High Grade Cling Film Wrapping Machine

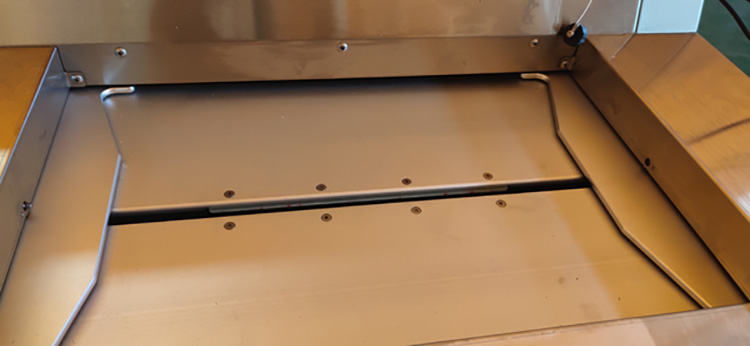

- Electroplated Stainless Steel Body

- Double Guide Rods

- Anti Slip Rubber

Cling Film Wrapping Machine

Allpack cling film wrapping machine is compact in structure, portable in size, and convenient in use. Packaged by this machine, food can be prolonged fresh in normal temperatures. It can also be used for food stored in the refrigerator, preventing odor and going off dehydration. The cling film wrapping machine can help you prevent your food from dirt so that it can be fresh longer. Its heater cutter can cut off the film without fumes and its heating board is at a tight seal. This machine is compatible with various wrapping films such as PE and PVC films. All Allpack cling film wrapping machines are easy to operate, fast to wrap, and save time. It has been widely used for packaging food to preserve freshness. The cling film wrapping machine adopts electronic constant temperature control for cutting and shrinking.

Cling Film Wrapping Machine

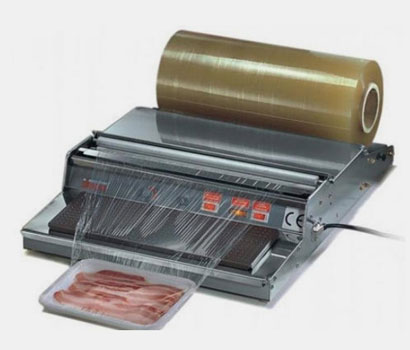

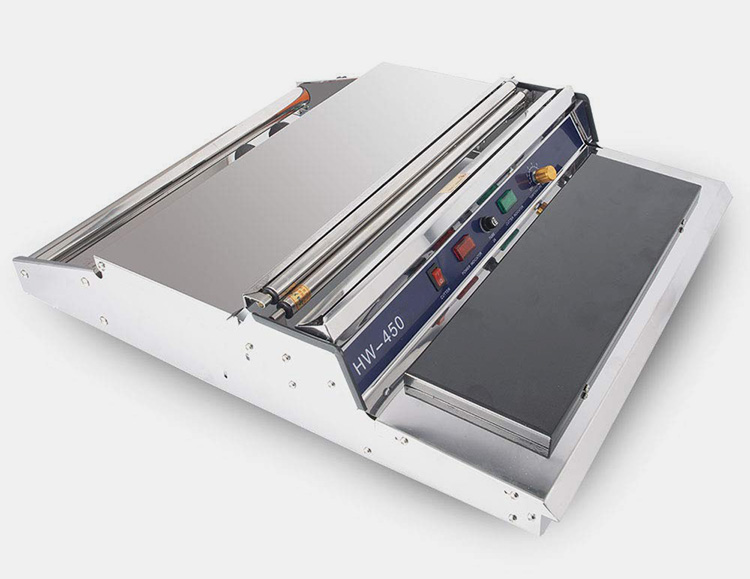

TW-450E Semi Automatic Cling Film Wrapping Machine

Allpack TW-450E semi-automatic cling film wrapping machine is used to seal and wrap food and other products, it wraps cling film on food to keep them fresh, so it is an ideal equipment for supermarkets, vegetable market, and buffet. This machine has compact design, it can be easily operated on a table top.The cling film wrapping machine is versatile, it can seal products whose width is between 0mm to 450mm. It is made of food grade stainless steel so that it is safe to pack all kinds of products.

Simple Operation

Fresh Keeping

Stainless Steel Body

TW-450F Easy Operation Cling Film Wrapping Machine

Allpack 450F easy operation cling film wrapping machine is available for PE, PVC films, it can seal product whose width is in the range of 0-450mm, it is widely used for food packaging. The cling film wrapping machine provides good freshness preservation, and it allows wet and dry dual use, which enlarge its application range. This cling film wrapping machine can realize fast heating so that the film will shrink in a high speed, which can increase the sealing efficiency.

Energy Saving

Convenient Control

Corrosion Resistant

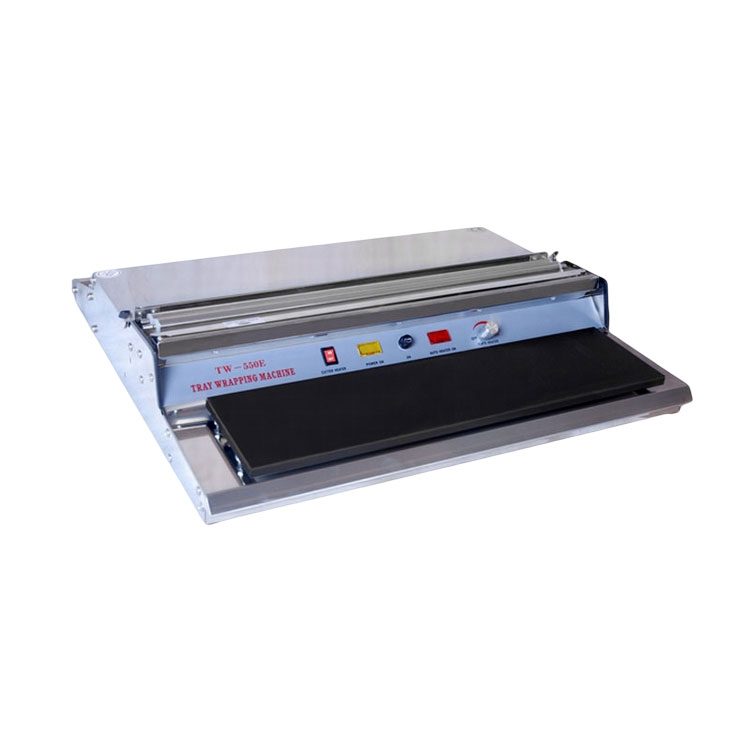

TW-550E Food Preservation Cling Film Wrapping Machine

Allpack TW-550E food preservation cling film wrapping machine is suitable for wrapping both food and non-food products whose width are between 0mm to 550mm, it is widely used in supermarkets, hotels, restaurants, family kitchens, vegetable markets, small factories and so on. This cling film wrapping machine is made of high level stainless steel, which makes it durable and hard, it is equipped with world class components so that it has excellent performance. It can be easily be operated by you, doesn't need too much training.

Strong Sealing Effect

Simple Packaging Operation

Compact Design

The Buyer's Guide

Cling film wrapping machine: The Complete Buying Guide in 2025

Preservation of food and other products have been a priority for all manufacturers globally. For producing products with extended life and making it secure from environmental effects, Cling film wrapping machine is also one of the best choice in this regard.

If you are interested in purchasing a cling film wrapping or tying to know more about this technique? This buying guide will assist you in buying a best cling film wrapping machine. Read it and take the most out of it to make your organization a profitable and productive one.

1.What Is Cling Film Wrapping Machine?

A cling film wrapping machine is one of the finest machines used for sealing and wrapping of food and other products. These machines are getting famous worldwide as the customer now is more focused more on product safety and its presentation.

Cling film wrapping machines are a series of wrapping machines that are used to pack both food and nonfood products. The packaging ensures preservation of food and prohibits the entrance of microorganisms. Cling film wrapping machines are used to wrap products like meat, fish, fruits, vegetables, ready to eat meals, chemical products, agricultural products and etc.

2.What Are the Applications Of the Cling Film Wrapping Machine?

Cling film wrapping machines are widely used in

Food Packaging

Food products like vegetable, fruits, eatables and other are commonly wrapped using a cling film wrapping machine. All these products are wrapped in cling film because of its defensive nature against microorganism and bacterial attacks.

Food packaging industry has the maximum usage of a cling film wrapping machine in almost every part of world.

Agricultural Industry

Agricultural products also use giant cling film wrapping machines to wrap products that can easily be carried to longer distances.

Pharmaceutical Industry

Cling film wrapping machines are globally present in cosmetic industries to wrap chemical and cosmetic products. As the products are directly related with human body, therefore great concern regarding the security of their chemical state is shown worldwide.

Chemical products are highly sensitive and when wrapped using a cling film wrapping machine, their strength and life gets doubled.

3.What Are the Working Principles Of the Cling Film Wrapping Machine?

A cling film wrapping machine has a same working phenomenon like other wrapping machines. It only differs when the type of automation is either manual or automatic. The working principle of a cling film wrapping machine is as

- All the external parameters of machines are to be checked at the first step. It can be temperature, pressure, electric supply, vacuum, film length and etc. All should be verified before the machine starts its operation.

- Thermostats are there to maintain the temperature of hot plate depending upon the category of wrapping material used.

- The film roll is also set according to the material which has to be wrapped and best fits the product.

- Now when all the parameters are set, the machine is allowed to preheat for 5 to 10 minutes so that it can smoothly run from the first product.

- Place the product on the cover plate and pull the film out to cover and wrap the product. In automatic process the machine itself performs this task.

- Then cutoff the bar to cut the film to the desired length of product. After that the product is placed onto the teflon coated hot plate where the product will be completely wrapped and sealed in 3 to 5 minutes.

- Airtight and sealed product is produced with efficiency and precision.

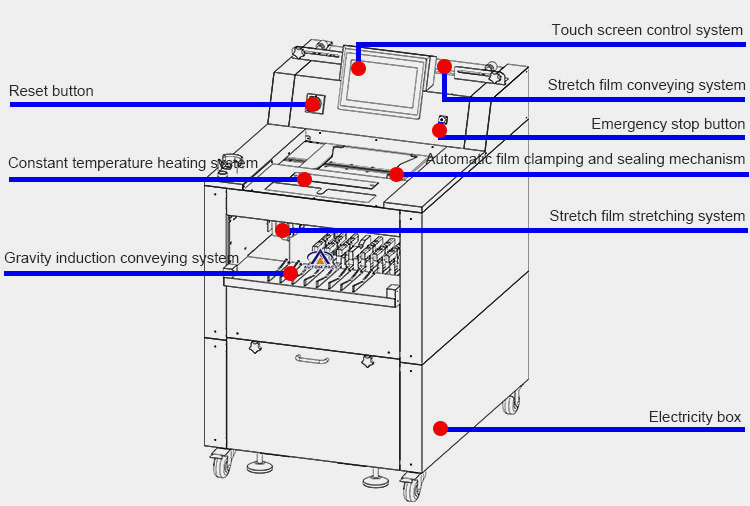

4.Describe the Structure Of the Cling Film Wrapping Machine?

The structure of a cling film wrapping machine is made up stainless steel to make it durable and long lasting. It is mainly consisting of heating system, stretching system, conveying system, induction conveying system, sealing system and some of the components in a cling film wrapping machine are controllers. Detail for some of the components is as follow

Power Supply

The initial power supply is given to the machine through this power supply unit which activates all the accessories in a cling film wrapping machine.

Controlling Knobs

As the machine gets operated all the parameters like temperature, pressure, conveying speed, reset box, roller speed, and release door time all are controlled through these controlling knobs.

Constant temperature heating knobs, quick release door knob, film roller positioning knob, quick release knob all are present on a cling film wrapping machine to maintain machines process.

Feeding Bracket

At the inlet, a feeding bracket or platform is there from where the product is feed into the system.

Conveying System

As the product is placed on the feeding platform, the operation of conveying system starts. Induction conveying system is there to enter the product automatically in to the wrapping platform and the release conveying system send the wrapped product back after process completion.

Film Roller

Here the cling film roller is placed which is used for wrapping purpose. This roller allows any type of roller irrespective of its size, length and diameter.

Wrapping Platform

This is the main unit of a cling film wrapping machine in which the wrapping is done. As the induction of product is done this platform rolls the film around the product and then automatically cut the film with perfection.

Human Machine Interface / Touching Screen

A touching screen is there which helps the operator to monitor all the activities that are performed by a cling film wrapping machine and also tells about the controlling factors of machine. Operator can directly control things with its help.

Temperature Heating Plate

After complete wrapping process the process is placed on a temperature heating plate which is already preheated to a certain temperature. These tights the cling film present at the bottom side so that no moisture or environmental factor can enter the product.

5.What Are the Different Types Of Cling Film Wrapping Machines?

There are three main types of cling film wrapping machines including manual cling film wrapping machine, semi-automatic cling film wrapping machine and fully automatic cling film wrapping machine.

Manual Cling Film Wrapping Machine

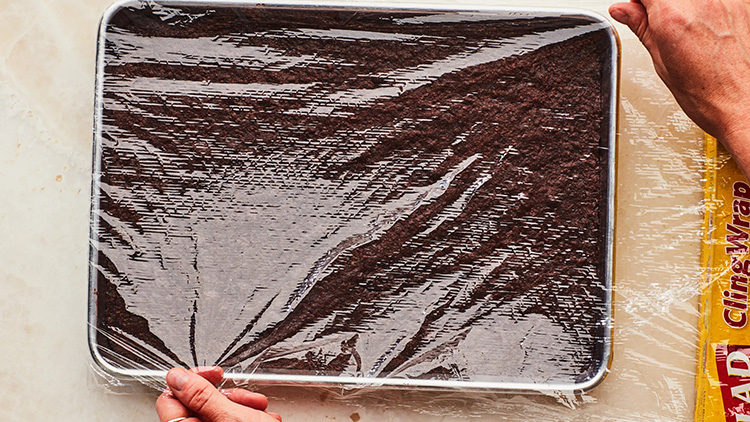

In a manual cling film wrapping machine, complete process is carried by the operator. The product is placed in tray and then manually the wrapping film of covered over the product.

The operator stretches the film over the product and wrapping is carried out. Further the product is placed on the heating plate to complete seal the wrapping film. The productivity is much slow as only 50-60 products can be wrapped in a complete hour.

Semi-Automatic Cling Film Wrapping Machine

In a semi-automatic cling film wrapping machine, both the operator and machine mutually perform their responsibilities. The worker is responsible to place the product on inlet station and then the machine itself wraps the sheet around it. The excess film is cut by the operator.

Then similar to manual cling film wrapping machine, the product is placed on heating plate for proper sealing. More than 150 trays can be produce using a semi-automatic cling film wrapping machine.

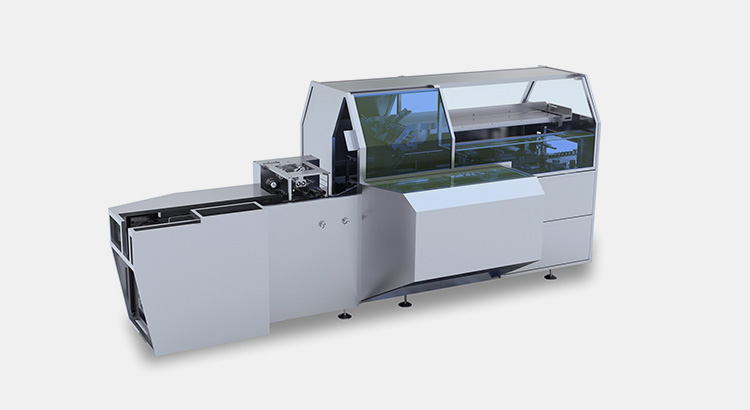

Fully Automatic Cling Film Wrapping Machine

A fully automatic cling film wrapping machine is almost same as a semi-automatic s cling film wrapping machine. The only difference is that here the extra film is also cut down by the machine itself.

Rest a single operate can produce for a longer time without any hurdle. Around 200-250 wrapped products can be obtained using a fully automatic cling film wrapping machine.

6.What Material Is Cling Film Made Of?

A cling film act as a wrap on material to increase their live and safe them from the environmental conditions. In this regard high level of study is required for selecting the right material composition. After several experiments, Scientist discovered that some static charges must be present on wrapping film to work well. This allows the film to properly stick on the product and gets all the gases out.

In this regard it was suggested that due to high molecular structure, polyvinylidene chloride (PVDC) plastic is best suitable for sticking on material and to maintain the concept. Nowadays most commonly polyvinyl chloride (PVC) is used because of its low-density nature and can tightly bound with the body of material. Series of polymers make the plastic to perform well and block all type of moisture and odors.

7.What Are The Advantages Of Cling Film Wrapping Machines?

Cling film wrapping machines are highly efficient in there process and maintains product life for a longer period. Some of the advantages of using a cling film wrapping machine are

Versatility

The most important benefit of a cling film wrapping machine is that it can be used for the packaging of multiple shapes and sizes. The machine is versatile in nature and increases attraction of products.

Secure Packaging

Cling film wrapping machines provide hygienic, sealed, dustproof and clean packaging of products that increases its life. The film packaging done by using a cling film wrapping machine resists the entrance of moisture and prevents contamination.

Quality Packaging

Defect free packaging is carried out by a cling film wrapping machine. The packaging reduces film wrinkles to a distinct level and increases the transparency of a product. Using a cling film wrapping machine makes the customer more attractive toward the product and reduces the cost created by commonly used plastic wraps.

Simple Replacement of Plastic Film

Another advantage that a cling film wrapping machine provides is that it helps the operator to replace the wrap comfortably. A simple process for changing wrap plastic is there in a cling film wrapping machine and reduces long change over times.

Ease in Operation

The operation of a cling film wrapping machine is also user friendly and helps the operator to easily get used to it. In a very less duration the operator can be fully trained regarding the machine.

8.Which Type Of Cling Film Wrapping Machine Is the Best?

We highly recommended you the fully automatic cling film wrapping machine, and the reasons are as following:

Fully Automatic Cling Film Wrapping Machine

A fully automated cling film wrapping machine is highly suitable these days for manufacturers to meet their production capacity. It ensures much quick operation in no time that more than 200 to 250 products can be produced in an hour.

A fully automated cling film wrapping machine does not requires extra man power for its operation as a single man can produce thousands of parts. Only input and output job is performed by an operator rest complete process is automated.

9.What Are The Differences Between Cling Film Wrapping Machine And Vacuum Packaging Machine?

When it comes to cling film wrapping or vacuum packaging techniques, there is always a mix concept that whether they are same or are there any differences. To better understand the differences between both of these wrapping and packaging machines, here are some of the key factors

Machine Design

A cling film wrapping machine is a simple type of wrapping machine which is comprised of few important components. Machines are made up of stainless steel to prevent rust and to increase its life. The design of a cling film wrapping machine include its main frame, film sealing system, heating system, conveying system, and other controlling equipment.

Whereas either a single chamber or double chamber vacuum packaging machine both are made up of SS material and have a simple designed structure. The operator finds no difficulty in handling of both types of vacuum packaging machine. Vacuum pump, Vacuum room, sealer frame and main frame are some of the basic components of a vacuum chamber machine.

Sealing Technique

A manual, semi-automatic and automatic cling film wrapping machine holds the same sealing technique as the product gets wrapped completely within the system. The end product after getting wrapped is kept of a sealing plate where the product edges are sealed.

A vacuum packaging machine removes the atmospheric oxygen from the product through vacuum pump and after that the sealing of edges is done. The product can then be utilized for a longer period.

Material Compatibility

Cling film wrapping machines are highly versatile with number of packaging materials like PVC, PET, PP, PR, PVDC, HPDE and LDPE depending upon the product requirement.

Mostly plastic aluminum composite film or plastic composite films are used ideally used for packaging in a vacuum packaging machine.

Application

A cling film wrapping machines are ideally used to wrap food and eatables. Such product get an increased life when wrapped with cling film material. The wrapping material is easily available.

Vacuum packaging machines are mostly used in packaging of food, electronics parts, cosmetics, medical instruments and hardware equipment. These products are used in vacuum packaging machine because oxygen is taken out to increase product life and makes it easily transferable from one place to another.

10.What Is The Gauge Of Material That Is Suitable For Different Sizes Of Products?

It is always advisable to use particular type of material according to the size of product because greater stretching force can tear the wrapping easily. The wastage of material can cause a lot to the manufacturer. This is always recommended to follow the following gauge and weight relation

| S.NO | Wrapping Material Gauge | Application | Loading Capacity

(lbs.) |

|

1

|

25 – 30 | Pre Stretching | A maximum of 2500 lbs. |

|

2

|

35 – 50 | Pre Stretching | The maximum lies between 1800 to 4000 lbs. |

|

3

|

37 – 42 | High Performance Stretching | A maximum of 2000 lbs. |

|

4

|

45 – 55 | High Performance Stretching | A maximum of 2500 lbs. |

|

5

|

60 – 65 | High Performance Stretching | A maximum of 3000 lbs. |

|

6

|

72 – 75 | High Performance Stretching | A maximum of 4000 lbs. |

|

7

|

50 – 60 | General Purpose Stretching | A maximum of 1600 lbs. |

|

8

|

70 – 90 | General Purpose Stretching | A maximum of 3000 lbs. |

|

9

|

90 – 110 | General Purpose Stretching | A maximum of 3500 lbs. |

|

10

|

120 and above | General Purpose Stretching | A maximum of 4000 lbs. |

11.What Additional Equipment Are Associated With A Cling Film Wrapping Machine?

A cling film wrapping process requires few additional equipment to complete the task with ease and perfection. Some of the additional equipment that are associated with a cling film wrapping machine are

Conveyors

Some of the semi-automatic and automatic cling film wrapping machines use conveyors at both in and out station. These conveyors are used to feed the product into the system and to exit it accordingly.

Heavy products that cannot be carried easily get help by these conveyors.

Inkjet Laser

To give proper finishing and identification, cling film wrapping machines use laser inkjets for displaying codes, barcodes and QR codes.

A customer directly gets attracted if the product have fine finishing and displayed in a proper manner.

Heater

Heating plate is often present in manual or semi-automatic cling film wrapping machine to provide strength sealing to products. The product after getter wrapped in placed on the heating plate and there all the edges are tightly packed so that no wastage of product may occur in future.

12.What Common Faults Occur In theCling Film Wrapping Machine?

Some of the common faults that occur in cling film machine are

Tearing Stretch Film

Tear in cling film directly cost productivity, safety and efficiency of a machine. It indicates that the safety and stability of product has been compromised at a point. It can also create machine downtime, damage products, hazards and risk.

Automatic or semi-automatic cling film wrapping machine can directly reduce this type of fault as it has proper setting of load containment.

Improper Load Containment

Incorrect load containment can cause lot of problems. In this way the material is not proper wrapped and causes production and material loss both.

Proper load contained can reduce this issue as load distribution can inlet required film only and the sheet will be used accordingly.

Wrong Type of Film

Before wrapping a product, it is always important to know that what type of film will be suitable for that particular product. Otherwise material, money and time loss will occur as a result of wrong material selection. Also, the concern worker can be affected.

Selection of proper material can reduce this of error and most importantly the worker should be properly trained regarding the application of film and wrapping process.

Wrong Size of Film

This is also another type of error that most commonly occurs. As there are always different size of products for wrapping, the size of film also be selected accordingly. Quality, presentation and material loss can be occurred by selecting wrong size of film for wrapping.

The size of film should initially be matched by the product length and then installed in the machine. Also, the operator training in this regard is much important.

Wrong Thickness of Film

Stretching of film is done in cling film wrapping machine. When the thickness of material is not selected according to product, it gets damaged and also may cause consistent tearing. This will cause a lot of material and money wastage.

Multiple problems can occur as a result of wrong thickness selection. So, appropriate thickness accordingly to product strength should be selected. Also, the gauges may be displayed for convenience of all concerns to save time and money.

Conclusion

A cling film wrapping machine produces safe and ling lasting products and this is why its demand is increasing drastically in the global world. Manufacturers can take a lot from it to produce high quality and reliable products. For further details you can also visit our website https://www.allpackchina.com/ and get our services 24/7.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586