Detergent Powder 4 Side Sealing Machine: The Complete Buying Guide In 2024

Detergent Powder 4 Side Sealing Machine: The Complete Buying Guide In 2024

Get tired of finishing your laundry in one day? Then why not looking for a better alternative? In fact, more and more people are now turning to done with their laundry every single day and secure a fresh and free weekend. For this, what can be more handy than using a single serving detergent powder! That's why, now manufacturers are trying to provide their consumers with 4 side seal detergent powder sachets which are easy to use. To fulfill this aim, Detergent Powder 4 Side Sealing Machine is always there!

This machine can perfectly create 4 side seal sachets for encasing your detergent powder. With its diverse specifications, convenient operation, and precise structure you can transform your existing production. Moreover, it allows you to gain much other benefits by utilizing its features. So, let's disclose all of its valuable aspects hidden in this buying guide!

1.What Is A Detergent Powder 4 Side Sealing Machine?

Allpack- APK-130 Automatic Horizontal Detergent Powder 4 Side Sealing Machine

Detergent powder 4 side sealing machine is a flexible packaging machine employed to deal with the packing of single serving detergent powder. It can create small perfect bags to enclose the precisely weighed detergent powder and sealing it stringently from all the four sides.

With its quality stainless steel body, it is fully protected against corrosion and bacteria thereby allowing you to conduct safe operation. In addition to it, the machine has automatic system to carry out its function effectively. Hence, it leads to the packaging accuracy, efficiency, and material safety.

2.Enlist The Features And Benefits Of A Detergent Powder 4 Side Sealing Machine?

Detergent powder 4 side sealing machine is tailored with astonishing features to responsibly pack detergent powder into packages. These characteristics can greatly benefit you by transforming your production processes. So, let's know these all which are enumerated below!

High Efficiency

Various detergent powder 4 side sealed tripid sachets- Picture Courtesy: ever.ph

The machine has automatic technology to perform its function of detergent powder packing. Thus, it does not require any manual intervention once started. This non-stop functioning of the machine results in the working efficiency and increased output ratio.

Consistency

Precisely finished detergent powder sachets- Picture Courtesy: rewardhospitality.com.au

Detergent powder 4 side sealing machine maintain high consistency during packaging. By using specialized filling system, it accurately measures the exact amount of detergent powder for each bag. Along with it, the machine support uniform sealing of all the 4 side sealed bags due to which each finished pack has same amount of material as well as appearance.

Durability

Allpack- durable single lane powder stick packing machine

Durability is what count on part of machine quality and this you will find in a detergent powder 4 side sealing machine which is made up of stainless steel that has resistant properties against corrosion and bacteria. It has small footprint and can be easily mobilized from one place to another.

Adaptability

Various 4 side sealed bags of different powders- Picture Courtesy: landpack.com

The most essential attribute of the machine is its high level adaptability and flexibility to accommodate different types of sealing and cutting designs. It also supports the weighing and filling of powders other than detergent powder in food and non-food sectors. Hence, it is the most versatile and reliable machine to have in your production line.

Ensure Safety

With automatic control system and sensors, detergent powder 4 side sealing machine is capable of reducing material waste and ensuring operator safety. For instance, by cutting the film on exact mark and filling the weighed detergent powder, material is saved from waste and the emergency stop and alarm light is there for alerting user.

3.What Type of Sealing Formats Are Offered By A Detergent Powder 4 Side Sealing Machine?

You may be thinking that a detergent powder 4 side sealing machine can only offer limited formats, however, it's not the case. Instead, this single machine can provide you with eclectic sealing formats with vibrant cutting designs. We have enlisted these all under the following headings:

Standard 4 Side Seal Bags

Standard 4 side seal detergent powder sachet

It is a commonly used format for packing single serving detergent powder. It may have a rectangle, square, or tubular shape. Such detergent powder bags can be easily made by detergent powder 4 side sealing machine.

Twin Bags

Detergent Powder twin bags- Picture Courtesy: citimartdelivery.com

Twin Bags refer to the dual packages which are interconnected to each other either through sealing or perforation. They are best to deliver variety of materials at once in separate sections. These twin bags can be conveniently created by using a detergent powder 4 side sealing machine.

Tripid Bags

Tripid packs of detergent powder- Picture Courtesy: ever.ph

This machine is also capable of producing beautiful and economical triple bags for encasing detergent powder. These tripid bags are separated by sealing in mid.

Strip Bags

Continuous detergent powder bags- Picture: tsl-detergent.com

As the name indicates, strip bags are individual bags being linked with one another via perforation. They are useful for displaying detergent powder in retail stores. As detergent powder 4 side sealing machine is flexible enough to deal with different kinds of packaging formats, so, it can be employed for forming strip bags.

Designed Sealed Bags

Straight sealed detergent powder 4 sealed sachet- Picture Courtesy: allday.com.ph

You may wonder after reading the term designed sealed bags. But yes! It exists and is valuable for every manufacturer who want to make their goods more attractive with beautiful and strong sealing. Similarly, detergent powder 4 side sealed bags can be sealed by applying different sealing designs such as square, serrated, triangle, and diamond type sealed. By changing sealing jaws, you can have these formats with this machine.

Designed Cut Bags

Detergent powder sachet with zigzag cut- Picture Courtesy: Behance

Detergent powder 4 side sealing machine offers variety in cutting designs for bags. You just need to fit the relevant type of cutter in machine and it will give you cut styles like zigzag, flat, tear notch, and perforated cut for beauty as well as convenience for opening the bags.

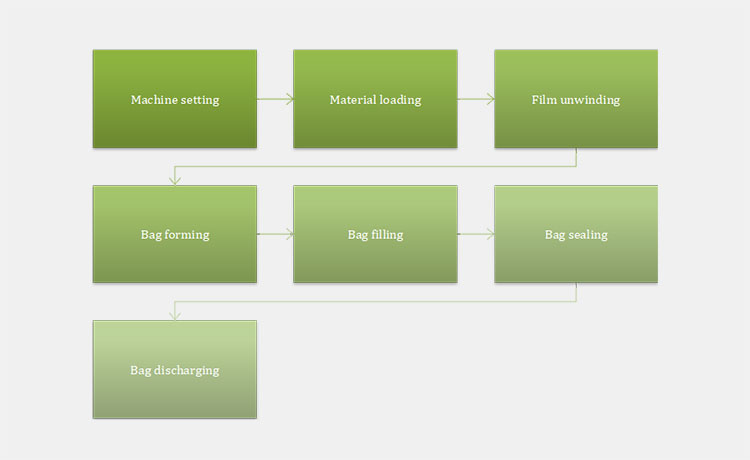

4.What Are The Working Principles Of A Detergent Powder 4 Side Sealing Machine?

Detergent powder 4 side sealing machine works on the underlying working principles:

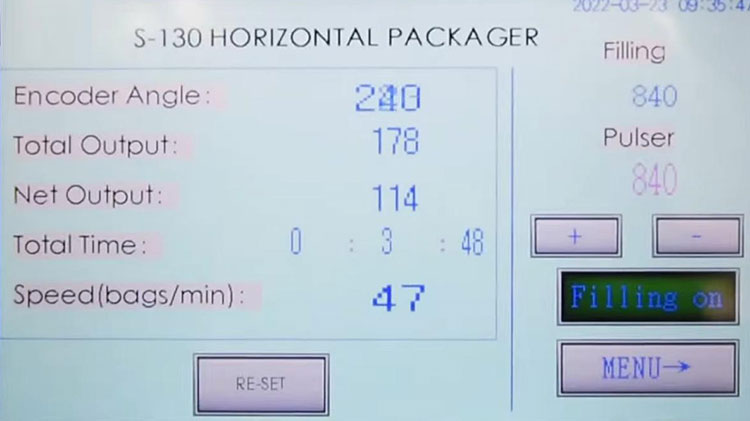

Machine Setting

Machine parameters setting on touch screen- Picture Courtesy: Acepack

The process of a detergent powder 4 side sealing machine gets started with the setting of basic parameters for its functioning. For this purpose, operator interact with the machine by using a touch screen interface to set data for printing over film, the amount of detergent powder to be filled in each bag, the temperature of heat sealing jaws, and the total output to be given by the machine.

Material Loading

Once setting of the machine is done, the processing material will be fed to the machine. In this step, operator will supply the hopper of machine with sufficient volume of detergent powder. Along with that, a roll stock of film will be fixed in the unwinding wheel and it should be further adjusted by the user on film guide before starting operation.

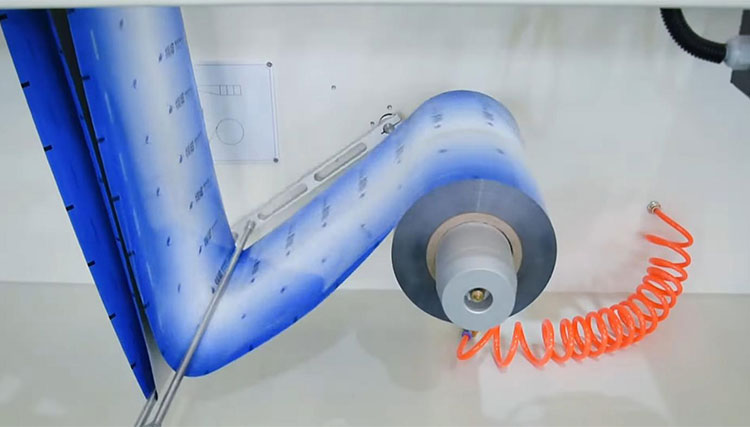

Film Unwinding

Film unwinding- Picture Courtesy: Acepack

Once the machine setting and loading is completed, detergent powder 4 side sealing machine is ready to be switched on. As the machine is powered on, the film will start unwinding film from roll. With the help of film guide located after certain intervals, the film layer will be drawn from roll stock towards bag forming unit.

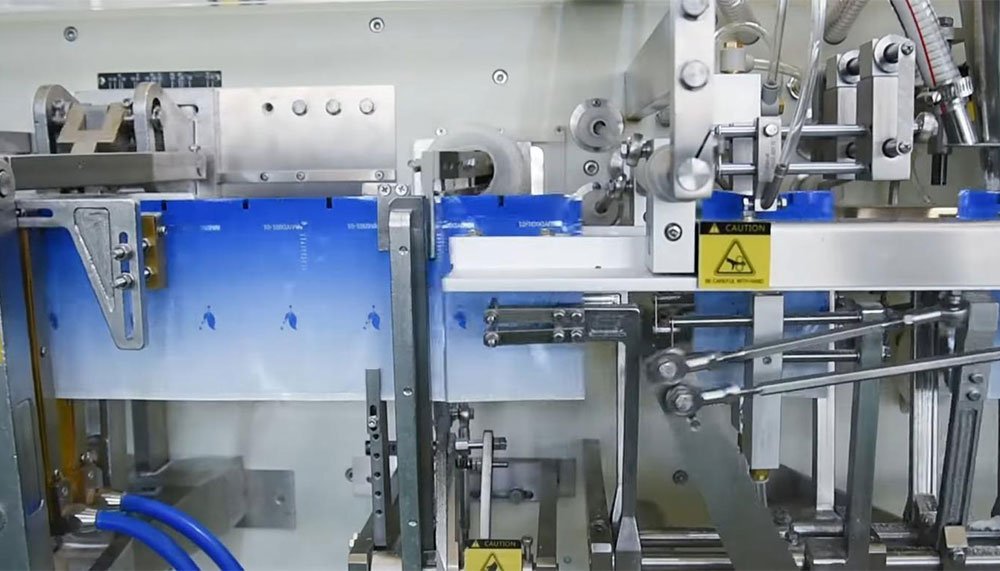

Bag Forming

Bag forming- Picture Courtesy: Acepack

Here, a fixed area on bag is detected by the machine for optional printing to print expiration date and batch no etc. In the same manner, unwinded film is moved ahead and folded from one side. As the film is folded, sealing from bottom and vertical sides is added into the film. It thus forms a beautiful bag which is ready to hold a dose of detergent powder.

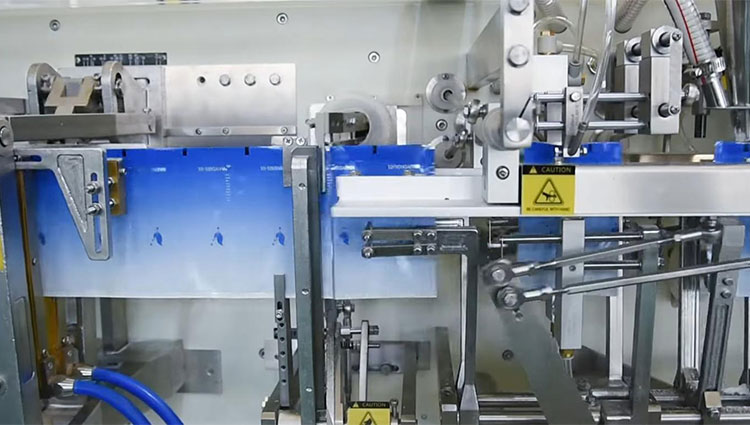

Bag Filling

Bag filling- Picture Courtesy: Acepack

Moving forward, the formed bags are separated through cutting and pushed ahead for filling. As they reach under the filling head, grippers hold them and open their top side. At this point, detergent powder 4 side sealing machine accurately measures the volume of detergent powder which is fixed by the operator. Similarly, the weighed detergent powder is filled into formed bags via heads or filling nozzles.

Bag Sealing

Once filled, these bags are then passed through a sealing phase for stringent closure against leak and material waste. During this phase, the opening of bags are closed when heated sealing jaws contact with them. Resultantly, strong sealing is realized and detergent powder 4 side sealed bags are ready for outlet.

Bag Discharging

Finished 4 Side Sealed bags- Picture Courtesy: Acepack

In the last step, finished detergent powder 4 side sealed bags are discharged out of the machine via chute and collected in a container for further packaging.

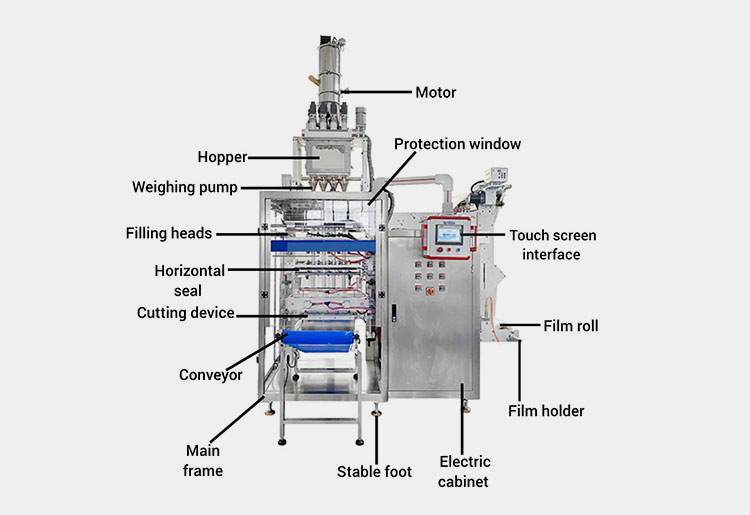

5.Describe The Major Parts Of A Detergent Powder 4 Side Sealing Machine?

Detergent powder 4 side sealing machine is composed of different components. All these parts are of major importance due to the role they play in machine's functioning. That's why, we have described some of the major parts of this machine for your help:

Major parts of Detergent Powder 4 Side Sealing Machine- Picture Courtesy: samfull.net

Motor

Motor is the power generator of a detergent powder 4 side sealing machine. It is located on the top of machine with prime function of energizing machine to carry out its task of packing.

Hopper

Hopper is a large size container situated on the top of machine under motor. Its structural design vary according to the characteristics of material being packed to ensure good flow. Similarly, it is very useful to hold the bulk of detergent powder inside it and supply the machine with it for consistent operation.

Weighing Pump

Another most significant part of a detergent powder 4 side sealing machine is weighing pump. It is used for measuring the amount of detergent powder before filling into bags.

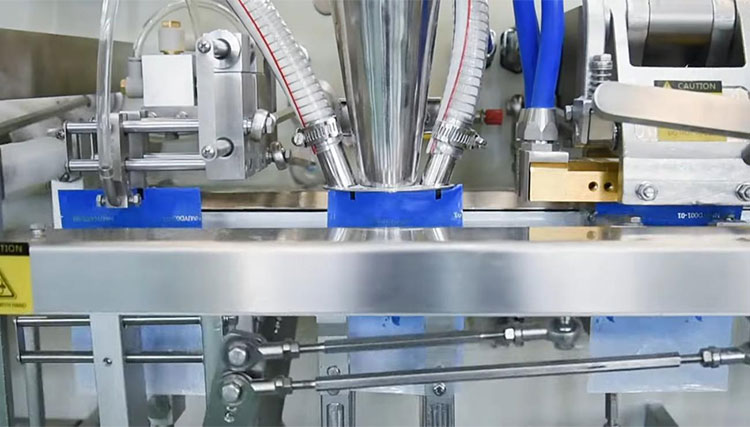

Filling Heads

Filling heads refer to the nozzles of machine whose function is to deposit weighed amount of detergent powder into formed bags. They are made from food grade quality stainless steel to avoid corrosion and bacterial growth. Moreover, the number of filling heads depends upon the type of machine being used such as single head or multi head etc.

Horizontal Seal

The machine also has a set of heat sealing jaws which can be categorized into horizontal seal and vertical seal. The former is used to add the bottom and top sealing to bags, while as, the latter is responsible to create longitudinal sides sealing of the bags.

Cutting Device

As a detergent powder 4 side sealing machine create multiple bags from single film, it has cutting device to split the film. Another cutting device is located at the bottom side of machine which is responsible to separate the finished detergent powder packages from one another. They can be of different types like zigzag or flat cutter etc.

Conveyor

Conveyor is another important part of the machine which is located at the end of machine. It is used to discharge the output detergent powder packages from machine towards collection container or adjoined secondary packaging machine.

Main Frame

The main frame of machine is highly durable and compact which is made from quality stainless steel. It keeps all the other parts united together and help in the stable performance of machine by restricting shaking.

Stable Foot

There are number of stable feet located underneath the machine. They are helpful in enabling the machine to stand upright above the surface.

Electric Cabinet

Detergent powder 4 side sealing machine runs through electricity. Therefore, every part of it has electric connection in form of wires and knobs. To safely gather all these connections in one place, a section of the machine is dedicated which is known as electric cabinet.

Film Holder

It is a device that is used to hold the film reel. The location of film holder vary from one type of machine to another.

Film Roll

Film roll is one of the essential components of a detergent powder 4 side sealing machine. It is a stock of film rolled over a device and is fixed into the machine to form bags from it.

Touch Screen Penal

Touch screen penal is an intuitive human machine interface that display multiple sets of information over it in form of digits and alphabets. Operator can simply interact with it to set commands according to which the machine will be executed.

Protection Window

The machine has a large transparent window placed in front of the working area. It has dual benefits; to secure the ongoing packaging process against environmental elements as well as ease operator in the administration of packaging cycle.

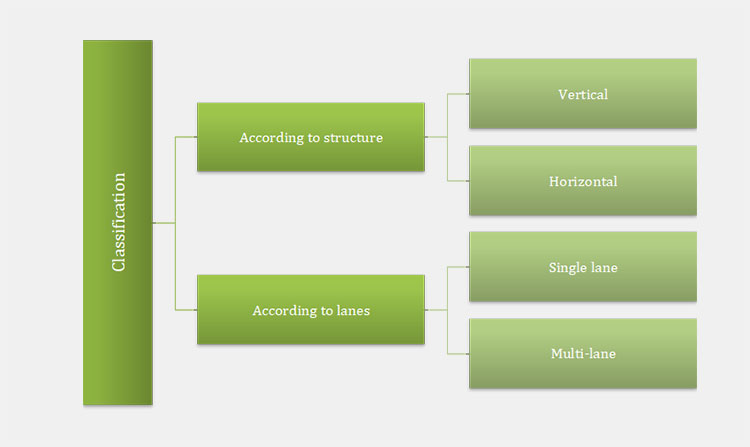

6.What Is The Classification Of A Detergent Powder 4 Side Sealing Machine?

Detergent powder 4 side sealing machine can be classified into different types. These are explained below:

According to Structure

Vertical Detergent Powder 4 Side Sealing Machine

LMSTS-450 Semi-Automatic Sachet Packaging Machine- Picture Courtesy: lenismachines.com

Vertical detergent powder 4 side sealing machine is a vertical design machine having precise body which occupy less space. However, it gives you high production efficiency. It is easily movable and can be integrated with other machines to automate your packaging line.

Horizontal Detergent Powder 4 Side Sealing Machine

Allpack- APK-130 Automatic Horizontal Detergent Powder 4 Side Sealing Machine

Horizontal detergent powder 4 side sealing machine is a sophisticated machine with complex body. Although, it will require a bit larger place for installation, but possess several benefits. Few such advantages include its high accuracy, adaptability to create twin bags, and production efficiency.

According to Lanes

Single Lane Detergent Powder 4 Side Sealing Machine

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine

Single lane detergent powder 4 side sealing machine is the most reliable machine with small footprint and cheap price. With a single lane to pack detergent powder, this machine is best suitable for small to medium scale industries. Despite being low in output ratio due to single lane, it is automatic, thus, ensuring packaging accuracy.

Multi Lane Detergent Powder 4 Side Sealing Machine

Sachet Detergent Powder Multilane Packing Machine- Picture Courtesy: bojupacking.com

This multi-lane detergent powder 4 side sealing machine is a wonderful equipment with cutting-edge automatic technology and advanced machinery. The machine is fully automatic and made with multiple lanes to facilitate larger production lines. It accept customization and offers diversity in filling material, packaging films, sealing and cutting designs.

7.Differentiate Between Detergent Powder 4 Side Sealing Machine And Detergent Powder 3 Side Sealing Machine?

Although, detergent powder 4 side sealing machine and detergent powder 3 side sealing machine are used for the same purpose of encasing detergent powder into flexible packages, yet, they are different from each other in many ways. We have explained these differences in the table below:

| No | Points | Detergent Powder 4 Side Sealing Machine | Detergent Powder 3 Side Sealing Machine |

| 1 | Used for | Detergent powder 4 side sealing machine is used to pack detergent powder into 4 side sealed bags. | Detergent powder 3 side sealing machine is employed to pack detergent powder into 3 side seal flexible packages. |

| 2 | Bag former | The bag former of machine is flat to simply make 4 side seal bags for detergent powder. | In contrast, it has conical shape bag formers which are used to wrap the film around them for creating 3 side seal bags. |

| 3 | Number of films used | It often uses two layers of films which are attached together through sealing. | While as, this machine uses single layer of film which is then folded and sealed from three sides. |

| 4 | Material holding capacity | Packages created by it has capacity of holding low amount of detergent powder. | On the other hand, the bags made by detergent powder 3 side sealing machine can hold a bit larger volume. |

| 5 | Benefits | It produces highly secured packages. | It offers cost-effective way for packaging. |

| 6 | Application | It is suitable for low volume powders in food, daily chemical, and pharmaceutical industry. | It is best for large volume and insensitive powders produced in pigment, cosmetic, and chemical industry. |

| 7 | Picture |

High Production 1-100gr Detergent Sachet Packing Machine- Picture Courtesy: samfull.net |

Multi row three side sealing powder packaging machine- Picture Courtesy: chengyipacking.com |

8.Highlight The Applications Of A Detergent Powder 4 Side Sealing Machine?

Detergent powder 4 side sealing machine is flexible enough to be used for numerous powders in different industries. These applications of the machine in multiple sectors are highlighted below:

Daily Chemical Industry

Detergent powder sachet- Picture Courtesy: Behance

First of all, this fantastic machine has wide application in detergent powder industry across the globe. It is because detergent powder has particles which may flow into air and get into the user eyes. But this machine process it efficiently in an enclosed environment.

Condiment Industry

Various types of power condiments

Condiments industry is an area where the production and processing of condiments powder is a routine task. That's why, you will find all kinds of packaging being used for their preservation. Among them, 4 side seal sachets are also very common to enclose instant noodles seasoning, chilli powder, pepper and salt etc. Therefore, to pack these seasonings, a detergent powder 4 side sealing machine can be utilized.

Food Industry

Tea sachets presentation idea

Another notable application of this sophisticated machine is food industry. Here, numerous powders including milk powder, instant coffee powder, beverage powder and chocolate powder are processed which also require safe packaging. Hence, they are packed in 4 side sealed packages by taking help from detergent powder 4 side sealing machine.

Healthcare Industry

Medicated powder sachets

Healthcare industry encompasses all the other subfields such as pharmaceutical, herbal, and nutraceutical industry. These all are directly or indirectly involved in delivery drugs and supplements in form of powders. Since, medication require strict administration and should be taken carefully, 4 side sealed single serving packages are always preferred for which a detergent powder 4 side sealing machine is eligible.

Beauty Care Industry

Beauty powder presentation idea- Picture Courtesy: topsante.com

How can beauty industry be left behind when the discussion is about importance of a detergent powder 4 side sealing machine. Simply put, this amazing equipment can handle the packaging of beauty related powders including hair dye powder, bleach powder, and face powder etc.

9.How To Examine The Quality Of A Detergent Powder 4 Side Sealing Machine?

Knowing the quality of your detergent powder 4 side sealing machine is very important as the machine is going to be your life time partner in dealing with detergent powder packaging. Now, the question is how can you check the machine quality? So, the answer is simple! It must be certified by certain quality standards. These standards are mentioned below:

ISO quality standard icon- Picture Courtesy: newleafsearch.com

GMP: It stands for Good Manufacturing Practices, a qualified standard that represent safety by establishing guidelines for products processing. In case of detergent powder 4 side sealing machine, it deals with its structural material that should be made from quality stainless steel.

ISO:International Organization for Standardization is another prominent quality standard which works for the mobilization of quality products and machines. Hence, a detergent powder 4 side sealing machine adhering to its principles will be a perfect one.

CE:If you are citizen of any European Union country, it is important for you to check the machine certification by CE. The reason is because this mark represent public safety regulations across these countries.

UL: Electric system is one of the core systems that keep your machine functioning. That's why, UL certification is given to all the equipment whose power electric system is safe against damage and breakdowns.

10.How To MaintainA Detergent Powder 4 Side Sealing Machine?

Man maintaining machine- Picture Courtesy: nanoprecise.io

Maintenance is the key to long working life of your detergent powder 4 side sealing machine. It simply means to keep yourself engaged with your machine on regular basis for proper maintenance. Below, we explained the preventive maintenance and maintenance after breakdown:

Preventive Maintenance:

It refers to adopt means and methods for keeping your machine maintained against breakdown. For this you should clean your machine every day when it is done with work to decontaminates it and avoid nozzle blockage. Similarly, you need to keep the movable parts lubricated to enable machine for smooth functioning against friction and premature parts wearing.

Maintenance after Breakdown:

Sometimes, due to negligence in following routine preventive maintenance steps can lead to the breakdown of machine in form of parts damage or failure. The reason can also be the old parts. However, in such case, it is crucial to examine the defective parts and change these parts timely to stop further errors.

11.Troubleshoot The Common Pitfalls Of A Detergent Powder 4 Side Sealing Machine?

In the table below, you will be shown some common pitfalls caused by a detergent powder 4 side sealing machine along with their possible causes and solutions:

| i. Film tracking error | ||

Highlighting film tracking error- Picture Courtesy: Syntegon |

Cause:

The tension control of film is poor. The film is misaligned. Roll stock is causing trouble in releasing film. |

Solution:

Adjust the film control setting through control panel. Check if the film is off track and realign it to center. Adjust the brake to allow smooth delivery of film. |

| ii. Irregularities in length of finished bags | ||

Marking the irregularities in length of finished detergent powder bags- Picture Courtesy: ios.net.au |

Cause:

There is fault in time setting of machine. Film pulling mechanism may be damaged. |

Solution:

Check and adjust the time setting for bag sealing and cutting. Examine the film pulling mechanism for wear and tear and change the defective parts if needed. |

| iii. Sealing integrity issue | ||

Detergent powder 4 side sealed bag with highlighted sealing |

Cause:

The temperature of sealing is either excessive or insufficient. Sealing jaws are damaged. Sealing jaws are dirty causing poor sealing. |

Solution:

Examine the temperature and set it according to the type of film being used. Inspect the sealing jaws for damage and replace if necessary. Clean the sealing jaws. |

| iv. Detergent powder trapped in seals | ||

Detergent powder sachet with highlighted sealed edge- Picture Courtesy: pentalfactorysales.com.au |

Cause:

Detergent powder is not settled when the sealing is added to bags. Overfilling can result in the powder trapping into seals. |

Solution:

Adjust the setting of machine by allowing more time for powder to settle in bag. Reduce the fill volume of powder in control penal. |

| v. Fill volume inconsistencies | ||

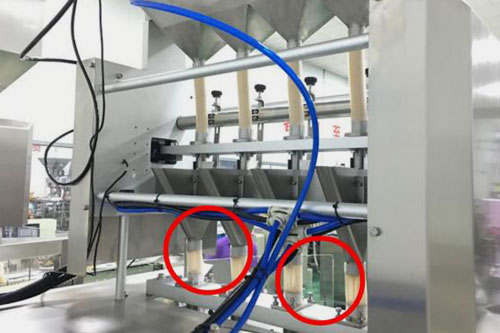

Encircled powder filling heads- Picture Courtesy: chengyipacking.com |

Cause:

The integrated filling system is not compatible to the properties of detergent powder. Filling time duration is wrong. |

Solution:

Use the type of filling system in accordance with powder properties. For example, auger filler for fine cohesive powder, while as, volumetric weighing system for granulated powders. Modify the filling time duration. |

12.Factors to Consider When Buying A Detergent Powder 4 Side Sealing Machine?

Every entrepreneur wishes to have the best machine in production line, as it can change the fate of business. Similarly, whenever you intend to buy a detergent powder 4 side sealing machine, don't forget to take a pause and think for a while about certain crucial factors. Considering these factors can uplift your benefits, while as, negligence may do adverse. So, have a look towards the underlying points!

Current Production

The first question starts from you which is simply examining your current production volume. Doing so will help you know the production requirements and opt for relevant machine. For example, a single lane detergent powder 4 side sealing machine is suitable for small to medium scale industry. In contrast, for large scale industry, multi lane machine will be a perfect choice.

Packaging Type

Type of detergent powder packaging- Picture Courtesy: southernpackaging.com

Another important factor asks you to determine your packaging needs which simply means to set whether you want to create your own packages or using premade bags. Similarly, you it will help you choose either premade detergent powder 4 side sealing machine or form, fill, and seal detergent powder 4 side sealing machine.

Spare Parts

Sealing jaws- Picture Courtesy: kenrayglobal.com

Your detergent powder 4 side sealing machine may need some spare parts frequently which should be present in your inventory all the time. Do, you should know about them in advance. Moreover, for different sealing and cutting designs you will have to use relevant sealing jaws and cutters. So, make sure to buy these parts along with machine.

Quality Assurance

Quality assurance icon- Picture Courtesy: talentmsh.com

Quality matters the most especially when you are going to incorporate a full fledged packaging machine in your production line. Therefore, make sure to ask your vendor for the quality certification of machine and its warranty policy.

Conclusion

So, we are about to conclude our buying guide on a Detergent Powder 4 Side Sealing Machine with few reminders that this autonomous machine is brilliant enough to deal with modern production facilities. Its adaptability, convenience, and durability has made it relevant in industries far beyond detergent powder. Its benefits are hidden from no one in the realms of packaging. If you are also desiring the same then make sure to consider the vendor expertise and warranty policy. Allpack is fulfilling both these conditions by having over 11 years of experience and offering one year of warranty. So, don't make delay and contact us ASAP!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Detergent Powder 4 Side Sealing Machine: The Complete Buying Guide In 2024 Read More »