Your Top Liquid Filling Machine Manufacturer

- Measuring Regulation

- Rugged Rotary Valve System

- Pneumatic Quantitative Filling

Liquid Filling Machine

Allpack liquid filling machine is compact and portable. The casing uses stainless steel material so it is durable and easy to clean. The filling machine has a self-prime pump that can suck the liquid from your container and then output via the nozzle. It can be used to fill many different types of clear thin liquid, including water, olive oil, fuel, drinks, vinegar, milk, etc, and low viscous liquid like water, wine, solutions, etc. Allpack liquid filling machine is not suitable for filling very thick liquid (sauce, detergent, etc), or liquid containing small particles. The tubes are made of silicone gel and the pump head is made of PVC plastic material so it can endure mild acid and alkaline solutions. The machine has a front control panel and digital display. You can easily enter your parameters by pressing the buttons on the control panel and the parameters will show on the LCD screen.

Liquid Filling Machine

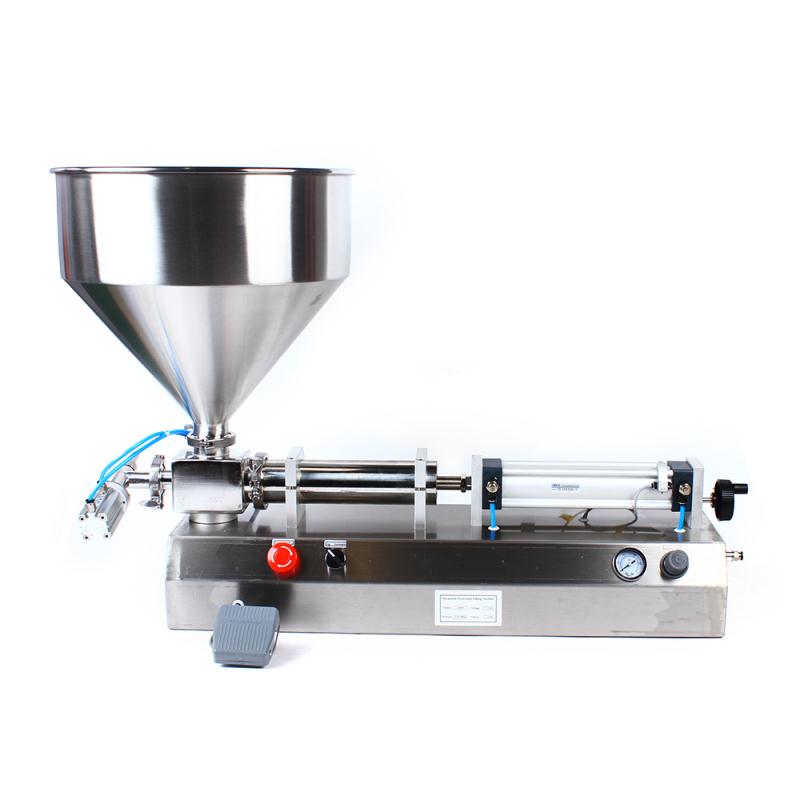

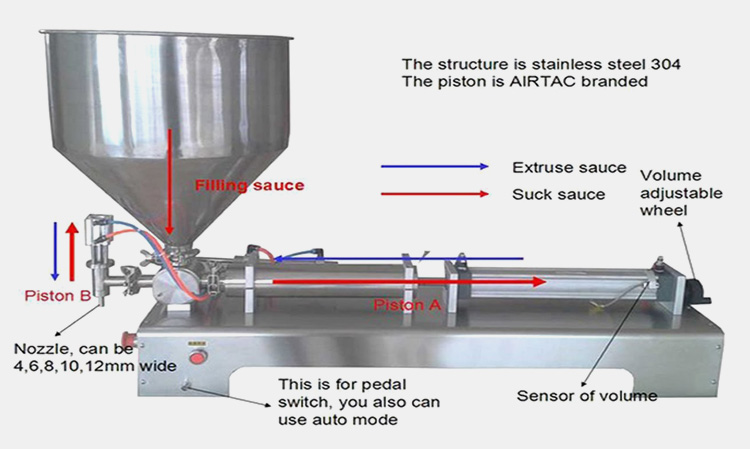

Viscous Paste Cream Alcohol Gel Bottle Mixing Filling Machine

The viscous paste cream alcohol gel bottle mixing filling machine is specially designed for quantitive mixing and filling high-viscosity pastes and liquids such as peanut butter, tomato sauce, honey, etc. This liquid paste filling machine is equipped with a blender for the paste mixing and works in a pneumatic way. The filling capacity is up from 25 to 40 pics per minute(depending on operator speed, product density, draw length, a fill speed, among others). The mixing and filling speed can be adjusted for your needs. Made of stainless steel 304, it meets with requirements of GMP. With reasonable design in a small volume, it is easy for you to operate and clean.

