Multifunctional Pulverizer: The Complete Buying Guide in 2025

A multifunctional pulverizer is a machine that uses to pulverize large-sized materials into the desired size items and this process of grinding is called pulverization. During pulverization through this equipment, an external force has been applied to crush the materials.

In the year 2023, the multifunctional pulverizer has numerous applications in different industries including agriculture, food industry, manufacturing industries, landscaping, pharmaceutical industries, printing, recycling, etc. This can be used for all kinds of materials either it is wet or dry. Before buying it, several questions arise in our mind related to its proper functioning and based on its cost. This article would be helpful to resolve queries that arise during buying of a multifunctional pulverizer, here we discuss.

1.What is Multifunctional Pulverizer?

A multifunctional pulverizer is a machine used to crush sawdust, waste materials from the furniture factory, wood chips, the cotton stalk, cornstalk, the beanpole, the peanut shell, wheat straw, and others. It is also called slimmer, it has various advantages as it can be used for simple material, although its operational principle is also stable, and have a good pulverizer effect. After pulverization, the crushed materials can easily be released from the crushing compartment of the multifunctional pulverizer.

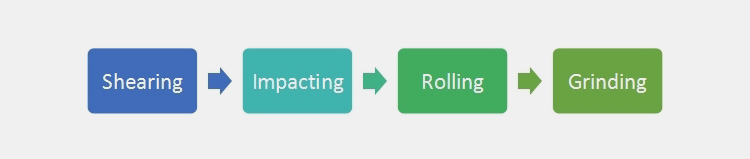

During pulverization, the external forces exerted on materials, include:

Shearing

The shearing is suitable for crushing fibrous, tough materials and large stones, it has applications in coarse crushing and crushing.

Impacting

The impacting is mainly suitable for crushing brittle materials and it is usually used in crushing work.

Rolling

The rolling is used mainly for each type of material and is applied for high-fineness and ultra-fine pulverization.

Grinding

The grinding is mainly for ultra-fine and for super-large pulverization machines, which can be further pulverized.

Nevertheless, in the real crushing method, many external forces are applied at the same time. These machines are mainly customized based on high-end crushers.

2.What are the Different Types of Multifunctional Pulverizers Available on the Market?

In fact,the multifunctional pulverizers can be divided into four main types,which include tabletop pulverizer machine,portable pulverizer machine,multipurpose dry and wet pulverizer and industrial pulverizer.

Tabletop Pulverizer Machine

Tabletop pulverizer machine,as the name implies,it is designed compact and small enough to be put on tabletop,very convenient to carry and operate.It always be used to grind products such as rice,wheat,chop,millet, pepper and so on.

The working principle of this type of pulverizer is quite simple,the materials are feed into the machine through the hopper,and then be delivered into the chamber,in the chamber,the materials are repeatedly beaten by the hammer until they become smaller particles or powder.

Portable Pulverizer Machine

Portable pulverizer machine is used to pulverize materials which is sticky,it is widely used in pharmaceutical,chemical,food industries,etc.

The working principle of portable pulverizer machine is friction between different gear discs,the machine is equipped with a moveable gear disc and a fixed gear disc.Once the machine begins working,the two gear discs impact and rub with each other,under the pressure and friction,the materials are pulverized.

Multipurpose Dry and Wet Pulverizer

This type of pulverizer machine is the most universal,it can work in a high speed,constantly grind,crush or pulverize materials,whether the materials are wet or dry.It can be used to pulverize a variety of materials such as food,spice,sauce,poultry feed and others.

The working principle of multipurpose dry and wet pulverizer is similar to that of portable pulverizer machine,they both take use of friction of different gear discs to pulverize materials,the difference is that the multipurpose one can pulverize more types of materials in a higher speed.

Industrial Pulverizer

The industrial pulverizer,is the most large one among the four types of multifunctional pulverizer,it is used for industrial applications.This machine is suitable for minerals, chemicals, spices, grains, herbs,etc.And its production capacity is excellent,it can pulverize a large amount of materials one time.

The working principle of industrial pulverizer is that,the materials are feed into the machine from the feed hopper,and then flow to the chamber,and after that,the hammer will constantly hit the materials to pulverize them.

3.What are the Differences between Grinder and Pulverizer?

In a certain degree,the grinder and pulverizer have common function,although the two types of machine have some similarities,they also have many differences,in this part,you will figure out the differences between them and have a deeper knowledge.

- In terms of the working principle,the grinder is to grind materials to small pieces by its grinding table,through constant grinding,the machine can reach its final purpose;As for the pulverizer,it is equipped with high speed rotating disc and knife,through the quick rotation of the rotating disc,the materials are constantly cut and hit,then becomes small particles or powder.

- In terms of production capacity,the pulverizer has higher production capacity than the grinder because its speed is faster than that of grinder.

- As for the effect,the grinder can grind materials to fine powder,the fineness of the materials which are processed by grinders is higher than the materials crushed by pulverizers.

- And,the pulverizers are more versatile than grinders,pulverizers can crush more types of materials than grinders.

4.What is the Working Principle of the Multifunctional Pulverizer?

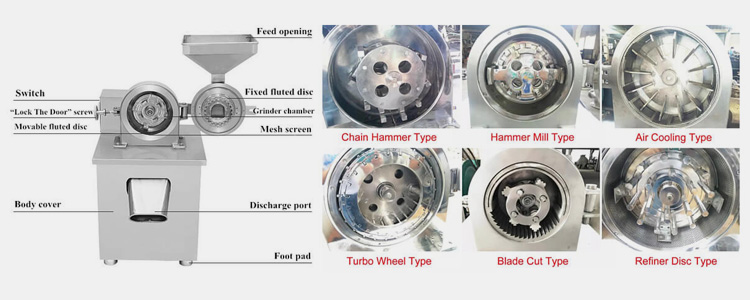

The working principle of a multifunctional pulverizer is quite easy and simple. It has a high-speed rotatable disc. Once the materials that are going to be pulverized from the multifunctional pulverizer are impacted it becomes rubbed by the discs and becomes grinds into small pieces. Then the ground materials that form, are exerted from the grinding chamber directly through the outlet of the multifunctional pulverizer components. In most cases, for the collection of ground materials, a cloth bag is used. Moreover, the fineness of the pulverized materials can be controlled by changing the screen.

5.What are the Components of a Multifunctional Pulverizer?

A multifunctional pulverizer consists of motor, feeding bin, body cover, principal axis, high speed rotating disc, knife,grinder chamber, foot pad,discharge port,mesh screen and fan

Feed Bin

The feed bin is an entrance of materials which need to be crushed by the machine,the function of this part is to feed materials.

Motor

The purpose of motor is to provide motivation to the machine,let the machine work normally.

Grinder Chamber

This is the space where materials are crushed into granule or powder.

High Speed Rotating Disc

The high speed rotating disc is one of the most vital components of multifunctional pulverizer,the function of this part is to crush materials,when the disc begin working,it is rotating in a quite high speed,which is enough to crush the materials.

Knife

The purpose of knife is the same as that of high speed rotating disc,it is to sharp enough to crush the materials.

Discharge Port

There is a feed bin,so there is a discharge port,the feed bin plays a role in feeding materials,so the discharge port plays a role in discharging processed materials,it is an outlet of granule of powder.

Mesh Screen

Mesh screen is to eliminate the substandard granule or powder,to ensure the materials which are discharged reach the requirement.

Fan

The fan is also can not be ignored,it is used to discharge the dust or waste powder which is produced in the working process of this machine.

6.What are the Advantages of Multifunctional Pulverizer?

As a practical and convenient device which is widely used in all kinds of industries,the multifunctional pulverizer has a lot of advantages,which will be explained to the below:

Simple and Stable Structure

The components of multifunctional pulverizer has been introduced in the last part,and you can see that the components of this machine are less than many other machines,in other words,it has a simple structure.

Even than the structure is quite simple,the machine is made of high quality stainless steel materials,and it is designed reasonable,therefore,the structure of multifunctional pulverizer is also very stable.

Easy to Use

Because of its simple structure and easy to understand working principle,the machine is user friendly,it is easy to use by anyone even if without professional training.You just need to put original materials which need to be crushed into the machine,and then turn on the machine.

Perfect Grinding Effect

The machine is equipped with high speed rotating disc and sharp knife,when it begins working,the rotating disc can grind the materials into fine granules or powder,it’s all according to your requirement.In a word,the machine has perfect grinding effect,which can largely help you.

Save Space

Generally speaking,the multifunctional pulverizers are design compact,the size of them will not be to large,as a result,you can simply put a multifunctional pulverizer in your workshop,even though you don’t have a workshop,you can put the machine in your home,it will not occupy too much space.

Universal

The multifunctional pulverizer is universal,it can be used to crush wood chip,food,waste materials,wheat straw,cotton stalk,peanut shell and many other materials,or you can say,once you have demand to crush something,the machine can perfectly help you.

7.What are the Industrial applications of Multifunctional pulverizers?

The multifunctional pulverizer are widely used in different industries because of its simple operation and outstanding performance,these applications are as follows:

Food Processing Industry

In food processing industry,there are quantities of demands of crushing,for example,meat,meat always need to be crushed into minced meat,which is convenient to be processed to other products.And besides meat,there are also many other food materials need to be crushed then be produced,therefore,multifunctional pulverizer is in need of food processing industry.

Pharmaceutical Industry

In pharmaceutical,there is also a demand for multifunctional pulverizer,no matter capsules or tablets,the production process of them can not lack drug powder,but the drugs,in particular,the herbs,they are not born in powder state.How can you make these drugs into powder?Of course that you need the help of multifunctional pulverizer,so this machine is applied in pharmaceutical industry.

Chemical Industry

As a matter of fact,chemical industry,from small laboratory to large chemical factories,they also have a need to crush materials,to crush their materials in a high speed,the best choice is the multifunctional pulverizer because this machine is versatile,it can be used to crush various materials.

Agriculture Industry

As is mentioned,the multifunctional pulverizer can be used to crush wheat stalk and other crop stalks,in the agriculture industry,there are many crop stalks need to be dealt,but the farmers can not simply burn these stalks since it will cause environmental pollution,so the best method to deal with these stalks is to use multifunctional pulverizer to crush them.

Building Industry

In building industry,there will be much waste materials every day,to deliver these materials,will consume too much manpower and material resources,so the industry choose to use multifunctional pulverizer to crush these waste materials,which is more convenient for the workers.

Metallurgy Industry

As is less known that,the multifunctional pulverizer also plays a role in metallurgy industry,it can crush metal and make them easier to be processed in the next technology process.

8.How to Operate a Multifunctional Pulverizer?

Multifunctional pulverizers are widely applied in a large range of industries,one of the reason why it is common in so many industries is that this machine is easy to operate,next you will learn how to operate this machine.

- Before turning on the power supply,check the components of the machine,make sure that they are complete and clean,if there are dust on the machine,you need to clean it on time.

- If the components are normal,now you can turn on the power supply,and wait for two to three minutes for the machine to run,check whether the machine can work normally,and check whether there are noise during the working process.

- When you ensure that the machine can works normally,now you need to feed materials into the machine through its feed bin.

- When the machine is working,the operator should stay there to observe the working process of the machine,to prevent from accidents.

- When the crushing process is finished,don’t turn off the machine right away,let it continue running for two to three minutes,to ensure the materials are totally discharged.

- When you finish using this machine,don’t forget to clean the machine,don’t directly use water to wash it,just use a wet cloth to swipe the feed bin,high speed rotating disc,discharge port and other important components.

- Pay attention to the maintenance of the machine,besides daily cleaning,remember to lubricate the machine regularly.And some components of the machine will be worn after long-time usage,you need to replace them regularly,too.

9.What are the Cautions during the Working Process of Multifunctional Pulverizer?

To be honest,during the operation and working process of multifunctional pulverizer,there are some cautions you need to remember,to prevent from accidents.

- During the working process of the machine,if there are noise,vibration,high temperature or other problems,you need to stop the machine and check the problems at once.

- During the feeding step,you need to feed materials evenly,to avoid blockage,if there occurs a blockage,the operator must not put his hands into the feed bin,or he will be hurt.

- Similar to the last point,remember to stand on the side of the machine,because if the materials are ejected,may cause hurt to the operator.

- When you feed materials into the feed bin,please check whether there are blade or other dangerous good which are mixed into the materials,if there are,you need to take them away.

- During the whole working process of the machine,the operator need to wear mask and work cap,tighten the sleeves to avoid injury.

10.Problems and Technical Issues of Multifunctional Pulverizer?

The multifunctional pulverizer machine can cause some problems, which may be:

Blockage of inlet due to excessive load:

During the working principle of a multifunctional pulverizer machine, multiple raw materials are added simultaneously during feeding. It can cause to block the function of the multifunctional pulverizer due to its overloaded. This problem can be solved by taking care of the loading of raw materials before the pulverization process.

If the loaded material is too much large, then ultimately you need to stop feeding within a while otherwise the motor can be burned out. During taking care, one must check whether this machine is low-power or high-power, in the case of a lower-power machine the materials must feed slowly if it is a high-power machine then one must use the feeder for feeding raw materials.

After pulverization, the outlet may be blocked

Due to the long-term usage of the multifunctional pulverizer, the blade can be worn during operation. It may cause to block the outlet channel. If this happened, so the main solution is to replace or repair the blade of the equipment in time.

Clogging of the pulverizer

During its operation, the air dust and air network must match the pulverizer for proper functioning. If in some cases, it blocks then the clogging of the grinder may take place. To avoid such a problem, the regular cleaning of the multifunctional pulverizer is essential.

Type of materials

The clogging of the machine can be possible, depending on the type of materials uses. Some materials require more water content whereas some do not require water. However, some materials are large and some so small, and as a result, clogging can take place. To avoid these issues, it is essential before buying a multifunctional pulverizer, must check its size, and whether it is compatible with your desired materials or not. So, the major solution to this problem is to replace the equipment.

Other reasons

During the processing of multifunctional pulverizers, there are many other reasons than those discussed above. These reasons may include blockage of screen holes, hammer wear, and blockage caused by high moisture content. To solve such a problem, it is essential for staff to properly monitor the function of the machine and to clean it regularly.

11.How to Choose a Right Multifunctional Pulverizer?

To choose a machine,you always need to consider many factors,think about what you really need so you can choose the most suitable machine for yourself,there are some factors you must consider before buying a multifunctional pulverizer,such as:

Size

Size is the most basic thing you need to consider,the size here doesn’t only refer to the size of machine,actually,you need to make it clear that what materials will you crush by a multifunctional pulverizer,the size of the materials.

After figuring out the size of materials,you need to think about the size of feed hopper of the machine,why?The size of the feed hopper should be matched with the size of materials,or larger than the size of materials.If it not,it is quite difficult for you to put your materials into the machine,not to mention the next process of crushing.

Material

In the last paragraph,it has mentioned that you need to consider the size of materials,and besides this,you also need to consider the property and the final required fineness of your materials.Make these things clear,will help you choose a proper multifunctional pulverizer.

Quality of Machine

And another important point you need to consider is the quality of the machine,before choosing a multifunctional pulverizer,you need to figure out its parameters,so you can know the whether the machine has a good performance.And try your best to choose machine which is made of famous manufacturers or has good feedback.

And,you also need to ask carefully that whether the machine confirms to all quality standards, if it does not,the machine need to be eliminated from your consideration scope.

Production Capacity of the Machine

When you choose multifunctional pulverizer,you need to ask the seller about the production speed and production capacity of the machine,to make it clear that the machine is more suitable for large scale production or small scale production.After that,you can choose a machine which is more suitable for your required production scale.

Budget

The last but not the least,your budget,how much money will you invest for a multifunctional pulverizer?In general,the price of the machine is proportional to the quality of it.So,it is suggest that you can choose a machine whose price is the most expensive within your budget.

12.What is the Development Prospect of Multifunctional Pulverizer?

The multifunctional pulverizer is a very useful device so it is applied in diverse of industries,and it is because the wide usage of the machine,it is attached great importance both in domestic and in international.Many famous manufacturers from various countries have innovated and developed the technology to improve the quality of multifunctional pulverizers.

As time goes on,the technology of multifunctional pulverizers will be more mature,which will help the machine be used for more industrial applications.What’s more? in the future,the multifunctional pulverizers can be used for industries which need higher accuracy.For example,the mineral industry,if the machine can be largely used in this industry,will reduce the exploitation difficulty and cost in human labor.

CONCLUSION

A multifunctional pulverizer is a machine, used to pulverize large-size materials into smaller ones. The proper functioning of the machine depends on the size of the materials and its other parts. Since it has various applications, so you need to buy those machines that best fit your desired purpose. You may find “Allpack” as the best manufacturer to provide an authentic multifunctional pulverizer based on your requirement.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide