High Ouput Hard Capsule Liquid Filling Machine

- Servo Motor Lifting Device

- Fully Automatic Discharging

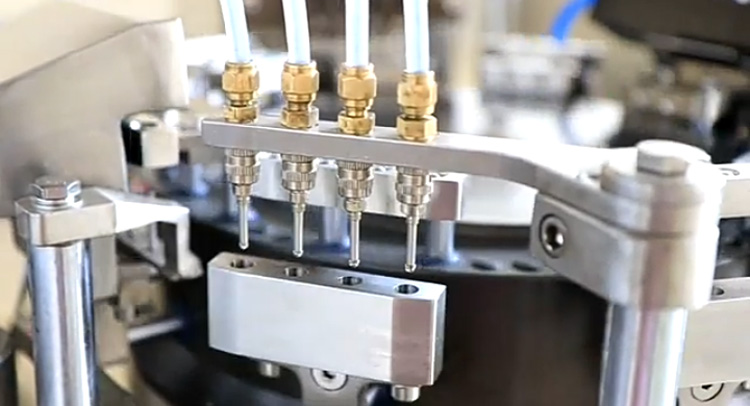

- High-precision Ceramic Pump

Hard Capsule Liquid Filling Machine

Allpack hard capsule liquid filling machine is used for filling hard capsule with solution, suspension, microemulsion. The machine adopts the stepless frequency converter, which is convenient and intuitive to operate. As a new and convenient mode of administration and filling concept in the new century, this machine is the latest filling equipment for developing high-end products in the pharmaceutical, health care, and other industries. All hard capsule liquid filling machines adopt a man-machine interface control system, which automatically lacks capsules and lacks material alarm. And all its capsule feeding machine has a vacuum positioning and separating mechanism so that the probability of the capsule is over 99%. The fiber is automatically detected, and the capsule is missing in the upper and lower mold holes.

Hard Capsule Liquid Filling Machine

NJY-300C Hard Capsule Liquid Filling Machine

Allpack NJY-300C hard capsule liquid filling machine can be filled in a hard capsule with solution, suspension, microemulsion. The ceramic pump is used to add liquid, and the servo motor controls the loading system to ensure the difference in loading. The machine with accurate measurement, fiber inspection, and automatic rejection. This liquid capsule filling and sealing machine adopts the stepless frequency converter, which is convenient and easy to operate. Highly accurate filling can be accomplished for any of the chosen dosage forms. Due to the innovative design of the intermittent operation, capsules dwell for a longer period in the filling section of the machine, therefore increasing the filling accuracy.

Adopts man-machine interface

Automatically alarm when lacks of capsules and material

Vacuum positioning and separating mechanism

NJY-600C Hard Capsule Liquid Filling Machine

Allpack NJY-600C hard capsule filling machine adopts man-machine interface control system, which will automatically alarm when lacks of capsules and material.Its capsule feeding machine has a vacuum positioning and separating mechanism, so that the qualified sowing rate of the capsule is over 99%. The fiber is automatically detected. Due to the innovative design of the intermittent operation, capsules dwell for a longer period in the filling section of the machine, therefore increasing the filling accuracy. With high-precision ceramic pump and servo motor dosing system ,it can control the difference of the loading amount to about ±2%, and the dosage is accurate.

Smooth running, low noise, vibration small

Fully enclosed turntable

Fully automatic discharging

NJYF-300C Automatic Hard Capsule Liquid Filling and Sealing Machine production line

Allpack NJYF-300C automatic hard-capsule liquid filling machine and sealing linkage line equipment are the first in-line equipment of our company based on our own multi-year capsule filling technology, self-developed design and production of hard capsule filling liquid and sealing. And exclusive proprietary intellectual property rights and a number of technical invention patents.The equipment adopts man-machine interface control system, which automatically lacks capsules and lacks material alarm.

High-precision ceramic pump

Servo motor lifting device

Vacuum positioning and separating mechanism

The Buyer's Guide

Liquid Capsule Filling Machine: The Complete Buying Guide In 2024

Are you scrolling down to get the best solution for your liquid capsule filling? If yes! You are few steps away from diving into the sea of world’s innovative liquid capsule filling machines offered by Allpack.

