Shrink Wrap Thickness Guide

Shrink Wrap Thickness Guide

Do you know shrink wrap is fabricated with different thickness levels? And each thickness level is for certain products?

Plastic comes in all forms and sizes to contain items. With innovation in plastic a new product wrap- shrink wrap was introduced in the market a few decades ago. For protecting, containing, and, storing a vast variety of consumer goods, it is widely utilized in industries.

If you are associated with a particular industry, if you are a novice in the packaging business or if you are looking to enhance the sturdiness of your shrink wrap then you have clicked on the right webpage. In this blog, we will discuss in detail the thickness of shrink wrap, its different units, industrial requirements for the thickness of shrink wrap and more.

1.What is Shrink Wrap?

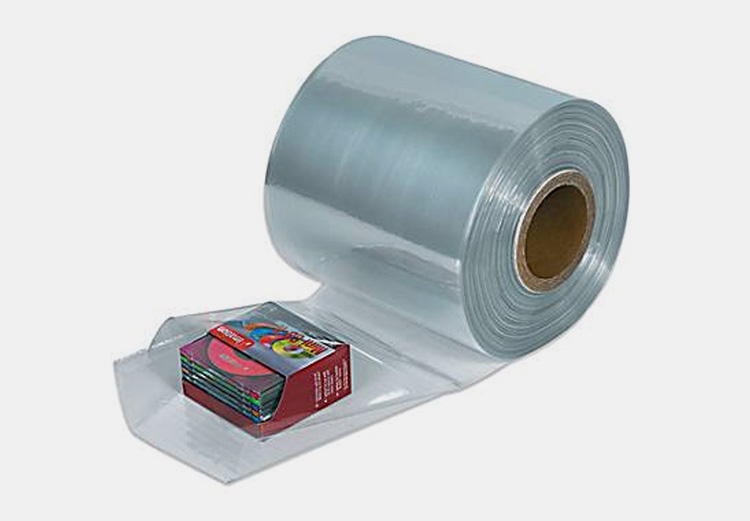

Shrink Wrap- Picture Courtesy: Saffire Blue

It is a type of polymer film formed from plastic materials. The name shrink wrap is derived from its shrinkage action which takes place when this film is subjected to high heat which then contracts and adapts to geometries and dimensions of products on heating and surrounds product from every side.

This leads to airtight and locked packaging with shrink wrap that fully envelops the consumer goods. Shrink wrap is sturdy and long-lasting protecting against harsh weather but it is integral in minimizing product tampering.

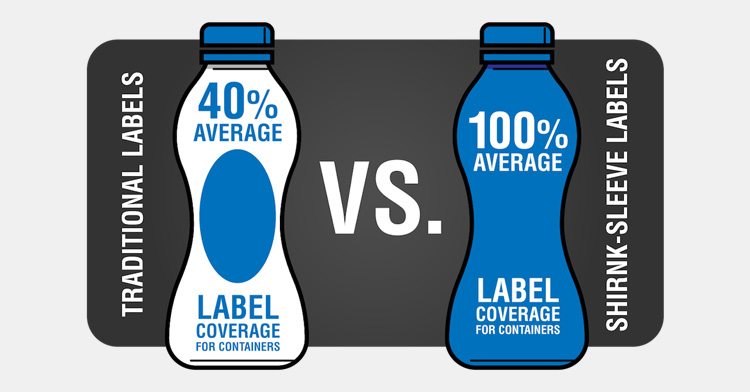

In addition to its protection for products on long hauls, shrink wraps are hugely popular due to, their product printing. Shrink wrap is customized to label products in three dimensions with striking graphics.

2.What is the Shrink Wrap Thickness Guide?

Shrink Wrap Thickness Guide- Picture Courtesy: Neopack Limited

End-users always get indecisive and overwhelmed by the variety of shrink wrap thicknesses that exist in the market. The shrink wrap thickness guide is a knowledge guide that is compiled through different resources to help users get the right shrink wrap thickness for their applications such as packaging, marine packing, and industrial palletizing.

Moreover, it informs users about factors that affect the selection of shrink wrap thickness and it also determines the durability of shrink wrap under different environmental settings.

By reading the shrink wrap thickness guide, buyers learn about the common units adopted by the industries for measuring the thickness of shrink wrap and different unit conversion formulas.

Although there is no specific account as to when the shrink wrap thickness guide started, it is a general belief that the history of shrink wrap begins with the invention of PVC and PE shrink wraps in the 1930s and 1950s, respectively.

Moreover, it became a standard norm to use the shrink wrap thickness guide by the 1970s and 1980s and to compare different thickness units of shrink wraps by using this guide.

3.What are the Different Units of Shrink Wrap Thickness? What is the Unit Conversion Chart for Shrink Wrap Thickness?

Due to the immense popularity and uses of shrink wrap in all regions of the world, different countries have adopted different units for shrink wrap thickness. Here are some details of important units and their definition for your understanding.

Gauge

Gauge Shrink Wrap Thickness- Picture Courtesy: ULINE

It is the measure of shrink wrap thickness. It ranges from 55 to 200. However, this unit is not a standard instead it is a common term employed by industries for measuring the thickness of the film.

It is typically referred to when describing premium shrink wrap. 1 gauge is about 0.3 inch or in the metric system it is equal to 7.6 mm.

Mil

This unit is a standard used all across the globe for defining the thickness of shrink wrap. It is about one thousand of inch that is .001 inch. Mil is more often employed for describing common polyethylene shrink wrap.

1 Gauge = 1/100 of a Mil

100 Gauge = 1 Mil

Micron

This unit is also commonly used for estimating shrink wrap thickness. It is used when referring to thin shrink wraps. 1µm is about 1/100000 m which is equal to 0.00039 inch.

1 Gauge = 0.254 Microns

100 Gauge = 25.4 Microns

1 Mil = 25.4 Microns

Millimeter

It is the unit of the metric system and is seldom adopted for shrink wrap thickness. 1 mm is about 0.039 inch.

Inch

This unit is used for estimating length or dimension across the United Kingdom and the United States. It is the oldest unit in length.

Unit Conversion Chart for Shrink Wrap Thickness

Different vendors use different measurements for shrink wrap thickness which often creates confusion among customers. Hence, here is a unit conversion chart for shrink wrap thickness to guide you in the decision process.

| Gauge | Mil | Micron | Millimeter | Inch |

| 35 | 0.35 | 8.9 | 0.0089 | 0.00035 |

| 40 | 0.40 | 10.2 | 0.0102 | 0.0004 |

| 50 | 0.50 | 12.7 | 0.0127 | 0.0005 |

| 60 | 0.60 | 15.2 | 0.0152 | 0.0006 |

| 75 | 0.75 | 19.1 | 0.0191 | 0.0007 |

| 80 | 0.8 | 20.3 | 0.0203 | 0.0008 |

| 90 | 0.9 | 22.9 | 0.0229 | 0.0009 |

| 100 | 1.00 | 25.4 | 0.0254 | 0.0010 |

| 120 | 1.20 | 30.5 | 0.0305 | 0.0012 |

| 150 | 1.50 | 38.1 | 0.0381 | 0.0015 |

| 180 | 1.80 | 45.7 | 0.0457 | 0.0018 |

| 200 | 2.00 | 50.8 | 0.0508 | 0.0020 |

4.What is a Widely Used Shrink Wrap Thickness Guide in Industries?

Nowadays, due to advancements in material fabrication, a wide range of shrink wrap thicknesses is common in use. Some most popular shrink wrap thickness guide is detailed below:

45 Gauge Thick Shrink Wrap

45 Gauge Thick Shrink Wrap- Picture Courtesy: Indifoodbev

It is one of the most popular shrink wrap thicknesses preferred by consumers. However, some consumers are biased towards even thinner 35 gauge shrink wrap. Generally, it is assumed that thinner gauges are not tough and resistant.

Nevertheless, with innovation in technology resin and high-tech extrusion devices, the thinner gauges of the recent era are stronger than ever.

45 gauge shrink wrap is formed by the cross-linking of polyolefin polymer that gives this shrink wrap high tensile strength. It is typically employed for protecting food items, bakery products, electronics, and many more.

60 Gauge Thick Shrink Wrap

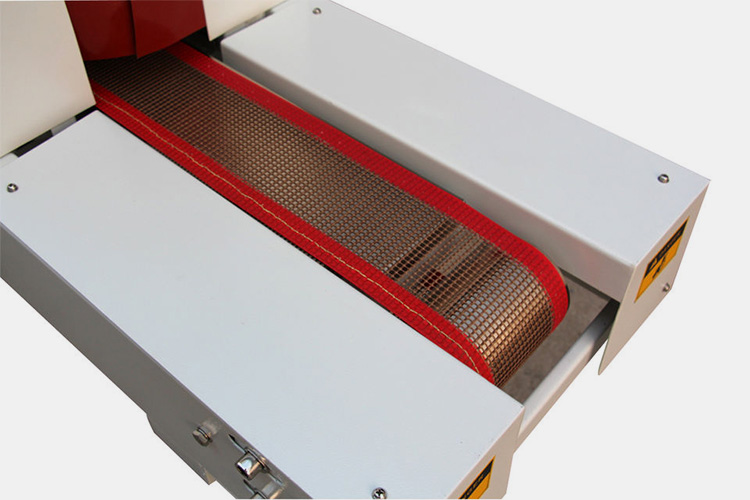

60 Gauge Thick Shrink Wrap- Picture Courtesy: Texwrap

Usually, shrink wrap of this thickness is fabricated using different types of plastic polymers such as PVC, polyolefin with cross-linking, etc.

It is best for lightweight applications and is mostly adopted by bakeries to package biscuits and other items. This thickness shrink wrap has also found its usage in the stationery industry for packaging pens, pencils, etc.

It is mostly for wrapping products with no sharp ends. It is easily moulded into contours of product with less heat application. Furthermore, it is convenient to open and form tamper-evident seals.

75 Gauge Thick Shrink Wrap

75 Gauge Thick Shrink Wrap

It is the most widespread thickness of shrink wrap for retail packaging, is manufactured with PVC and polyolefin, and is considered the standard thickness for both these types of shrink wrap. It is suitable for wrapping products weighing about 15 lbs.

Polyolefin shrink wrap having a 75-gauge thickness is more flexible and puncture-resistant. However, it is not suitable for shipping boxes and parcels.

100 Gauge Thick Shrink Wrap

100 Gauge Thick Shrink Wrap- Picture Courtesy: Fastpack Packaging

This thickness shrink wrap is mostly used in wrapping and packaging heavier items weighing over 25 lbs. It is used for packaging goods when there are issues like burns or tears with the thinner shrink wraps.

It is typically employed for enveloping heavy metallic and wooden items. Furthermore, 100 gauge formed by cross-linking polyolefin can wrap products with a weight of about 50 lbs.

125-150 Gauge Thick Shrink Wrap

120-150 Gauge Thick Shrink Wrap- Picture Courtesy: International Plastics

These thickness shrink wraps are created by a variety of plastic polymers including PVC, polyolefin, polypropylene and polyethylene. This type of shrink wrap is perfect for packing heavier loads for instance shipping containers because of its higher strength.

200 Gauge Thick Shrink Wrap

200 Gauge Thick Shrink Wrap- Picture Courtesy: Product Packaging Supplies

It has a thickness of about 2 Mil (200 gauge). It is a common industrial standard thickness of shrink wraps and is often employed for bundling a dozen bottles weighing up to 12 oz. Mostly polyethylene and polypropylene are used for manufacturing 200-gauge thickness shrink wraps.

4 Mil-12 Mil Thick Shrink Wrap

4 Mil-12 Mil Thick Shrink Wrap- Picture Courtesy: AAA Polymer

Shrink wrap of high thicknesses weighing more than 4 Mil (400 gauge) is typically formed using polyethylene film. 4 Mil thickness shrink wrap is seen in furniture wrapping while shrink wraps having 6 Mil thickness are used for covering boats.

Shrink wraps with high thickness mostly come as a multi-fold roll and are blue or white.

5.What Is The Thickest Shrink Wrap?

Thickest Shrink Wrap- Picture Courtesy: SkiSafe

The thickest shrink wrap is about 12 Mil is equal to 305 Microns (1200 gauge). It is extra-thick, strong, and employed in industries for wrapping heavy transport pallets. This thickness shrink wrap is one of the resilient shrink wraps regularly used without padding.

It is best for enveloping construction structures and is recommended by experts for encapsulating heavyweight objects, for instance, industrial machinery, furniture, etc. It is known for its high-level protection.

6.What Is The Thinnest Shrink Wrap?

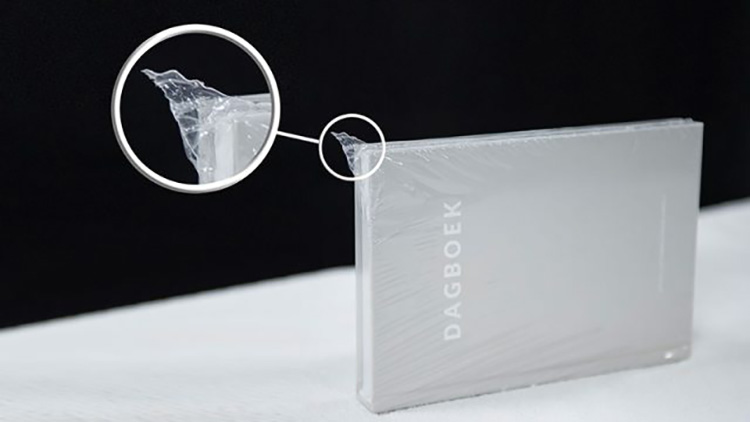

Thin Shrink Wrap- Picture Courtesy: Polythene UK

The thinnest shrink wraps have miscellaneous functions in many industries and are favoured by manufacturers for their higher shrink rate that better adapts to the product shape It has about 35 gauge thickness (8.9 microns). Some of these commercially offered shrink wraps are 12.5 or 13 microns (50 gauge).

This shrink wrap comes with a huge range of benefits and is important for lightweight packaging. It offers high product visibility. It is ideal for packaging delicate products, for instance, pharmaceutical bottles, fresh produce, and lighter electronic goods.

In addition to packaging, it is also utilized as a tamper-evident seal for beverages and pharmaceutical products.

7.How You Know About Different Types of Shrink Wrap and Their Thickness?

Shrink wraps come in various styles and forms; however, there are three main kinds of shrink wraps. Their detailed discussion is penned below for your understanding.

PVC Shrink Wrap

PVC Shrink Wrap- Picture Courtesy: Rising Star Plastic

It stands for polyvinyl chloride shrink wrap. When it was introduced for packaging, it was one of regularly utilized shrink wraps. But now its use is limited to wrapping DVD and CD cases, gaming boxes, and retail packaging. It is not used for packaging food items as it is not safe for food contact and leach chloride upon heating therefore, is not recommended by the FDA.

Its benefits include high tear resistance and cost-effectivity but upon shrinking it becomes brittle and thus is not ideal for bundling numerous items.

PVC shrink wrap has varying thicknesses in the range of 60-150. However, 75-gauge PVC shrink wrap is most prevalent in industries for packaging goods.

POF Shrink Wrap

POF Shrink Wrap- Picture Courtesy: Rising Star Plastic

Polyolefin shrink wrap has surpassed PVC shrink wrap in terms of usage. Due to its versatility and robustness, it is used for wrapping various types of industrial goods including food products. This is because it is considered safe for direct food contact and is FDA-approved shrink wrap.

POF shrink wrap has two qualities- economic and premium. It has high clarity and takes a soft flexible look and feel upon shrinkage.

One of its prime advantages is that it has diverse thicknesses ranging from as low as 35 to as high as 150 gauge. 40, 60, 75, and 100 are its frequently produced thicknesses.

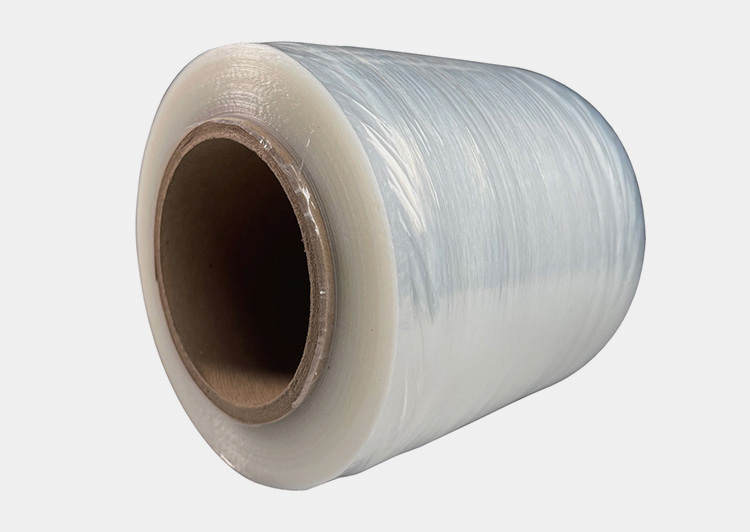

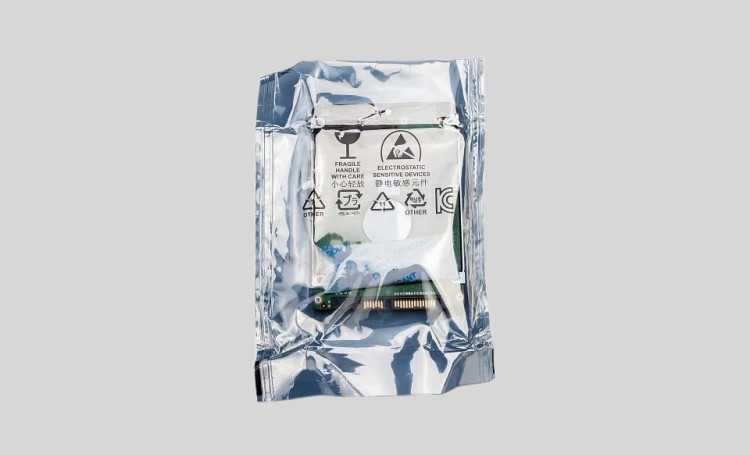

PE Shrink Wrap

PE Shrink Wrap- Picture Courtesy: ISOCELL

It is sturdiest of all shrink wrap and is best known for its heavy-duty industrial wrapping. Low-Density Polyethylene (LDPE) is mostly used for shrink-wrapping in industries. It has added strength and long-lasting protection and, therefore, is routinely employed for wrapping heavy pallets and multi-packs of drinks.

POF and PVC shrink wraps have a maximum gauge thickness of around 150 gauge. PE shrink wraps have a high thickness of up to 1200 gauge which is ideal for marine use. However, it does not have a high shrink rate.

8.What are Centerfold Shrink Wrap and Single Wound Shrink Wrap and Their Thicknesses?

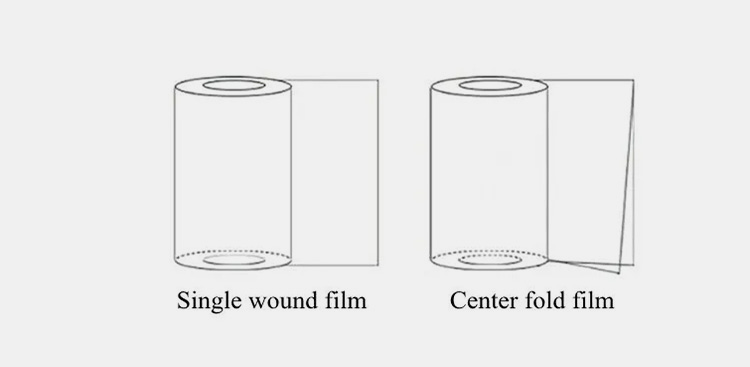

There are two common types of shrink wraps depending upon their arrangement on the roll. These are discussed below:

Centerfold Shrink Wrap and Single Wound Shrink Wrap

Centerfold Shrink Wrap

This type of shrink wrap is typically folded in half and then wrapped around a centre to form a large film roll. For instance, a 10 cm centrefold shrink wrap is unwounded to give a 20 cm shrink wrap. This shrink wrap is available in 35-100 gauge thicknesses while 60 and 75 gauge are commonly used.

Single Wound Shrink Wrap

It is also known as single-layered shrink wrap. It is available as a flat sheet wound around the core. However, this type of shrink wrap is twice as heavy as centrefold shrink wrap. It comes in a 35-150 gauge range. Ultra-thin single-wound shrink wrap ranging between 35-50 gauge is favoured by users.

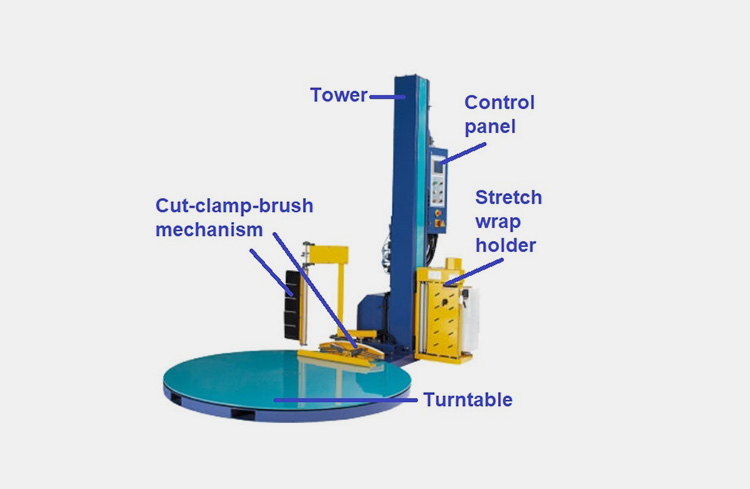

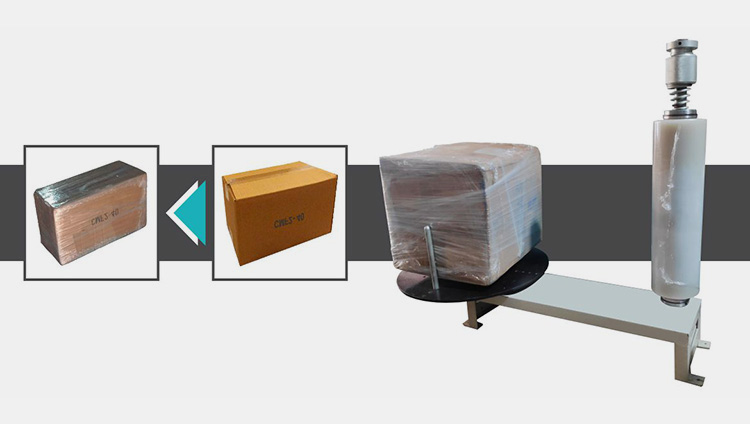

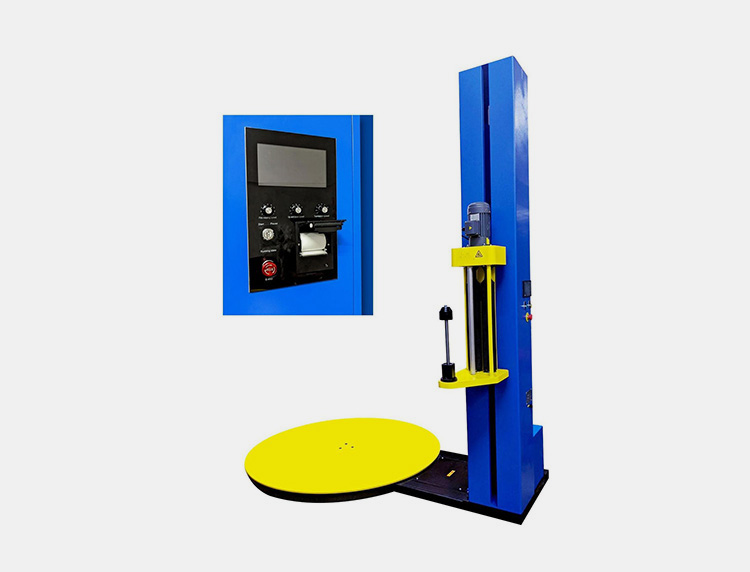

9.Is There a Difference Between Heat Shrink Wrap Thickness and Stretch Wrap Thickness?

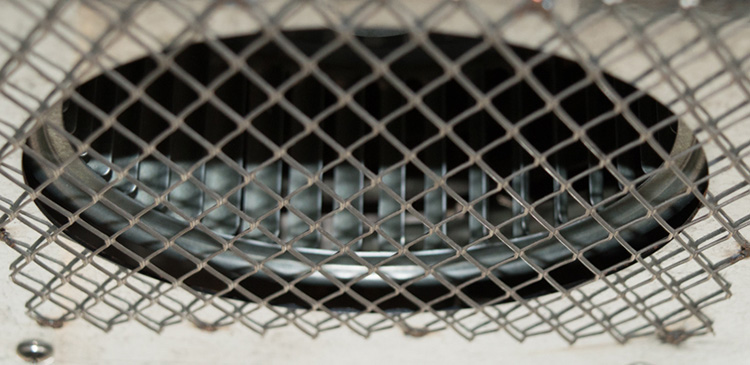

Shrink Wrap Thickness and Stretch Wrap Thickness- Picture Courtesy: U.S. Packaging & Wrapping

Heat shrink wrap and stretch wrap differ in their mode of application. Heat shrink wrap shrinks on applying heat and adapts to the curves of the product being wrapped. Stretch wrap is applied by stretching and completely envelops the product.

Consequently, both these wraps also differ in their thickness. Stretch wrap is way thinner than heat shrink wrap. It is because with stretch wrap not much protection is needed.

When packing smaller items, the heat shrink wrap of 1 Mil (100 gauge) thickness is used while stretch wrap of thickness 0.75 Mil (75 gauge) is utilized for the same function.

Similarly, when bundling large cargo pallets, the thickness of heat shrink wrap could be as high as 12 Mil but for palletizing purposes, the stretch wrap with a thickness of up to 5 Mil is utilized.

Furthermore, the highest thickness level of heat shrink wrap is 12 Mil (1200 gauge) and for stretch wrap maximum thickness is 5 Mil (500 gauge).

10.What Is The Relationship Between Gauge And Shrink Wrap Thickness?

Gauge and Shrink Wrap Thickness- Picture Courtesy: Cantwell Cleary

The gauge has paramount usage in industrial settings and is commonly used for mentioning shrink wrap thickness. The value of the gauge is directly proportional to the thickness of the shrink wrap. This means that if the shrink wrap has a lower gauge value it means that it is thinner and vice versa.

For instance, 40 gauge shrink wrap is thinner while 140 gauge is thicker. Moreover, thinner gauge shrink wrap contracts and encloses around the product without needing much heat. However, the shrink wraps with higher gauges necessitate a significantly higher amount of heat for wrapping.

11.How Does The Thickness Of Shrink Wrap Impact Its Price?

Shrink Wrap- Picture Courtesy: Industrial Products

The price of the shrink wrap is directly influenced by its width, type, and, thickness. Generally, the thicker shrink wrap has a higher price cost than the thinner shrink wrap. This is because the manufacturing cost of thicker shrink wrap is higher.

The thick shrink wrap demands more starting material and is fabricated with more quantities of plastics, resins, and additives. Furthermore, the thick shrink wrap needs specialized equipment for extrusion that runs on high power. The equipment running cost also influences the price of shrink wrap.

In addition to these factors, the application of thick shrink wrap is also a deciding aspect when it comes to its purchase price. Thick shrink wraps are heavy-duty thus their buying cost is higher.

Thinner shrink wraps are fabricated using fewer raw materials and are not processed with specialized machines, therefore, these shrink wraps are fairly inexpensive than their thick counterparts.

12.Do the Size and Weight of Products Affect Shrink Wrap Thickness?

Heavier Objects and Shrink Wrap Thickness- Picture Courtesy: The Wickery

Yes, the size and weight of products are pivotal factors that impact the shrink wrap thickness. Heavier and larger objects such as boats, and pallets have large surface areas, consequently, they are enclosed in thicker shrink wrap as there is a higher chance of their damage during rough transportation and treatment. These thicker shrink wraps offer products ultimate protection.

Thicker shrink wraps are more robust and long-lasting. They can endure higher strain and do not rupture or tear due to heavier loads. Thinner shrink wraps are normally for lightweight and smaller items that do not need heavy protection.

Besides size and weight, the contours and designs of products impact the thickness of shrink wrap. Usually, objects with sharp corners and irregular designs are packed in thicker shrink wraps. These sharp corners of products can rip the shrink wrap, so, they are enveloped in thicker shrink wraps because the latter withstand the tearing or puncture.

13.How Do Environmental Conditions Influence The Durability Of Shrink Wrap Thickness?

Yes, environmental conditions significantly impact the durability of shrink wrap thickness. These harsh surroundings can degrade the shrink wrap and affect its protectiveness. The relation between environmental conditions and durability of shrink wrap thickness is listed below:

Temperature

Temperature and Shrink Wrap- Picture Courtesy: Market Prospects

Both high and low temperatures affect the effectiveness of shrink wrap thickness. Elevated temperature for a long time could lead to the compression of shrink wrap as a result they lose their protective properties.

On the other hand, storage of thick shrink wraps at extremely low temperatures, results in their brittleness making them more prone to ripping and snapping

Humidity

Humidity and Shrink Wrap- Picture Courtesy: tufwrap

High humidity rates could be the reason for the compression of shrink wrap thickness and cause loss of their stretchability. Consequently, it is problematic to cover products with them. Furthermore, high moisture promotes the growth of moulds that deteriorate the bonding between polymers of shrink wrap and lead to degradation of the thickness of shrink wrap.

UV Light

UV Light and Shrink Wrap-Picture Courtesy:360 Eco Packaging

High UV radiations from direct sunlight pose a significant risk to shrink wrap thickness because these high-energy radiations break connectivity between shrink wraps of high thickness. Thus, they fail to protect products against mechanical damage and rough handling.

14.Why Choosing the Right Shrink Wrap Thickness Guide Matters?

Shrink Wrap Thickness- Picture Courtesy: Nobelus University

Nowadays, in the market, there is a huge range of shrink wrap thicknesses. But choosing the right type of shrink wrap thickness guide would bring you fruitful results. Here is a list of reasons why it is crucial to choose the right kind shrink wrap thickness guide:

| Protection | The main purpose of shrink wrap thickness is to protect items from damage and harm. Consequently, with the use of the right shrink wrap thickness guide, the users will get more knowledge about the different barrier capabilities of shrink wrap thicknesses. This will lead to stronger protection against elements. |

| Presentation | Furthermore, by using better shrink wrap thickness, the product appeal and presentation are enhanced. Thicker shrink wrap offers packed items a professional and premium look, whereas, products wrapped in thinner shrink wraps look flimsy. |

| Cost-Cutting | The selection of the wrong shrink wrap thickness guide is detrimental to the expanding business and results in revenue loss. The usage of thicker shrink wraps than required will elevate material and transport expenses. On the other hand, the application of thinner shrink wraps will cause significant product defects. |

| Ease in Application | It is imperative to opt for the correct shrink wrap thickness guide because wrapping products in thicker shrink wraps is time-consuming, troublesome, labour-intensive and requires specialized equipment, consequently increasing operational expenses. |

Conclusion

Shrink wrap has diverse industrial uses and is one of the most sought-after films for packaging. Due to different uses, shrink wraps are innovated in different thicknesses that diverge in their applications. The shrink wrap thickness guide is an information source that guides users at each step to select shrink wraps of appropriate thickness. Two important units for describing shrink wrap thickness are gauge and Mil. The higher the gauge thicker the shrink wrap. It is a common rule that the thickest shrink wraps are for heavyweight wrapping and products larger in size. Thin shrink wrap is for lighter-weight items. Hope you have learnt about prime aspects of shrink wrap thickness by going through this guide. Still indecisive about selecting shrink wrap then contact our Allpack customer care for shrink wrap selection guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Shrink Wrap Thickness Guide Read More »