Your Trusted Thermoforming Machine

- Automatic Position Correction Function

- Electronic Magnetic Preloading Device

- Waste Membrane Collection Device

Thermoforming Machine

Allpack thermoforming machine is a new type of required product developed in light of pharmaceutical standard GMP and food standard QS. The machine adopts a fully automatic flow covering blow molding or plastic sucking molding, punching, and die cutting as the special properties of the product require of the users. It is with advanced technology, safe and simple operation, which will avoid the consumption of labor on the manual punching and contamination from the touch with the employee. Therefore, the quality requirement is secured during production. This thermoforming machine can realize automatic control through the combination of a programmable controller (PLC), man-machine interface, encoder, photoelectric system, etc., and the operation is simple and intuitive. Forming, punching, pulling, and punching stations are on the same axis.

Thermoforming Machine

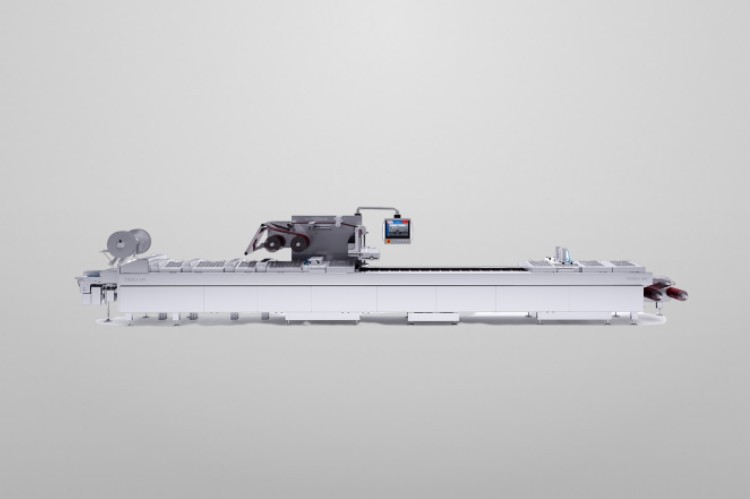

HVR-320A Horizontal High Speed Thermoforming Machine

Allpack HVR-320A horizontal high speed thermoforming machine is used to pack different types of plastic products such as trays and boxes, it is widely used in food, chemical, medical, hardware, electrical industries, etc.It can realize continuous operations such as film forming, product feeding, vacuuming, sealing and cutting.

Customizable Molds

Recycling System For Waste Material

Accurate Positioning

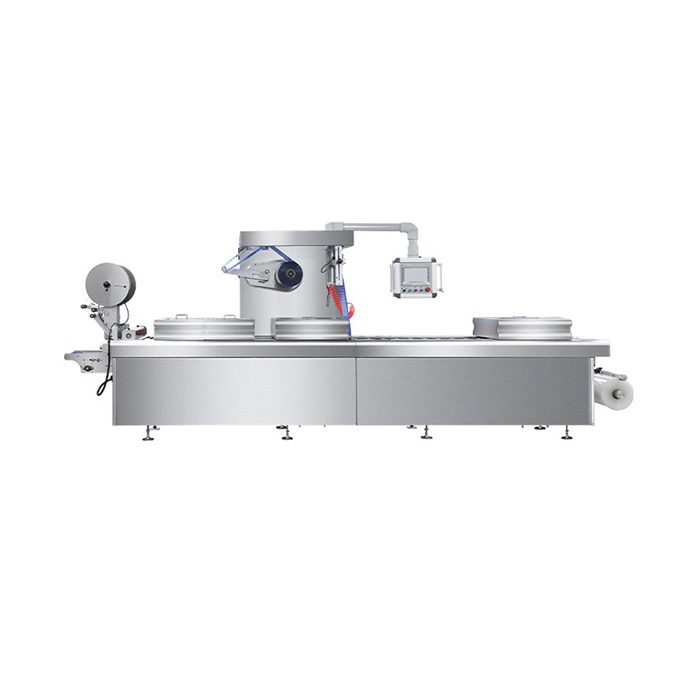

HVR-420A Horizontal High Speed Thermoforming Machine

Allpack HVR-420A horizontal high speed thermoforming machine is widely applied to pack meat, snacks, medicines, hardware, chemicals and so on, it can automatically complete working procedures such as film forming, product feeding, vacuuming, sealing and cutting. This thermoforming machine adopts recycling device which can deal with waste material so that there will be no pollution for environment.

Water Cooling System

High Production Efficiency

Low Energy Consumption

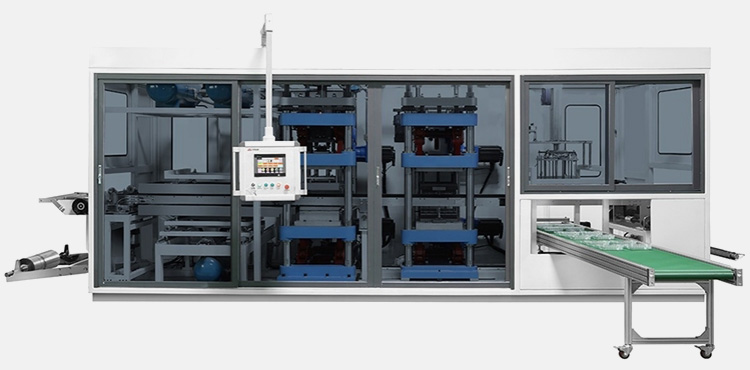

HVR-520A Horizontal High Speed Thermoforming Machine

Allpack HVR-520A horizontal high speed thermoforming machine is used for vacuuming, gas flushing and packaging a a variety of products such as food products, sauces, fruit jam, meat, metal products, seafood, medicines, etc. This thermoforming machine has a full stainless steel construction and reasonable structure, the components of it work orderly to let the machine run normally.

Food Grade Vacuum Pump

Advanced Coding System

Easy-to-change Mold

The Buyer's Guide

Thermoforming Machine:The Complete Buying Guide In 2025

Packing different things in plastic materials or making plastic trays, boxes, etc is always hard for different industries including medical, food, and chemical.

The thermoforming machine is one of the most used accessories in different industrial fields. It is used to produce different kinds of plastic materials to make your packing process easy and simple.

It is a machine which is highly recommended in making different kind of plastic and plaster products for packaging. In this guide, I am going to explain each and every important point about the thermoforming machine from how it works and how you get the final product step by step.

So, without wasting any time let’s get into the main topic.

1.What is Thermoforming machine?

The thermoforming machine is a kind of equipment or specially designed machine used to transform different types of transforming materials like plastics etc into a proper shape usable item.

Most of the Thermoforming machines use a heating process to mold different types of materials so, that you can easily pack different kinds of items in those products. Most of the plastic boxes and other packing items that we see in markets are prepared with the thermoforming machine.

Production of different kinds of items depends on the type of machine and the type of molding process that the machine uses. It can be used to produce any kind of non-solid products like plastic sheets, plastic bags, polystyrene, acrylic, etc.

Thermoforming is one of the most used machines in almost every industry providing ease and reliability in packing different type of products.

2.How Thermoforming machine works?

The working strategy of the thermoforming machine depends on its different parts from the starting to the end product the machine do all the works by itself to provide you every type of benefit and help you in saving your time.

Step-1

In the beginning, the plastic sheet or polymer sheet which you want to mold entered into the hopper is called a thermoformer. What this unit does in the machine it checks the type of material in terms of engaging to the specific product type. Choose the thickness of your material according to the type of your production.

Every type of initialization process is proceeding in this step before putting or implementing any sheet in the machine just make sure that machine is in proper running condition and working freely without any existence.

Step-2

When the sheet enters the molding terminal then the heating oven comes into action then you need to set the heat inside the oven according to the provided manual or if you are using an automatic machine then the temperature will be settled only once then the machine will automatically start the heating process whenever the plastic or polymer sheet enters the thermoformer component.

Step-3

When the temperature is set accordingly the molding process started. And then the sheet enters the molding part where the heat of the oven when combined with air pressure or vacuum mold the sheet into the desired shape. Air or vacuum usage depends on the type of machine.

A molding tray is used to transform the sheet into the your desired product shape there are many types of molding units that are used in the thermoforming machine to give different types of shapes to your product according to your packing.

Step-4

In this step when your product is ready and gets the final shape then it is sent towards the cooling unit where the finalized product pass through a cooling fan which makes your product firm & cools for further processing.

Step-5

When your product is ready then the conveyor tray exhales the product into the trimmer where your product is delivered for further use. In the trimming process, the product which has been given the proper shape is then further cut into the desired design.

Like many of the food, boxes have an upper part and lower container type part which is used to store the food item, and the upper cover is used as a cap to cover the container. You can cut the box according to your desire shape.

When the trimming is done then the final version of your product is delivered into the collecting bin.

That is the whole process which Thermoforming machine does while transforming a plastic raw sheet into a productive usable item.

3.What type of products can you produce with the help of Thermoforming Machine?

Usually, there are many types of products that you can produce with the help of thermoforming machine which can be used in different industries.

Medical Packing Products

In the pharmaceutical industry, there are many types of blister & plastic packing products that are used to pack different kinds of medication and all of these products are obtained with the help of thermoforming machine.

As you know different injection bottles that are made of glass, they are packed in a plastic tray for safe travel and just like that different types of capsules & tablets are also packed in plastic or blister packing.

Blister Packing Products

There are some of the main blister products that are produced by using the thermoforming machine.

- PVC

- PETG

- KPS

- PP

- PS

Along with these products, there are blister based electric trays to carry different kinds of electric devices and blister tape for carrier is also one of these products.

Electric trays made up of blister are used in different electric products are used to store different small parts of that specific product.

Food Packing Products

Many of the food boxes that are used to store different food items are made with the thermoforming machine. Disposable plates, glasses, and other types of disposable products that are used in the food industries are all thermoforming machine productions.

Most often when you buy coffee from Starbucks or from any other brand they will provide you in a plastic or blister-based cup made up with the help of a thermoforming machine.

4.How many types of Thermoforming machines are there?

There are many types of thermoforming machines that are present in the market according to their work functionality.

Here are the following thermoforming machine types:

Manual Thermoforming Machine

In manual thermoforming, all the types of functions are performed manually with the help of an effort from a person. In the starting process blister sheet or plastic sheet is provided to the feeding unit by the person and in this way, the machine will start working.

The heating temperature in the oven is set manually according to the specific type of product after every pack of product passed away and molding is also done manually that is the reason manual thermoforming machines are cheaper to buy because they require a person’s effort to operate them.

Manual thermoforming will cost you in terms of labor because you will require a person or two to work with the machine.

Semi-Automatic Thermoforming Machine

In a semi-automatic thermoforming machine, some of the parts of the machine work automatically and some of the parts require a person’s effort. It is expensive to buy a semi-automatic thermoforming machine as compared to a manual thermoforming machine.

There are some specific parts of the machine that you need to operate manually like at the first step the feeding unit is provided with the sheet manually then the further processing will start.

Fully Automatic Thermoforming Machine

A fully automatic thermoforming machine is a best solution if you want to operate all the functionalities of the machine automatically without any person’s effort, it will require a person only to set the functionality according to the product type.

A fully automatic thermoforming machine will save your labor cost it may be expensive to buy as compared to manual and semi-automatic thermoforming but it is very efficient and effective to give you the best output.

Working with a fully automatic machine will save your time and will help you to meet the customer requirements within less time period. By using this machine you can reach new market values because of its quick and accurate production.

5.Explain difference between Pressure Thermoforming & Vacuum Thermoforming?

There are different types of forming based on the type of forming which the specific machine support.

Here is the difference between vacuum thermoforming and pressure thermoforming.

Vacuum Thermoforming

In vacuum thermoforming the heating oven when heating the sheet up to the required level then vacuum is created in the molding cavity and this vacuum is used to suck the plastic sheet into the molding shape unit.

The vacuum pressure created in the molding unit sucks the soft sheet into the deforming unit where the sheet gets into contact with the mold unit and when it sticks in the molding unit it gets the required shape. And this is how vacuum thermoforming is made.

Pressure Thermoforming

Pressure thermoforming is done with the help of air pressure when the heating is done on the sheet it deforms the sheet into the molding cavity.

Air pressure when applied on the thin soft plastic sheet it goes down into the molding unit and cools down when gets in contact with the molding base and the desired shape product produces. Air pressure thermoforming is more accurate and you can easily gain the required shape by using less temperature rate in the oven.

The molding process in the air pressure thermoforming is quick and more precise as compared to vacuum thermoforming.

6.Which type of industries use Thermoforming Machine?

There are many industries in which thermoforming machine is used to produce different kinds of plastic & thermoplastic or polymer products and these products are used for packing purposes.

Here are some of the following industries in which you can use Thermoforming Machine.

Food Industry

In the food industry many of the food items that we often see came in plastic buckets & bowls these thermoplastic bowls are made with the help of a thermoforming machine. In this way by packing the food items in the plastic bowls and boxes the inner item remain safe during traveling and can be easily stored for longer purpose.

The thermoforming machine is very helpful to make different packing products for food & grocery items. You can use this machine to produce coffee cups, noodles jars, food boxes, and all of these products are made with a thermoplastic sheet by a thermoforming process.

Pharma Industry

In the medical field, there are many items we often see that are packed in plastic boxes like injection bottles or vials are mostly packed in a plastic sheet which protects them from getting any damage.

Glass-made products in the medical industry are packed in plastic boxes to make them safe for traveling purposes and to keep the medicine secure from outer temperature. By using the thermoforming machine you can easily meet the medical packing requirements for different products.

Electrical Industry

There are a lot of electrical equipment that are packed in blister shells or in plastic shells to keep them safe from getting any kind of damage. Blister trays are used to store different kinds of nuts, electric cables and other small electric gadgets so, that if you want to carry them around then it will be easy for you to handle.

Most of the electric machines have a tray inside made of the plastic shell which holds every type of small parts of that machine are equipped in that shell.

Different type of PVC material is used in making plastic trays that we use in electrical appliances.

7.What type of material does Thermoforming Machine use to produce different products?

There are different types of plastic materials that are used in the thermoforming machine to produce different types of products.

Here are some of the thermoplastic materials that are used in thermoforming.

- ABS

ABS is a thick plastic material that is one of the best plastic used for thermoforming processes with high resisting quality and longer durability. This material is very easy to maintain & reliable in thermoforming.

- Acrylic

It is also one of the strong plastic used in thermoforming fully transparent and available in different kinds of colors. This plastic material is very hard and hard to break mostly used for safety items in medical & food industry.

- CAB

A clear plastic sheet with flexible quality and easy to mold in any kind of shape. It also came in blister type and in thermoplastic form as well.

- Polystyrene

Polystyrene is very durable & flexible for thermoforming process. It is cheap to buy as compared to the other plastic materials.

- PVC

PVC is a flexible plastic and can be easily expanded while heating. PVS materials often have light weight.

- Polycarbonate Sheet

This plastic is flexible and transparent with a high durability rate. This is one of the generally used sheets for thermoforming process.

- PPSU

This plastic material is very hard to mold it requires greater heat as compared to other plastic sheets and more durable if you want to manage different high-temperature items in it like hot food items in fast food restaurant.

- Surlyn

Surlyn is a soft plastic sheet and clears in terms of see-through with excellent durability & having great characteristics of thermoforming.

- PETG

PETG is a thin plastic sheet with fine flexible quality and very useful in the thermoforming process.

- PSU

PSU plastic is also very hard to break and very durable to deal with high temperature and it is semi-transparent having some brown shade in it.

- Blister Sheets

The blister is also used up to some extent in thermoforming process because of its great flexibility and durability in packing purpose.

Here are some other thermoplastic materials that can also, be used in the thermoforming process.

Polypropylene

- Cellulose Acetate

- Low & High-density polyethylene

- Polymethylmethacrylate

These are some of the useful materials that can be used in the thermoforming machine for thermoforming process.

8.Explain different advantages of Thermoforming Machine?

Using Thermoforming machines in any type of industry where you need some specific type of packing will be very beneficial not only that it will help you to reach new market demands as well with quick production rate.

Here are some of the following advantages you will get while using the Thermoforming machine.

It will help you to get a great amount of production while consuming less time and effort.

You will get same type of product without any change while working with the thermoforming machine because while working manually your production size and shape may get changed.

Easy to handle & user-friendly during the thermoforming process.

Your labor cost will be saved because most of the tasks in the thermoforming machine are operated automatically.

While working with the thermoforming material manual you will lose a lot of material scrap during the molding process but there will be a minimum rate of losing thermoforming material when you work with the thermoforming machine.

There will be very less amount of effort required after the molding to give the product final look when it is out from the machine.

Durable and reliable to be used in different industries.

Thermoforming machine will help you to save your tool cost because you will require many tools working manually.

Easy to adjust & design different kinds of product shapes according to the customer’s needs.

Very flexible to work with different types of thermoforming materials.

Fast production rate to meet new customers easily.

Molding process is very clean and smooth as the molding material will not stick in the molding unit.

9.What are the disadvantages of Thermoforming Machine?

If you want to enhance your production rate & quality then you might ignore these advantages which I am going to explain to you.

It will require a huge amount of money to be invested in the thermoforming machine to start the thermoforming process but a big investment will be needed only once.

It will be hard to design different kinds of shapes while working with the single type of machine so, to design different kinds of shapes you will require to design the shaping unit according to the customer requirement.

During the industrial production rate the thermoforming machine will be costly at the potential point in the running time.

10.How many parts does Thermoforming Machine have?

The thermoforming machine is not only based on a single component there are different components present in the machine that work together to form a complete machine.

Here are some of the important and key components that work in the machine & get in contact with the production material.

Sheet Feeding Unit

This unit is used to feed the sheet to the conveyor for further processing. The main work of this component in the thermoforming machine is to start the thermoforming process by providing a thermoplastic sheet.

Sheet Conveyor

The sheet conveyor receives the sheet from the feeding unit and then this sheet is set on the conveyor unit for entering into the heating unit. The Conveyor unit mostly consists of conveyor belts for moving the product from one part to the other.

Heating Unit

The heating unit consists of ceramic heating plates that work to provide heat for thermoforming sheets when the sheet enters the heating unit it is softened with the help of heat coming from the ceramic plates so, that molding can be done easily.

Ceramic plates got heated quickly within a short time period and they are reliable to use in any kind of electric equipment.

PLC Control

A touch screen console is used to operate all the functionalities of the machine with just a click without making any huge effort. With the help of this control system, you can easily work with the machine and operate the machine without getting any major concerns.

Every type of operation is easy to perform and every single detail will be mentioned on the screen that which process is running and what will be the next one!

Punching Station

This station in the thermoforming machine is used to mold the plastic sheet when it gets in touch with the molding unit. When the plastic sheet enters the molding part and settled on the shaping unit then punching unit punch the sheet in the required direction to give the desired shape to the sheet.

Cutting Unit

When the boxes or containers are formed in the molding unit they are further processed in the cutting unit where the cutting of edges and shaping the box according to the customer requirements is done.

Cutting is usually done to divide the plastic box into two parts one part is used to store the food item or any other item in it and the other part work as a cap to cover the item to save it from outer environment.

Collecting Bin/Unit

Any type of material that gets wasted during the thermoforming process is collected in the collection bin. Not only that when cutting is done of the formed product the waste of this product is collected in the bin.

The plastic sheet which is collected in the bin it can be reused depending upon the damage quantity and quality of the sheet. If the rare part of the sheet is damaged during the thermoforming process it can be reused.

When the product is ready and finalized then it is delivered into the collecting unit with the help of a conveyor belt.

These are some of the main parts of the machine which helps the Thermoforming machine to perform the thermoforming process easily.

11.What are the specs of Thermoforming Machine?

Specifications of the machine help you to understand better about the quality of material which is used in the manufacturing of the thermoforming machine and all the important point about the thermoforming machine.

Here are some technical specifications of Thermoforming machine. These specifications are not fixed for all type of machines. Specifications of the thermoforming machine depend upon the type and size of the machine.

| Dimensions | 13000mm*4700mm*2750mm |

| Plastic Sheets Suitable for the machine | PVC, PP, PLA, PETG, etc. |

| Weight of the machine | 26T (Depend upon the size) |

| Suitable Min & Max Sheet Thickness | 0.2mm to 2.0mm |

| Total Power | 50Hz, Alternative Current 380V |

| Power used in heating | 119KW |

| Suitable sheet width | 725mm |

| Pressure of Air | 0.6mpa to 0.9mpa |

| Thermoforming Speed | 30 ycles/min (Max) |

12.How durable & reliable it is to use Thermoforming Machine in the food industry?

The thermoforming machine is widely used in making different food products for packing purposes and very durable and reliable to install with the food production unit.

Different food items need to be secured from the outer environment and with the help of thermoforming machine you can protect your product from any kind of damage.

Talking about durability you can produce different types of plastic trays to store different kinds of food items.

Egg Tray

The egg tray is used to store eggs in it depending upon the customer’s demand you can produce 10 to 30 cells tray to store eggs. You can use PV, PET, or a thermoplastic sheet to produce an egg tray.

Disposable Food Boxes

There are many food items that we often see in the food market stored in a plastic box for the longer storing purposes of food items all of these food boxes are manufactured with the help of a thermoforming machine.

In the making of these boxes, hard plastic-based sheets are used so, that your food does not get rusted and remains germ-free.

Fruit Boxes & Plastic Bowls

Different fruits can be stored in plastic boxes and then refrigerate these boxes in the refrigerator for later use. There are also many food bowls that also came in the form of plastic-like portable noodle boxes that we buy from a noodle shop.

As I explained durability of the thermoforming machine is not limited to one industry there are multiple food products that you can produce by working with the machine and because of its user-friendly function and easy access to all the functions through touch screen thermoforming machine is also very reliable.

13.What certifications does Thermoforming Machine must fulfill during manufacturing?

During manufacturing, there are different types of certificates that a thermoforming machine needs to fulfill because these certificates help the customers to deliver quality products.

CE

CE is a mechanical certificate that works to check the manufacturing of the machine is made according to the latest technology use. It tells that the product is passed by the European Union and reliable to use.

GMP

This certification tells that what types of practices are made on your product during the manufacturing. Good manufacturing practices help you to deliver an authentic and reliable products as per the important requirements.

ISO

ISO standardization in machinery manufacturing helps to deliver safe & secure the product by telling you that what type of materials are used during the making of thermoforming machine and what type of products you can not use.

CCC

This certificate is usually used in the Chinese market that every product which is manufactured in China must pass this certification to say that your product fulfills all the environmental & security precautions.

These are some important certificates that your thermoforming machine must have during its manufacturing level.

14.How much versatile is Thermoforming Machine in terms of product size & shape?

The thermoforming machine is pretty versatile when you want to produce different products by using different plastic materials in different shapes and sizes.

You can use this machine to produce food bowls, boxes, containers, trays, etc. The size of products depends upon the molding unit of the machine that up to what size thermoforming machine can produce a box or bowl.

And when you talk about different shapes it is hard to draw or deliver multiple shape boxes because the molding unit can produce the same type of boxes in a single cycle. If you want to change the shape of the box then you will be required to change the molding shape unit and fix the other one to draw the shape.

It is easy to get different shape boxes just by changing the molding shape unit you can mold the plastic sheet in any shape according to the customer demands.

The thermoforming machine is very versatile to work with different plastic sheets and materials. And you can also this machine to draw different types of plastic packing products in different shapes.

15.How can I maintain the shape & quality of the machine?

There are some key points that you need to understand to maintain the quality & shape of your thermoforming machine.

Cleaning

After working a day or two make some effort to clean the machine to save it from rusting. Cleaning will help to look your machine sharp & smooth. If any kind of outer material got stuck to the inner or outer surface of the machine it may work as a resisting force to damage your machine parts.

By cleaning the machine will remain safe & neat from rusting.

Lubrication & Oiling

After a week or a month utilize some power to lubricate the different moving/working parts of the thermoforming machine. This will help your machine to work smoothly and freely without any resistance. It will ease the forming process and will increase the speed of your machine.

For better performance rate & efficient production rate lubrication plays a very important role.

Quality over Quantity

Operate your machine at moderate speed as this will save your machine from getting heat up because a quick speed rate will also increase the safety risks or may be some component of the machine get torn during the operation.

Use moderate speed and produce fewer products but quality ones as they will satisfy the customer’s needs.

Operational Check

Before starting the thermoforming process operate the machine for a minute or two and check all the working parts. If you see any damaged parts in the machine consider replacing these parts with new ones to save your machine from further problems.

Start the thermoforming machine and leave it for 5 minutes in the idle state so, that all the running parts get the rhythm.

16.Why you should use Air Pressure Thermoforming Machine rather than Vacuum Thermoforming?

Some of the points describe that pressure thermoforming is better as compared to vacuum thermoforming. Here is the comparison between these two thermoforming machines.

| Air pressure Thermoforming machine | Vacuum Thermoforming machine |

| It is easy for you to control the dimensions of the product while working with air pressure thermoforming. | It is hard to control dimensions of the product while using vacuum in the molding process. |

| The production cycle in the molding unit is quicker in air pressure thermoforming. | The production rate in vacuum thermoforming is slower as compared to air pressure forming. |

| Sheet can be easily molded by using low temperature. | It requires comparatively high heating temperature in the molding process. |

| Air pressure will act as a force for molding purpose and for quality production. | A small hole in the vacuum pump will cause the disturbance in the thermoforming process. |

17.How to select which Thermoforming Machine is best for your industry?

There are multiple applications in which thermoforming machine is used where you need packing of different materials.

You need to select the thermoforming machine according to your requirements.

Production Type

Choose what type of production you are going to make with the help of a thermoforming machine. By defining the specific type of production it will be easy for you to select a specific type of machine as per the requirements because there are many thermoforming machines available in the market.

There are many products that you can produce with this machine-like disposable trays, boxes, bowls, etc.

Installation Area

Always choose the right size thermoforming machine according to the area in which you are going to install it. Because if the machine size is large you may adjust it in that area but it will be hard for you to work in such a small space. Select the size of the machine according to the space or area.

Material for Thermoforming

There are several types of thermoforming materials that we can use in the manufacturing of a packing product so, select the thermoforming material according to your packing items like most of the food industries use PVC plastic for making food trays & bowls.

Automation Level

Check the automation level of the machine before buying it. A fully automatic thermoforming machine will help you to get quick production and will help you in saving your labor cost. If you use a semi-automatic or manual thermoforming machine they will require some person’s effort for their operation.

Type of Packing Items

If you are having a food industry and you want bowls and boxes to pack different kinds of grocery items then select the machine that can give you the packing product according to the item that you want to pack in these boxes because sometimes thermoforming machine only works to produce plastic trays or bowls so, select the shaping unit accordingly.

18.Explain difference between Hydraulic Thermoforming & Blister Thermoforming Machine?

Both of the machines work in a different way from each other in terms of the molding process and product making. Here is a difference between these two types of machines.

| Hydraulic Thermoforming Machine | Blister Thermoforming Machine |

| In this machine plastic sheet is used for thermoforming process. | Blister sheet is used for thermoforming process. |

| Hydraulic press is used to make the shape of the product under the cavity. | Blister material after heating stretched into the molding cavity for getting a shape. |

| You can mold the sheet even at low oven temperature. | Require more heating oven to mold the blister film or sheet. |

| Works on hydraulic press. | Works on vacuum. |

19.Which machine is cheaper to buy Thermoforming or Injection Molding Thermoforming Machine?

Basically, there are two main molding machines that are mostly used in different industries depending upon the specific type of production Thermoforming machine & Injection molding machine.

Let me explain to you some basic differences between these two machines along with their applications.

Thermoforming Machine

The thermoforming machine works on the principle of heating the plastic sheet and then mold it into a shape with the help of air pressure or vacuum thermoforming. It works on a single side control fabrication process.

The molding cavity unit is limited for some shapes you will require to change the molding unit to get another shape product.

Applications

Electrical & Automotive components like the dashboard for different vehicles, electric trays, air ducts, the interior of seat, etc.

Medical components like injection trays for storing injections.

Food components like disposable bowls, glasses, trays, lunch boxes, food boxes, etc.

Injection Molding Machine

Injection molding machine designed in a more unique way to produce different shapes with the same molding unit. It is designed to produce small plastic components with the molding process it does not use any plastic sheet or film.

A heated plastic liquid is injected into the molding unit where air pressure is used for the molding process in this way the shape or design of the product came in action. There are multiple cavity options in the injection molding machine.

Applications

In construction use, there are many components that are formed with the injection molding in the likes of locks for windows & doors, handles, different types of hand tools, etc.

In automobiles, there are some components that are produced in the injection molding like panels to hold electric parts of the vehicle, gear cover, etc.

In the medical industry components like prep kits for surgery, different X-ray components, etc are made with the injection molding.

Different plastic hooks, caps for different plastic vials, bottles, and containers are also made with injection molding.

Price Comparison

Every machine has its own working capability and work efficiency depending upon the automation level. In thermoforming machine, you will require to invest 2,000 to 10,000 USD according to the size, type, and automation level of the machine.

If you are in need of an injection molding machine then it is cheaper to buy as compared to thermoforming machine because it has a smaller size compared to a thermoforming machine. It will cost you from 1,000USD to 8,000USD depending upon the size and type.

20.How much it will cost to have a Thermoforming Machine?

Every thermoforming machine works differently according to its automation level, type and size as well. You can not buy all the machines in a single price tag every machine works according to its functionality & production rate.

A fully automatic Thermoforming machine will be costly as compared to other manual and semi-automatic thermoforming machines because they work automatically and save you time and money that you may spend on labor while working with semi-automatic thermoforming. You can buy a fully automatic thermoforming machine by spending 20,000 to 25,000USD.

Semi-automatic depending upon its working capability it will cost you between 8,000 to 10,000USD. Some parts of this machine work manually whereas some parts of the machine work automatically.

The manual thermoforming machine is cheap as compared to both semi-automatic and fully automatic thermoforming machines because manual thermoforming will require more person effort rather than doing all by itself. You can buy the manual thermoforming machine in between 2,000 to 8,000USD.

These are the price tags in which you can buy thermoforming machines with different functionalities

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586