Your Ideal Strapping Machine Manufactruer

- Precise Strapping

- Intelligent Induction

- Electronic Tension Control

Strapping Machine

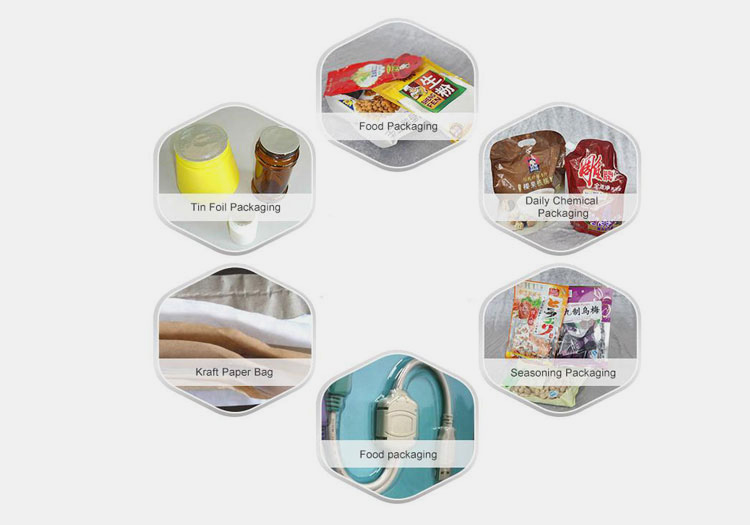

Allpack strapping machine has the "Auto-Feeding" function that can automatically feed strapping tapes for each application. And the "Auto-Positioning" system of this machine can automatically position and secure the strapping tapes efficiently for each cycle. The actual production of the strapping machine will vary depending on package size, chute size, and operator dexterity. The strapping machine has a wide range of applications, it is applicable to the chemical fiber industry, tobacco redrying enterprise, pharmaceutical industry, publishing industry, refrigeration and air conditioning industry, home appliance industry, ceramic industry, pyrotechnics industry, food industry, pharmaceutical industry, appliance industry, etc. And it can be applied to the automatic packing of normal goods such as carton, paper, the package letter, medicine box, hardware tool, porcelain and ceramics ware, car accessories, style things and so on. The machine is equipped with three powerful motors for smooth operation and strong performance. The high strength alloy gantry design is strong and durable, in other words, Allpack strapping machine is more stable.

The Buyer's Guide

Strapping Machine: The Complete Buying Guide In 2025

Multiple handling of different products could be very tough for you if you perform the packaging and sealing operations manually.

But there is a smart device that you can encounter with to easily solve the packaging and sealing problems and this device is called strapping machine.

If you are more than curious about how the strapping machine works under what circumstances & how it can be useful, hurry no more, we are going to discuss everything in this article.

1.What is the main purpose of strapping?

Strapping a box or carton is a purposeful technique in which product safety and security is accomplished.

The soul purpose of strapping a box is to make sure your inner product remains safe, secure and environment impact free because during travel your product can get damage.

But strapping will take the security of your inner product to next level by working against environmental pollution and outer clattering damage to your boxes.

2.What is a Strapping Machine?

Strapping machine is a specialised machine that uses straps or sheets of different materials to pack stock of goods tightly together to ensure the safety of the goods and the package. The strapping machine has revolutionised the process of packing of goods’ pallets and has a huge application in the industries that need their goods to be transported in bulk.

3.How the Strapping machine works?

The strapping machine mainly detects the box or the package to be strapped by using the sensors. The strap material is fed into the strapping machine through the pulley system or spool and this material is then strapped or rolled around the target box or package through the rotation of the arms or the mechanical spinners of the strapping machine.

The rotation of the target box or package is either manual or automatic depending on the type of the strapping machine that you are using.

4.In which ways a Strapping machine can help your business?

Strapping machine is a basic need of most of the industries. It is a very common machine as it is used in all kinds of industries for strapping the packages of their products, both the finished products and raw materials. Some of the uses of the strapping machine are described below.

Increases Productivity

A strapping machine is a very efficient machine and save you a lot of time by increasing the process of strapping many folds. It can boost the process of strapping two to three times contributing to the overall productivity enhancement of your industry. In this way, the strapping machine can save your precious money too.

Accuracy

A strapping machine uses high quality sensors so its operation is very accurate and the chances of errors are very low.

Makes Transport Easier

A strapping machine is an efficient mean to tightly and safely pack your goods together. This makes them ready to be shipped anywhere easily.

Decreases Cost

A strapping machine decreases your overall production cost. When using the automatic strapping machine, you don’t need to hire more employees for completing your work. Lesser number of employees will give you a great number of products strapped in a very short time. This ultimately leads to a greater profit and in this way the strapping machine gives you financial advantage.

Prevents Shipping Damages

A strapping machine straps your products in such a way that they are safe for transport. After you have strapped your goods by using the strapping machine, you don’t have to worry about your goods getting damaged during shipping because the strap provides extra strength to the package. This extra strength holds them together during the entire journey.

5.What are the basic & necessary components of a Strapping machine?

A strapping machine is a combination of many components working in coordination with one another to perform the strapping function. These parts are described below.

The Strap Dispenser

It is the part of the strapping machine that supplies the strapping to the sealing head. The strap coil also gets mounted here. Smooth functioning of the strapping machine depends greatly on the smooth functioning of the strap dispenser.

The Strapping Head

It is the most important part of the strapping machine. It is responsible for feeding the strap around the box or the package to be strapped. The tension with which it rolls the strap around the box can be custom controlled by the operator according to the needs. After rolling or feeding the strapping material around the box, the ends of the strapping material are sealed together and then finally, the strap is cut to allow the free movement of the box out of the strapping machine. The strap is again fed for the next cycle of strapping. The position of the strapping head in the strapping machine varies for different conditions.

The Strap Track

The strap track is the part of the strapping machine that is used for guiding the strap material around your box. This part of the strapping machine is most important for high efficiency. The efficiency of the strapping machine depends on how well the strap track is guiding the strap material. The strap track is fully automated in the automatic strapping machine, while in case of semi-automatic strapping machine, the operator has to guide strap around the box himself.

The Sensors

The strapping machine uses high quality sensors for doing its operation with high level of accuracy and with minimum errors.

The Power Conveyor

The automatic strapping machine has this unique part named power conveyor. The function of this power conveyor is to take the target boxes or products in to and out of the machine.

The Control System

The control system work with the power conveyor. It has sensors that detect the exact position of the box or package so that the packing can be done correctly

6.What is a strap & how it is made?

A Strap is a long ribbon or flap that is used for various purposes in different industries. They are used in clothing, bags, buckles, etc. They also find a great application in the packaging industry to package different boxes or parcels.

The process of making strap is somewhat complicated. For example, the making of polyester (PE) strap requires the following processes. First of all, a sheet of polyester is stretched to a great extent. The final ratio of the stretch is 5:1. It must be noted that during the process of stretching, the temperature of the stretch is raised for some time to increase the strength of the strap.

After this, the strap surface is treated so that the brittleness of the strap can be reduced and the weldability can be enhanced. An important part of this treatment is flattening of the strap profile.

In this way, the polyester (PE) strap is made.

7.What are the multiple types of strapping tape you can use?

Many types of the strapping tapes have been manufactured and are available at the markets. Some of them are described below.

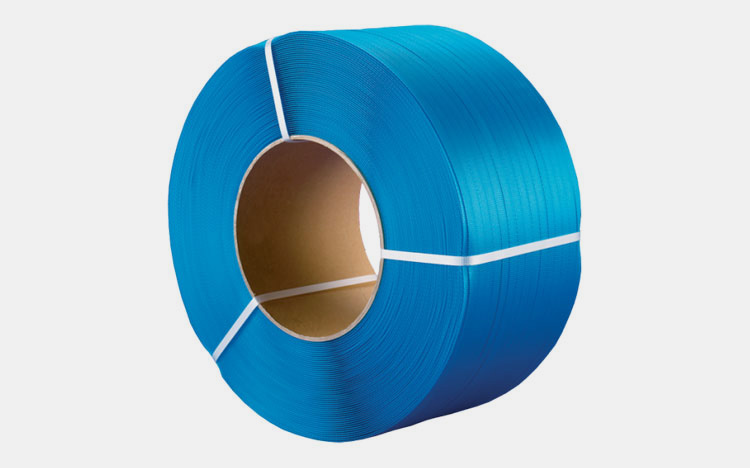

Polyester Strapping Tape (PET Strapping Tape)

The polyester tape is prefered type of strapping tape when you need to package heavier goods. The reason for this preference lies in the fact that polyester strapping tapes has a high flexibility, durability and strength It also has a great resistance against the ultraviolet radiations, heat and the atmospheric moisture. It is rust free and thus can be used where the goods need to be stored for an extended period of time. All of these reasons make the polyester tape the best candidate for strapping the heavier goods.

Polypropylene Strapping Tape (PP Strapping Tape)

The polypropylene strapping tape is the best option when you need to package the lighter goods. The main reason lies in the fact that they are relatively much cheaper than others and have great resistance temperature changes. It is also resistant against moisture and rust.

Metal Strapping Tapes

When you need to strap rigid or very heavy goods, you cannot use polyester strapping tape or polyene strapping tape because they are not strong enough to hold goods that are heavier than 1000 kg. In this case, you need to use a material that is strong enough to hold your goods. The best available option in such cases is metal strapping tape. The metal strapping tape is the strongest strapping tape present out there and thus can be used effectively for heavy goods.

The Spun Polyester Strapping Tape

The spun polyester is used for strapping the most fragile and delicate goods or products. The reason behind this lies in the fact that the spun polyester has a very light texture which does not damage your goods. It is also resistant to getting teared and thus can also be used for heavier goods.

These are the different types of strapping tapes that can be used for strapping. Depending upon your needs, you can choose the one that suits you the best.

8.What are the different types of Strapping Machines?

Strapping machines come in different types based on their working. A strapping machine can be manual, semi-automatic and, fully automatic. These types are explained below.

Manual Strapping Machine

As the name indicates, the manual strapping machine requires manual operation. The manual variant of the strapping machines has many advantages over others. The most important advantage is being less costly. It is comparatively cheaper and thus you do not have to invest much to buy a manual strapping machine.

It is suitable for small industries where the production rate is not very high. It is a very flexible machine when it comes to its usage because it can be easily used at any place and in any direction.

The strapping capacity of a manual strapping machine is around fifty straps an hour.

Working

A portable, handheld or manual strapping machine operates in a simple way when the carton or box came nearby the sensors detect the box and the strap feeder feeds the strapping element.

In this process a person just needs to holds the strapping machine & set the box in a the required position.

Advantages

- Portable & lightweight so you can carry it around easily.

- Less expensive as compared to automatic strapping machine.

- Flexible machine for small industrial use.

Drawbacks

- Not quick enough to meet the business requirements on urgent basis.

Working Components

Here are some handheld strapping machines working parts.

Hand Grip

Usually, a hand grip is like a handle which an operator holds. It simply allows you to control the movement of the machine.

Strapping Shaft

The basic working of the strapping shaft is to hold the strapping element and when the product enters the strapping unit strap it with the strapper.

Semi-Automatic Strapping Machine

The semi-automatic strapping machine is half automated but needs an operator for the rest of the job manually. The operator is required for placing and then removing the box to be strapped in and out of the machine. Inserting the strap into the slot and looping the strapping tape around the box is also the job of the operator. The tightening of the strap, sealing of the strapping tape, and cutting of the strap are done by the machine.

The semi-automatic strapping machine is suitable for the mid-ranged industry where manual strapping machines can not meet productivity requirements.

Working

A semi-automatic strapping machine work with the combination of automatic and manual processing.

In the working of this machine you need to align the boxes on the assembly and also put the strap end point into the strapping slot to begin the strapping process and after that everything will be done automatically.

Advantages

- Much more productive as compared to manual strapping machines.

- You can easily move them around in your space area for adjustment.

- Require a little effort as compared to manual one.

Drawbacks

- Not that much quick and fast but woks at a normal speed.

- Need human effort to begin the strapping process.

Working Components

Below are some semi-automatic box taper machine parts and their presence inside the machine.

Base Wheels

Wheels present at the bottom of semi-automatic strapping machine helps your team to move around and these wheels can be locked as well once you set the machine at required position.

Strapping Roller

A strapping roller is installed under the semi-automatic strapping machine conveyor you fixed it on the rotation bar which helps the roll to rotate and provides the strapping tape.

Conveyor with Pully

Conveyor usually has a strapping element in the centre and the edge pully on both sides to keep your box inline when the strapping takes place.

Fully Automatic Strapping Machine

The fully automatic strapping machine is the fastest and the most efficient equipment for strapping goods. From the feeding of the strap to giving out the end product, the whole process is automated. The operator just needs to control the machine from the control panel.

It uses high-quality sensors that ensure high accuracy and very low risk of error. The production speed of the fully automatic strapping machine is also the greatest and so it is suitable for larger industries.

Although it is a bit expensive but if you own a large industry, it will save your time and money by reducing the need of hiring more employees. So, it can be a great value for money.

Working

A fully automatic strapping machine first fetch the box from the conveyor belt and then measures the size of box after that the boxes settled on the assembly and then strap feeder strap the box.

Advantages

- Automatic working capability & fast operation.

- Price effective & efficient for large production.

- Flexible enough to handle different size boxes.

- Safe packaging without damaging the boxes.

Drawbacks

- A bit expensive as compared to all other types strapping machines.

- It is also costly for you to maintain this machine.

Components

Automatic strapping machine is designed and prepared in a different way as compared to other strapping machines so it also consists of some different parts.

Portal Frame

When you look at the automatic strapping machine there is a metal frame at top of it which helps the machine to fix the boxes at the required position then it dispatches the strap around the box.

Control Panel

It is important to choose a machine that has all the necessary action buttons and a screen to display the ongoing operations in this way you will know what action you need to take next.

Strapping Roll Controller

At one side of the automatic strapping machine a strapping roll controller rotates the strapping wheel to dispatch the required amount of the strapping element.

You can adjust the rotational speed of the roller according to your production requirements and machine handling.

9.How many ways you can seal the strap end using a Strapping machine?

Sealing the strap ends is a very important and crucial step while strapping your goods. It can be done in many ways. These methods are described below.

Friction Welding

This method is used for sealing polypropylene straps and polyester straps. The principle behind this welding is that friction produces heat. In this process, the ends of the strap are rubbed against each other. Friction between the ends produces heat which causes the melting of the polypropylene or polyester at the ends and it ultimately results in the fusion of the free ends together. In this way, friction welding is done and the strap is applied.

Hot Blade Heat Sealing

The hot blade heat sealing also works in the somewhat same way as the friction sealing. It also melts the free ends of the strapping tape and then fuses them but the method of heating is different from friction welding. The hot blade heat seal has a tongue that gets heated and is then inserted between the open ends of the strapping tape and in this way the ends get melted. The hot blade heat sealing is commonly used for sealing the PP (Polypropylene) strapping tape. The sealing of polyester strapping tape is very rare because it gives off a lot of smoke which is hazardous to the environment.

Ultrasonic Sealing

The ultrasonic heating uses an entirely different method to heat the free or open ends of the strapping tape. It uses vibrations of very low amplitude and very high frequency to melt the free ends of the strapping tape. The melted ends then get fused and get strongly sealed together. The ultrasonic sealing can be effectively used for polyester and polypropylene straps. The main advantage of the ultrasonic sealing is that this method is smoke-free.

10.Important factors to consider while purchasing a Strapping machine?

Buying a strapping machine for your business is a crucial step and thus requires careful decision-making. While buying the strapping machine, you should always consider the following factors.

Best Quality

Quality is the basic and the most important thing that you need to prefer while buying the strapping machine. Always look for the best quality equipment. You should make sure that you do not go for the cheaper strapping machine just to save money because the quality of the cheaper machine will definitely not be that good and it will not give you the desired productivity.

Compatibility

While buying the strapping machine, make sure that the strapping machine you are going to buy meets all your needs and can perform all the desired tasks. You should make sure that the machine has the capacity to meet your production requirements.

Trustworthy Seller

Always buy the strapping machine from a trusted seller. Make sure that the company from which you are buying the seller machine, is trustworthy and approved by the government. There are many online scams on the internet, beware of them. Always check customer reviews before buying any strapping machine.

Repairability of the Strapping Machine

Make sure that the strapping machine you are going to buy can be easily repaired and that you can easily find a trained technician or mechanic to repair your strapping machine if needed.

Best Price

When buying the strapping machine, always look for the value of money. This means that try to find a strapping machine that has the best quality, all the features you need, and at a reasonable price. In this way, you can save money without compromising on the quality of the strapping machine or the quantity of the features it offers.

11.How can you know which strapping elements is best for you?

When you select a strapping machine there is another step you need to take in which you decide that which strapping element is best plastic or metal.

Firstly, it entirely depends on your inner product for example if you are packaging electronic goods inside a carton then it will be safe to strap the box with metal strapper or may be with the plastic one.

In most of the cases a plastic strapping tape without any adhesiveness considered ideal for using because it has the flexibility and it can face environmental problems easily.

Conclusion

The strapping machine has revolutionized the process of packing the goods for efficient delivery and storage. It can prove to be a great addition to your industry as it can save your time and money and can ultimately increase your productivity and profit. ALLPACK China is your best solution master with unique and perfectly manufactured strapping machine. Do not hesitate to reach us Any Time!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586