Your Professional Tablet Coating Machine Manufacturer

- Constant Track Movement

- Air Supply Spraying System

- Clean and Closed Rotational Cylinder

Tablet Coating Machine

If you want to mask the taste,odor and color of your drug,or if you want to provide physical and chemical protection for your drugs,a tablet coating machine is a good choice for you.A tablet coating machine is a mechcnical device that apply an essentially dry, thin layer of coating material to the surface of tablet dosage forms in order to confer specific benefits over uncoated variety. It is an equipment that coats the outer surface of tablet with a thin layer of coating material.Tablet coating machine has been widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc. And it has such characteristics as good appearance in design, high efficiency, low energy consumption and small floor area, etc.

Tablet Coating Machine

BG-40 Series High-efficient Gum Film Coating Machine

Allpack BG-40 series tablet coating machine can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film, etc. In such fields as of pharmaceutical, food and biological products etc. And it has such characteristics as good appearance in design, high efficiency, low energy consumption and small floor area, etc. The tablets make complicated and constant track movement with easy and smooth turning and frequent exchanging in the clean and closed rotational cylinder of the film coating machine.

Automatic run of various process flow in sequence

PLC automatic control

Easy to operate and control relevant technological requirements

BG-80 High Efficiency Tablet Film Coating Machine

Allpack BG-80 tablet coating machine is used for carrying out sugar coating and film coating to the core of Chinese traditional and Western tablets. It integrates strong power, weak power, hydraulic and pneumatic. It is a new type of equipment that improved on the basic of the original common type sugar coating machine. It is composed of the mainframe, a controllable normal-temperature hot air system, an automatic liquid supply, and air supply spraying system, etc. The motor adopts a frequency converter.

High-efficiency, energy-saving,

Safe, clean, and mechatronics equipment for coating tablets

Slow and controlled release film

BG-150 Pharma Tablet Coating Machine With Air Filter

Allpack BG-150 tablet coating machine consists of major machine, slurry spraying system, hot-air cabinet, exhaust cabinet, feed and discharge device, and computer programming control system.It can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc. And it has such characteristics as good appearance in design, high efficiency, low energy consumption and small floor area, etc.

Convenient to operate

Easy to master and flexible controlled technological requirement

Uniform density and particle in spray pressure

BG-400 Pharmaceutical Tablet Film Sugar Coating Machine

Allpack BG-400 tablet coating machine, the tablets make complicated and constant track movement with easy and smooth turn frequent exchanging in a clean and closed drum of the film coating machine. The coating mixed round in the mixing drum is sprayed on tablets through the spray gun at the inlet inaction of the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure 100,000 clean hot air supplied by the air exhaust cabinet is exhausted from the fan at the sieve meshes through tablets.

Good appearance in design, high efficiency,

Low energy consumption

Small floor area

BYA-300 Pharmaceutical Tablet Pill Sugar Coating Machine Tablet Coating Machine

Allpack BYA-300 tablet coating machine is used to sugar coat tablets and pills for the pharmaceutical and food industries. It is also used for rolling and heating beans and edible nuts or seeds. As its feature, the sugarcoating round pot is elevated with an elevation of 30° to the horizontal, and the heater such as a gas or electric heater can be placed directly under the pot. A separate blower with an electric heater is provided with the machine. The full consolidation of the cladding surface after the crystallization of sugar produced can prevent oxidative deterioration of chips.

Steady Transmission, good performance

Convenient to wash and maintain

High thermal efficiency

BYA-400 Pharmaceutical Tablet Film Tablet Coating Machine

Allpack BYA-400 tablet coating machine is used to carry out sugar coating and film coating to the core of Chinese Traditional and Western tablets; it integrates strong power, weak power, and hydraulic pressure with pneumatic operation. Mainly by the host (original sugarcoating machine), controllable temperature hot air system, automatic for the liquid, gas spray systems, exhaust, and other components. The main motor has the function of frequency speed control, it sprays the coating purposed auxiliary materials to the tablet surface with a high atomized spray gun automatically, meanwhile, the tablets make continuous and complex track movement in the coating pan, letting the coating fluid cover the tablet core evenly.

Easy to operate, one-sided smooth

Bright, delicate

Saving accessories, maintenance

BYA-600 Full Automatic Pharmaceutical Tablet Process Equipment Tablet Coating Machine

Allpack BYA-600 tablet coating machine is mainly composed of main engine (former sugar coating machine), controllable room temperature hot air system, spray system for automatic liquid supply and air supply, etc.The main motor is adjustable in frequency and speed. It sprays the coating auxiliary materials on the surface of the tablet with a high-atomization spray gun by means of automatic control by electrical appliances. At the same time, the tablet moves in a continuous and complicated trajectory in the coating pot to make the coating liquid uniform,wrapped on the core of the tablet.

Reliable safety sealing system and dust-proof system

High visibility isolated door to prevent cross contamination

Easily remove parts for quick machine's maintenance

BYA-800 Tablet Coating Machine

Allpack BYA-800 tablet coating machine is mainly used in pharmaceutical industry, pills, sugar-coated tablet production, can also be used to roll-food, light industry, chemical industry, spherical or granular materials, mixing and lighting. For example: chocolate polishing, bag of peanuts, sugar, spices, manufacturing dumpling, pearl powder round, rolling desiccant, production of chemical packing, aluminum hydroxide ball, alumina ball, balls molecular sieves, catalysts coated polished the sugar-coated tablets, with a bright color appearance, the full consolidation of the cladding surface after crystallization of sugar produced.

Easy to operate

Materials feeding is convenient and efficient

Easy to clean, coating pan can be disassemble

BYA-1000 Tablet Coating Machine

Allpack BYA-1000 tablet coating machine can make sugar coating of the tablets and pills for pharmaceutical and food industries. It is also used for rolling and heating beans and edible nuts or seeds. The sugar coating round pot is elevated with an elevation of 30 degrees to the horizontal, and the heater such as gas heater or electrical heater can be placed directly under the pot. A separated blower with electrical heater is provided with the machine. The pipe of the blower stretches into the pot for heating or cooling purpose. The thermal capacity can be selected in two levels.

Materials feeding is convenient and efficient

High visibility isolated door to prevent cross contamination.

Easily remove parts for quick machine's maintenance

The Buyer's Guide

Tablet Coating Machine: The Complete Buying Guide In 2025

Sleek, elegant, and colorful tablets are essential for patient compliance. But how do tablets have such a glossy and attractive appearance?

Well, the answer to this question is by tablet coating machine. These instruments apply a thin shiny layer of polymer solution onto the tablet surface to improve its aesthetics. These machines are also useful in upholding the integrity of tablets.

If you are considering buying this handy equipment then read this informative guide “Tablet Coating Machine: A Buying Guideline in 2025” to learn about the classification, working, benefits, and troubleshooting of the equipment.

Let’s have an insight!

1.What Is Tablet Coating Machine?

A tablet coating machine is a traditional equipment that coats the exterior surface of a tablet with a thin layer of film, thus increasing patient acceptance of tablets. It is used to enhance the protection against degradation from environmental elements. Tablet coating machines are employed in wide-ranging applications from pharmaceuticals to food, cosmetics, agriculture, etc.

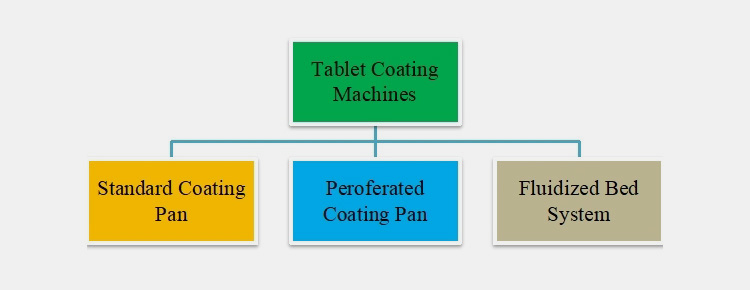

2.What Are the Major Classes Of Tablet Coating Machine?

There are a variety of tablet coating machines present in the market differing on their design construction and type of application. The basic classification is discussed below:

CLASSIFICATION BASED ON DESIGN

Based on the design, there are three major classes of tablet coating machines.

Standard Coating Pan

These are traditional types of tablet coating machines. They consist of metallic pans having a diameter of about 6-80 inches. The pan is inclined towards the bench top with an angle of 45. Pan is rotated via a motor. The tablets are loaded inside the bed and tumbled in bed multiple times for even and uniform coating.

Working Principle of Standard Coating Pan

The coating solution is introduced onto the tablet with spraying or lading. The drying is carried out by incoming heated air. The incoming air is introduced via air let while air goes outside of machine by means of duct present in front of the pan.

Perforated Coating Pan

These equipment are employed for aqueous-based coating and they have the benefits of being explosion-proof since volatile substances are not used in these machines for coating.

Working Principle of Perforated Coating Pan

This has a drum or pans with multiple holes and the drum is enclosed inside a container. This is rotated around the horizontal axis and with the help of nozzles located inside the drumcoating solvent is dispersed on the tablet.

Fluidized Bed System

These are the vertical columns in which tablets are suspended. So, this equipment is also called air suspension coater. A fine atomized coating of the solution is deposited on the tablets by means of spray nozzles. The nozzles are found at the top or bottom depending upon the type of fluid bed system.

Working Principle of Fluidized Bed System

Heated air is used for moving tablets in an upward direction and they fall down due to gravity. This cycle of rising and tumbling is repeated various times for getting a fine layer of coat on tablets.

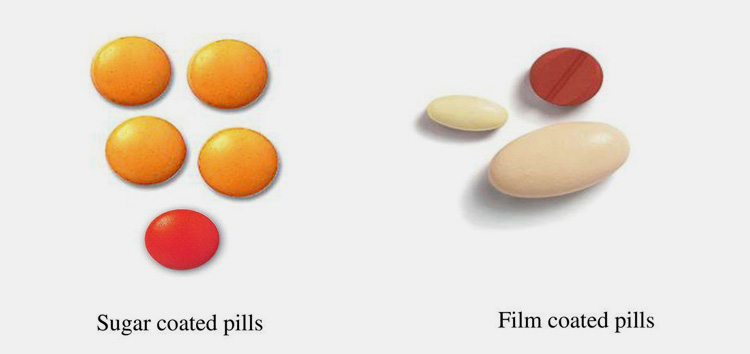

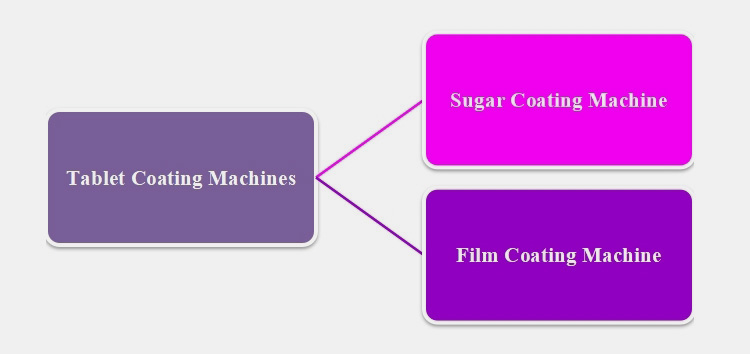

CLASSIFICATION BASED ON APPLICATION

There are two major types of tablet coating machines based on coating application.

Sugar Coating Machines

These are conventional kinds of machines employed in the pharmaceutical and confectionary industry for covering core tablets with sugar solutions.

Sugar coating machines consist of traditional coating pans in which products are loaded by means of shafts. The movements of the pan cause the tumbling of products, so these products pass numerous times through spray zones resulting in their fine coating.

Working Principle of Sugar Coating

The working of sugar coating is very simple and easy. A sugar solution (sucrose, icing sugar, and dextrose are sprayed over the rotating tablet bed where a solvent is evaporated using heat ultimately giving you a fine layer of sugar coating.

Film Coating Machine

They are evolved forms of sugar-coating machines. They are used for maintaining the potency and efficacy of core drugs. Film coating machines apply a thin layer of film on tablets and make them a suitable vehicle for delivering a drug.

They have several advantages such as brand recognition by application of film and assist in the release of drugs by controlling the disintegration of protective film.

Working Principle of Film Coating

It involves the deposition of a uniform polymer-based layer over the surface of tablets, capsules, pills, or granules under controlled conditions such as optimum spray, drying, distance, and rate of delivery.

3.How Does Tablet Coating Machine Benefit Your Business?

Do you want to protect the integrity of your active drug compound in tablets? The best way to do this is by using tablet coating machine. These systems offer quite a number of advantages to your business, some of which are:

High Coating Uniformity

By using tablet coating machines, you will achieve high coating uniformity. The use of spray guns provides consistent superior-quality deposition and there will be little batch variation.

Reduce Contamination

These equipments are efficient and autonomous thus operators are not in contact with tablet which lowers the chance of tablet contamination.

Control on Drug Release

These machines apply a uniform coating that controls the release of drugs from a tablet. This also aid in decreasing the dosing rate as coating allows sustained and steady release of drugs.

Tamper-Resistant

By smearing coating solvent on the tablet exterior, tablet coating machines perverse the shapes of tablets and prevent their tampering.

Boosting Aesthetic Appeal

These devices offer the tablets a smooth finish and aid in masking the unpleasant bitter flavor, unappealing color, and disagreeable odor of core drugs.

Prevention of Mechanical Damage

The tablet coating machine helps in maintaining the mechanical coherence of tablets and lowers their damage by frictional force and rough handling during packaging.

4.What Are The Major Parts Of Tablet Coating Machine?

Tablet coating machines are the concurrent unit in which various parts are working together for ensuring productive working. Some parts of this equipment are discussed below for your understanding:

| Guide Plate

Tablet coating machines mix and coat solvents with the aid of a guide plate. This facilitates the easy and smooth tumbling of tablets. |

|

| Spray Nozzles

These nozzles spray coating solution onto tablets while they are tumbling inside the drum or bed. These offer uniform atomization and spray coverage of the coating solution. |

|

| Electric Motors

These motors transform the electric energy and then provide this energy to various parts such as pumps, blowers, coating beds, and air pipes. |

|

| Control Panel

This component is comprised of electric switches and sensors for managing machine operations. These buttons on the control panel are used for regulating speed, temperature, and pressure. |

|

| Peristaltic Pumps

These pumps maintain constant pressure inside the machine for atomized spray. They aid in smooth spray coating. |

|

| Air Exhaust Pipes

They eliminate fumes and dust produced in the coating process. This prevents drug dust contamination. |

|

| Touch Screen System

Tablet coating machines are equipped with touchscreen displays or human-machine-interface for seamless coating operation. These also display the report of operation. |

|

| Discharge System

The tablets are removed from a drum with the help of a clipper and the shaft fixed on the drum or tablets are moved via pipes to the collecting bin. |

|

5.What Are The Industrial Uses Of Tablet Coating Machine?

Tablet coating machines are the need of the day in almost every industry and are used for improving the appearance of end products. Some useful applications of this equipment are penned below:

| Pharmaceutical Industry

In the pharmaceutical industry, tablet coating machines are used to mask the smell, color, and taste of inner drugs. These also aid in the prevention of tablet damage by harsh temperatures, moisture, and oxidation. |

|

| Nutraceutical Industry

The production of nutraceutical products requires delicate handling of ingredients. Tablet coating machines preserve the quality and safety of tablets by application of a thin film. |

|

| Food Industry

This equipment is routinely used in the coating of candies, fruits, nuts, and snacks. These are employed in confectionaries and food processing plants. |

|

| Agriculture Industry

In the agriculture industry, the equipment is employed for coating the seeds with thin film for their protection against microbes and insects. |

|

| Cosmetic Industry

The machine is used in the cosmetic industry for improving and boosting the appearance of perfumes and skin products. |

|

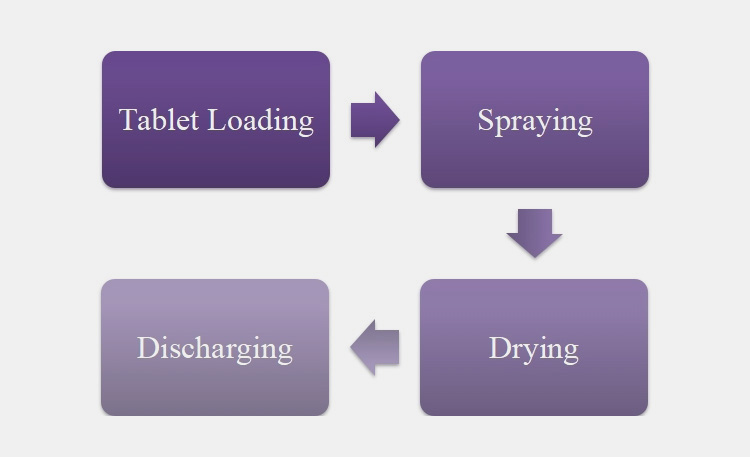

6.How Do Tablet Coating Machine Work?

There are four stages that encompass the working of tablet coating machines which are explained below:

Tablet Loading

In first stage, uncoated tablets are placed inside the equipment by means of shaft or a clipper. The pipes present in some machines are also used for loading of pills.

Spraying

This step is different in various types of tablet coating machines. The coating solution is sprayed on the tablets when they are rotated in coating pans. In coating pan, tablets are shaken on tablet beds for ensuring uniform covering of tablets.

In fluid bed coating machines, tablets are dropped down in the column and atomized spray nozzles spray solution from top or bottom.

Drying

Drying of the excess coating solution is carried out by blowing the hot air on tumbling tablets in fluid bed systems or on tablets placed on tablet beds in coating pans.

Discharging

Ultimately on drying of coated tablets, they are removed from equipment either by shaft or pipes and are placed inside hoppers or collecting bins.

7.What Are The Problems That Arise In The Tablet Coating Process? How Will You Solve Them?

The tablet coating process is not without errors, but these can be easily solved by employing various useful hacks. Some of these are discussed below:

| Problems | Cause | Remedy |

| Variation in Tablet Color | The quantity of coating solution is too low.

Inadequate number of spray guns The speed of the machine is low. The content of solids in coating solvents are high. |

Increase the quantity of coating solvent.

Increase the number of spray guns. Increase the velocity of the machine. Lower the contents of solids in coating solvents. |

| Peeling | Mechanical potency of coating solution is less.

Stickiness of coating solvent on tablet exterior is low. The quantity of lubricant in the formulation is too high. |

Use a formulation that has high mechanical strength.

Choose a formulation with good adhesion properties. Select excipients with strong lubrication characteristics. |

| Cratering | Inadequate drying time

High quantity of coating solution. |

Increase the drying time

Lower the quantity of coating solution. |

| Blooming | High quantity of plasticizer

Plasticizer has low weight |

Reduce the ratio of plasticizer in coating solution.

Use the plasticizer that has high molecular weight. |

| Logo Infilling | The inability of coating solution to scatter which cause droplets to penetrate the intagliations and buildup in latter. | For improving droplet dispersion use alcohol in coating solution or use fine nozzle for efficient spray atomization. |

8.What Factors Impacts On Efficiency Of Tablet Coating Machine?

The efficiency of tablet coating machines are influenced not only by tablet characteristics but also construction of machine itself. Some of these factors are penned below:

Distance Gun between Tablet-Bed

This distance between spray nozzles and the tablet bed considerably affects the performance of tablet coating machines. If the tip of spray gun far away from tablets this leads to decreased spraying speed and large diameter of coating solution droplet.

This causes the drying of solution before even reaching the tablets. On the other hand if gun is too close to the tablets then more amount of solution is coated on tablets leading to poor drying.

Spray Rate

Increasing the spray rate increases the diameter of coating liquid globules which results in poor performance of tablet coating solution because most of the solution goes to wastage.

If the spray rate is low then tablets might not get properly coated with the coating solvent.

Humidity Level

The moisture content inside the coating pan influences the efficiency of tablet coating machines. High humidity enhances the roughness of tablets which in turn increases the frictional force between moving tablet beds.

This force causes tablet to stick with each other as well as the coating pan.

Temperature

Increased temperature of bed leads to quick drying of solvent resulting in loss of coating solution and weight variation between tablet batches.

Conversely, decreased temperature of tablet bed can cause tablet defects like sticking or tablet twinning.

Speed of Rotating Drum

The velocity of the pan or bed also has an impact on the functioning of tablet coating machine. High speed might be the reason of tablet breakage during coating while decreased pan speed hampers the movement of tablets consequently leading to poor coating.

Viscosity of Coating Solution

Viscous coating liquid significantly affects the atomization rate of solvent. A thicker solution obstructs the spray gun due to the presence of high solid material and poor liquid flow hence optimal coating is not accomplished.

9.How Does Tablet Coating Machine Offer An Anti-Counterfeit Product?

Not only do packaging and labeling make counterfeiting of drugs difficult but also tablet coating machines are essential in preventing the forgery of tablets.

Microtags

With innovation in tablet coating machine, they are leading the battle against counterfeiting by using (R)mark On-Dose ID micro tags.

- These micro tags are customized and encoded with information such as batch number, country code, symbol, etc. for legitimacy of tablets.

- They are applied on tablets during film coating without altering any features of tablet coating film. This saves the need of having additional equipment for counterfeiting.

- Microtags are usually developed from FDA-approved excipients and have encrypted fingerprints with unique identity from vendor. These are invisible to eye but can be seen under a microscope for proving authenticity of pill

Pearlescent coatings

Film coating comprised of pearlescent pigments are best for preventing counterfeiting of tablets.

- These pigments change colors which are difficult to copy if you do not have prior knowledge of coating processing steps and combination of various ingredients.

- Doctors, patients, and chemists recognize these color shifts of tablets. Besides this, these pearlescent pigments also facilitate in creating unique brand identity.

10.How To Clean Tablet Coating Machine?

Cleaning is essential for healthy life of your tablet coating machines. Regular cleaning prevents the accumulation of debris, dust, and rust on machine equipment that can otherwise minimize your tablet coating machine efficiency.

Some cleaning tips are:

- Always wear weak acid or base proof gloves while cleaning the tablet coating machine.

- Secondly, before cleaning if your equipment has HMI then ensure it is properly covered with a plastic bag prior cleaning process.

- Close the valve of the drainpipe before cleaning

- Dismantled spray gun and other components of the equipment. Place each part of the spray gun in a plastic covering.

- Pour water in pan and rotate it at 50RPM

- Scrub the inner side of pan wall with a nylon brush for removing product debris

- Pour the 15% NaOH in pan and thoroughly wash it with this solution

- For removing piled material, it is best to clean the interior of tablet coating machine with sodium carbonate solution.

- Clean the exhaust pipes, air inlet, and spray gun with sterilized water for 20 minutes.

- After cleaning, reassemble spray gun and other parts of machine.

11.Choosing The Best Tablet Coating Machine Manufacturer

Investing in tablet coating machines is good for the success of your tablet production. However, the selection of substandard equipment results in poor quality tablets which will decrease your sale margin.

Weigh several options before choosing the right tablet coating machines manufacturer. Some factors should be of due importance when deciding on your desired machines.

Technical Aspects

Prior to buying tablet coating machines first it is essential that you must decide your coating process, how would you load tablets in machines, and what should be your drying process.

These features will assist in selection of various parts of tablet coating machines such as pumps, spray nozzles, coating vessel, drying air cylinders, etc.

Ergonomic Construction

Look for tablet coating machines manufacturer who offers an ergonomic design. Perfect equipment should be safe and have ease of operation. Consider the safety of your operators when you choose tablet coating machines.

These instruments should have user-friendly functionalities that decrease the workload of workforce.

Durable Materials

Always select those companies which manufacture machines using stainless steel alloy. This alloy is usually long-lasting and resistant to rusting. Some vendors fabricate non-contact parts such as wheels, outer covers, etc with AISI 304 stainless steel.

On the other hand, the parts of that come in contact such as coating pan, spray gun, etc. with tablets are constructed using AISI 316 stainless steel. This offers higher resistance against chemicals even at high temperatures.

Repair and Maintenance

It is imperative that you choose a tablet coating machine manufacturer whose machines can be dismantled and reassembled quickly. Because, this feature of equipment aids in instantaneous cleaning and maintenance. Easy assessable parts also help in fast machine repair and troubleshooting.

This aspect is vital in reducing your downtime and production costs.

Advanced Technology

A good quality tablet coating machine manufacturer offers products equipped with advanced and futuristic technology for accurate tablet coating. The Tablet coating machine must have a touchscreen HMI for convenient machine programming. This also provides a process report and has a self-diagnosis feature in case of machine failure.

Furthermore, these machines have safety sensors alarms and dust extraction units for managing drug dust and emergency situations. Therefore, choose this technological advance equipment for the best results.

12.What Are The Future Trends Of Tablet Coating Machine?

The market value of tablet coating machines was USD 0.81 billion in 2021 and is expected to grow with an annual CAGR of 5.2% from 2022-2030. Fluid bed systems have shown increased growth and exhibited the highest CAGR of 6.1%.

Future coating machines will apply the principle of continuous coating as opposed to current batch coating. These machines will be less costly, consume less energy and be more productive. They will employ dry coating or electrostatic dry coating. Furthermore, tablet coating machines will be efficient and reduce coating wastage.

Futuristic machines will be equipped with advanced electronics, sensors, and computerized technology for minimizing human error in coating and increasing the efficiency of the coating.

Conclusion

Tablet coating machine is a diverse equipment varying in design and used in far-ranging industries for providing products with a smooth elegant finish and upholding the integrity of their contents. Selecting the right kind of tablet coating machines is imperative for your business and this automation aid you in creating your unique brand profile. In this blog, several important aspects of this equipment are discussed for your understanding. However, if you have additional concerns regarding this automation, You Can Contact Our Customer Service Technicians Who Are Always at Your Service.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours