Your Premier Single Punch Tablet Press Machine

- Continuous Automatic Tablet Machine

- Rational&Small&Easy To Operate

- Dust Pollution Prevention

Single Punch Tablet Press Machine

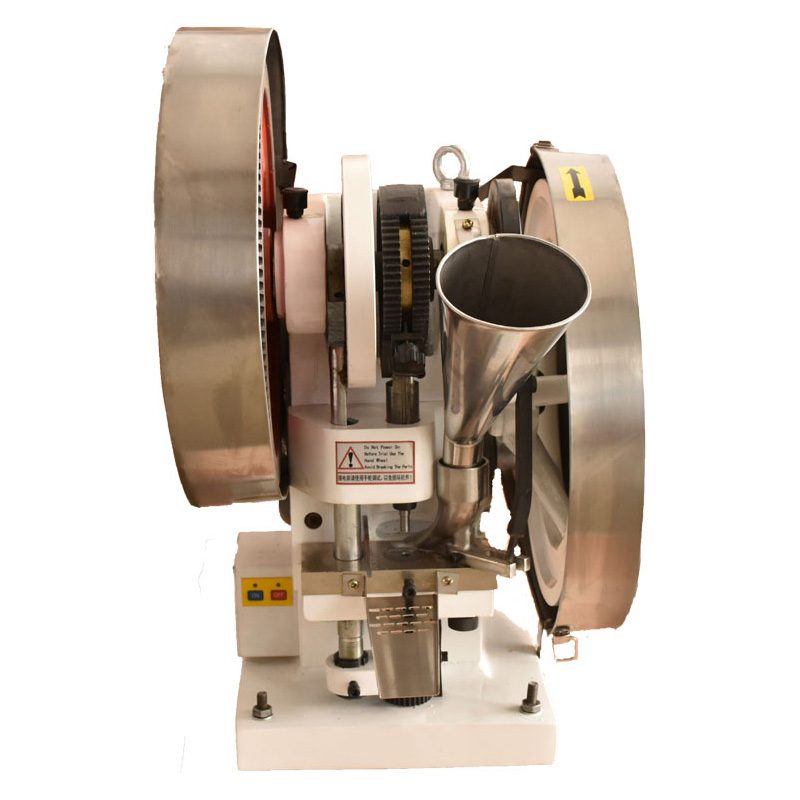

Allpack single punch tablet press also called eccentric press or single station press is the simplest machine for tablet manufacturing. Single punch tablet as the name implies employs a single set of station tooling that is a die and a pair of upper and lower punches. The machine can be used for pressing a variety of small particles, coarse powder pressing round or irregular tablets. The compaction force on the fill material is exerted by only the upper punch while the lower punch is static; such action is equivalent to hammering motion and as a result, the single punch press is referred to as the stamping process. The machine provides the option for stamping designs onto the top of the tablet, either to provide an appealing finish or for identification purposes. Both filling depth of material and thickness of tablet are adjustable.

Single Punch Tablet Press Machine

DP30A, DP40A Single Punch Tablet Press Machine

Allpack DP30A/40A single punch tablet press machine is widely used for pressing tablets in the pharmaceutical, chemical, food, and metallurgy industry. It can press round or special-shaped tablets from various granular materials. Its features, high precision of filling, low noise, low consumption of material, and smooth operation. It is reliable and efficient for laboratory use in research & development and for small-batch production. The minimum consumption of lab material is just 200g.

High precision in filling

Operating reliably with low noise

Lower consumption of material

TDP-1 Single Punch Tablet Press Machine Oral Steroid Powder Press Machine

Allpack TDP-1 single punch tablet press machine is used for pressing different kinds of granular raw materials into round tablets. It is applicable to trial manufacturing in lab or batch production in small amount different kinds of tablets, sugar pieces, calcium tablets and tablets of abnormal shape. It features a small desktop type press for motive and continual sheeting. It can also be hand-operated. Only one pair of punching die can be erected on this press. Both filling depth of material and thickness of tablet are adjustable.

Stainless steel hopper

Automatic protection device

Adjustable pressure

TDP-2 Pharmaceutical Health Care Single Stroke single punch tablet press machine

Allpack TDP-2 single punch tablet press machine is used for pressing different kinds of granular raw materials into round tablets. It is applicable to trial manufacturing in lab or batch production in small amount different kinds of tablets, sugar pieces, calcium tablets and tablets of abnormal shape. It features a small desktop type press for motive and continual sheeting. It can also be hand-operated.

Small volume & light weight

Low noise, convenient operation

Continuous pressing, continuous output

DP-60A Single Punch Tablet Press Machine Tablet Press Equipment

Allpack DP-60A electric single stamping machine (New)/single punch tablet press machine is a kind of pharmaceutical, chemical, food, metallurgical laboratory laboratory compression machine, can be classified into various types of powder granular raw materials into a circular or special-shaped tablets. The utility model can be mainly used for laboratory products such as hospital preparation room, scientific research institution, factory laboratory trial product, medicine, etc.

Mechanical and electrical integration

Variable speed operation

Get rid of bonding dust

TDP-0 Pharmaceutical Desktop Manual Single Punch Tablet Press Machine

Allpack TDP-0 Single punch tablet press is a kind of equipment which can continuously press powder and particle into round, special-shaped and ring-shaped pieces. It is the first choice for

pharmaceutical, chemical, electronic, food and other enterprises for mass production, which

meets the requirements of GMP production.It is a small desktop electric continuous tablet press machine, which can also be hand cranked.Only one die can be installed on the machine, the filling depth of the material and the thickness of the tablet can be adjusted.

Small size, flexible movement

Simple and convenient operation

Small desktop electric continuous tablet press machine

TDP-1.5 Low Consume Stainless Steel (Aluminum) Single Punch Tablet Press Machine

Allpack TDP-1.5(Aluminium) single punch tablet press machine is created to be installed on a bench, but can also easily be detached and relocated. The equipment provides an adjustable fill depth with a maximum depth of 16 mm and can produce tablets up to 8mm across and 6mm thick. The TDP1.5 doesn't restrict you to standard-shaped products. By simply swapping the mold on the appliance you can easily create tablets of nearly any shape you choose. Additionally, you can alter the density of the candy tablet being manufactured. , and the machine provides the option for stamping designs onto the top of the tablet.

Compliance with the GMP requirement

Overload protection

Different kinds of impellers for force feeder

TDP-2 Single Punch Tablet Press Machine for Laboratory Model Calcuim Tablet

Allpack TDP-2 single punch tablet press machine is used for pressing different kinds of granular raw materials into round tablets. It is applicable to trial manufacturing in lab or batch production in small amount different kinds of tablets, sugar pieces, calcium tablets and tablets of abnormal shape. It features a small desktop type press for motive and continual sheeting. It can also be hand-operated. Only one pair of punching die can be erected on this press. Both filling depth of material and thickness of tablet are adjustable.This kind of machines can make the powder material become tablet. It can be widely used in pharmaceutical, chemical plants, hospitals, research institutes, laboratories, prototype and small batch production.

With excellent performance

Good adaptabliity ,convenient use

Easy maintenance

TDP-5 Single Punch Tablet Press Machine Pill Maker Pill Press Machine

Allpack TDP-5 single punch tablet press machine is designed for pressing tablets from various granular materials,which is used for pharmaceutical,chemical,food, hospital,science research institution is applicable to trial manufacturing in lab or produce in small amount different kinds of tablet, sugar piece, calcium tablet and tablet of abnormal shape.It features a small desktop type press for motive and control sheeting.It can also be hand -operated easy to be operated and maintained ,small volume, light weight. one set of punch and de is mounted the depth of the filling material tablet press and thickness of the tablets can be adjusted

High precision of filling

Low-noise, low-consumption of material

Works smoothly

TDP-6 Single Punch Tablet Press Machine Pill press machine

Allpack TDP-6 single punch tablet press machine is a small desktop machine, easy to operate, driven by a motor can be continuously pressing tablets. The machine can be a variety of small particles, coarse powder pressing round or irregular tablets. It has the advantages of simple structure, convenient operation, and a tablet-making high degree of automation, which is suitable for various shaped tablet presses. Only one pair of punching die can be erected on this press. Both the filling depth of the material and the thickness of the tablet are adjustable. The machine is also can be called, a pill press machine, tablet compression machine, and tablet making machine,

Tablet making machine

Pill making machine

lab tablet press

THDP-3 Single Punch Tablet Press Machine for Pharmaceutical Used

Allpack THDP-3 single punch tablet press machine can press powder and granular raw materials into tablets. It is widely used for trial production and small batch production in pharmaceutical factories, chemical plants, food factories, hospitals, scientific research institutions and laboratories.This machine has good performance, strong adaptability, small size and light weight. Besides, it is easy to use and repair. When power supply is unavailable, it can press tablets by manually rotating the big handwheel. It is only equipped with one set of punch dies and filling depth and tablet thickness are adjustable.

High pressure light weight

Easy to operate

Automatic protection device

THDP-5 High Speed Pill Mold Press Single Punch Tablet Press Machine

Allpack THDP-5 single punch tablet press machine can press the powder material into tablet and can be widely used in pharmaceutical factory, chemical factory, hospital, R&D institution, laboratory. It is suitable for small batch production.Compare to original TDP model press machine, it is enlarged the machine intensive and engine power with bigger strength. In the meantime enlarge the filling depth, hence to expand the specification range of tablet. Therefore, this machine can meet the demand of different kinds of Chinese traditional medicine and Western medicine and other similar product's requirements. It's deeply welcome by our customers in different field.

Good performance, strong suitability

Simple operation, easily repairs

Small cubage

TDP-1.5 Laboratory Model Single Punch Tablet Press Machine

Allpack TDP-1.5 single punch tablet press machine is designed for pressing tablets from various granular materials,which is used for pharmaceutical,chemical,food, hospital,science research institution is applicable to trial manufacturing in lab or produce in small amount different kinds of tablet, sugar piece, calcium tablet and tablet of abnormal shape.It features a small desktop type press for motive and control sheeting.It can also be hand -operated ,easy to be operated and maintained ,small volume, light weight.

High precision of filling

Low-noise, low-consumption of material

Works smoothly

THDP-5 Milk Tablet Single Punch Tablet Press Machine

Allpack THDP-5 single punch tablet press machine is an important part of tablet press, in the industry, also known as tablet press die. The die of a tablet pressing machine is divided into three parts: upper punching die, middle punching die and lower punching die. In the material, heat treatment, grinding, polishing and other processes contain many years of technical experience. Especially the selection of material, especially the selection of imported steel to improve the quality of the mold. In the technical specification, always adhere to the manufacturing standards.

Wide range of use

Tablets of different shapes can be suppressed

Aluminum alloy material

TDP-5N 6N Single Punch Tablet Press Machine Salt Tablet Press Pressing Machine

Allpack TDP-5N 6N single punch tablet press machine is designed for pressing tablets from a variety of granulated materials. The Single punch tablet press is a pressing machine driven by motor or hand. One punch die set is included. Filling depth, tablet thickness, and punch pressure are all adjustable. Our Single-punch tablet press is an ideal equipment for laboratory, research department and small manufacturers.

Can be continuously pressing tablets

Simple structure, convenient operation

High degree of automation

TDP Series Single Punch Tablet Press Machine

Allpack TDP series single punch tablet press machine is easy to use, small in size and light in weight. This machine is only equipped with one pair of punching dies (other round or special-shaped dies can be replaced), the filling depth, tablet thickness and weight of the material can be adjusted, which can meet the requirements of the pharmaceutical industry for pressing Chinese and western medicine tablets and other industries. Similar to the requirements of the product.

Low noise, convenient operation

Convenient movement

Simple working principle of the machine

TDP-0 Single Punch Tablet Press Machine Electric Tablet Pill Making Machine

Allpack TDP-0 Single punch tablet press is easy to use, small in size and light in weight. This machine only installs a pair of punching dies (other round or special-shaped dies can be replaced). The filling depth, tablet thickness and weight of the material can be adjusted.The TDP-0 Manual Tablet machine can meet the requirements of the pharmaceutical industry.

Small and light weight

Easy to use and maintain

Interchangeable dies

TDP-6C Single Punch Tablet Press Machine

Allpack THDP-5 single punch tablet press machine can compress various granular raw materials into discs and various geometric shapes, which is suitable for laboratory system and small-scale tablet production.It is a small desktop electric tablet press, with continuous tableting, maximum diameter 25MM, 6 tons pressure, large output, speed control, frequency conversion speed regulation.You can install a pair of dies, by changing the dies, tablets of different shapes and sizes can be pressed.

Low noise

Convenient operation and convenient movement

Output is adjusted by frequency converter

TDP-0 Food Candy Upgraded Single Punch Tablet Press Machine

Allpack TDP-0 upgraded single punch tablet press is the latest research and production of small tablet presses in our company. the weight of the press machine is only 20 kg, this single press machine applicable to the pharmacy, laboratory, home, school or other places to apply. Motor is not needed,so it is suitable for any remote areas,it is good for energy saving, reducing carbon emissions. Although without the motor, but its performance is same as ordinary 1.5 T tablet press, this single punch tablet press machine is of the broad masses of users on choose!.It has small volume light weight, easy to carry, But will make all kinds of powder and granular material into suppression.

Manual tablet press is easy to carry

Easy to install and operate

Automatic feeding, light hand cranking

YDP Series Single Punch Tablet Press Machine

Allpack YDP series single punch tablet press machine is applicable to industries such as pharmaceutical ,chemical ,electric ,and foodstuff for pressing the powder or granular materials into tablets automatically in a continuous way. It features advantages such as low waste of materials ,reasonable structure ,easy operation ,compact size .large compression ,low noise ,small deviation of weight ,with the filling depth and thickness of the tablet continuously adjustable and all the functionality indicators reaching the level the similar imported machines.

High material utilization ratio,

Reasonable structure

Convenient handling, small dimension

The Buyer's Guide

Single Punch Tablet Press Machine: The Complete Buying Guide In 2025

Wondering how active pharmaceuticals and excipients acquire tablet form? How does granular mass get compressed?

Tablet Press machines are the reason for tablet compression. A tablet press- Single punch tablet press machine- is of chief importance in small and medium-sized businesses. These instruments are useful in round or oblong-shaped tablets having a size of about 1 mm to 25 mm.

If you are buying these machines for the first time, this guide “Single punch tablet press machine: A buying guideline in 2025”, will aid you in the selection process. Different aspects of this automation for instance working, applications, benefits, and so much more are reviewed for your information.

Without Further Ado Let’s Start!

1.What is Single Punch Tablet Press Machine?

This equipment is known by various names such as eccentric press, single station press machine or stamping press. It is the simplest kind of tablet press machine.

Single punch tablet press machine as the name indicate is comprised of single set of die, a pair of upper and lower punches. This instrument is suitable for small scale or home based productions. It has minimum production capacity that is about 60-85 tablets per minute.

2.What Is Working Principle of Single Punch Tablet Press Machine?

Various parts of single punch tablet press machine work as a group for efficient tableting. Understanding the working principle behind the operation assists in repair and maintenance of single punch tablet press machine.

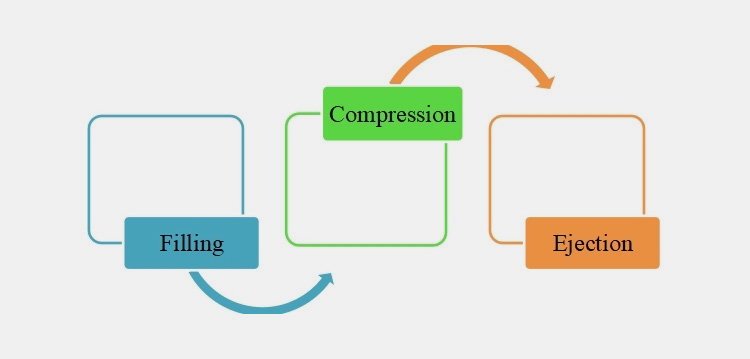

Some operational stages in working of these equipment are penned below:

STEP 1: Filling

First granules are loaded inside the hopper. After that, upper punch is moved in upward direction and bottom punch is moved in downwards to create a passageway in the die cavity. Feeder is moved over the top of die and granules go down to die from hopper due to gravitational force.

STEP 2: Compression

In compression stage, the feeder is moved away from die while the upper punch is moved down to die cavity with the help of cam track. The movement of upper punch in die provides necessary force for compression of granules into tablets.

STEP 3: Ejection

At ejection stage, the upper punch moved upward while the lower punch is raised in order to remove the tablet from machine. This cycle is repeated many times until all the feed material is used.

3.What are Basic Parts of Single Punch Tablet Press Machine?

The principal components of single punch tablet press machine are detailed below for your understanding.

| Cam tracks

The function of these parts is to direct the movement of punches. These play an integral role in tableting process. |

|

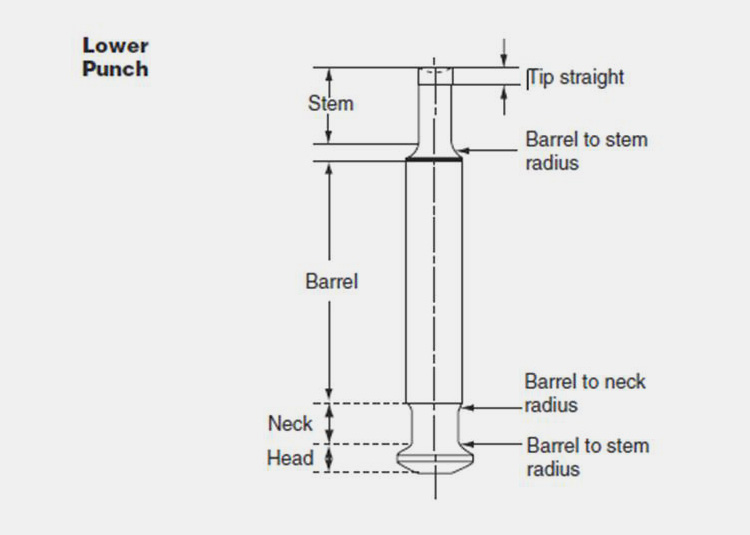

| Punches

The upper punch is moved up and down exerts pressure on the granules. The lower punch is moved for ejecting the tablet from the tablet press. |

|

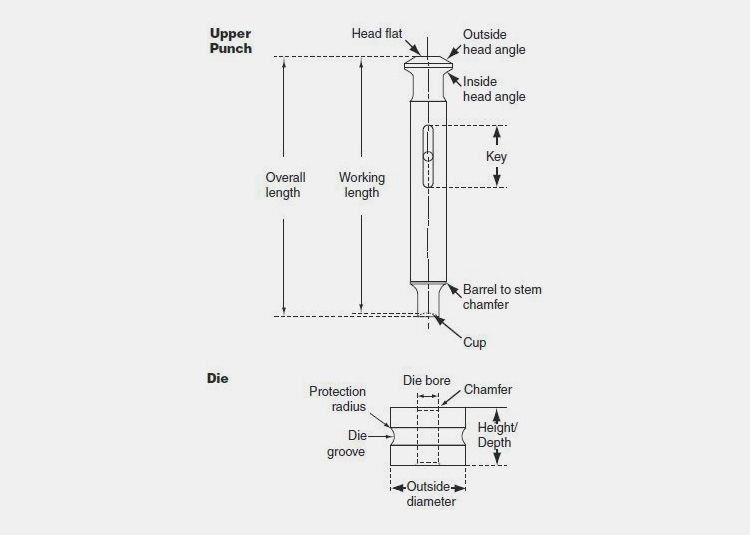

| Die

It is the part where compression of granules into tablets happens. The design of die cavity determines the shape, size, and thickness of the end products. |

|

| Hopper

The granular material is loaded inside the hopper before the compression. The hopper is connected to feeder. The material is manually place inside the hopper. |

|

| Outlet Hopper

This part is used for removing the tablets from the machine. |

|

| Motor

Single punch press machines are equipped with motors to provide adequate mechanical energy for movement of various parts such as punches. |

|

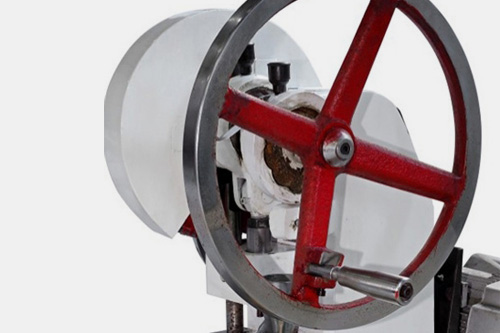

| Flywheel

It is rotated with the help of handle manually to provide mechanical energy for movement of punches. |

|

4.What Advantages Does Single Punch Tablet Press Machine Offer?

Single punch tablet press machines have positive impact on tablet production in small scale businesses. Some benefits of these equipment are:

| Portable | These types of equipment are small, lightweight, and easy to carry. These can be moved anywhere without any difficulty. |

| Ease of Use | Single punch tablet press machines are easy to operate without requiring special training. The functions of these machines are simple and easily understood. |

| Low Weight Variation | There are fewer chances of weight variation in tablet batches as these have one pair of punches. |

| Reduced Maintenance | They require little to no maintenance. Components of single punch tablet press machines are effortlessly disassembled for cleaning. |

| Versatility | These machines can produce odd shaped end products having maximum diameter of 20 mm. |

| Little Power Consumption | Your utility expenses are lowered by using these devices in your production since they have low power consumption and can be operated by hand. |

| Low Noise | These types of equipment produce less noise and vibration while running. |

5.What Is The Difference Between Single Punch Tablet Press Machine And Rotary Tablet Press Machine?

Single punch tablet press machines and rotary punch tablet press machines, both perform the same function but there are major differences between these two pieces of equipment. Some differences are explained below:

| Single Punch Tablet Press Machine | Rotary Punch Tablet Press Machine |

|

|

| These equipments have one series of punches and only upper punch is employed for compaction of granules in tablets. | They have numerous punches and both set of punches (upper and lower) are utilized for compression of tablets. |

| Single punch tablet press machine produces small number of tablets per hour (5000 tablets per hour). | Rotary punch tablet press machines manufacture have high rate of productivity and can manufacture up to 25000 tablets per hour |

| These equipments come in handy for small sized businesses and laboratories. | They are generally employed in mass scale tablet production lines. |

| They have simple machine operation and are easily set up. | These devices have complex operation and are difficult to install usually requiring special expertise. |

| Since these equipments are operated by humans so they have high error rate leading to wastage of end products. | These machines are self-autonomous so they have minimal error rate resulting in less percentage of product being wasted. |

| These systems have little power usage. | Rotary punch tablet press machines require high power to operate resulting in high utility expenses. |

6.What Is The Difference Between Upper Punch And Lower Punch?

| Upper Punch | Lower Punch |

| It has a shorter stem | It has a longer stem |

| It compresses the powder into a tablet. | It helps to eject the tablet after compression. |

| During the process, the punch moves downward for firm compression. | During the process, the punch moves upward in order to eject the tablet. |

7.What Are Industrial Uses of Single Punch Tablet Press Machines?

Single-punch tablet press machines are employed in wide-ranging industries. Some industrial uses are detailed below for your knowledge.

Pharmaceutical Industry

It is employed in small-scale pharmacies to manufacture different kinds of tablets such as chewable tablets, sugar pieces, etc. They are also used for the compression of granules into irregular-shaped tablets such as kidney-shaped, hexagonal, etc.

Herbal Industry

In the herbal industry, single punch tablet press machines are employed for the formulation and compression of various types of herbal tablets.

Clinical Research and Hospitals

These equipments are well-suited for clinical trials and hospitals. Researchers can easily formulate test drug into tablets with the aid of these machines without any heavy investment. Furthermore, single punch tablet press machines are utilized in research laboratories.

Nutraceutical Industry

In the nutraceutical industry, these machines are employed for manufacturing nutraceutical vitamin and mineral supplements. They are useful in manufacturing phytochemical formulation and dietary nutritional tablets.

Food Industry

Single punch tablet press machines are used in food industry and confectionaries to formulate single or multi layered candies, chewing gums, etc.

Cosmetic Industry

These equipments are utilized in cosmetic industry for producing skin care and dermal tablets. Moreover, these are also employed in compression of granular mass into bath bombs.

8.A Single Punch Tablet Press Machine: What Are Different Designs of Punches And Die?

Single punch tablet press can be customized with tooling varying in design. These tooling (punches and die) are used for creating tablets of different shapes. Some designs of punches and die are discussed below:

Round Shaped tooling

These punches and die are circular in shape and are routinely employed tooling employed for compression of tablets. They are present in different sizes and concavity. Round-shaped toolings are often found their use in pharmaceutical, cosmetic, herbal, and chemical industry.

Oval-Shaped tooling

These tooling have oval or egg like shape. They are secondly most employed design of punches and die. Oval-shaped tooling are often used to press powders in oval or ellipse shaped tablets.

Capsule-Shaped tooling

These punches and die are frequently utilized in pharmaceutical, nutraceutical, and confectionary industry and are oblong in shape. Capsule shaped or oblong tablets are produced are produced by capsule-shaped tooling. These oblong tablets are also known as caplets.

Geometric-Shaped tooling

They are available in several shapes such as square, rhombus, triangular, trapeze, and rectangular. These compress tablets of respective shapes. Geometric-shaped tooling are not only used in pharmaceutical industry but also in metallurgy process.

Irregular-Shaped tooling

These punches have various unique designs such as a leaf, double oblong, key hole, teardrop, etc. Irregular-shaped tooling is sometimes utilized for creating fruit-shaped, animal-shape, or kidney shape pills.

9.What are the TSM Standard and EU Standard of Tablet Tooling?

These are internationally assigned standards used for tablet tooling accepted exclusively across the globe. The prime purpose is to get uniform dosage, great efficiency, and provide an aesthetic appearance.

TSM Standard

TSM or Tablet Specification Manual is recognized in the US that is established by the American Pharmacist Association and used in tablet compression production for uniform distribution of active ingredients, excipients, and appearance.

EU Standard

EU or Euro-standard is recognized as a European standard widely employed in production activities than TSM. Moreover, their tooling configuration is not governed by any association.

10.What Factors Affect the Performance of Single Punch Tablet Press Machine?

Several factors impact the working efficiency of single-punch tablet press machines. Physical characteristics of powders as well as machine design have a role in the compression of tablets. Some important factors are:

Particle Size of Powders

Single punch tablet press machine require particles of optimum sizes. Large particles of powders result in denser compacts that are prone to fragmentation. Right sized particles for compression also decrease the weight variation in the tablets.

Lubricants

Adding excessive amount of lubricants during granulation can reduce the compressibility of the granules because it lowers the binding force between particles. Hence tablets produced by compression do not have considerable hardness.

Humidity

Single punch tablet press machine need dry environment for optimal compression of tablets especially when handling moisture sensitive drugs.

However, surrounding with excessive dryness also impacts compression. Dry environment causes buildup of electric charges which results in accumulation of powders in die and punches.

Temperature

High temperature also negatively affects the working efficiency of single punch tablet press machine. Compression of tablets usually results in fragmentation if temperature of environment is greater than 37°C.

Moreover, higher temperature leads to melting of powder ingredients thus leaving sticky residues on equipment which reduces efficiency of single punch tablet press machine.

Powder Flow

Poor powder flow is often the reason of problems during compression. These powders traps the air molecules so adhere to die and punch. This results in weight instability of resultant tablets and poor output of single punch tablet press machine.

11.What are the Technical Problems and Solutions of Single Punch Tablet Press Machine?

Tableting process is not without the errors. To resolve the issues which arise in single punch tablet press machine, operators should have a complete and thorough knowledge of the tableting process.

Some troubleshooting hacks are discussed below for solve the problems that occurs during tablet compression.

| Issues | Cause | Solution |

| Sticking Granules adhere to the end of punches |

Granules are not completely dried.

Punches are not properly polished. Powder blending is incomplete. |

Increase the drying time of granules.

Properly polish the punches. Thoroughly dissolve lubricant in granular mass. |

| Picking The sticking of granules to design embedded in punches. This design is used to create logos onto surface of tablets. |

Inadequate punch pressure.

High speed of machine. Decrease compression force. |

Increase the punch pressure.

Lower the speed of equipment. Increase the compression force. |

| Binding Tablets adhere to die and are not discharged properly from machine. |

Inadequate finishing of die.

Damaged die due to rusting or abrasion. Inadequate size of dies. |

Properly polish die tooling.

Replace the worn out die. Use die of proper size. |

| Lamination Fragmentation of tablets at any place except around edges. |

Excess compression of tablets.

Use of flat and cylindrical die. Improper amalgamation of fine particles. |

Use lighter pressure at the pre-compression stage for binding of particles.

Replace flat die with tampered ones. Decrease the velocity of tablet press. |

| Capping The fracturing of tablets around the edges. |

Excess air is trapped inside particles of granules.

High speed of the equipment. |

Adjust the depth of the upper punch to remove surplus air.

Lower the speed of machine. |

| Double Impression Creation new impression on the top of already formed impression |

Free rotation of upper punch during tablet discharge | Use key in tooling to prevent punch movement

Use an anti-turning tablet press |

| Cracking Small fracture lines are present on front and back side of tablets. |

Size enlargement of tablets on ejection due to the presence of trapped air | Use tampered or dome-shaped punches. |

12.What Is Maintenance Schedule of Single Punch Tablet Press Machine?

Inability to follow proper maintenance schedule can affect the performance and running life of single punch tablet press machine. Buildup of debris and poor lubrication of parts can cause rusting of components as well as jamming of punches and dies.

Hence proper maintenance can guarantee high work efficiency of single punch tablet press machine. Basic maintenance schedule of single punch tablet press machine is detailed below:

Daily Maintenance

- Regularly wipe out and clean external surface of machine.

- Clean punches, die, and hopper at the end of shift.

- Tighten the nuts and bolts on the daily basis.

Weekly Maintenance

- Oil the joints, transmission line, and oil cups.

- Spray the corrosion free spray to prevent rusting of parts.

- Use vacuum or compressed air to thoroughly clean the equipment.

Monthly Maintenance

- Perform complete checkup of machine after every month to identify equipment damage.

13.How Can You Customize Single Punch Tablet Press Machine?

Customization single punch tablet press machine according to your needs can speed up your production at a very small price.

Some customization tips are:

Die and Punches

Installing custom-made die and punches in your single punch tablet press machine results in tablet productions of varying designs, shapes, and forms.

Moreover, using dome-shaped punches reduces the amount of trapped air inside granules leading to lower issues of capping and lamination.

Fill Cam

Equipping your machine with right cam tracks is essential in cleaning of equipment as well as preventing batch variation in tablet weight. Depth of fill cams should be right for avoiding problems of overfilling and spillage.

Vibrator Rod

By placing vibrator inside the hopper you can shake the granular mass which can accumulate inside hopper and cause feeder starvation or bridging.

Motor and Gear Belts

You can increase the production rate by furbishing your single punch tablet press machine with motor and gear belts. These components provide high energy for the movement of various machine parts.

14.What Are Buying Consideration Factors for Purchasing Single Punch Tablet Press Machine?

Single punch tablet press machine is a handy investment for your home-based business, pharmacies, or laboratories. It is imperative to ponder on different factor before buying these machines.

An ideal single punch tablet press machine should be compatible with your production needs. Some buying factors to be considered are:

Budget

Financial aspects should be given topmost priority when buying single punch tablet press machine. It is best to decide on budget before going in market for procurement of this equipment as sometimes people tend to go overboard on their when buying machines for their businesses.

Reputable Manufacturer

Secondly, you should consult various platform and website for finding reputable manufacturer. As there are numerous fake vendors that sell substandard equipment. Therefore, you should choose your potential vendor after going through reviews of their past customers. Positive feedback of patrons is the best measure of integrity and honesty of manufacture.

Product Shape and Size

Tablet shape and size is determined by the design of punches and die. First decide the characteristics of your end product so should select the single punch tablet press machine accordingly.

Production Volume

Production volume is the measure of amount of tablet produced per minute. Knowing beforehand your production volume allows you to select single punch tablet press machine that is right fit with your output requirements

Durability and Hygienic Design

Always go for the single punch tablet press machine that is made with durable metal and alloys. These metals are rust-proof and robust giving your single punch tablet press machine long operational life.

Furthermore, it is ideal to select machines with easily accessible that offer high cleanability. Single punch tablet press machine having hygienic design also fulfill international quality standards.

Conclusion

Single punch tablet press machines have a significant role in the tableting process, especially in small-sized pharmacies, foods, and apothecaries. The compaction of granules into final tablet form is executed via these types of equipment. AllPack is China’s best manufacturing Company offering wide range Packaging and Production Lines for Pharmaceuticals, Food, Cosmetics, Chemicals and Engineering Industry worldwide. If you have additional queries regarding this equipment then you are welcome to Contact Our Team Right Now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours