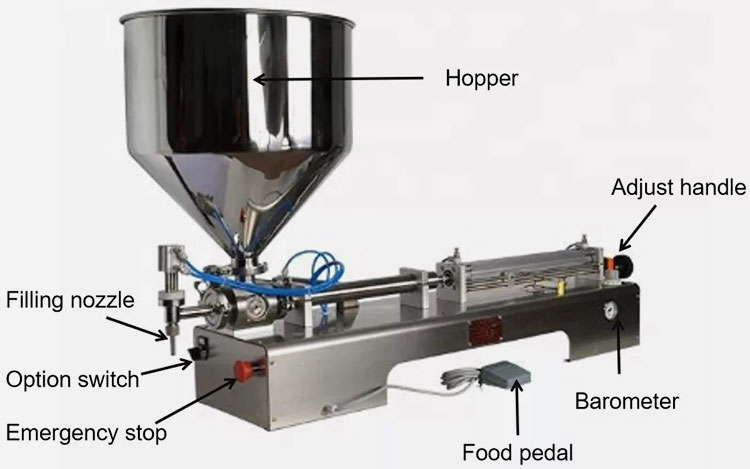

Structures of Semi-automatic Liquid Paste Filling Machine

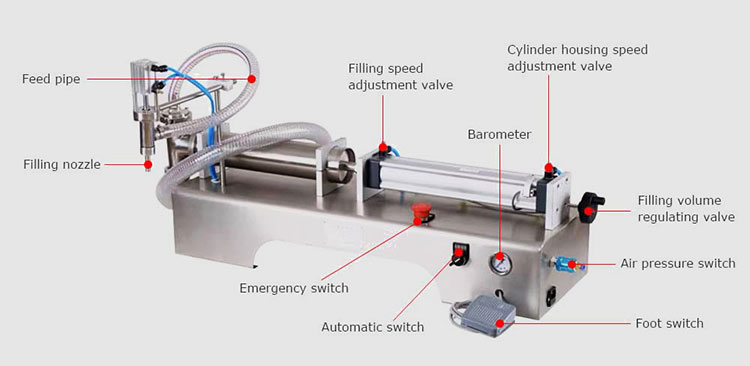

There are total 7 parts of the semi-automatic liquid paste filling machine including hopper, filling nozzle, option switch, emergency stop, adjust handle, barometer and food pedal.

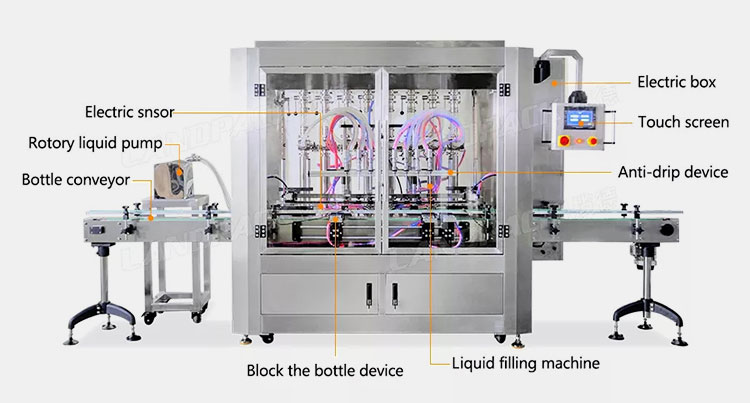

Structures of Fully Automatic Liquid Paste Filling Machine

There are total 8 parts of the fully automatic liquid paste filling machine including electric sensor, rotatory liquid pump, bottle conveyor, block the bottle device, liquid filling machine, anti-drip device, touch screen, electric box.

After knowing the structures of liquid paste filling machine, you may understand how these liquid paste filling machine work.

5.What Are The Characteristics Of The Liquid Paste Filling Machines?

Design Method

Horizontal Design of Liquid Paste Filling Machine

Liquid paste filling machine adopts a new horizontal design, light and convenient, automatic pumping. For more viscous paste, it can be added to the hopper.

Way of Working

Working Way Of Liquid Paste Filling Machine

Liquid paste filling machine is equipped with manual and automatic switching functions. When the machine is in the “automatic” state, the machine automatically performs continuous filling at the set speed.

When the machine is in the “manual” state, the operator steps on the pedal to complete the filling. If the staff keeps stepping on it, it will also change to the state of automatic continuous filling.

Semi-automatic Liquid Paste Filling Machine

System Status

The liquid paste filling machine is equipped with an anti-drip filling system. When the machine is filling, the cylinder moves up and down to drive the bulkhead. Cylinder moves upwards, and then dull head upwards.

When the valve is opened, the machine starts filling materials; otherwise, it stops filling. And put an end to the phenomenon of dripping and drawing.

Disassembly of the Machine

Disassembly of Liquid Paste Filling Machine

The material tank and tee part of the liquid paste filling machine are connected by handcuffs without any special tools. That is, the loading and unloading of the machine is very convenient.

6.How To Operate And Maintain The Liquid Paste Filling Machine?

Liquid paste filling machine is divided into automatic and manual type.

Operation Of Liquid Paste Filling Machine

Operation Of Liquid Paste Filling Machine

Manual Type: When the machine is in manual gear, you only need to push the touch tongue with the mouth of the bottle. Be careful not to hold the tongue when the machine starts to suck material.

Automatic Type: When the machine is in automatic gear, the bottle must be placed under the discharge port. This is where you can activate the switch and the machine will automatically do the filling. You need to pay attention and replace the bottle in time.

MaintenanceOf Liquid Paste Filling Machine

When filling, if the metering is found to be unstable, check the feed check valve in time to see if there is any debris, which will lead to poor sealing and affect the filling volume.

If material leaks from the lower part of the cylinder, it means that the piston seal is worn. You need to replace the sealing ring in time.

7.What Are The Main Optional Accessories For The Liquid Paste Filling Machine?

Apart from the main part of the liquid paste filling machine, there are three main optional accessories for liquid paste filling machine which are needle filling tip, ball valve control system, and hopper.

Needle Filling Tip

Liquid Paste Filling Machine Filling Needle

Some diameters and lengths of this needle can be customized according to your container specifications. This accessory is suitable for filling products in small diameter bottles or tubes. You can replace filling heads of different sizes and sizes according to the container specifications of your own films.

Ball Valve Control System

Liquid Paste Filling Machine Ball Valve System

This accessory is suitable for material products with different viscosities or containing particles. The ball valve control system can solve various pressure problems caused by high pressure or high pressure supply. It can make the running process of the machine more smooth, and the fluidity of the product is stronger.

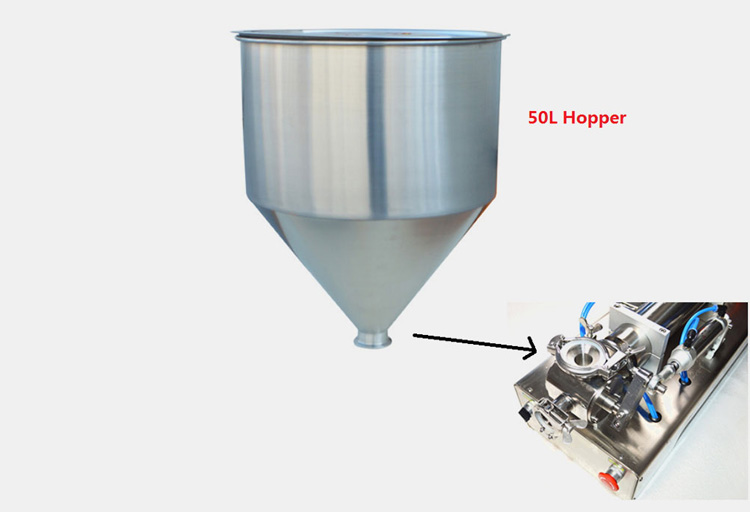

Hopper

Liquid Paste Filling Machine Hopper

When the product you need to fill has a relatively high viscosity, it is recommended to configure different types of hoppers. By using different hoppers to match products with different viscosities, you can get the best filling results.

All these accessories, you can match by yourself and by the application.

8.What Are The Differences Between Liquid Paste Filling Machines And Powder Filling Machines?

The differences between liquid paste filling machines and powder filling machines mainly lies in filling materials, filling methods, and the filling parts. They have different application and usage. If you want to know more about other type liquid paste filling machine, you are welcome to consult us.

From the Perspective of Filling Materials

Liquid Filling

Liquid paste filling machines are suitable for filling liquids and pastes that are not highly concentrated and contain few impurities, like water, beverage, sauces, cooking oil, soup, etc.

Powder filling machines are suitable for filling powdery and granular materials with poor fluidity.

From the Perspective of Filling Method

Powder Filling

Liquid paste filling machines apply the principles of piston or impeller to pressurize the material to complete the filling process. This filling method can reduce the generation of air bubbles during the filling process of liquid paste filling machines. And liquid paste filling machines are suitable for filling various liquid cream and other materials.

Powder filling machines mainly include two filling methods. One of them is to control the weight of the material through the screw, and then fill the powder-like powder object with certain fluidity. Such as pharmaceutical powder, milk powder, facial mask powder, etc. Another filling method is weighing type. This method is often used in large-dose powder filling. Such as industrial cement and industrial powder, etc.

Powder Filling Machine

From the Perspective of Filling Parts

Liquid paste filling machines have 10 main filling parts for the semi-automatic type including feed pipe, filling nozzle, emergency switch, automatic switch, foot switch, air pressure switch, filling volume, barometer, cylinder housing speed adjustment valve, and filling speed adjustment valve.

Filling Parts Of Semi-automatic Liquid Paste Filling Machines

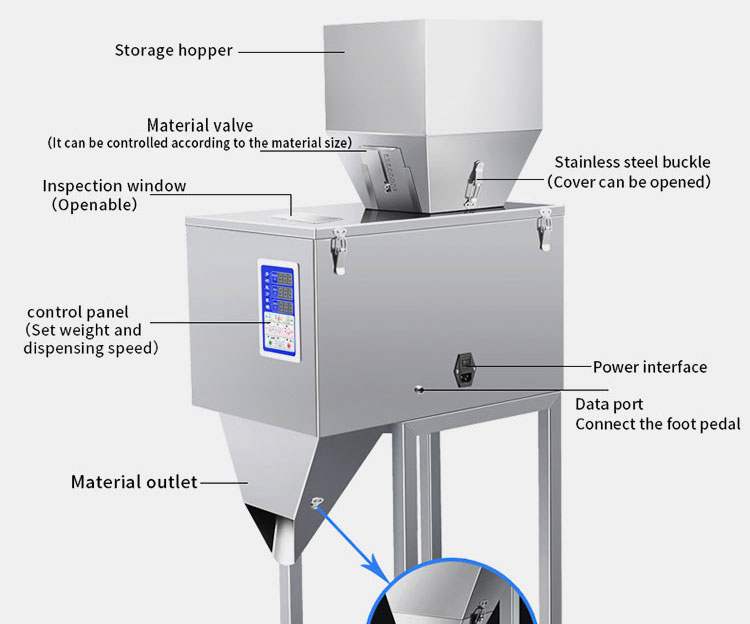

Powder filling machines have mainly 8 filling parts for the semi-automatic type including storage hopper, material valve ( It can be controlled according to the material sizes), inspection window, control panel (openable), control panel (set weight and dispensing speed), material outlet, data port (connect the foot pedal), power interface, stainless steel buckle (cover can be opened).

Filling Parts Of Semi-automatic Powder Filling Machines

After knowing all the three main differences from liquid paste filling machines and powder filling machines, have you ever wondered how liquid paste filling machines benefit you?

9.How Will You Benefit From The Liquid Paste Filling Machine?

As the liquid filling machine can help you to save time and energy, it will be a big advantage for your business. It can be used to fill the products in a short time, which meets the requirement of different products.

There are five main benefits from the liquid paste filling machines.

Customizable

Water Filling Of Customizable Sizes

The machine is equipped with a variety of filling materials, so you can choose according to your requirements. Here are a few justifications for why you should have to buy this top service provider product.

It Is Upgradable

As the business is growing and the production needs serious help, fillers are upgradable without and replacement in the machinery.

It Accelerates Production

Chain Production Of Liquid Filling

In contrast to the hand-filling method, fillers can bottle a greater number of containers. The fill-heads of machine and the viscosity of the liquid both affect speed. Sixteen fill-head machines can typically produce up to 120 bottles per minute. This makes it possible to fill thousands of bottles every day.

Consistent In Production

Consistent In Liquid Filling

Another very interesting feature of this machine is that it is consistent in production. Hand filling may lead to changes while filling a product into container.

Long-term Usage

Industrial filling equipment is built to last a lifetime and not break down, especially when a lengthy production run is required. This guarantees that companies can continue to operate for a long time. Daily expenses can be reduced in terms of labor costs and energy consumption with proper maintenance inspection performed within a month and a small workforce.

Versatility In Fillings

Versatility In Liquid Paste Fillings

When settings are adjusted, bottling machines can fill any sort of product with any specific measurement since fillers do not always bottle the same type of product in the same kind of container.

Varying from those benefits, you may have your own choices and choose whether to buy it or have it on other usage.

10.What Should You ConsiderBefore Buying A Liquid Paste Filling Machine?

Equipment for filling liquids and paste can be manual, semi-automatic or automatic but when picking between the three types, that quantity is typically the deciding factor.

Manual liquid paste filling machines are the best choice for your own use or individual business. If you have your own business or you individual business then we are highly recommend you the manual liquid paste filling machine.

ReasonsFor Considering Manual Liquid Paste Filling Machine

Sizes Of Manual Liquid Paste Filling Machine

Manual liquid paste filling machines are in small sizes that these types are easy to be packed or stored.

Manual liquid paste filling machines are low energy consumption and environmentally friendly but with low efficiency. With low packaging weight and speed that suits individual use.

Semi-automatic liquid paste filling machine is generally the best choice for smaller-to-medium batch sizes and shorter runs.

ReasonsFor Considering Semi-automatic Liquid Paste Filling Machine

Sizes Of Semi-automatic Liquid Paste Filling Machine

Semi-automatic liquid paste filling machine’s packaging speed is faster than the manual liquid paste filling machines but lower than the fully automatic liquid paste filling machines.

If you own a medium company and have a need for batch sizes and shorter runs, fully automatic liquid paste filling machine is your best choice.

With the filling speed of 10-20 bottles per minute, and the power supply of 220V, you can perfectly apply this for your small and medium business use.

Fully automatic liquid paste filling machine will be your best choice if you are consistently generating a greater amount of product, it can be worthwhile to invest in completely automatic filling machinery.

ReasonsFor Considering Fully Automatic Liquid Paste Filling Machine

Fully Automatic Liquid Paste Filling Machine

Automatic liquid paste filling machines are fully controlled by electricity with high accuracy and speed which are suitable for large commercial and large factory use.

Automatic liquid paste filling machine needs daily maintenance and monthly check for safety and security which need more funding that are suitable for large investment company use.

With power of 3.5KW, filling range of 50-1000ml (Customizable), and filling speed of 30-40BPM(100-500ml range), this type can totally fulfill your large quantity needs.

Liquid Filling Chain

All in all, whether choose a manual liquid paste filling machine, semi-automatic liquid paste filling machine, or a fully automatic liquid paste filling machine, you can consider from your overall economic strength, product filling scale, filling use, filling speed and accuracy requirements are considered.

Conclusion

A liquid paste filling machine is a very useful machine which helps you perform different functions at a time. You can easily fill up your products of different quantities and sizes in a very short time. Allpack Machines uses latest technologies which make them unique from others. If you are looking for a good liquid paste filling machine do Contact Us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours