Jam Filling Machines In Allpack

Jam filling machines are widely used to fill jars and other containers with viscous fluids, such as jelly or preserves. It is an automated device that dispenses the product into each container quickly and accurately. Jam filling can be done either by weight, volume, or both.

Allpack jam filling machines are designed to be fast and efficient, increasing production speeds for your businesses. They can handle a wide range of viscosities, from thick to thin jams and preserves, as well as different flavors and colors.

The jam filling machines from Allpack can be widely applied for your jams, jellies, sauces, syrups, creams, lotions, chemicals, pesticides, etc. It can increase your productivity by several times compared to manual or semi-automatic processes.

Pneumatic Filling Machine

Allpack pneumatic filling machines use compressed air as power and are composed of precision pneumatic components to form an automatic filling system. This pneumatic filling machine is simple in structure, sensitive and reliable in action, easy to adjust, and suitable for filling various liquids, viscous fluids, and pastes. With the stainless steel construction design, this paste-filling machine is easy to clean and maintain.

- Model: Liquid paste filling machine

- Rugged rotary valve system design

- Sanitary stainless steel quick disconnect fittings

Piston Filler

Allpack piston filler mainly adopts pneumatic components to complete the jam filling. With an anti-drop, anti-down drawing, and filling valve, the piston filler works in cylinder drive with a piston and rolling valve to draw out and output the fluid sauce. The magnetic switch will control the journey of the piston. With adjustable filling heads, you can make the arrangements from your own needs and designs.

- Model: PPF-50

- Adjustable filling quantity and speed

- Easy to operate, simple to maintain, and clean

Capping Machine

Allpack automatic high-speed capping machine has wide applications. It is equipped with three pairs of friction wheels, which can automatically adjust the tightness of the bottle cap. This high-speed capping machine only needs to adjust some parts to complete the operation of changing bottles and caps. In order to ensure the quality of capping, you can strengthen the capping torque control. By configuring the self-diagnosis system, any errors in leaked bottles or leaked caps will be ruled out.

- Model: APC-D903

- Self-diagnosis system

- Capping torque control

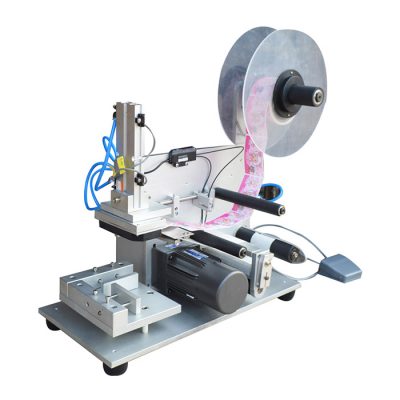

Semi-Automatic Labeling Machine

Allpack semi-automatic labeling machine is suitable for self-adhesive labels, self-adhesive films or electronic barcodes, etc. This semi-automatic labeling machine applies the suction method to stick the label on various square workpieces, such as cosmetic flat bottles, packaging boxes, plastic covers, etc. The labeling device can be replaced on uneven surfaces such as concave and curved surfaces.

- Model: MT-60

- Convenient maintenance

- Used on any regular or irregular surface

Automatic Labeling Machine

Allpack labeling machines are applicable to side face labeling for square, flat, tapered, cylindrical, and other bottle shapes, etc. This automatic labeling machine can offer you a highly stable labeling operation and an extremely low failure rate. The tensioning design gives you high coding quality, accurate control, and suitable labeling length and uniformity. With the SIEMENS high-power servo control system, this high quality labeling machine can work with high and stable speed.

- Model: APC-T3

- PLC control system

- High-power servo control system

Jam Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586