Easy To Operate And Clean

Made Of Stainless Steel 304

Reasonable Design In A Small Volume

A03 Manual Paste Liquid Precision Filling Machine

A03 manual paste liquid precision filling machine is suitable for filling honey, peanut butter, toothpaste, and other high-viscosity product in the food, daily chemicals industries, etc. It has a wide range of applications and can meet all your requirements. With a metal filling port, that makes the filling more accurate. The solid support base makes the support firmer and safer to use. It is simple and easy to fill with the manual handle. The stainless steel storage is not easy to corrode which is easy for you to clean and for longer use. This precision filling machine is equipped with a 304 stainless steel lid, which can prevent foreign matter from entering the hopper while working.

Manual Handle

Solid Support Base

Paste Liquid Precision Filling

YT180-1 Single Head Small Volume Magnetic Gear Pump CNC Liquid Filling Machine

YT180-1 single head small volume magnetic gear pump CNC liquid filling machine is widely applied in filling the majority of liquids(for example various drugs, chemical reagents, oils, skin lotions, beverages, and other particle-free liquids). The CNC liquid filling machine is especially suitable for clean filling with high precision and free of secondary pollution.

High Filling Precision

Stepper Motor Control

Free Of Secondary Pollution

YT180-2 Single Head Small Volume Magnetic Gear Pump CNC Liquid Filling Machine

YT180-2 single head small volume magnetic gear pump CNC liquid filling machine adopts the micro-pump in the filling time, motor speed, and other factors to achieve a uniform, minimally repeatable liquid filling method. This CNC liquid filling machine is widely used in pharmaceutical, chemical food, beverage, oil, cosmetics, and other industries, for low viscosity particle-free liquid dispensing, and small-batch production.

Stable Operation

Thermal Protection

Magnetic Gear Pump

LT-I Single Head Magnetic Force Pump Liquid Filling Machine

LT-I magnetic force pump liquid filling machine adopts high-precision miniature magnetic pump speed and pump working time to determine the filling volume. The body of this magnetic force pump liquid filling machine is corrosion-resistant and versatile and can be used to fill almost all liquids and fluids. The force pump liquid filling machine adopts the pump head and motor imported from Japan, the time regulator of the international brand Omron, and other well-known manufacturers' parts, which can provide you with a durable and comfortable structure.

Both For Manual And Pedal Use

Magnetic Force Pump Liquid Filling

High-precision Miniature Magnetic Pump Speed

LT-II Double Head Magnetic Force Pump Liquid Filling Machine

LT-II double head magnetic force pump liquid filling machine is applicable for filling almost all liquid that can flow, especially for oil, washing liquid, alkali liquor, and highly corrosive liquid. This magnetic force pump liquid filling machine is driven by magnetic force with a gear pump. The pump head is not connected to the motor with no shaft. The pump head and motor are imported from Japan. Other components are produced in Taiwan. The filling machine uses a frequency converter to start and brake and uses a potentiometer to adjust the motor speed to ensure accurate filling time, making the filling error less than 1%.

Frequency Converter

Magnetic Force With Gear Pump

Double-head Magnetic Force Pump Liquid Filling

The Buyer's Guide

Liquid Filling Machine: The Complete Buying Guide In 2025

Industries that are involved in filling procedures are now focused on improving their productivity and use modern techniques. Liquid filling machine is one of the best choices for industries all over the world to increase their productivity, quality and most importantly their business.

This buying guide will assist you regarding the application, types and working principle of a liquid filling machine. So get the most of it!

1. What Is A Liquid Filling Machine?

Liquid filling machines are mostly used in the pharmaceutical, cosmetics, beverages and food industries where liquid is to be filled in various types of containers, jars, and bottles. Liquid filling machines are highly precise and the volume of liquid has a filling tolerance of only ± 0.5 ml. This makes them too accurate and efficient for production setups.

It is an easy way to fill liquid in a quick manner using a liquid filling machine and replacing the traditional filling practices where human errors were a common disadvantage. A liquid filling machine also ensures less wastage of material.

2. In Which Industries Are These Liquid Filling Machines Used?

Common applications of a liquid filling machine are

Food and Beverages Industry

Liquid or viscous products are also filled, sealed, and wrapped using a liquid filling machine. Beverages in bottles and containers are also properly filled with high quality and precision.

Cosmetic Industry

Liquid materials used as cosmetic products like creams, lotions, creams, moisturizers, and others are filled using a liquid filling machine.

Medical Industry

Liquid filling machines are used to store sterilized liquid products like medicines and others in sterilized conditions. It helps to avoid cross-contamination and increases the shelf life of products. Products like hand wash and shampoo are also filled using a liquid filling machine.

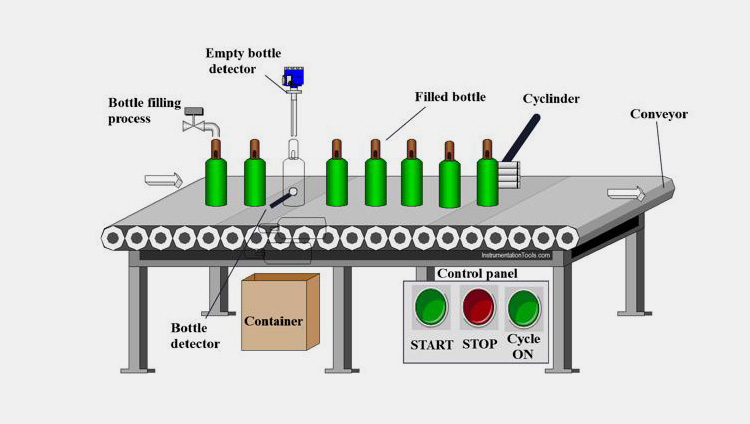

3. What Is The Working Principle Of A Liquid Filling Machine?

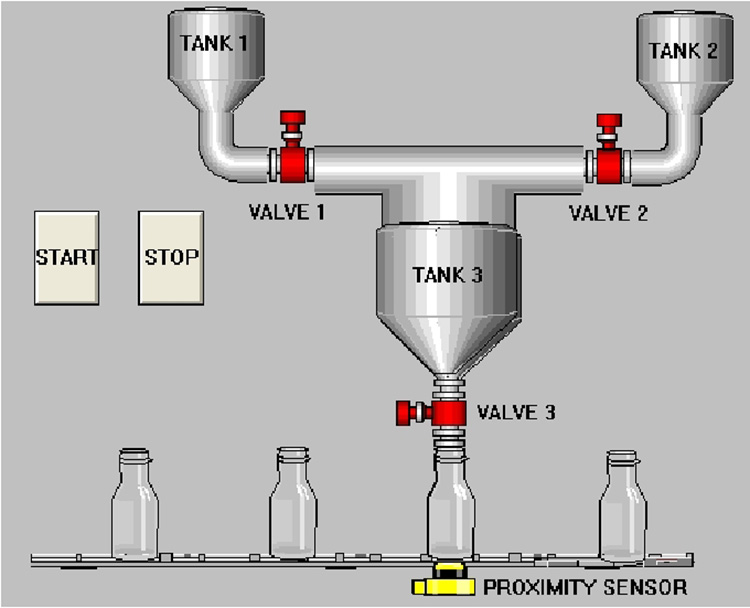

Like other filling machines, a liquid filling machine also has the same working principle. The only difference between them is that a liquid-filling machine requires high pressure to fill the containers or bottles in a precise manner. Following is the working principle of a liquid filling machine.

- Initially all the parameters of the machine like speed, temperature, pressure, etc. are set according to the viscosity and nature of the liquid.

- After that the feeding pan is filled with the mixture that is to be filled in the container. The pan mixes it well to achieve the desired composition.

- The liquid then travels from the feeding pan to the discharge tube where it exits the system. Meanwhile, containers are set in a proper conveyor system and moved in sync with the help of sensors.

- As the liquid and container both reach the filling head, the container gets filled and proceeds to the next step.

- Rotations are also done for proper wrapping, covering, and sealing of containers in a single machine. Highly efficient working is carried out to have the same products of the same quality.

4. What Are The Main Components Of A Liquid Filling Machine?

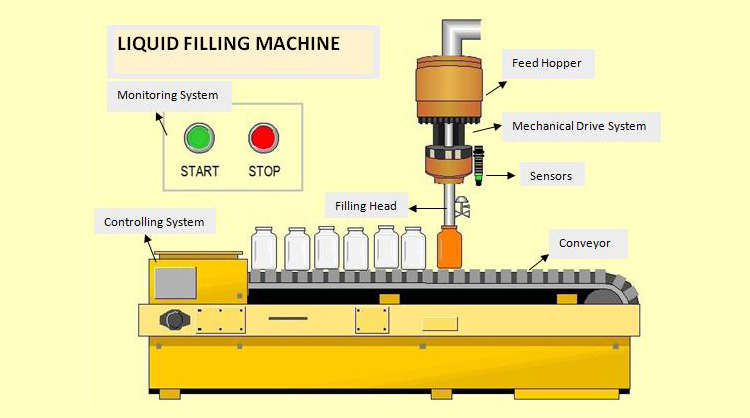

Main Components of a Liquid Filling Machine

Some of the main components of a liquid-filling machine are

Feeding Pan / Hopper

The most important component of a liquid filling machine is a feeding pan. This is the area where the product actually gets mixed and is prepared to be filled in the filling object. Hoppers are also there to control the exit of feeding material.

Filling Head

A filling head is a part that gets contact with the packaging material like a bottle, jar, container, etc. It allows the mixed product to enter those packaging materials.

Mechanical Drive System

This drive system is responsible for the mechanism of the whole packaging material movement. A mechanical drive system ensures that the movement of packaging material is synchronized with that of the amount of liquid released from the filling head. A minor delay or excess speed can damage the whole production line.

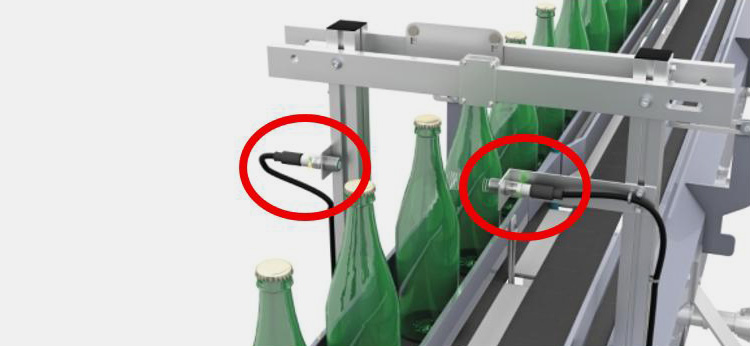

Sensors

Sensors transmit signals that indicate the presence of packaging objects. These are also responsible for making a synchronized relationship between the movement of the object and the filling unit. It allows the container to enter the filling unit only when it is empty to avoid overlapping of containers.

Control Panel

The operational parameters like speed, quantity, liquid volume, power, and others of a liquid filling machine are controlled through this control panel.

Control System

The automation of a liquid filling machine is through this control system. Nowadays mostly PLCs (Programmable Logic Controllers) are used to monitor and control all the activities performed by these liquid filling machines.

Monitoring System

HMI or Human Machine Interface is the virtual display of all the activities that are carried out in a liquid-filling machine. It allows a monitoring display to the operator which helps to control the operations of the machine.

5. What Are The Types Of Liquid Filling Machines Available?

Out of a number of liquid-filling machines, the most usable and productive liquid-filling machines available in the modern world are

Paste Liquid Filling Machine

For thick liquids like paste, toothpaste, Vaseline and etc., a paste liquid filling machine is used. The machines are available in automatic, semi-automatic, and pneumatic operations.

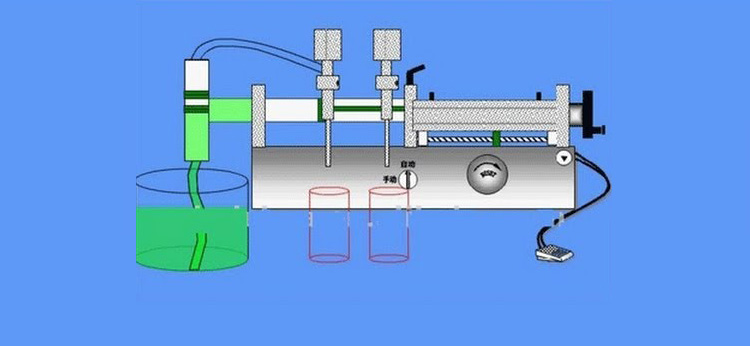

Pneumatic Liquid Filling Machine

Pneumatic supply is used for machine operations instead of an electric one in a pneumatic liquid filling machine. For flammable liquids and paste, a pneumatic liquid filling machine is ideal as it reduces the chances of spark and other hazardous things.

Inline Liquid Filling Machine

An inline liquid filling machine is highly compatible with all types of liquids and is arranged using a conveyor system.

Rotary Liquid Filling Machine

In a rotary liquid filling machine the containers are rotated to different stations in a single machine. The container circulates in filling, sealing, wrapping, capping, and other stations in a rotation or sequence.

Manual Liquid Filling Machine

A manual liquid filling machine is used in places where productivity is not much high. The machine requires complete manpower for its operation and is suitable for small-scale businesses.

Semi-Automatic Liquid Filling Machine

Semi-automatic liquid filling machines have less involvement of manpower and the majority of work is carried out by the machine itself. Medium-scale businesses mostly require this semi-automatic liquid filling machine.

Fully Automatic Liquid Filling Machine

No human interface is required in this type of machine. Thousands of products can be prepared in no time but today these automatic liquid filling machines have spread their network. Fully automatic liquid filling machine is used in large-scale businesses where productivity is too high.

6. What Are The Differences Between Semi-Automatic And Fully Automatic Liquid Filling Machines?

Differentiating a semi-automatic liquid filling machine to an automatic liquid filling machine is never an easy task. As most of the things are common in both of them, but machines can only be distinguished on the basis of its structure, working principle and functionality.

Functions

Semi-automatic liquid filling machines are ideally used to fill containers ranging from 5 ml to 1000ml. More than 500 containers can easily be filled in one hour. Human involvement is also an important thing in this machine.

Completely automatic functions are present in an automatic liquid filling machine. Liquid ranging in between 100 ml to 10000 ml are filled with a capacity of filling around 1500 containers in an hour.

Construction

A semi-automatic liquid filling machine is mostly made up of stainless steel and is robust in nature. These machines have nozzles, fillers, syringes and other equipment that are compatible with both manual and automatic operations.

An input and output conveyors are mostly associated with the structure of an automatic liquid filling machines. The speed of conveyors is controlled according to the production requirement. Increasing head in a fully automatic liquid filling machines, the productivity increases directly.

Filling Methods

Bottles are placed by the operator in a semi-automatic liquid filling machine and then automatically filled by the machine.

The containers and bottles are placed on the conveyor and it moves automatically throughout the system. The conveyor and liquid filler work together in a synchronized manner during the process.

Product Movement

Human push is always necessary in a semi-automatic liquid filling machine but automatic conveyor movement of product is present in a fully automatic liquid filling machine.

7. What Are The Different Liquid Filling Systems That Are Present In A Liquid Filling Machine?

Globally there are two types of liquid filling systems that are commonly found in a liquid filling machine. Those are

Level Filling System

When the requirement of the system is to fill the bottles only to a level that has have specified by the manufacturer. There is no concern regarding the level of liquid because a level-filling system only works on the principle of filling bottles regardless of ideal productivity.

Same product can be filled in different packaging sizes and only the level of the filling system is maintained. Filling of liquid in glass containers and bottles are most suitable to be filled under a level filling system.

Volumetric Filling System

Volumetric liquid filling systems are used when an exact amount of solution is to be filled. These are also applicable at places where the system remains synchronized in terms of liquid filling. Each bottle or container holds the same amount of solution.

Highly precise and accurate results are obtained when volumetric systems are used in filling machines. Only fillers are to be purchased for each type of bottle or container.

8. What Is A Liquid Filling Machine Made Up Of?

Some of the materials that are commonly used for making liquid filling machines are

SS Material

SS is the best type of material available for any type of processing machine. This keeps the structure free from contamination and increases its life even if kept in humid conditions. SS as compared to other materials is always set on priority also because it keeps the dust away from the body which can later on disturb the working procedure of the machine. Hard-layered stainless steel keeps the boiler, heater, and sealer secure from any type of hazard.

Mirror Polished

Another material that has been used for making a liquid filling machine is a mirror polished surface. The body of the tank where the liquid is kept is mostly made up of a mirror polished surface as it keeps the rust away from the system and blocks the entrance of environmental microbes.

German Technology

Due to high-speed production setups, the structure in the most fully automatic liquid filling machine is made up of German technology material. The material provides a proper sealing feature to the machine and can be suitable for high rpm setups. German material can cope up with a running rpm of up to 5000 cycles per minute.

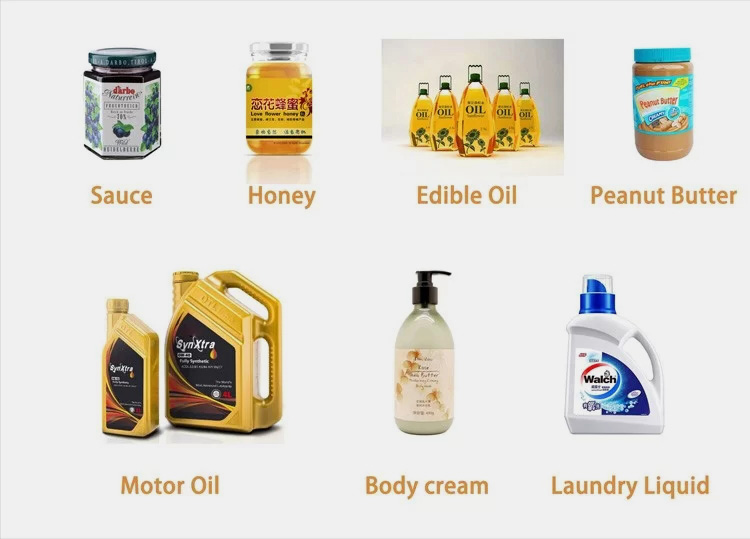

9. What Type Of Materials Filled Using A Liquid Filling Machine?

The material used in a Liquid Filling Machine

Liquid filling machines are highly sensitive when it comes to filling material selection. It is a much more important task to select liquid depending upon its nature, viscosity, temperature effects and atmospheric impacts.

- It is mostly used in the beverages industry to fill cokes and other fresh juices.

- In Food industry, oil and liquids are mostly filled using a liquid-filling machine

- In Medical industry syrups and other vials are filled using these machines.

10. What Are The Advantages Of A Liquid Filling Machine?

Liquid filling machines can be highly economical and revenue generating when used in industries. It can increase the productivity and provide number of benefits like

Accuracy

Liquid filling machines are highly accurate and give a filling accuracy with an only tolerance of ± 0.5%. 100% consistent, precise and accurate results are obtained when products are filled using a liquid filling machine.

Precision

Brushless DC Motor drive makes a liquid filling machine highly precise. Also no measuring instrument is used after the production due to this important factor. Thick and thin, both liquids can be filled

Easy Operation

The operation of a liquid filling machine is very simple due to the rotative fillers in it. Simple filling procedures are there that no individual has to get training for it.

Saving of Time and Energy

Production of thousands of filling objects is carries in no time and also due to less manpower, the required energy loose a distinct level.

Consistency

No bottle in the production line differs from others. Each one has the same quality ad filling of liquid. Its consistency can be reflected whenever a quality check of a batch process is carried out.

Speed Filling

A liquid filling machine can give a filling capacity of up to 12 liters in a single minute which makes it highly productive and reliable for industrial purposes. A greater volume of productivity can be achieved using a liquid filling machine which is impossible if done manually. Thousands of products can be filled in no time.

11. What Common Faults Occur In A Liquid Filling Machine And What Are Their Remedies?

| S.NO | Errors | Fault Cause | Troubleshooting |

| 1 | No Display on LCD | Blowing of dose of power plug is off. | Replace the fuse

Reinsert the plug. |

| 2 | Error in Pump Wheel | Roller of pump wheel stuck.

Driver circuit board is faulty. |

Installation of bump head. Checking of circuit board. |

| 3 | No Liquid Transportation | Damaged hose pipe | Replacing the hose and adjusting the pump head cover. |

| 4 | Sliding of Hose | Hose is not fixed properly | Checking if hose and tightly knotting it with screws and cards. |

12. How Are Liquid Filling Machines Maintained?

Maintaining smooth product in liquid filling machines purely depends upon timely maintenance and cleaning of the machine. Following are the steps taken to maintain a liquid filling machine.

- Standard operating procedures (SOPs) given by the manufacturer of liquid filling machines should be followed strictly and routine checks are necessary to be performed.

- At the end of each production process, the operator must check every part of machine that whether there is any blockage, rust, excess liquid or dust present in the machine. Such materials should be promptly cleaned and services should be done if required.

- Long production lines may have contamination is filling spaces that are neglected during production, an adequate drainage should be allocated to those areas to get rid of excess liquid.

- Schedule maintenance of liquid filling tanks, raw materials is an important task to do especially when different type of material is to be filled in same type of tank.

- Checking of all equipment as per plan can help the operator to identify the faulty ones and can easily replace those before the occurrence of any mishap.

- All the maintenance and cleaning procedure may be applied by an expert that has complete command in machines operation. A new individual can cause damage to personal and machines both.

- Finally, complete checking sheets and procedures should be designed by the buyer so that they may maintain the machine as per plan. Proper maintenance and cleaning can avoid accidents to a distinct level.

13. What Are The Important Factors That Should Be Considered Before Buying A Liquid Filling Machine?

Before going to purchase a liquid filling machine is always necessary to consider the production targets of an organization as it requires a lot of initial investment. Some of the important factors to be considered before buying a job are.

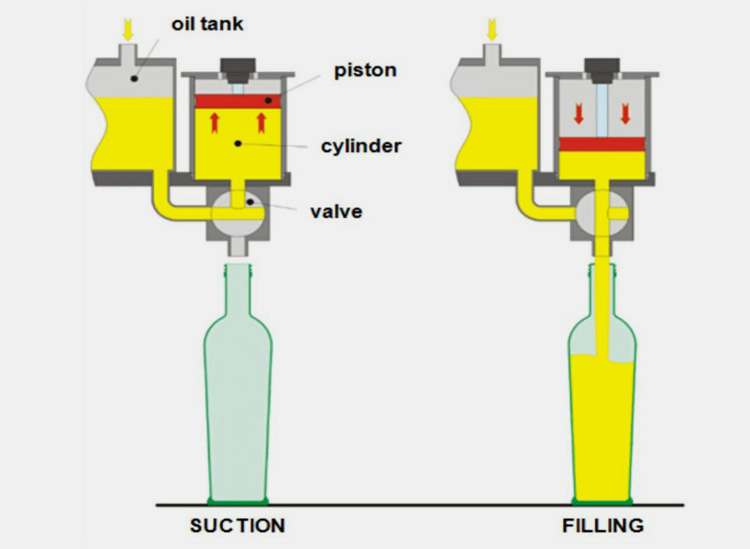

Piston Pressure

Mostly the filling process of a liquid filling machine depends on the power and pressure of pistons that are present in the cylinders of filling tank. The material and strength of these pistons should be closely monitored because these are the main components to handle mass production requirements.

Product Viscosity

There are different types of products that are filled using a liquid filling machine. Each of the liquid has its own viscosity and this lies as the main feature of those. The greater the viscosity, the greater the filling time will be there if the machine is not selected properly. Versatile machines that can handle every type of viscous liquid are always a better consideration by different industries.

Liquid Filling Productivity

Small, medium or large-scale industries should select liquid filling machines depending upon their annual production need. Manual liquid filling machine offers the least rate but automatic machine can fill thousands of bottles per hour.

Type of Container

It is always under consideration what type of liquid container is incorporated along with the machine and what is the structure made up of. As liquid stays there for a longer period therefore material of the container should be moister, humid and contaminated resistive.

Also, the size of the container means a lot. Small containers cannot be used in large scarce industries or heavy production setups.

Conclusion

The usage of liquid filling machines is increasing drastically nowadays. Industries are moving towards these machines for making high-quality, precise, and efficient filling products to increase their productivity and meet the needs of the global world. This article in detail explains all liquid filling machines and their usage. Allpack provides its customer best solutions for liquid filling machines with a variety of options and easy operational machines. You can feel free to ask us anything anytime or visit our website for further details and assistance.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours