Your Best Piston Filler Machine

- High-quality Air Cylinder

- Automatic Pneumatic Filling

- Precision Pneumatic Components

Piston Filler

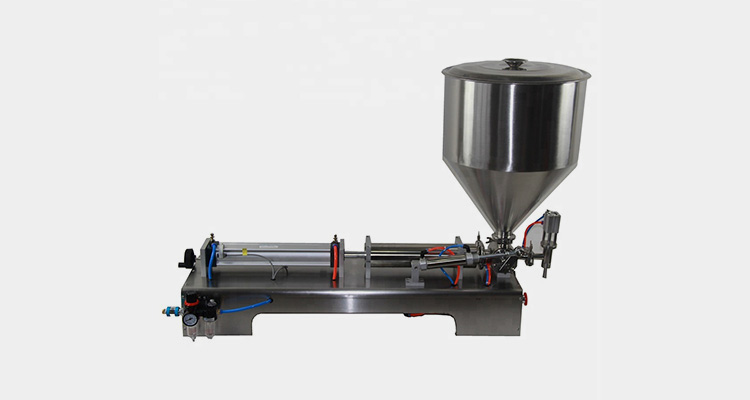

Allpack piston filler is mainly for filling liquids, semi-liquids, paste packing and filling in vial, bottle, jar, can, pail, barrel, drum, and other various shape container and is widely used in food, pharmaceutical, chemical industries, etc. This piston filler adopts the pneumatic components and its position is made of polyvinyl chloride and 304 stainless steel material. Its filling volume and filling speed can be adjusted. The filling valve adopts anti-drop, anti-down drawing, and filling equipment .

The piston filler can be modified according to your requirements, and it can be redone, such as multi-heads, explosion-proof type, and overflow filling system. The machine works on the three-way principle to adjust the filling quantity that a cylinder drives a piston and a rolling valve to draw out and output the fluid, and then the magnetic switch controls the journey of the piston.

Piston Filler

LPF-50/250/500/1000/2000/5000 Semi-automatic Pneumatic Piston Filler For Liquids

LPF-50/250/500/1000/2000/5000 automatic pneumatic piston fillers are all types from the LPF series. It mainly applies pneumatic filling as the automatic filling system that it uses compressed air as power. So there is no need for electricity as power which can save your cost and offer you high efficiency. This pneumatic piston fillers consist of precision pneumatic components and a compact structure that can offer you long and safe operation. Designed with floor type, it is easy for you both to stand and sit operationally.

Pneumatic Filling

Airtac Air Cylinder

Automatic Filling System

LPF-50T/250T/500T/1000T/2000T/5000T Semi-automatic Pneumatic Piston Filler For Liquids

LPF-50T/250T/500T/1000T/2000T/5000T semi-automatic pneumatic piston fillers are all types from the LPF-T series. They are all semi-automatic and designed for filling products with any liquid. These semi-automatic pneumatic piston fillers are suitable for medicine, chemistry, lube, daily merchandise, etc. It mainly applies pneumatic filling as the automatic filling system that uses compressed air. So there is no need for electricity as power which can save your cost and offer you high efficiency.

Pneumatic Filling

Automatic Filling System

Suitable For All Kinds Of Liquids

PPF-50/250/500/1000/2000/5000 Semi-automatic Pneumatic Piston Filler For Liquids

PPF-50/250/500/1000/2000/5000 semi-automatic pneumatic piston fillers are all types from the PPF series. They are all semi-automatic designed and for filling products with any kind of liquid with viscosity. With high filling precision, the filling quantity and speed can be adjusted to your needs. The contact part is all made of 304 stainless steel which is easy for you to clean and maintain. Part of the air cylinder is chosen with Airtac which ensures you good machine quality. You can set it to manual mode or automatic mode. When you are operating this pneumatic piston filler, you need to load the liquid materials manually.

Good Machine Quality

Semi-automatic Designed

Manual Or Automatic Mode

PPF-50T/250T/500T/1000T/2000T/5000T Semi-automatic Gas Filling Piston Filler For Pastes

PPF-50T/250T/500T/1000T/2000T/5000T semi-automatic paste gas-filling piston fillers are all types from the PPF-T series. They are all semi-automatic designed and for filling products at any kind of ropy pitch from aquiform to viscosity. With the table design, you can adjust and operate this piston filler easily and simply. These semi-automatic paste gas-filling piston fillers are suitable for medicine, chemistry, lube, daily merchandise, etc. The filling nozzle is made of high-quality 304 stainless steel, which is food grade.

Gas Filling

High-quality Air Cylinder

High-quality 304 Stainless Steel

The Buyer's Guide

Piston Filler: The Complete Buying Guide In 2025

Have you ever come across a piston filler? Do you know how a piston filler works? You are at the right place! A piston filler is an automated machine that can fill containers with liquids, pills, powders, or granular products quickly. This essential piece of equipment can make the packing process much faster and easier.

In this blog post, we’ll explore the various types of piston fillers available on the market, their features, benefits, and applications, as well as what factors should be considered before investing in one. We hope that after reading this blog, you will have all the information necessary to make a decision about whether or not to invest in a piston filler. Let’s get started!

1. What Is A Piston Filler?

A piston filler is a type of automated machinery used to fill liquids, pastes and other liquid into containers. This tool uses a piston or plunger to draw product from a hopper and dispense accurate amounts into each container as they pass through the machine on an assembly line.

The piston filler is designed to handle a wide range of products, from thick sauces and gels to thin liquids such as juice and water. Piston fillers are also capable of handling food-grade ingredients without cross-contamination so they are suitable for the food industry.

These piston fillers come in semi-automatic and fully automatic models, allowing you to choose the level of automation that best suits your needs. Also, some piston fillers feature an adjustable filling head which allows for quick and easy changeover between different product sizes

2. What Type Of Products Can Be Packaged Using A Piston Filler?

Here are some of the products that can be packed using a piston filler.

Food Products

Piston fillers can also be used to package food items such as sauces, syrups, honey, and condiments. These machines are capable of filling small bottles or large jars with food items, and can also be used to package products with thicker consistencies.

Pharmaceuticals

Piston fillers are commonly used to package pharmaceutical products including ointments, creams, and liquids. These products require precise dosage measurements; which piston fillers can deliver with great accuracy.

Personal Care Products

Piston filler s are also used for packaging a wide range of personal care items such as lotions, gels, shampoos and conditioners. These machines are ideal for quickly and accurately packaging personal care products in containers of various sizes.

Cosmetics

Piston fillers are commonly used for packaging cosmetics such as foundations, lipstick, and eye shadow. These machines are capable of accurately packaging a wide range of cosmetic items in various-sized containers.

Industrial Products

Piston fillers can also be used to package industrial products such as adhesives, sealants, and lubricants. These machines are highly accurate and can deliver precise measurements of these products in containers of various sizes.

3. What Are The Components Of A Piston Filler?

Filler Piston

The piston of the piston filler is a mechanical device that moves liquid or solid products into the containers to be filled. It works by using a piston to push the material through an outlet into the container.

Cylinder

The cylinder serves as the chamber in which the piston operates. It is made of material such as aluminum or stainless steel and is sealed so that the product does not leak out.

Hopper

The product hopper is usually located at the top of the piston filler system and is where the product to be filled is placed. The hopper has a piston or auger that will move the material from the hopper into the piston chamber.

Valve

A piston filler typically uses a valve to control the amount of product that flows through the piston into the container. The valves can be either manually or automatically operated.

Container Tray

The container tray is the platform on which the piston filler places the containers for filling. The container tray is usually adjustable so that different sizes of containers can be accommodated by the piston filler system.

Nozzles

In order to ensure that each container has a consistent amount of product, piston filler s can be equipped with nozzles. These nozzles direct and dispense the product into the container for a precise fill.

Pressure Control System

The pressure control system regulates the amount of pressure being applied to the piston, which determines how much liquid is pushed out of the piston filler at any given time. This allows for accurate and consistent filling of containers.

Pneumatic System

The pneumatic system is responsible for controlling the pressure in the piston chamber when a product is being dispensed into containers. This ensures that the piston moves at a consistent speed regardless of container size or the amount of product being filled.

Vibratory Bowl Feeder

This device helps ensure that the product is delivered consistently to piston chambers for efficient piston-packing operations.

4. What Are The Applications Of A Piston Filler?

Piston fillers are used in a wide range of industries and applications. Here are some of the most common uses:

Pharmaceuticals

Piston fillers can be used to accurately fill containers with liquid medication, ensuring that each dose is as precise as possible.

Cosmetic Production

Piston fillers are also used in the production of cosmetic products such as lotions, creams and gels.

Food Processing

Piston fillers are used in the production of food products, such as sauces and condiments.

Beverage Industry

Piston fillers are used in the production of beverages, such as beer, juice, and soft drinks.

Automotive Industry

Piston fillers can be used in the automotive industry to help fill a variety of containers with oil, coolant or other fluids.

Chemical Industry

Piston fillers are used to accurately fill containers with chemicals such as cleaners, solvents or other liquids.

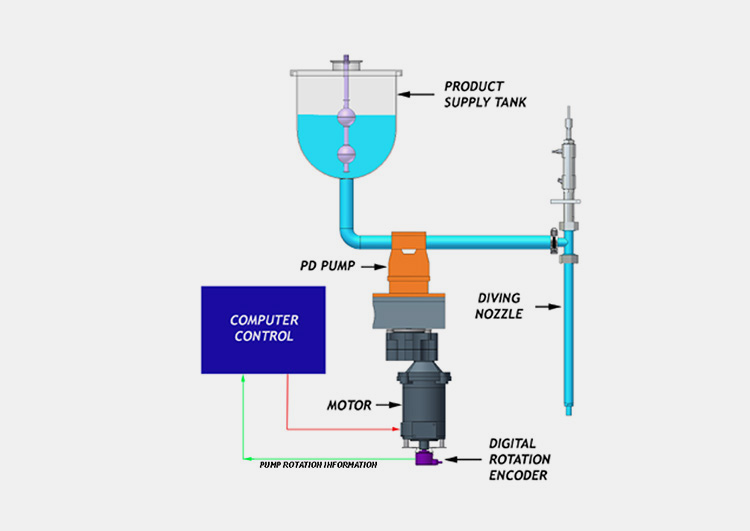

5. What Are The Working Principles Of A Piston Filler?

A piston filler works by drawing liquid from the material source, such as a tank or hopper, into a piston chamber. The piston then pushes the liquid product out of the piston chamber in equal amounts into each container below.

The piston filler contains three key components that help to ensure the piston filler process is successful: a piston chamber, piston rod or plunger, and a valve system. The piston chamber can be designed to contain different volumes of material that the piston will need to draw into it.

The piston rod or plunger is attached to the piston chamber and is used to draw material into the piston chamber. As the piston moves downward, it creates a vacuum that draws liquid material into the piston chamber.

Once filled, the piston rises again and pushes liquid product out of the piston chamber in equal amounts into containers below. The valve system helps to control the flow of product and ensure that containers are consistently filled with a precise volume.

The piston filler also contains various sensors and controllers to monitor the speed, pressure, temperature, and more. This helps to maintain accuracy and consistency while filling containers.

6. What Are The Different Types Of Piston Fillers Available On The Market?

a) Automatic Piston Fillers

Automatic piston fillers are ideal for high-volume applications and feature a piston mechanism that dispenses product into containers in a continuous manner. Automatic piston fillers are ideal for a wide range of products, including liquids, pastes and creams. These machines provide fast and accurate filling of multiple containers at the same time, without manual intervention.

Applications

Automatic piston fillers are ideal for a range of industries including food and beverage, pharmaceutical, cosmetics, and industrial products. Common applications include filling liquids, such as sauces, pastes, creams, lotions, gels, oils, and other viscous materials into containers ranging from small bottles to large drums.

b) Semi-Automatic Piston fillers

Semi-automatic piston fillers are designed for products with a thicker viscosity, such as sauces and creams. They feature a piston mechanism that dispenses products into containers in batches, allowing them to be used in applications where multiple fill volumes may be required.

Applications

Semi-automatic piston fillers are commonly used in industries such as food and beverage, pharmaceuticals, chemicals, cosmetics, personal care products, and other semi-viscous liquids. They are mainly used to fill liquids into containers with accurate volumes without spillage.

These semi-automatic piston fillers can be used for various applications, such as filling bottles, jars, cans, and other containers with semi-viscous liquids. They are ideal for applications where accuracy is required in terms of the volume of liquid being filled.

They can also be used to fill semi-viscous liquids into a variety of different-sized containers ranging from small vials to large drums.

c)Volumetric Piston filler

These piston fillers are commonly used for products with a viscosity similar to water or lighter and provide a high degree of accuracy and control over the fill volumes. They feature an adjustable piston mechanism which allows for precise control over the volume of product that is dispensed.

Applications

Volumetric piston fillers are used in a variety of industries and applications. They are typically used to fill rigid containers, such as cans or bottles, with liquid products such as beverages, edible oils, sauces, detergents and cleaners, dairy products, and other liquids that require precise volumetric measurement.

This type of filling machine can also be used for semi-liquid and semi-solid products, such as creams, gels, pastes, jams, puddings, peanut butter, and other food products.

d)Linear Piston fillers

These piston fillers are ideal for high-production lines as they offer a much faster filling rate than other piston fillers. They feature a linear piston mechanism that moves back and forth in the product container, allowing for increased speed while still providing accurate fill volumes.

Applications

Linear piston filler is ideal for applications where precise amounts of the product must be filled quickly with consistent accuracy. These machines are used extensively in the food and beverage, pharmaceutical, and industrial chemical industries. They can also be used for a variety of other liquid-filling applications.

7. What Are The Differences Between Automatic Piston Fillers And Semi-Automatic Piston Fillers?

a) Automatic Piston Filler

b) Semi-Automatic Piston Filler

The major difference between semi-automatic and automatic piston filler s is the extent of automation. Semi-automatic piston fillers require manual operation, such as loading product containers onto the machine and removing them once filled. The operator must also set the fill volume for each container, as well as check for accuracy before continuing to the next container.

On the other hand, automatic piston fillers are operated by a single operator who need only to load and unload the containers for each batch. The machine performs all of the filling operations without any manual intervention, providing greater accuracy and quicker production time.

In semi-automatic machines, product is loaded into the hopper above and then dispensed into the containers below. This filling process can be stopped or started at any time; however, semi-automatic machines are not designed to run continuously.

Semi-automatic piston fillers are more cost effective than automatic machines; however, they require manual operation and do not provide as much accuracy or speed of production as automatic machines.

8. What Are The Differences Between Piston Fillers And Liquid Fillers?

a) Piston Fillers

b) Liquid Fillers

The piston filler is used to fill containers with a wide variety of semi-viscous products, such as sauces, condiments, edible oils, and peanut butter. Piston fillers are highly accurate and can be adjusted to dispense exact amounts of product. Also, piston fillers are more precise and faster than liquid fillers, thus suitable for high-production applications.

In contrast, liquid filling machines are best used for products such as juices, beverages, and liquid detergents that are less viscous. In addition, Liquid fillers are much slower than piston fillers due to their lower speed and accuracy.

9. How Can Advanced Piston Fillers Boost Production Speed?

The piston machine works by compressing the product into a piston which is then driven forward, quickly filling the container with the desired amount of product. The piston can be adjusted up or down depending on how much product needs to be filled. This allows you to easily adjust production speeds as needed and significantly reduce the amount of time it takes to fill containers.

The piston filler can also be used in conjunction with other machines, such as cappers and labelers, which can help increase production speed even further. By using multiple machines at the same time, you are able to get more done in a shorter amount of time, allowing you to focus your efforts on other tasks.

10. What Are The Common Problems In Piston Fillers And How Can You Resolve Them?

Leaking Fill Nozzles

A piston filler relies on the pressure of a piston pushing liquid through fill nozzles in order to accurately dispense product into containers or packages. If those nozzles become worn out or clogged, they can leak and cause product loss.

Solution

Regularly clean the piston filler and check for any signs of wear or damage.

Incorrect Fill Volumes

If piston fillers are not calibrated correctly, they can dispense incorrect amounts of product into containers.

Solution

Regularly calibrate piston fillers to ensure accuracy in fill volumes. Additionally, you should closely monitor the piston’s speed and adjust it as needed to ensure accurate fills.

Corrosion

Due to the nature of piston fillers, they can be exposed to a variety of chemicals, cleaners, and solvents that can cause corrosion over time.

Solution

Use only approved cleaning solutions on piston fillers and inspect them regularly for signs of wear and corrosion.

Jammed Components

If piston fillers are not properly maintained, components can become jammed or stuck, resulting in inaccurate fills and product loss.

Solution

You should regularly inspect piston fillers for signs of damage and make necessary repairs as soon as possible to ensure proper functioning.

11. How Can You Select The Right Piston Filler For Your Application?

a) Determine the type of product you plan to fill

Piston fillers are designed to handle a variety of products, including liquids, pastes and gels, so it is important to understand what type of material needs to be filled before selecting a piston filler.

b) Consider your production volume

Piston fillers can accommodate various production volumes, so it is important to determine how much product needs to be filled and select a piston filler with suitable capacity.

c) Understand your filling speed needs

Piston fillers are available at a range of speeds, so it is important to consider the type of product and production volume when selecting a piston filler with an appropriate speed rating.

d) Inspect the piston filler for quality

piston fillers are precision pieces of equipment, so it is important to inspect them closely for signs of wear or damage before making a purchase.

e) Compare piston fillers from different suppliers

Piston fillers come in a variety of shapes and sizes, so it is important to compare piston fillers from different suppliers to ensure that you select the right piston filler for your application.

Conclusion

Piston fillers are really useful when it comes to producing bottles of products that require a precise and consistent measure for accuracy and efficiency. They are easy to clean, maintain, and operate and can last for a long time if taken care of properly. Furthermore, piston fillers can help reduce labor costs significantly depending on the production needs of a business. If you thinking about purchasing one for your business, it’s best to contact a reputable supplier like Allpack to ensure quality and safety with every purchase. So what are you waiting for? Contact Allpack today, if you need an affordable solution that is sure to satisfy your production needs!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours