Your Best Rotary Premade Pouch Packing Machine Supplier

- Automatic Changeover For Different Bag Size

- Pouch Presence Detection – No filling&No Sealing

- Various Filling Systems

Allpack Rotary Premade Pouch Packing Machine

Allpack Rotary premade pouch packing machines are all dis type fully automatic pouch filling equipment,are widely used for packing liquid,sauce,condiment,powder,granule,piece,etc products in food,pharmaceutical industries.All the rotary premade pouch packing machines have convenient switching bag specifications, fast packaging speed as well as excellent packaging effect.With the rotary premade pouch packing machine,you can make various pouches like doypack,zipper and irregular,etc.And it is mostly suitable for customers with large specifications and high-speed production needs.

Rotary Premade Pouch Packing Machine

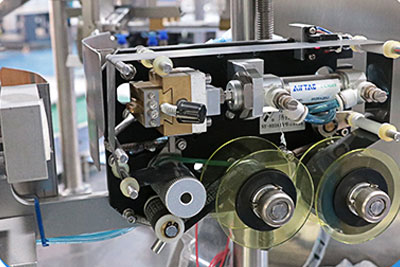

APK-820P High-speed rotary premade pouch packing machine with screw feeding system

APK-820P High-speed rotary premade pouch packing machine with screw feeding system is made of high-quality 304 stainless steel, which meets GMP requirements,the container is automatically positioned and filled with materials,with PLC touch screen control system, all Chinese interface, simple operation,servo system measurement, filling volume and filling speed can be adjusted arbitrarily, with high precision.The packaging quantity can be automatically displayed, and the workload of the machine can be conveniently counted.

No bag feeding, no filling and no sealing

PLC control with touch screen operation

Simple and convenient operation

APK-820D High-speed rotary premade pouch packing machine with double screw feeding system

Allpack APK-820D High-speed rotary premade pouch packing machine with double screw feeding system is easy to operate with PLC controller,HMI system,fault indication on the touch screen.It is easy to adjust,all working process in one station.The speed can be adjusted by frequency conversion within the range.This high-speed rotary premade pouch packing machine also has high automation,unmanned in weighing and packing process, machine will show alarm automatically when failure.8 sets of gripper can be adjusted hand wheel at one time.

High speed pouch filling

Fast changeover for various sized pouches

Precision pouch positioning

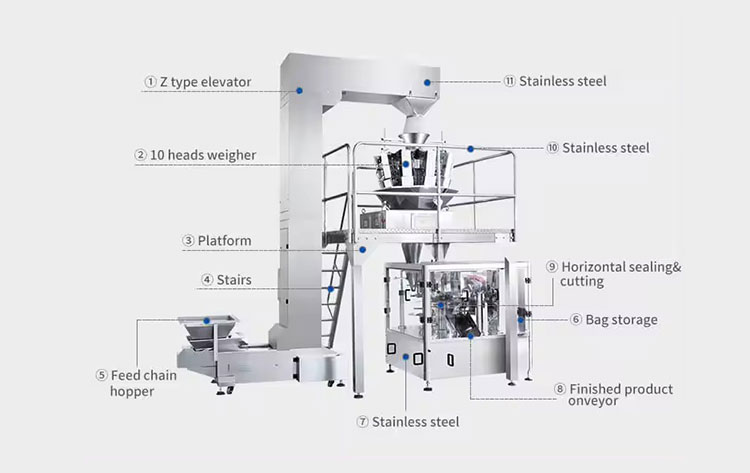

APK-820W High-speed rotary premade pouch packing machine with multi-heads feeding system

APK-820W High-speed rotary premade pouch packing machine with screw feeding system is made by the “Z” shape feeding conveyor,electric weigher,rotary packing machine and plateform. The multi-heads weigher is suitable for high measuring precision and easy crushed bulk material quantitative packing.With the open zipper device,all kind of zipper pouches can be opened automatically.You can adjust the packing speed,temperature,capacity,bag length,all display at the touch screen and you can print the manufacturer expire date up to 4 lines on the date printer.

Diverse filling capabilities

PLC controller HMI system makes easy operation

No filling no sealing

APK-820M Mini Type High-speed rotary premade pouch packing machine

Allpack APK-820M Mini Type High-speed rotary premade pouch packing machine machine is applicable for powder dosing, filling and sealing, and packing with a pre-made pouch.This machine is applicable for automatic packing of various powdered foods, medical powder, powdered daily necessities, chemical raw materials powder and other powder products. Like chili powder, protein powder, wheat grass powder, milk powder, sugar powder, cacao powder, seaweed powder, flour, ground coffee, tea powder, juice powder, detergent powder and so on.

Automatic intelligent operation

Simple operation

Easy to use&stable performance

APK-780M Min type rotary premade pouch packing machine

APK-780M min type rotary premade pouch packing machine can be equipped with electronic scales, liquid metering pumps, servo screws, bowl type and other feeding systems according to the materials. It is suitable for fully automatic pouch feeding packaging of liquids, sauces, powders, particles, blocks and other materials. And it has the characteristics of convenient switching of bag type specifications and good packaging effect. It can achieve filling and sealing of standard self-supporting bags and irregular bags, etc.

Excellent design

Wide range of applications

No pouch or open error, no filling

The Buyer's Guide

Rotary Premade Pouch Packing Machine: The Complete FAQ Guide In 2024

Why the market size of the rotary premade pouch packing machine is increasing day after day?

The market size of this machine is estimated to be about 1.9Bn USD in 2023 and it is anticipated to grow about 2.6Bn USD in 2032.

This rise in market size is because the rotary premade pouch packing machine is essential in rationalization the packaging process, ascertaining the quality of packaging, increasing efficiency, and reducing labour needs.

The rotary premade pouch packing machine has unmatched convenience, and flexible functionality, and is also sustainable. Now let’s explore the amazing and unparalleled world of the rotary premade pouch packing machine in this FAQ guide.

1.What is Meant by a Rotary Premade Pouch Packing Machine?

Rotary Premade Pouch Packing Machine

A rotary premade pouch packing machine is referred to as a machine that packs already-made pouches. This machine does not use packaging film to form pouches but uses premade pouches for packaging both liquid and solid products in different industries.

It only fills and seals the pouches, unlike other packaging machines. It consists of a rotary star wheel carousel that has different stations for opening, inflating, coding, filling, and sealing pouches. It adopts a continuous motion technology that allows it to process pouches at much faster rates. This machine has efficient production and a higher output rate.

2.Why Rotary Premade Pouch Packing Machine is So Popular?

The rotary premade pouch packing machine is the need of different industries because it provides these industrial sectors with the highest profit margins. Some of the useful advantages that play an immense role in the popularity of a rotary premade pouch packing machine are penned below:

No Inaccuracy Error

No Inaccuracy Error by Rotary Premade Pouch Packing Machine- Picture Courtesy: Dieline

Rotary premade pouch packing machine is made of sensitive and precise filling and sealing devices. This means the machine packages pouches with 100% accuracy and there is no filling error in the packaging process. Each pouch produced by this machine has the exact volume of products as written on the product label.

No Break in Packaging

No Break in Packaging by Rotary Premade Pouch Packing Machine- Picture Courtesy: Dieline

A rotary premade pouch packing machine is a one-stop invention that packs pouches without taking any breaks. It runs 24/7 and processes large batches easily. This is because it has a durable design and long-lasting service. This reliable design increases the performance of the machine.

Increased Efficiency

Increased Efficiency by Rotary Premade Pouch Packing Machine- Picture Courtesy: Micoope

This machine is made with fast-acting parts that allow a rotary premade pouch packing machine to achieve higher packing efficiency. Its rapid and immediate pace allows production to fulfil higher production demands in a timely fashion. In this way, businesses easily meet packaging deadlines.

Versatile Packaging

Versatile Packaging by Rotary Premade Pouch Packing Machine- Picture Courtesy: Dieline

Versatility in packaging allows businesses to produce different pouches that are unique and have conspicuous prominence on the display shelves. Rotary premade pouch packing machine has value in this regard as it easily and swiftly fills and seals versatile pouches with a quick change of format.

All-Rounder Machine

All-Rounder Machine-Rotary Premade Pouch Packing Machine- Picture Courtesy: Dieline

A rotary premade pouch packing machine is an all-rounder machine that performs different packaging operations with its harmonious parts. Whether you want filling, coding, nitrogen flushing, or sealing, it is capable of quickly performing all these steps with simple adjustments. This saves manufacturers from the hustle of buying and integrating different machines in production lines.

3.What is the Design of the Rotary Premade Pouch Packing Machine?

This machine has a typical rotary design due to the presence of a star wheel that has different packaging stations for synchronized fast-paced packaging. The different design features of these machines are detailed below for your understanding.

Design of Rotary Premade Pouch Packing Machine

| Z Type Elevator | It is named a Z-type elevator because the two conveyor belts that form this elevator are arranged in a Z configuration. The role of this elevator is to lift the granules, powders, or other small particles from the feed hopper to the weighing heads. |

| Head Weigher | It is also called multi-head weigher. It is a filling device that precisely loads the volumes of the products in the pouches. It has multiple measuring channels for quick loading. |

| Platform | This part acts like a pillar and supports and balances the entire machine. It also presents a stable surface for maintaining and cleaning the machine. It also increases the safety of the machine. |

| Stairs | These are attached to the machine for accessing the top areas of the equipment. Stairs are important for boosting the serviceability of the machine. |

| Feed Chain Hopper | It is a square-shaped reservoir present below the Z-shaped elevators. It stores the products before they are taken up by the elevator. |

| Bag Storage | It is also called a bag-loading magazine. As the name suggests, this part is used for housing the empty bags for the packaging operation. |

| Stainless Steel Frame | The frame of the rotary premade pouch packing machine is made of stainless steel. It is a durable exterior part that protects inner packaging stations. |

| Finished Product Conveyor | The finished pouches are discharged on the finished product conveyor and are carried to the different subsequent packaging equipment. |

| Horizontal Sealing | The airtight lateral seal is made by the horizontal sealing bars. It seals the top edges of the pouches after filling and gas flushing using heat or pressure. |

| Cutting | These are the integrated sharp blades that trim away the sealed edges of the packed pouches. |

4.Are There Any Types of Rotary Premade Pouch Packing Machines?

Yes, there are different types of rotary premade pouch packing machines based on design and filling type. Let’s explore all the different types of rotary premade pouch packing machines.

Based on Design

Double Lane Rotary Premade Pouch Packing Machine

Double Lane Rotary Premade Pouch Packing Machine- Picture Courtesy: Viking Masek

This type of rotary premade pouch packing machine has two lanes for packaging (filling and sealing) pouches. It packs multiple pouches at the same time. Hence, it has double the speed of a single-lane rotary premade pouch packing machine. It has more footprint and higher throughput than a single-lane rotary premade pouch packing machine.

Mini Type Rotary Premade Pouch Packing Machine

Mini Type Rotary Premade Pouch Packing Machine- Picture Courtesy: Shantou Dachuan

As the name indicates, this type of rotary premade pouch packing machine has a smaller size than the standard or typical type of rotary premade pouch packing machine. Its compact design allows this machine to be installed in productions with space constraints. Despite its size, it is capable of producing pouches at the same speeds as that of a typical rotary premade pouch packing machine.

Single Lane Rotary Premade Pouch Packing Machine

Single Lane Rotary Premade Pouch Packing Machine

It is a standard type of rotary premade pouch packing machine having only one lane for filling and sealing different pouches. It has a smaller footprint than a double-lane rotary premade pouch packing machine. Due to having one lane, it has low throughput rates. However, it is a flexible and versatile machine.

Based on the Filling Type

Auger Rotary Premade Pouch Packing Machine

Auger Rotary Premade Pouch Packing Machine

This machine consists of a closed auger structure which reduces the rate of contamination. It has auger plates and auger screws and with the rotation of the latter, it loads accurate quantities of powder particles inside the pouches. It is a frequently utilized machine for powder filling.

Multi-head Weighing Rotary Premade Pouch Packing Machine

Multi-head Weighing Rotary Premade Pouch Packing Machine

This machine consists of multiple channels, weighing buckets, and load cells for simultaneously loading products inside the pouches. Due to the presence of multiple weighing channels, it has precise and fast loading of product. It is used for loading powders and granular products.

Piston Rotary Premade Pouch Packing Machine

Piston Rotary Premade Pouch Packing Machine

The filling mechanism in this machine is piston and cylinder. The movement of the piston is crucial for dosing different viscosity liquids in the pouches. The forward and backward motion of the piston exerts pressure for fluidizing liquids from the hopper to the filling nozzles.

Pump Rotary Premade Pouch Packing Machine

Pump Rotary Premade Pouch Packing Machine

It is yet another type of rotary premade pouch packing machine. It is used for volumetric filling of liquids in the pouches. The filling device in this machine is a pump, with the rotation of which liquids flow into the filling hose and then to filling nozzles. Both free-flowing and non-free-flowing liquids are filled by this machine.

5.How Rotary Premade Pouch Packing Machine Package Premade Pouches?

Rotary premade pouch packing machine packaged premade pouches through different steps that are discussed below:

| Pouch Loading

Pouch Loading- Picture Courtesy: Packaging Machine |

At first, the operators manually load the empty pouches in the blank magazine or bag loader. These pouches are already formed and have zippers or spouts present. One side of these pouches is unsealed for loading of the products. These pouches from the product conveyor are moved to the rotary star wheel. |

| Pouch Opening and Inflation

Pouch Opening and Inflation |

The grippers carry the pouches to the opening station where they force open the empty pouches. Afterward, compressed air is filled inside the pouches for their bulging. |

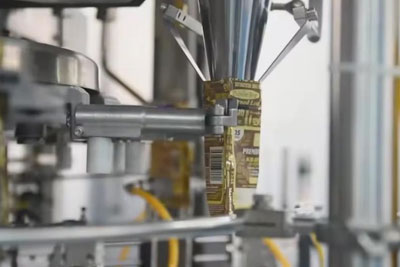

| Filling

Filling |

After inflation, the pouches are moved to the filling station where these pouches are filled by the desired product. Different fillers like augers, pumps, pistons, and multi-head weighers fill the preset quantities of the product. |

| Sealing

Sealing |

To uphold the freshness of the products, the pouches are sealed using different techniques. High pressure and temperature are used for welding the top layers of filled pouches. |

| Discharging

Discharging |

After sealing, the next step is discharging in which the finished pouches are loaded on the product conveyor which transports them to next-in-line packaging machines. |

6.What is the Difference between a Rotary Premade Pouch Packing Machine and a Vertical Form Fill and Seal Machine?

The rotary premade pouch packing machine and the vertical form fill and sealing machine take different approaches to packaging different products. These two machines differ from each other based on construction, footprint, function, and applications. Here are the key differences between both these machines.

| No | Features | Rotary Premade Pouch Packing Machine | Vertical Form Fill and Seal Machine |

| 1 | Application | This machine packs pre-made pouches. These pouches are already formed and available in different sizes. | This machine creates bags from the packaging film. |

| 2 | Design | It consists of a rotary carousel and different stations are integrated into this rotary turn table. | It consists of rollers, film holders, forming stations, vertical sealer, and horizontal sealer. It has a vertical upside-down configuration. |

| 3 | Packaging Process | The pouches are opened, inflated, filed, dated, and sealed in this machine. | The pouches are formed, filled, sealed, and coded in this machine. |

| 4 | Footprint | This machine has a higher footprint. | This machine has a lower footprint. |

| 5 | Versatility | It offers more flexibility and versatility than the VFFS machine because of its quick changeovers. | It has less flexibility in terms of pouch handling because changing between various pouches styles is slower. |

| 6 | Presentation | The premade pouches used in this machine have improved aesthetics. | The film used in the VFFS machine has lower pouch aesthetics. |

| 7 | Cost | The purchase cost of the rotary premade pouch packing machine is higher than the VFFS machine. | Its purchase cost is less as compared to a rotary premade pouch packing machine. |

| 8 | Picture |  |

|

7.What Products are Packed by Rotary Premade Pouch Packing Machine?

Rotary premade pouch packing machine packs fine, coarse, free-flowing, non-free-flowing, pasty, viscous powders, granules, and liquids. It has flexibility when it comes to product packaging. Some of the important products packed by this machine are listed below:

Snacks

Snacks

These food products are widely popular among young adults and grownups. Snacks including chips, popcorn, nuts, and crisps are consumed between the meals. This machine packs different volumes of snacks in the pouches.

Coffee and Tea

Coffee and Tea

These two are widely popular drinks in the world. Now, different types of teas and coffee are filled by the rotary premade pouch packing machine in unique styled pouches.

Beverages

Beverages

Both liquid and powdered beverages like juice mixes, instant juices, energy drinks, fizzy drinks and lemonades are packed by this machine. Beverages are consumed alike in both summers and winters.

Dairy Products

Dairy Products

There is diversity in dairy products processed by the rotary premade pouch packing machine. Dairy including milk powder, fresh milk, cream, cheese, butter, and ice creams are now available in pouches.

Confectionery and Baked Goods

Confectionery and Baked Goods

Yes, different types of confectionery like chocolates, gummies, and baked goods like cookies and biscuits are seen on aisles in pouch packaging.

Pet Food

Pet Food

Due to advancements in flexible packaging, now pet treats and snacks like meat chunks, gravies, biscuits, and kibbles also come in pouch packaging. These items are delicately packed by this machine.

Pharmaceutical and Nutraceutical

Pharmaceutical and Nutraceutical

This machine also packs different types of pharmaceutical and nutraceutical products like pills, capsules, powdered dietary supplements, mineral powders, and herbal extracts. Rotary premade pouch packing machine tightly seals these products to preserve their quality, efficacy, and integrity.

Cosmetic and Personal Care

Cosmetic and Personal Care

This machine is also utilized for packing cosmetic and personal care products like shampoo, creams, moisturizers, lotion, body washes, foundation, face powders, and many more. These products are made with delicate products so this machine gently processes these items.

8.What are the Pouch Styles Processed by Rotary Premade Pouch Packing Machine?

Rotary premade pouch packing machine has processing flexibility in pouch styles. Some of the important pouches packed by this machine are discussed below:

Standup Pouch

Standup Pouch- Picture Courtesy: Behance

It is one of the most prevalent types of pouches. It has a flat bottom that increases its indispensability. Stand-up pouches pack bulk quantities of products and are most economical when it comes to bulk packaging.

Flat Lay Pouches

Flat Lay Pouch- Picture Courtesy: Behance

These pouches are sealed at all 4 sides and they are best for packaging products that do not require standability as these pouches do not have flat bases; hence lay on their backs on display shelves.

Pillow Pouch

Pillow Pouch- Picture Courtesy: Behance

It has a central seal and bulging in the middle; hence the name pillow pouch because of its pillow resembling look. It is used for packing snacks and confectionery items.

Doypack Pouch

Doypack Pouch- Picture Courtesy: Behance

It is similar to the standup pouch but with a gusset bottom. This bottom creates a more stable base on filling. It has high aesthetic appeal and is more popular because of its functionality.

Spout pouch

Spout Pouch- Picture Courtesy: Behance

This pouch has a spout at the side or in the centre. It is used for packing liquids like beverages, pastes, and condiments because they require controlled dispensing.

Vented Pouch

Vented Pouch

These pouches have small venting holes at the bottom of the top seals for releasing gases like carbon dioxide out of the packaging. It is used for packing freshly roasted coffee beans as they exhale carbon dioxide.

Re-closable Pouch

Re-closable Pouch- Picture Courtesy: Behance

Rotary premade pouch packing machine also processes re-closable pouches. These pouches incorporate zipper, sliders, and tin ties for ease in reclosing the pouch after utility.

Flat Bottom Pouch

Flat Bottom Pouch- Picture Courtesy: Behance

These pouches have a box-like look because of their rectangular appearance. They have a flat base and a distinct top seal. They are also called 8-seal bags. Moreover, they have better permanency and visibility on retail shelves.

Side Gusset Pouch

Side Gusset Pouch- Picture Courtesy: Behance

This pouch has folds on its sides that expand upon packaging the product. It packs more quantities of product than the standup pouch. This pouch is flexible when it comes to product packaging.

Pouch With Hole

Pouch With Hole- Picture Courtesy: Vista Print

This pouch has a hanging hole or euro slot for hanging the pouch for the display area or peg boards. A hole is present at the top of the pouch for increased accessibility.

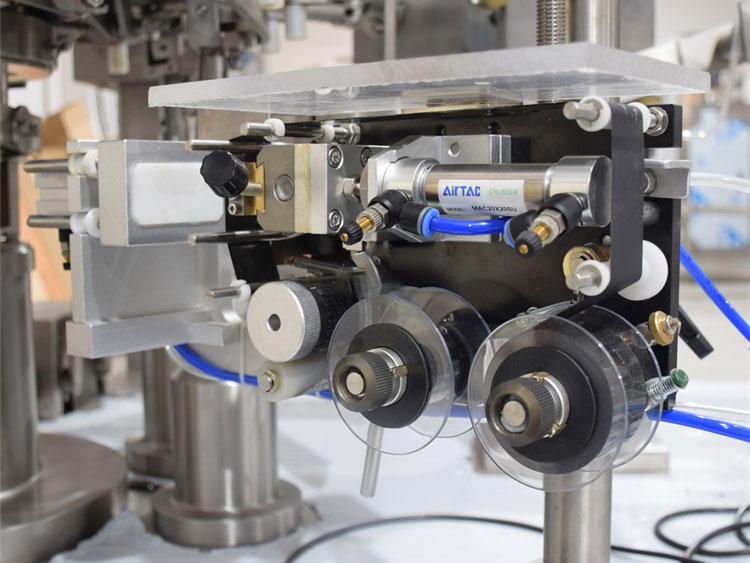

9.Does the Rotary Premade Pouch Packing Machine Offer Date Coding?

Date Coding in Rotary Premade Pouch Packing Machine

Date coding is an important feature present in numerous types of rotary premade pouch packing machines. It is an essential feature in this machine and it prints necessary information like dates, expiry dates, batch identification numbers, bar codes, etc. It directly prints necessary information directly on the pouches.

The date coding by the rotary premade pouch packing machine is performed by different types of printers like inkjet printers, thermal transfer printers, etc. The dates are also marked on the pouches by hot stamping, embossing, and laser marking in this machine.

10.Is Gas Flushing Performed in Rotary Premade Pouch Packing Machine?

Gas Flushing in Rotary Premade Pouch Packing Machine

Yes, gas flushing is performed in some types of rotary premade pouch packing machines. Some of these machines have gas flushing capabilities depending upon the make and model of the rotary premade pouch packing machine.

Gas flushing is a crucial feature that increases the shelf life of different packed products. Gases namely nitrogen and hydrogen are introduced in the packaging before the pack sealing. These gases change the internal air composition by removing oxygen from the pouch.

Due to this, oxygen does not react with the food and other products and spoil them. It also inhibits microbial development and maintains the texture, aroma, nutritional quality, and taste of the products.

11.What are the Sealing Options Available in the Rotary Premade Pouch Packing Machine?

There are different sealing options available in the rotary premade pouch packing machines. These sealing types are detailed below for your information.

Heat Sealing

Heat Sealing- Picture Courtesy: Dieline

It is one of the most frequently employed sealing types in the rotary premade pouch packing machine. It uses high temperatures to melt and join the two layers of the pouch films. It forms a secure sealing by fusing layers with heating them.

Cold Sealing

Cold Sealing- Picture Courtesy: World Brand Design Society

It is used for heat-sensitive pouch materials that lose their integrity upon heating. It uses pressure to weld two adhesive pouch layers together.

Ultrasonic Sealing

Ultrasonic Sealing- Picture Courtesy: Behance

In this sealing technology, high-energy ultrasonic waves are used for heating and melting the pouch layers. These melted layers are then joined together. It is suitable for pouch materials with different melting points.

Impulse Sealing

Impulse Sealing- Picture Courtesy: Behance

Unlike heat sealing, a short impulse of heat is applied to the pouch materials. This heat in controlled amounts is used for joining heat-sensitive materials. These materials are damaged upon encountering high temperatures.

Radio Frequency Sealing

Radio Frequency Sealing- Picture Courtesy: Behance

It follows the same working principle as that of the ultrasonic sealing. However, instead of using ultrasonic waves, it uses radio waves to form a strong adhesive bond between the pouch materials.

12.Does the Rotary Premade Pouch Packing Machine Have any Energy-Saving Features?

Energy Saving Features of Rotary Premade Pouch Packing Machine

The rotary premade pouch packing machine has several energy-saving features. This machine automatically changes its working mode to standby mode which saves energy. Also, the rotary premade pouch packing machine has a servo motor installed instead of an AC motor. The former limits the energy consumption.

It has proper insulation that retains the heat and saves the machine from wasting the energy that is consumed on reheating. It has optimized heat sealing techniques that save energy and ensure proper sealing. Moreover, the machine automatically stops when there is no pouch to be filled. All of these features contribute towards the energy efficiency of the rotary premade pouch packing machine.

13.Does Rotary Premade Pouch Packing Machine Complied with Industrial Standards?

Yes, a rotary premade pouch packing machine is typically constructed to abide by different applicable industrial standards and guidelines. These regulations ascertain that this machine fulfils ad hoc criteria for the safety and quality of the packaging process. Some fundamental industrial standards that this machine may comply with are:

ISO Standard

ISO Standard

This international standard publishes guidelines for designing and producing the rotary premade pouch packing machine. Compliance with this industrial regulation ensures the quality and reliability of the packaging stages.

CE Marking

CE Marking

It is essential for the rotary premade pouch packing machine sold in the European Union. This certification focuses on the health safety of the operator and the environmental protection during the packaging process by this machine.

FDA Regulation

FDA Regulation

This certification of the rotary premade pouch packing machine tells that this machine is safe for use in the pharmaceutical and food industries. It ensures the safety and quality of different end products.

GMP Certification

GMP Certification- Picture Courtesy: Logowik

This certification ensures the accuracy and uniformity in the packaging process. Compliance with this certification indicates the reliability of packed goods and quality control at every stage of manufacturing.

ANSI Standard

ANSI Standard

This certification is necessary for packing machinery like rotary premade pouch packing machines. It ensures the efficiency and operability of the machine.

14.What are the Technical Problems and Solutions of the Rotary Premade Pouch Packing Machine?

Although this machine is advanced technologically, yet, it still experiences different technical problems that increase production time and decrease production efficiency. However, with every problem, there comes a solution and this saying is true for rotary premade pouch packing machines as well.

Here are some technical problems and their solutions for the rotary premade pouch packing machine.

| Image | Cause | Solution |

| Incomplete Pouch Seals | ||

Incomplete Pouch Seal- Picture Courtesy: Yahoo Finance |

Sealing elements are dirty and damaged.

Insufficient seal temperature. Insufficient seal pressure. Incorrect pouch alignment with the sealing jaws. |

Clean the sealing elements and ensure their correct working order.

Increase sealing temperature. Increase sealing pressure. Realign the pouch properly with the sealing jaws. |

| Variation in Fill Quantity | ||

Variation in Fill Quantity |

Filling devices are out of calibration.

Error in the fill settings. Jamming or blocking in product pathway. |

Recalibrate properly the filling devices.

Change the fill settings on HMI Clear the jamming in the product pathway. |

| Incorrect Pouch Alignment | ||

Incorrect Pouch Alignment- Picture Courtesy: Packaging Machine |

There is an error in the pouch loading mechanism

Guides and sensors that position the pouch are not aligned properly. |

Readjust the pouch loading mechanism.

Align the guides and sensors properly for correct pouch alignment. |

| Issues in Pouch Opening | ||

Issues in Pouch Opening |

Issues in pouch opening assembly.

The opening blades are dull and damaged. Incompatibility of pouch material and opening mechanism. |

Check the working condition of the opening assembly.

Sharpen the opening blades and replace them if needed. Ensure there is compatibility between pouch material and loading assembly |

| Blurry Date Coding | ||

Blurry Date Coding |

Dirty printing heads

The ink cartridge is empty. Damaged ink cartridge. Incompatibility of print settings and pouch material. |

Clean the printing heads.

Refill the ink cartridge. Replace the damaged ink cartridge. Ensure that print settings and pouch materials are compatible. |

Conclusion

In summary, a rotary premade pouch packing machine is an advanced equipment having a rotary turn table with which this machine is capable of performing packaging processes at high speeds. It has a robust build that contributes to its durability and long serviceability. It is a turnkey solution that allows you to modify its components to suit various packaging needs. So, you should not wait and immediately buy this handy equipment to attain maximum production benefits. Just click on the main website and purchase Allpack's valuable services.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586