The history of manufacturing liquid filled capsules goes back to 1980s, when pharmacists introduced the concept of hard-gel liquid filled capsules as an alternative to soft gel capsules due to its vary advantages. This method of securing essential oil, vitamins and minerals is quite convenient in scaling, ensures quick absorption as well as provide chance of mixing numerous items together in a single capsule. Meeting the growing demands for liquid filled capsules, now every pharmaceutical company desire to have a full scale production line for liquid capsule filling.

For such searchers, this detailed review is of immense significance. Just keep reading and explore everything about a liquid capsule filling machine!

1.What Is Liquid Capsule Filling Machine?

A liquid capsule filling machine is advance pharmaceutical machinery which is employed to fill liquid substances into empty capsules. This way of filling capsules is quite fast and easily manageable as whole mechanism runs through fixed commands.

By using a liquid capsule filling machine you also fill include other materials into liquid filled capsules like pellets, granules and small hard dosage capsules. There are many types of liquid capsule filling machine that are used by relevant industries like pharmaceutical, nutraceutical and healthcare sectors etc.

2.For Which Purpose Does A Liquid Capsule Filling Machine Is Used?

The fundamental purpose of using a liquid capsule filling machine is to secure the different types of liquids such as oil, paste, liquid-granules and oil-pellets, in a way that their quality cannot be comprised. They are easy to swallow and have quick absorption with less excipients and no plasticizers.

This machine also seals the liquid filled capsules to fully assure that they are protected and would not face leakage during transit.

Another main objective behind adopting this method for capsule filling is that scaling of hard gel capsule filling is easier than that of soft gel capsule filling.

3.How To Operate A Liquid Capsule Filling Machine?

This question carries great importance for your true understanding of how a liquid capsule filling machine works, and what are the major working principles required for operating it. For this, we have enumerated following points which encompasses the entire mechanism. These are:

Capsule Loading

Before starting operation, hollow capsules are loaded into the hopper. These capsules are then conveyed through multiple tubes in horizontal form.

Capsule Sowing

In this step, capsules are one by one released from delivery plates. For placing down the body of capsule in lower mold, horizontal fork push it from middle side and vertical fork adjust its position. Now, capsules are fixed accurately in lower mold.

Capsule Splitting

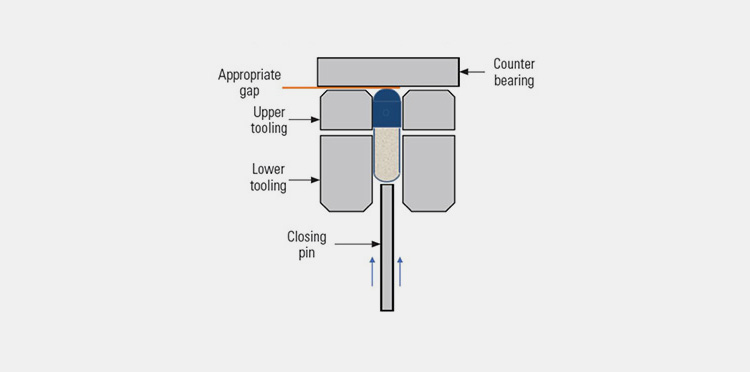

When capsule plate reaches to the splitting station, upper molds catch the caps of capsules and hold tightly. While as, body of capsules remains in lower mold for filling.

Capsule Inspection

After passing through splitting phase, capsules are inspected by detector through red light, to ratify the presence of uncapped capsules. By doing so, the filling needles do not deliver dosage in empty molds and reduce waste.

Capsule Filling

This is the actual step of filling capsules. When capsule tray comes under the liquid filling tubes, liquid dosage is dispensed by narrow needles into empty capsules.

Capsule Locking

The circular capsule trays of lower and upper mold rotate at same time. At this point, locking rods push the filled capsule bodies towards upward direction and capsules are tightly locked with caps over them.

Capsule Discharging

Finally, the capsules are discharged from the initial stage of filling. This is done by ejection rods which push the capsules upward out of the mold hole.

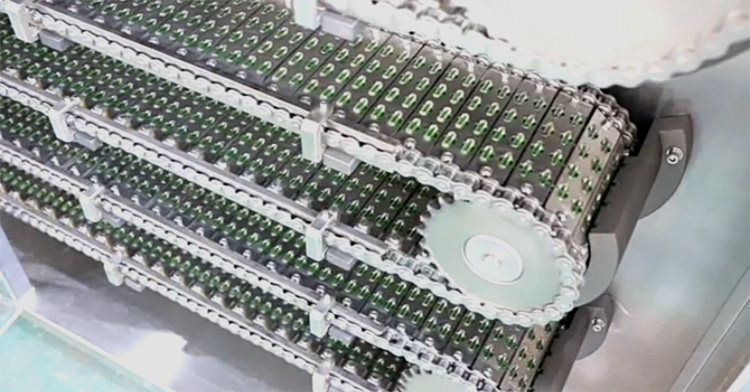

Capsule Sealing

Only locking the liquid filled capsules may not be a vigilant decision, but their appropriate sealing is a necessary requirement to overcome the fear of leakage and control of the liquid flow. Thus, when filled capsules are released through discharged chute, they are fixed in empty capsule shape boxes. They are passed through a roller having sticking strip which seals the capsules in center where body and cap of capsule meet.

Capsule Drying

In last stage, all sealed capsules are dried through air, during their transfer to collection tank.

4.What Are The Benefits Of Using A Liquid Capsule Filling Machine?

Using a liquid capsule filling machine would give you substantial benefits which other type of capsule filling machine might not be able to provide. These advantages are as follows:

Efficient

No doubt, a liquid capsule filling machine is the most efficient and effective equipment that give high production output. It can fill over 200 capsules in one minute.

Adaptable

One of the greatest features of this machine is its adaptability. This machine has the ability to adapt itself for processing capsules of small to large size. With existing tooling, you can fill various types of capsules

Versatile

Another advantage of the machine is variation of filling material. By using a single machine, oil based, water based, paste, liquid granule or liquid powder dosage can be conveyed into capsules. It indicates the degree of versatility it possesses.

Extend Shelf-life

Storing the essential liquid in form of capsule can prolong their shelf life because it would create a strong barrier against moisture, dust and oxidants.

Reduce Waste

The most significant quality of the machine is the reduction of waste during and after operation. Its inspection principle for empty slots or unopened capsules revokes the filling tube from dispensing dosage into slot. On the other hand, effective sealing adds into long-lasting safety of capsules.

Compact Design

A liquid capsule filling machine is prepared from standard quality products like stainless steel and other durable plastic for carrying liquid complying international standards. Moreover, it ensures safe operation for an operator.

User Friendly

The entire system of machine is quite easy to understand. It is controlled by touch screen control panel which give the user a command to easily handle all parts of machine with single touch.

5.What Types Of Capsules Are Filled By A Liquid Capsule Filling Machine?

A liquid capsule filling machine is designed to fill numerous kinds of solid to liquid ingredients along with liquid dosage. They are shown below:

Water FilledCapsules

It is the common type for filling capsules. Wide spectrum of water based solutions is filled in capsules which are obtained from food sources or herbs etc.

Oil Filled Capsules

Another type of capsule dosage is oil based which is also popular among people. Instead, they used to take oil filled capsules for healthy skin, hairs and reducing diseases. Under this category, pomegranate seeds oil, safflower seed oil, groundnuts oil and fish oil are prominent examples which contains good amount of vitamin K, E, A and omega 3 respectively.

Liquid-pellet Capsules

It is the combination of liquid and solid ingredients, where solid granules or pellets do not lose their existence by dissolving into liquid, instead remain in their original form. In such combination, liquid dosage gets dissolved immediately, while as pellets show gentle melting.

Paste Filled Capsules

Paste based capsules not only mean semi liquid substances but ingredients having high viscosity can be also included under this term. Paste materials are often taken from herbal sources and other natural elements like plants and seeds extracts.

Capsule In Capsule Type

A small capsule is filled with solid dosage and put inside the large capsule having liquid dosage is what we call capsule in capsule type. This process is adopted for maintaining zero contact between both due to incompatibility of molecules they contain.

6.Describe The Structure Of A Liquid Capsule Filling Machine?

The structure of a liquid capsule filling machine is highly durable that is composed of different components such as

Material Hopper

Hopper is a cylindrical or conical type tank which holds the flowing material before their entrance into machine. For adding granules or pellets this hopper is used during liquid capsule filling.

Capsule Hopper

It is the place where empty capsules are poured before their filling.

Liquid Tank

To hold the liquid dosage for capsule filling, a corrosion resistant, stainless steel liquid filling tank is used.

Control Panel

It is the crucial part of machine which display you entire mechanism of machine and provide you easy usability for controlling the functioning of machine.

Liquid Filling Tubes

These tubes are attached to liquid tank and at their end they are having thin needle from where liquid is flowed into capsules.

Capsule Turntable

The core component of any capsule filling machine is obviously a turntable, which has hollow holes for capsules. It carries non-stop rotation and takes a pause at different station for capsule taking, inspection, splitting, filling, locking and at the end capsule discharging.

Capsule Sealing Belt

It is large belt that holds thousands of capsules at same time and pass them through sealing drum for their sealing. It moves through motors.

Sealing Drum

This drum holes thin sticky strips which adheres to the capsules body during their passing under sealing drum.

Collection Tank

All capsules are collectively gathered in a tank, known as collection tank.

7.What Are The Major Types Of A Liquid Capsule Filling Machine?

Following are the two prominent types of a liquid capsule filling machine along with their structure, mechanism of action and applications:

Hard Capsule Liquid Filling Machine

Hard capsule liquid filling machine accomplish the entire task in one run with good performance. Under this category, there are two models NJY-300C and NJY-600C. The difference is only of capacity; the former can give you production rate of 300 capsules while as later can fill up to 600 capsules. This model is integrated with improved design and ensures better control while keeping the hygiene of capsules safe. Its filling accuracy is quite high and the operation of machine becomes simple with human touch interface.

Components

The structure of liquid capsule filling machine is composed of stainless steel frame, control panel capsule holding hopper, material holding tank, capsules turntable, capsule delivering tubes, capsule opening station, capsule filling station, capsule inspection device, liquid filling needles, capsule binding device and capsule discharging station etc.

Working Principles

The operation starts when the empty capsules fall down from hopper and their position is corrected by horizontal and vertical forks. Now, the separation of cap from body is occurred. Inspection device then inspect through detecting light if there is any capsule left unopened. Just after that, capsule turntable reach to filling station and capsules are filled with liquid via tubes. Once they get filled, locking is done and capsules are kicked out by rods into collection container. After that, for sealing these filled capsules you have to done it with separate machine.

Application

Due to its capacity, the machine is helpful for small to medium scale capsule processing industries like cosmetic, healthcare and herbal industries etc.

Automatic Hard Capsule Liquid Filling and Sealing Machine

This type of liquid capsule filling machine is fully automatic which performs both the capsule filling and sealing. The machine ensures stable performance with low maintenance requirement. It gives you highest throughput by filling up to 18,000 capsules per hour with six holes.

Components

Main components of this machine includes human touch interface, empty capsule hopper, liquid dosage tank, filling tubes, circular capsule trays, capsule locking station, correction forks, capsule splitting station, capsule inspection device, discharging rods, sealing drums, cooling system and collection tank etc.

Working Principles

Its process include both capsule filling and sealing which are carried by single machine. The hollow circular capsule tray revolves under the machine and empty capsules are delivered by capsule conveying tubes. When capsule dies are filled with empty capsules’ bodies, the station keeps rotating and stop for a while where liquid dosage is dispensed from filling tubes through narrow needles. The same movement goes on and capsules are joined together through upper and lower mold overlapping. Eventually, all prepared capsules are delivered via discharge chute to collection tank.Now, these capsules are taken by long belt that gently passed through sealing deym. The sealing strip is move around the center of capsules and process get finished.

Application

Automatic liquid capsule filling and sealing machine is mostly suitable for large volume production sectors like pharmaceutical, nutraceutical and veterinary industries etc. Where huge number of pills and capsules are prepared everyday.

8.Highlight The Areas Where A Liquid Capsule Filling Machine Is Mostly Utilized?

To know, how vast the application of a liquid capsule filling machine, look into the below areas:

Pharmaceutical Industry

The term pharmaceutical is carrying high responsibility as well as great role in providing this world with every possible treatment for curing enormous diseases. Thus, it is an obligatory part of a pharmaceutical industry to have a liquid capsule filling machine for fulfilling their tasks.

Nutraceutical Industry

Nutraceutical are active ingredients taken from food sources to supply body with enough supplements, so it would be able to maintain good health and combat maladies. These are often gathered in liquid form for which a liquid capsule filling machine is brought into operation.

Herbal Industry

Many people still believe in the traditional way of curing various ailments, and they preferred taking herbal medicines. These include capsules which are filled with herbal and botanical paste, eventually require proper way for packaging result in demand for a liquid capsule filling machine.

Cosmetic Industry

Owing to the customer drift for beauty supplements, cosmetic industry is now more focused on using advance technology for preparing and supplying such essentials in form of liquid filled capsules.

Veterinary Industry

One of the biggest revolutions which can be observed in veterinary industry is the digitalization of drugs manufacturing. Now, more zoologists are busy in treating their patients with liquid filled capsules that are no doubt produced by liquid capsule filling machine.

9.What Are The Support Equipment For A Liquid Capsule Filling Machine?

For full scale capsule filling manufacturing, where no step has been left from the dosage preparation till packaging of capsules, you would need the service of machines pointed below:

Capsule Inspection Machine

It is the simple way to get rid of broken and damaged capsules. Capsule inspection machine is usually a type of table, where all the processed capsules are laid down and with the help of detector; machine separates good quality capsules at one side and disabled or oversized capsules at the other side.

Pulverizer

Pulverizer is the electromechanical equipment attached to the liquid filling machine for grinding herbs, medicinal ingredients and other elements in order to form liquid paste or small granulated particles for filling into capsules.

Capsule Sorting Machine

Capsule sorting machine is an innovative technology to eliminate the empty and uncapped capsules aside from filled capsules.

Vacuum Conveying Machine

Vacuum conveying machine is designed to take the powder, granules or pellet-like substances from one tank to another vessel. Along with that, it has full scale integrated system for filtering these materials where all dirt and dusty particles are filtered and collected in bin. This way of conveying particles is safe, hygienic and fast enough.

Capsule Counting Machine

This is an advance liquid capsule counting machine, operated by electric supply. This equipment utilizes infrared technology for accurate counting of capsules. It has versatile usability due to its wide application for soft gel, hard gel capsules and other types of tablets and pills.

Capsule Polisher

When capsules are passed through production phase including material filling and capsule sealing, they are prepared for polishing purpose and put into the capsule polisher, so the left dirt or waste particles over capsules could be completely remove out. It also gives the capsules charming and glossy look.

Plunger Filling Machine

Plunger filling machine is used to carry liquid dosage of capsules and deliver it to capsule filling machine through tubes. It helps to infiltrate the correct dosage into capsule filling tubes.

Blister Packaging Machine

Blister packaging machine is an inevitable part of your capsule production line, as it digs out the way for securing your liquid filled capsules for long-lasting duration. Blister pack is usually formed from aluminum plastic which is transparent or alu-alu material which is silver-like, that hide pills under its cover. These blister packs are carrying small bubble shape area on upper side for holding capsules or tablets, so they can be separately consumed without touching the rest capsules. This way of packing capsules is very beneficial.

10.Are There Any Disadvantages Of A Liquid Capsule Filling Machine?

You should have proper knowledge of the pros and cons of a liquid capsule filling machine as it will shape the destination of your business. These include:

Expensive Price

No doubt, a liquid capsule filling machine is highly expensive due to the heavy duty and consistent workload it performs. It is the result of many complex components whether it is of filling capsules, capping and uncapping, carrying and sealing capsule gadgets. However, it will benefit you in so many ways, but before that you have to spend your good amount of money.

Experts Requirement

From installation till the assembling and dismantling of a liquid capsule filling machine, you would definitely require experts for assistance, because your little mistake can cause big loss.

Difficult Mobility

You may have observed from the discussion, that a liquid capsule filling machine is huge in its size. Not that, when you connect it with capsule sealing and other auxiliary devices, its mobilization would be somehow impossible because it is not easy to move such settled machinery frequently.

11.How To Maintain A Liquid Capsule Filling Machine To Enable Smooth Performance?

If you want to make your equipment stay longer and work smoother, you are bound to follow few obligations such as:

- Keep the surrounding of machine neat and clean. Keep the temperature under control, so it would not affect the quality of your capsules.

- When starting operation, observe that all mechanical parts of machine are moving freely. In case of abnormality in any part, do lubricate it for soft and noise free functioning.

- Clean different parts of machine especially liquid filling station and filling tubes, as it will prevent creating disturbance during operation and reduce the risk of dosage blockage.

- Change the oil of machine after 12 months.

- Keep examining the chains and screws of moving parts, and tight them well.

- Always check the ground wire of liquid filling before starting machine to confirm that tubes are is not leaked.

12.Explain The Major Pitfalls And Their Countermeasures For A Liquid Capsule Filling Machine?

Sometimes, when operating a liquid capsule filling machine you may counter some abnormalities in form of capsule defects or content filling. To overcome these faults, read below solutions:

| No | Pitfalls | Possible Causes | Countermeasures |

| 1 | The position of capsules is incorrect | Problem in vertical and horizontal fork often leads to push the cap down and body upward | Manually check the horizontal and vertical fork position and always use stainless steel devices instead of plastic as it can create electrostatic charge |

| 2 | Capsule deformed during process | This mostly happens due to moisture absorption, because capsules are temperature sensitive | Make sure that capsules are away from heat when passed through uncapping, filling and locking stage |

| 3 | Capsule break during uncapping | Quality of capsule is not good due to weak stuff they quickly get break before opening | Use good quality capsules having thick and flexible shell |

| 4 | The content delivered to capsules is insufficient | It mostly occurs when debris or dirt particles stuck in the nozzle of needles | You have to clean the needles by passing water through it |

| 5 | The capsule tray is not moving freely | There might be insufficient power supply or the rotating wheel is dry | Make sure that machine is connected with strong power supply and lubricate the moving wheels for free movement |

| 6 | Capsules have dents over body | It is due to applying too much pressure during locking capsules | Reduce the pressure, so shape of capsules could not be damaged |

13.How To Select The Best Liquid Capsule Filling Machine?

Below factors would help you in choosing the best liquid capsule filling machine:

Production Volume

Before making any decision, first measure the ratio of your daily production. By doing so, you would have an idea that which type of machine whether automatic or semi-automatic should be purchased.

Auxiliary Devices

Suppose, you are buying a fully automatic capsule filling machine, then think about supportive devices for it, because an automatic machine needs other devices for accomplishing its task.

Remote Support

From installation till maintenance, you would need assistance from expertise, which can be perfectly given be the vendor. So, completely satisfy yourself with asking every necessary question from the vendor, that what their support policy for customer care is.

Warranty Policy

Purchasing machinery with such high cost is not a game, but it should be done after thorough study, which also includes the warranty policy of the supplier. Always, choose a brand which gives you full security for equipment in form of warranty.

Complying Quality Standards

The last but important question for which you should get positive answer, is that a machine you are intending to pick is complying international quality standards like GMP’s, CE and ISO etc. If the machine is recognized by these organizations, it is made with quality material.

Conclusion

To sum up, a liquid capsule filling machine is highly innovative and fully automated filling equipment. Its use is becoming more popular and necessary in different industries especially related to medication. May be, after this thorough study you have also gotten your answer, and might be interested in purchasing this machine. So, we recommend you to consider Allpack, for booming your production with full customer support and warranty policy. For further information you can get our services by clicking on the link given.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586