Your Specialized Vacuum Feeder

- Adopt Cyclone Separation Filter

- Big-discharge Pneumatic Valve

- Overload Alarm Device

Vacuum Feeder

Allpack vacuum feeder is a newly developed product. It is the most advanced and ideal vacuum conveying equipment specially used for conveying powdery and granular materials. The vacuum feeder can not only automatically transport a variety of materials to mixers, packaging machines, injection molding machines, and pulverizers, but also directly transport mixed materials to V-type mixers, two-dimensional mixers, three-dimensional mixers, etc. This vacuum feeder can reduce labor intensity and prevent dust from spilling. Pharmaceutical and food factories can use it to promote clean production, and it has passed GMP certification. This vacuum feeder can be integrated into the production line to deliver the material. The main function of a vacuum feeder is that it is used for transportation. You can also use the vacuum feeder for feeding the granules, powdery.

Vacuum Feeder

QVC-3 High Quality Pneumatic Air Compressor Vacuum Feeder

QVC-3 high-quality pneumatic vacuum feeder uses compressed air to convey materials through the high vacuum generated by the vacuum generator. The pneumatic vacuum feeder does not require a mechanical vacuum pump. The advantages including simple structure, small size, maintenance-free, low noise, convenient control and elimination of material static electricity, and conforms to GMP requirements. The vacuum generator produces a high vacuum, which can avoid material stratification.

Vacuum Generator

Conforms To GMP Requirements

Simple Structure, Small Size, Maintenance-free, Low noise

QVC-4 High Quality Pneumatic Air Compressor Vacuum Feeder

QVC-4 high-quality pneumatic vacuum feeder uses compressed air to convey materials through the high vacuum generated by the vacuum generator. When the compressed air passes through the vacuum generator, the vacuum generator generates negative pressure to form a vacuum airflow. The material is then sucked into the suction nozzle. Through the suction tube reach the loader cavity. The filter completely separates the substance from the air. When the cavity is full of materials, the controller will automatically cut off the air source.

Low Noise

Vacuum Generator

Convenient Control

ZKS-1 Powder Vacuum Feeder With Vibrating Sieve For Powder Granules

ZKS-1 powder vacuum feeder with vibrating sieves is specially designed to feed granules and powders into the hopper of higher position machines, such as packaging machines, injection molding machines, pulverizers, vibrating sieves, etc. The powder vacuum feeders are widely applied in food, medicine, chemical, and other industries to transport powder, granular, block solids, tablets, and other industries. Vacuum feeders can also feed powder into mixers (such as V-shape mixers, swing mixers, 3D mixers, ribbon mixers, double cone mixers, etc.).

Cost Saving

Convenient Control

Powder And Granule Feeding

ZKS-2 Powder Pneumatic Vacuum Feeder With Vibrating Sieve

ZKS-2 powder pneumatic vacuum feeder with a vibrating sieve is a pneumatic device for feeding loose, uniform, powder, or granular products. This vacuum feeder is a pneumatic device for feeding loose, uniform, powder, or granular products. This vacuum feeding method can prevent dust pollution, improve the working environment, reduce the pollution of the environment and personnel to materials, and improve cleanliness. Because it is pipeline transportation, it occupies a small space and can complete the powder transportation in a small space, making the space of the workroom beautiful and generous. Especially not limited by the length and distance.

Improve Cleanliness

Reduce Labor Intensity

Improve Work Efficiency

ZKS-3 Powder Granular Vacuum Feeder With Vibrating Sieve

ZKS-3 powder granular vacuum feeder for vibrating sieve is mainly used to convey powder and granular materials, such as raw material medicine powder, chemical powder, metal oxide powder, capsules, tablets, pills, small food granules, etc. However, this vacuum feeder is not suitable for conveying too wet, sticky, and heavy materials. The vacuum feeder is powered by a vortex air pump. The pump is oil-free, water-free, and requires no maintenance. The entire conveying process is completed in a completely closed state, preventing dust pollution. The machine is a building block mechanism, and the barrel is connected by a quick-opening clamp.

Vortex Air Pump

Requires No Maintenance

Convenient And Quick To Disassemble And Clean

ZKS-6 Powder Granular Vacuum Feeder With Vibrating Sieve

ZKS-6 powder granular vacuum feeder for vibrating sieves is designed with a relatively simple structure. The vacuum feeder adopts an assembled modular design, which can effectively prevent dead ends, and is connected by quick-release clamps, which are easy to disassemble and clean, and then it is more convenient to install. The vacuum feeder uses a vortex air pump as a power source, the pump does not need oil and water and is easy to maintain. The feeding machine adopts a closed pipeline for transportation so that the material is not easy to leak during the transportation process.

Convenient To install

Assembled Modular Design

Easy To Disassemble And Clean

ZKS-7 Powder Granular Vacuum Feeder With Vibrating Sieve

ZKS-7 powder granular vacuum feeder for vibrating sieves uses compressed air to control a series of processes such as negative pressure feeding, back-blowing cleaning, valve feeding, vibration beating, etc. No heat is generated during work, static electricity of materials is eliminated, and it is safe and explosion-proof. The vacuum feeder has been widely used in some industries such as food, medicine, chemical industry, building materials, agricultural sideline, plastics, etc. Hygiene is ensured for edible materials, and flammable materials explosive materials are under safety protection.

Vortex Air Pump

Easy To Maintain

Negative Pressure Feeding

ZKS-10-6 Powder Granular Vacuum Feeder With Vibrating Sieve

ZKS-10-6 powder granular vacuum feeder for vibrating sieve's entire conveying process is carried out in a closed system, and the materials in it will not leak. For special material feeding, you can choose the matching nitrogen protection device. This type of vacuum feeder is very convenient to install and disassemble. The equipment has no gaps or dead spots where material can accumulate, which allows for easy visual inspection. Apart from the discharge foot valve, this device has very few moving parts. Therefore, the overall maintenance and accessories of the equipment are less required, and it is reliable.

Convenient To Install

No Gaps Or Dead Spots

Nitrogen Protection Device

ZKS-20-5 Powder Granular Vacuum Feeder With Vibrating Sieve

ZKS-20-5 powder granular vacuum feeder with vibrating sieve adopts a single air as the power source, which is intrinsically safe and explosion-proof equipment. This powder granular vacuum feeder is also suitable for conveying flammable and explosive materials on occasions with high explosion-proof requirements. Since only stainless steel pipes and flexible connections are used, the equipment is easy to install and convenient to repair and maintain. Its positioning speed has a great influence on positioning accuracy. This is because the energy of the moving parts that must be dissipated varies with the positioning speed.

Single Air As Power Source

Explosion-proof Equipment

Easy To Install And Convenient To Repair And Maintain

The Buyer's Guide

Vacuum Feeder: The Complete Buying Guide In 2025

Loading of multiple kinds of products such as granules and powder or you can say to load any kind of material into a processing machine it can be done by using single unique equipment.

And this equipment is Vacuum feeder which is considered a multi-purpose machine to load different types of elements into the processing machine used in pharmaceutical industry and also in other industries.

So, to learn all about vacuum feeder and its working along with benefits and features keep on reading this helpful & knowledgeable guide. You will get an overall understanding about vacuum feeder.

1. What Is A Vacuum Feeder?

Vacuum Feeder

A vacuum feeder is a type of manufacturing equipment that uses a vacuum to move materials from one place to another. They are often used to move delicate materials that could be damaged by other types of conveyance methods, such as belts or augers.

The main function of a vacuum feeder is that it is used for transportation. You can also use the vacuum feeder for feeding the granules, powdery, and other solid materials in the pharmaceutical industries.

So, basically, the vacuum feeder is a mechanical machine that can handle every type of feeding easily and smoothly.

2. Explain The Advantages Of Vacuum Feeders?

Advantages

A vacuum feeder is a type of automated equipment that uses vacuum pressure to move small parts or powders from a hopper to a downstream process.

There are many advantages of vacuum feeders. These advantages are as follows:

Prevents the Dust Pollution

The very first advantage of a vacuum feeder is that it prevents dust pollution during working or feeding.

It also makes sure that the dust particle does not enter the powder or granules during the transportation process.

Does Not Require A Large Space

The vacuum feeder does not require a very large space for working. It occupies a very small space. So, you can do your transportation process easily in a very narrow space too.

Easy to Operate

The third advantage of a vacuum feeder is that it is very easy to operate. You can easily start your transportation process with this type of vacuum feeder.

So, there is no need for any rocket science to work. You just have to study the helping book of the vacuum feeder before starting the machine.

3. What Is The Working Principle Of The Vacuum Feeder?

Working Principle

A vacuum feeder is a device that uses a vacuum to move materials from one location to another. The working principle of a vacuum feeder is simple. It uses a vacuum to create suction that pulls materials through a tube or hose to the desired destination.

The suction feeder of a machine has an air pressure in it. Also, the suction pipe of a vacuum feeder is connected to the barrel. The opening of the barrel is called the lower part of it. There is also a suction tube present in the suction feeder.

Moreover, the filter system is present that uses to filter and remove the extra dust particles from the material. There is a center cylinder and a swirling cavity that is connected to the air-pressure suction tube. The center of this machine is sealed.

The filter completely removes the dust particles and other raw materials. The power supply automatically shuts down when the filter is filled with the raw material. The door of the vacuum feeder opens automatically to remove the dust material.

Moving on to the next, the vacuum feeder also has an air compression that automatically removes the dust particles from the filter. And provides you the clean material.

After that all cleaning and removing, the vacuum feeder starts the feeding process after getting the signal. This process is done automatically.

The above is the working principle of a vacuum feeder. As the vacuum feeder easily and simply feeds the material.

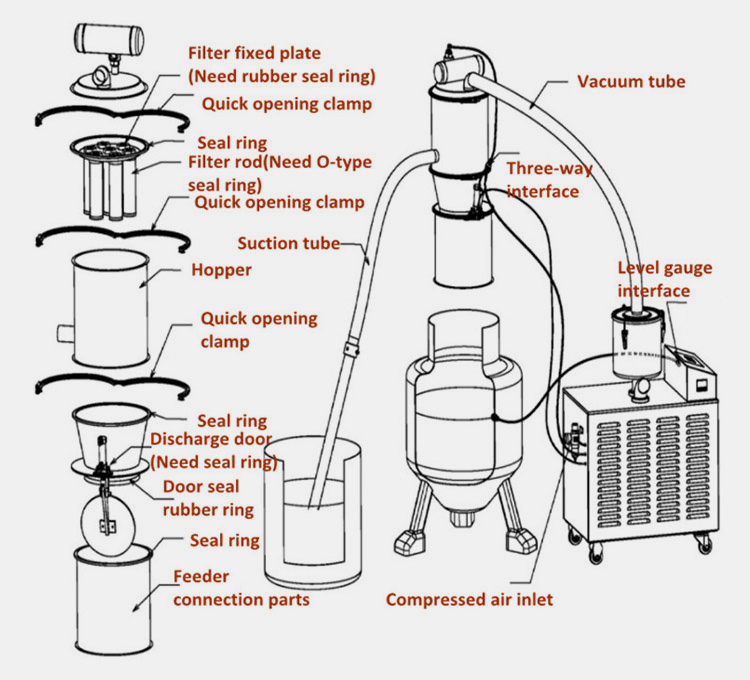

4. What Are The Main Parts Of The Vacuum Feeder?

The vacuum feeder contains different types of parts. The main parts of this machine are as follows:

Vacuum Belt Feeder

The very first and main part of the vacuum feeder is the vacuum belt feeder. The vacuum belt feeder is there to move the material. All type of movement is controlled by this vacuum belt feeder.

Filter Device

The next main part of the vacuum feeder is the filter device. This device is mainly used to filter the material that is used to feed. It removes every type of dust particle from the material.

Suction Tube

The suction tube is the third main part of the vacuum feeder. This also helps in sucking the material that is present in the vacuum feeder.

Barrel

The fourth main part of the vacuum feeder is the barrel. That is connected to the suction tube. The barrel has a filter device.

Vacuum Pump

The fifth main part of the vacuum feeder is the vacuum pump. This vacuum pump mainly removes the air and other material from the vacuum feeder.

Hopper

The last important part of the vacuum feeder is called a hopper. In the hopper, there is a filter device that fully separates gas and other raw material from the vacuum feeder.

Above are all the main parts of the vacuum feeder. These main parts play a key role in the working of the equipment.

5. How Many Types Of Vacuum Feeders Are There?

There are two types of vacuum feeders: suction and gravity. Suction feeders use a pump to create a vacuum, which sucks the food into the tube. Gravity feeders use a sealed container with a small hole in the bottom. As the food is eaten, gravity pulls more food down into the tube.

There are several different types of vacuum feeders, each designed for a specific purpose. These types are as follows:

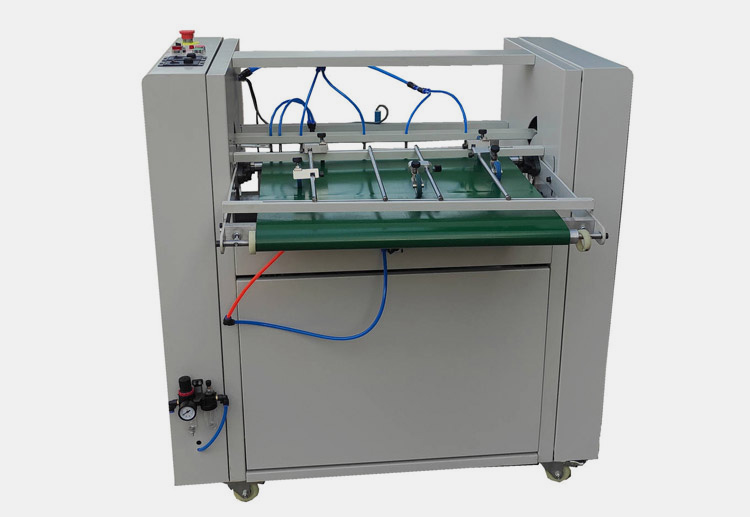

Industrial Vacuum Feeder

The very first type of vacuum feeder is the industrial vacuum feeder. It is considered the most common type of vacuum feeder. This type of vacuum feeder is basically used to move large quantities of dry materials such as powder or granules.

Working

The industrial vacuum feeder works very simply. The industrial vacuum feeder works by creating a vacuum within a sealed chamber. This chamber is connected to a feeding tube that leads to the destination where the materials need to be moved.

When the vacuum is turned on, it creates a strong suction force that pulls the materials through the feeding tube and into the chamber. The materials are then moved through the chamber and out of the vacuum feeder.

Advantages

- The price of an industrial vacuum feeder is reasonable.

- It gives the deeper cleaning of the products.

- It cleans everything very fast.

Disadvantages

- It is not efficient in terms of working with different products.

- The degree of vacuum suction of this machine is also not good.

Parts

Conveyor Belt

The conveyor belt is a very common part of industrial vacuum feeders. The function of this belt is to move the product.

Motor

The motor is considered a very crucial part of this vacuum feeder. The motor helps the vacuum feeder for sucking purposes.

Medical Vacuum Feeders

The next type of vacuum feeder is called the medical vacuum feeder. The medical vacuum feeders are basically used to draw liquids or semisolids into a syringe. This type of vacuum feeder is mainly used in pharmaceutical industries.

Working

Medical vacuum feeders mainly work in the pharma industries. This type of vacuum feeder makes the work easier. In industries, the working is somehow the same as in others.

Advantages

- They are superior in quality

- During the working powder production, the machine doe not destroy the material

Disadvantages

- The cross-contamination can take place during the feeding

- The dust can cause many problems during the cleaning or feeding

Parts

Conveyor Belt

The first part of this equipment is the conveyor belt which is the same as others. The working of the belt is the same as it controls the movements of the product.

Feeding Tube

The feeding tube is the common part of the medical vacuum feeder. The feeding tube helps the material to be reached the needed destination.

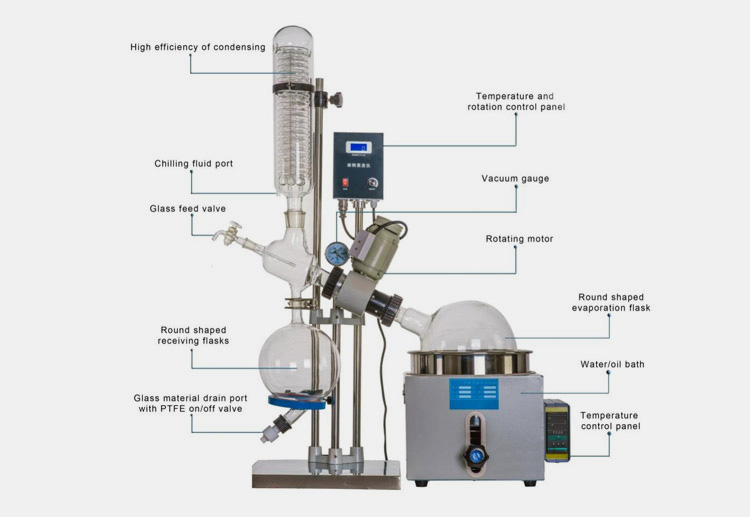

Laboratory Vacuum Feeders

The third type of vacuum feeder is laboratory vacuum feeder. This type of vacuum feeder is mainly used in laboratories to draw a small amount of material into a test tube.

Working

Laboratory vacuum feeders can be understandable easily by the name. The suction pump creates a vacuum that pulls air and materials through the wand and into the destination container. The control panel regulates the strength of the vacuum and the speed at which materials are moved.

It also controls the direction of movement for the wand, which allows operators to target specific areas.

The material handling wand is connected to the suction pump via a hose. It has a nozzle on one end that directs the flow of air and materials, and a grip on the other end for operator comfort and control.

Advantages

- The laboratory vacuum feeder mainly reduces the need for labor

- Working efficiency is greatly improved

Disadvantages

- The maintenance of the vacuum can be expensive

- You have to keep the away from the dust as they require a clean and dust-free environment

Parts

Suction Chamber

The suction chamber is where the vacuum pressure is generated. This can be done with a variety of methods, including an electric pump, a compressed air system, or even a hand-operated pump.

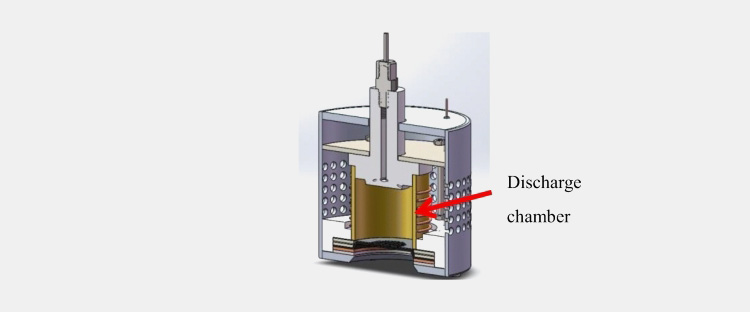

Discharge Chamber

The discharge chamber is where the material is moved by the vacuum feeder ends up. This can be a container, another conveyor belt, or any other type of receiving device.

Suction Cup Feeder

The fourth type of vacuum feeder is the suction cup feeder. This type of device uses a suction cup to draw materials into a container. The suction cup is attached to a tube, which is then connected to a vacuum source.

Suction cup feeders are typically used for small, light materials such as powders or pellets.

Working

The working of the suction cup feeder is almost as the others. It also loads the material into it and take it to the desired location. But there is only one difference is that it mainly uses light material for loading purposes.

Advantages

- The machine again provides the quick service

- They are very accurate

Disadvantages

- Due to the interruption of the power supply, the equipment restarts manually. This is the only disadvantage of this machine

Parts

Hopper

The hopper is filled with the material to be moved.

Discharge Tube

The discharge tube is connected to the destination point.

Rotary Vane Feeder

Another type of vacuum feeder is the rotary vane feeder. This type of device uses rotating vanes to draw materials into a chamber. Rotary vane feeders are typically used for larger, heavier materials such as nuts or bolts.

Working

It consists of a rotating drum with vanes or blades that create pockets of low pressure as they rotate. This causes the material to be drawn into the pockets and conveyed along with the drum. Rotary vane feeders are often used in pneumatic conveying systems to meter the flow of material into the system.

Advantages

- You can use this machine for a variety of different materials

- This is the most versatile equipment

Disadvantages

- The only disadvantage of the rotary vane feeder is that it is not as effective as the other types

Parts

Motor

The motor is there that helps in the rotation of equipment

Blades

The blades are present for creating pockets of low pressure as they rotate

Handheld Vacuum Feeder

The next type of vacuum feeder is handheld vacuum feeder. This type of feeder is great for small jobs or for those who don’t have a lot of space to work with.

They are lightweight and easy to use, making them a great choice for anyone who needs a quick and easy way to vacuum their home or office.

Working

The handheld vacuum feeder works very smartly. It cleans the desired location quickly. It works just like others but works with great efficiency.

Advantages

- Provides fast service

- Perfect for small-scale industries

Disadvantages

- Does not efficient for large-scale industries

Parts

Vacuum Pump

The vacuum pump is there to suck all the dust from the air.

6. How Installation Of A Vacuum Feeder Can Be Done?

Installing a vacuum feeder is a simple process that can be completed in a few minutes. You just have to follow the steps to install the vacuum feeder. These steps are as follows:

Determining the Desired Location

First, determine the desired location for the feeder. The location where you want to install the machine for working.

Provide Mounting Hardware

Next, using the provided mounting hardware, secure the feeder to the chosen location.

Connection of Power Supply

Once the feeder is mounted, connect the power supply and vacuum hose according to the manufacturer’s instructions.

Testing of Vacuum Feeder

Finally, test the vacuum feeder by placing some food in the hopper and turning on the power.

7. How To Troubleshoot The Vacuum Feeder?

Assuming your vacuum feeder is not working. You can solve the problem of troubleshooting in just some small steps. These steps include:

Checking the Power Supply

The first step is to check if there is power going to the unit. If there is no power, the unit will not work.

Filter Cleaning

Once you have verified that there is power going to the unit, the next step is to check if the filter is clean. A dirty filter can cause the unit to not work properly.

Clearing the Blockages

At last, check to see if there are any blockages in the hose or tubing. If there are, clear them and see if that fixes the issue.

8. How Vacuum Helps Vacuum Feeder In Loading Different Sorts Of Materials?

A vacuum feeder is a device that uses suction to move materials from one place to another. This can be useful for loading different sorts of materials into a machine or for moving objects around in a factory setting. Vacuum feeders are often used in assembly line applications where it is important to keep things moving smoothly and efficiently.

Vacuum feeders work by using a powerful pump to create negative pressure, or a vacuum, inside a chamber. This chamber is usually connected to a tube or hose that goes to the object that needs to be moved. When the negative pressure is strong enough, it will pull the object toward the chamber, and once the object is inside, the pressure will hold it in place.

Some vacuum feeders can be used with multiple materials; others are designed for specific materials like powder or granules. The type of material being moved will affect the design of the vacuum feeder as well as how much suction is required.

Vacuum feeders can be an efficient and effective way to move materials around in a variety of settings. They are often used in industrial and manufacturing applications but can also be used in other contexts like food service or even at home.

If you need to move something from one place to another, consider using a vacuum feeder!

This is how you can load the material into the vacuum feeder.

Conclusion

Vacuum feeders are the best equipment to transport material and granules from one place to another place in the industry. It is also the best for the feeding process. ALLPACKCHINA vacuum feeder is the best in the market. You can easily boost your business by using this in your industry. If you have any queries regarding the vacuum feeder, you can contact us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours