Your Best Cream Filling Machine Manufacturer

- Powered By Compressed Air

- Pneumatic Quantitative Filling

- Pneumatic Control With Measuring Regulation

Cream Filling Machine

Allpack cream filling machine is a semi-automatic filling device that uses compressed air as power and consists of precision pneumatic components. The cream filling machines can be used to fill paste-like materials of various foods, cosmetics, medicines, and chemicals. The cream filling machine can be used to fill products of various viscosities from pastes to cream. It is an ideal filling machine for daily chemical, pharmaceutical, food, pesticide, and other industries. The cream filling machine integrates electromechanical and pneumatic and has the characteristics of reasonable design, compact structure, beautiful appearance, stable and reliable performance, high filling accuracy, strong adaptability, simple operation, and convenient maintenance. Allpack model cream filling machine is equipped with a big hopper 90L that is enough for your need.

90L Paste Stir Mixing Filling Machine For Chili Sauce Pepper Sauce Cream Butter

90L paste stir mixing filling machine adopts pneumatic control and owns a wide application scope, simple measuring regulation, good shape, and convenient cleaning, suitable for the explosion-proof unit. The mixing and filling machine are designed with U type of filling machine structure which is more reasonable, high precision, simple and easy operation. This stir-mixing filling machine is ideal for food, pharmaceutical, chemical sauce mixing, and filling such as beef sauce, beans sauce, pot sauce, etc. This model liquid filling machine is equipped with a big hopper 90L that is enough for your need. With the mixing function, you can fill the pastes and sauces more smoothly and stir evenly.

Pneumatic control

Measuring regulation

High precision, simple and easy operation

50~5000ml Double Heads Nozzle Liquid Cream Paste Quantitative Filling Machine

50~5000ml double heads nozzle liquid cream paste quantitative filling machine is ideal for filling peanut butter, chili butter, bean paste, colloid, cream, shampoo, moisturizer, lotion, cosmetics, oil, honey, etc. This liquid cream paste filling machine is made of high-quality raw material, which meets with requirements of GMP. The hopper and filling head are equipped with release clips for is easy removal without the aid of a wrench. It can be filled automatically and repeatedly and also can be moved to fill. Food contact places are 304 stainless steel materials with corrosion resistance, wear resistance characteristics, and more health and safety.

Quantitative filling

Double heads nozzle

304 stainless steel material

Cream Filling Machine: The Complete Buying Guide In 2025

With the development of the cosmetics industry, more and more business have an increasing demand for cream filling machines. Cream filling machine is suitable for filling various cream and paste products. Let’s get to know this special machine together!

1.What Is the Cream Filling Machine?

Cream filling machine is an automatic filling system that uses compressed air as power and consists of precision pneumatic components. Cream filling machine can be used to fill paste-like materials of various foods, cosmetics, medicines and chemicals.

Cream filling machine can be used to fill products of various viscosities from pastes to cream. It is an ideal filling machine for daily chemical, pharmaceutical, food, pesticide and other industries.

Cream filling machine integrates electromechanical and pneumatic, and has the characteristics of reasonable design, compact structure, beautiful appearance, stable and reliable performance, high filling accuracy, strong adaptability, simple operation and convenient maintenance.

2.What Creams Are Mostly Filled Bythe Cream Filling Machine?

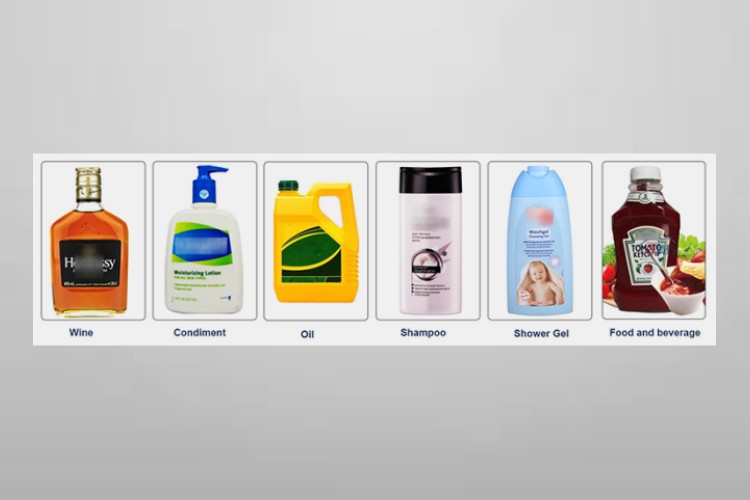

There are plenty types of cream mostly filled by the cream filling machines in your daily life, and they are food creams, cosmetic creams, pharmaceutical creams and chemical creams.

- Food Creams

Food creams also called food pastes. Cream filling machines can be applied for filling food creams in the food industry. The food creams include honey, syrup, food sauces like ketchup, mayonnaise, mustard、food seasoning sauces like vinegar, soy sauce, oyster sauce,food paste like chocolate paste, ginger and garlic paste, chili paste, etc.

- Cosmetic Creams

Cosmetic creams also called as cosmetic lotions. Cream filling machines can be applied for filling cosmetic lotions in the cosmetic industry including hand cream, face cream, body lotion, face foundation, face and body sunscreen, body treatment cream, shampoo, body wash cream, etc.

- Pharmaceutical Creams

Pharmaceutical creams include various medicinal creams. These pastes come in viscous or semi-solid forms. Cream filling machines can be applied for filling various pharmaceutical creams including vitamin e cream, Erythromycin ointment, various ointments for acne, frostbite cream, anti-mosquito bite cream, ointment for burns, ointment for bleeding wounds, etc.

- Chemical Creams

Chemical creams also called as chemical pastes. Cream filling machines can be applied for filling various chemical pastes including toothpastes, pigment pastes, glues, detergent, etc.

With all these creams can be filled by the cream filling machines, there must be a cream filling machine that can meet your requirements.

3.Why You Need A Cream Filling Machine?

With the wide applications of the cream filling machine, you can applied this machine for filling a wide range of cream and pastes materials. There also are various advantages of the cream filling machine which are wide application,

- Wide Application

Cream filling machines are widely used in the filling of creams materials in various industries. It can even work in flammable and explosive environments. This filling equipment can be widely used in pharmaceutical, chemical, food, cosmetic and other industries. And it is the most ideal equipment in the cosmetics industry.

- Automation

The automation of cream filling machines can complete all filling processes, including feeding, weighing, bottling, plastic sealing, etc. All programs can be realized through PLC control panel. This can greatly reduce your manpower and material resources and save you costs.

- High Filling Precision

Cream filling machines are designed with pneumatic filling or piston filling which has great pressure. The filling heads are designed with larger sizes and anti-dripping setting. So the filling can be high precision that you can rest assured.

- Adjustable Filling Speed

Cream filling machines have manual type, semi-automatic types, and fully automatic type. All the filling speed are adjustable. This way you can control your filling rhythm very well.

- Customized Filling Heads

There are various filling head sizes of the cream filling machines for your needs. At the same time, filling heads can also be customized and adjusted. If you have larger sizes or special filling head shapes, all these requirements can be met.

With all the advantages, cream filling machines can help your business a lot and give you a promising future.

4.How Many Types of Cream Filling Machines Are There?

From the point view of machine automation, cream filling machines can be divided into manual cream filling machine, semi-automatic cream filling machine, and fully automatic cream filling machine.

- Manual Cream Filling Machine

Manual cream filling machine also called as hand operated cream filling machine or manual paste filling machine. Manual cream filling machines are in small size and dimension with easy operation and high precision. Manual cream filling machines adopt piston structure with manual filling.

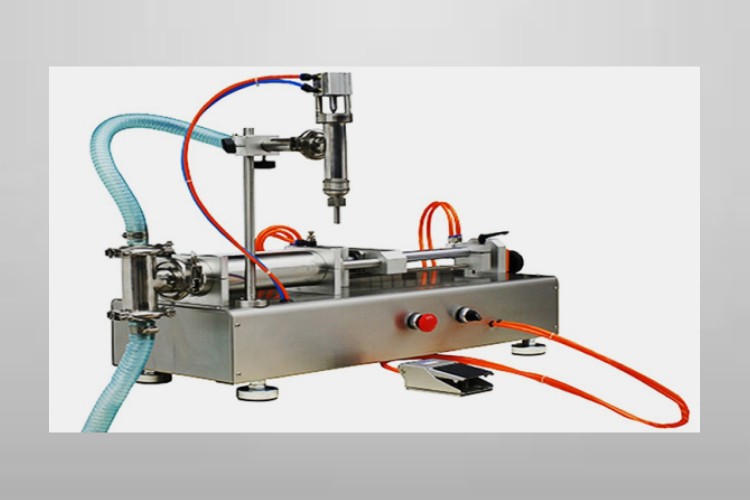

- Semi-automatic Cream Filling Machine

Semi-automatic cream filling machines also called as semi-automatic paste filling machines are mostly applied for filling the water, oil, sauce, honey, etc.

The packaging types can be cans, bottles, stand-up pouch, bags and pouches. This type cream filling machine need to be operated both with hand work and machine work. The efficiency of the semi-automatic type is higher than the manual type.

- Fully Automatic Cream Filling Machine

Fully automatic cream filling machines also called as fully automatic cosmetic fillers are widely applied for filling products in beverage industry, food industry, chemical industry, cosmetic industry, and pharmaceutical industry.

With piston pump, the fully automatic cream filling machine can fill liquid, paste, cream products with quick speed and high efficiency. The fully automatic cream filling machines are suitable for the whole filling lines.

From the point view of machine design, cream filling machines can be divided into single head vertical cream filling machine, double head horizontal cream filling machine.

- Single Head Vertical Cream Filling Machine

Single head vertical cream filling machine is a semi-automatic type cream filling machine and it suits for products with slightly fluidity in creams and lotions. Single head vertical cream filling machines are mostly applied in filling cosmetics, pharmaceutical materials, food creams and sauces, washing lotions, etc.

Single head vertical cream filling machine use piston and gravity skills to fill high viscosity materials.

- Double Head Horizontal Cream Filling Machine

Double head horizontal cream filling machines are filling with double filling heads which can greatly increase your efficiency. With cylinder and three-way valve that can ensure your filling accuracy. With the piston, it can greatly improve your productivity.

From the point view of filling methods, cream filling machines can be divided into pneumatic cream filling machine and tube cream filling machine, rotary cream filling machine.

5.What Are the Main Parts of the Cream Filling Machine?

Different types of cream filling machine have different main parts. You will learn from the machine automation type of the different main parts of the machine.

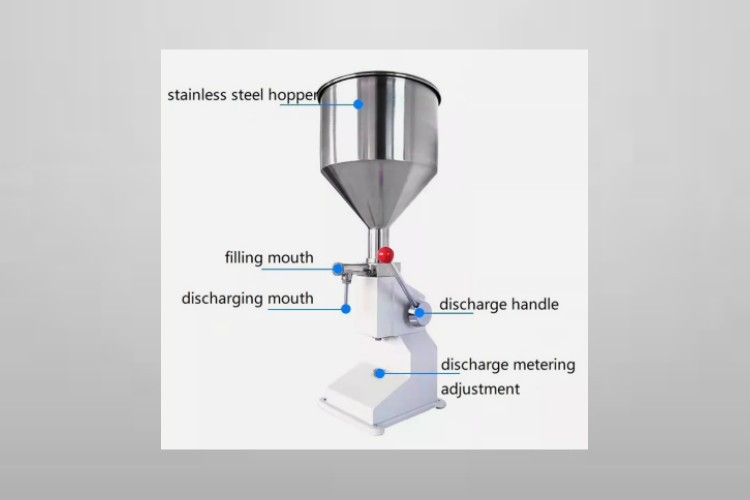

- Main Parts of Manual Cream Filling Machine

The structure of manual cream filling machine is quite simple and the main parts of manual cream filling machine are stainless steel hopper, filling mouth, discharging mouth, discharging handle, discharging metering adjustment.

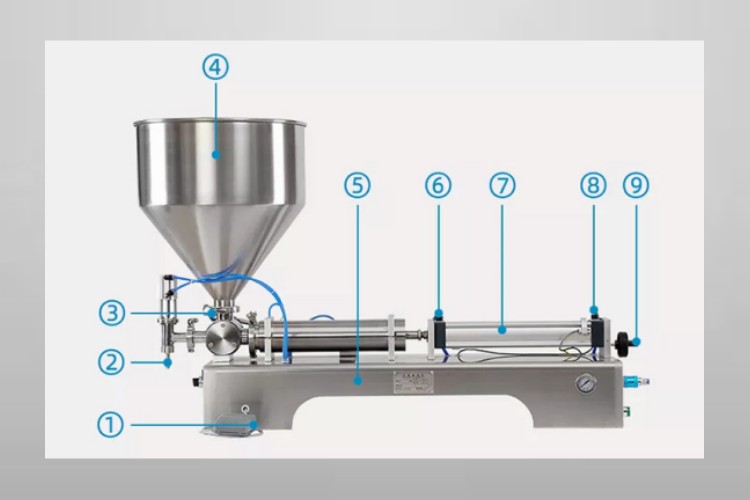

- Main Parts of Semi-automatic Cream Filling Machine

There are 9 main parts of the semi-automatic cream filling machine including food switch, outlet, clamp, hopper, stainless steel body, can speed adjustment knob, cylinder return speed adjustment knob, and quantitative joystick.

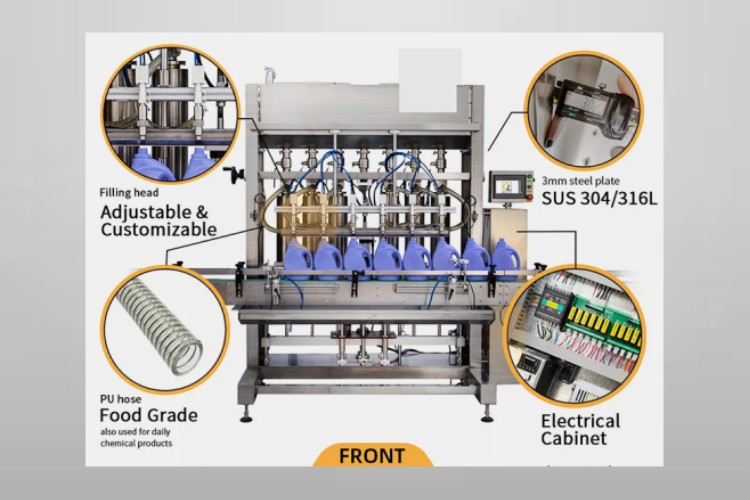

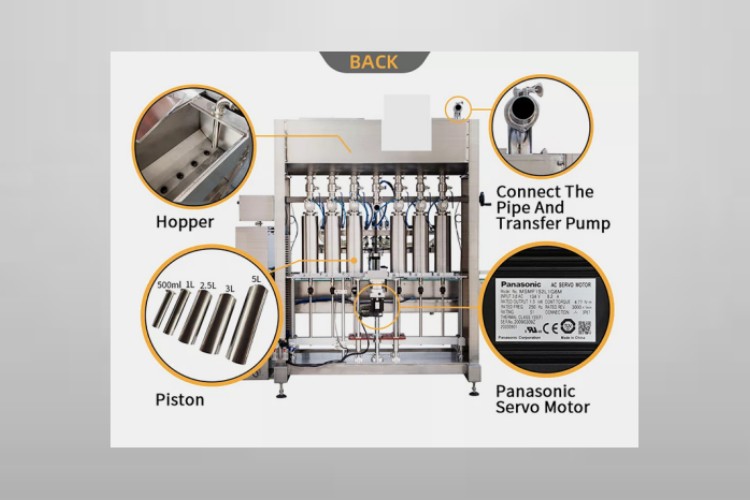

- Main Parts of Fully Automatic Cream Filling Machine

From the front view, the main parts are adjustable and customizable filling heads, PLC control panel, PU hose, and electrical cabinet. All the materials of the fully automatic cream filling machine are SUS 304/316L.

From the back view, the main parts are feeding hopper, piston, and servo motor.

There are some main parts that from every type of cream filling machines and they are filling nozzles,

Filling Nozzles

The filing nozzles are the outlets of the cream filling machines, and they are all designed with anti-drip. It can ensure the filling speed and accuracy.

Filling Valves

Different sizes of filling nozzles need to be equipped with different sizes of filling valves. And the filling valves can be adjusted and customized.

The fully automatic main parts are most complicated but with the best functions.

6.What Are the Features of Cream Filling Machines?

The main filling principle of the cream filling machine is pneumatic piston filling. You will learn the main features from the pneumatic piston cream filling machine.

- Pneumatic Piston Cream Filling Machine

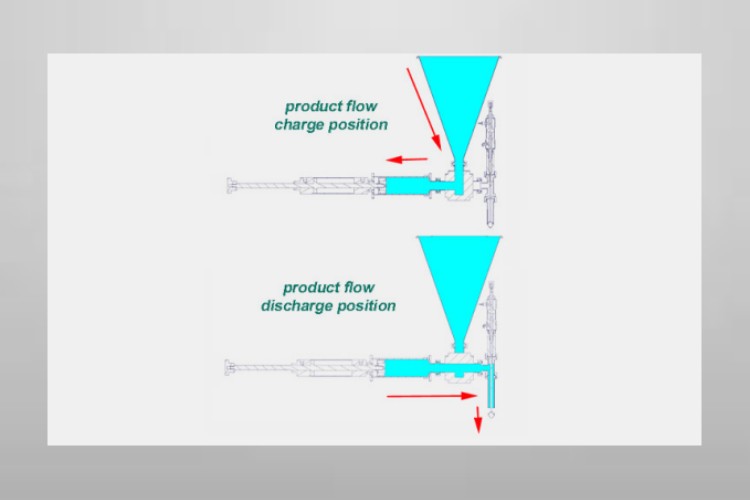

Pneumatic piston cream filling machine refers to the device that uses compressed gas as the power source for filling. The cylinder drives a piston and the three-way principle of the rotary valve to extract and discharge high-concentration materials.

The main feature of this type machine is the pedals, piston, filling volume, filling ranges, working principles.

Pedals

By controlling the pedals with your feet, the air will be compressed and then continuously sent into the valve. This type of machine can produce the pneumatic pressure of 0.4Mpa.

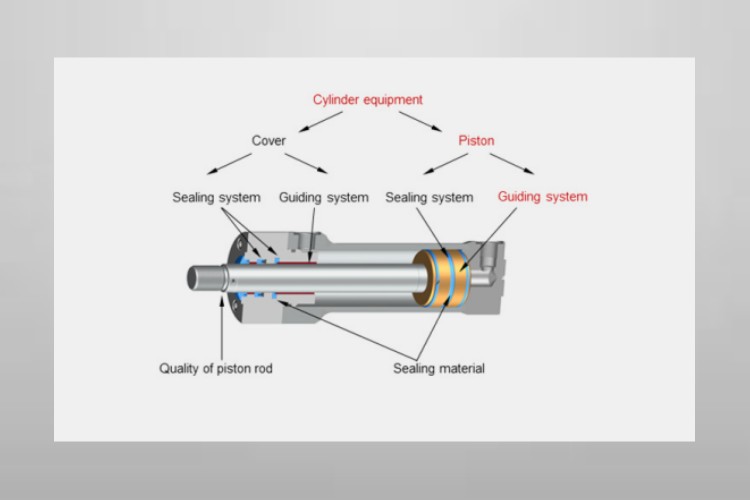

Piston

Pistons are the parts of the cylinder that complete the reciprocating motions which can help the cream filling. The cylinder drives the piston of the metering cylinder to move downwards and upwards that keeps the filling.

Filling Volume

The filling volume of this machine is convenient and quick to adjust, with beautiful appearance, compact structure and high filling speed.

Filling Range

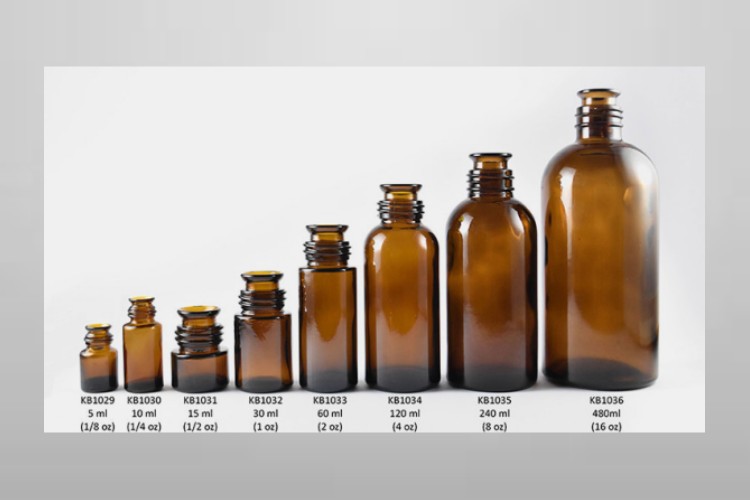

With wide filling range, the cream filling machines can fill with the filling range of 10-150ml, 25-250ml, 100-1000ml, 250-2500ml, 500-5000ml.

Working Principles

When the cylinder drives the piston of the metering cylinder to move downward, the lower valve of the material tank opens. The metering cylinder absorbs the material, and the piston moves to the bottom end, then the metering cylinder is full of material, and the valve closes.

When the piston of the metering cylinder moves upwards, the valve core of the filling nozzle sinks and the filling starts, until the piston of the metering cylinder moves to the uppermost end, the filling stops.

7.What Will Affect the Filling Accuracy and Filling Speed When Running the Cream Filling Machine?

When the machine is in operation, you may encounter such a problem: why the filling speed and accuracy will be affected when each cream is filled. Let’s take a look at the factors that affect the filling accuracy and filling speed.

The Factors That Will Affect the Filling Accuracy:

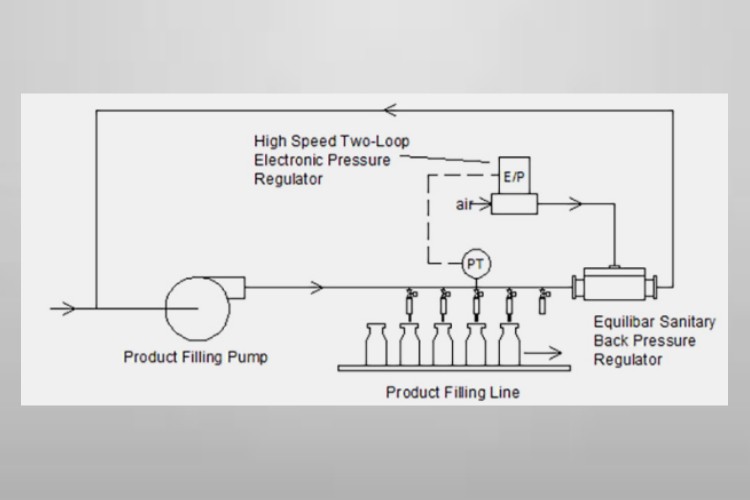

- Compressed Air Stability

Some types of cream filling machines designed with pneumatic, so the air will be compressed to drive the creams and lotions. If the compressed air is not stable, then the filling accuracy will be affected. So you need to apply the stable compressed air for the machine then the filling accuracy will be greatly improved.

- Cream Balance

Material here is the filling materials. Never mix up the liquid with the creams or mix the granules with the creams then it will break the filling balance then the filling accuracy will be affected.

You need to make sure that the materials are evenly creams with little fluidity and keep the material balance of the filling materials, then the filling accuracy will be greatly improved.

- Filling Speed

The filling speed need to be adjusted from the filling materials and the filling machines. If you are filling materials with high fluidity like pastes and liquids, then the filling speed can be a little fast.

However, if you are filling materials with no fluidity or little fluidity, then the filling speed should be a little lower. Then the filling accuracy will not be affected.

The Factors That Will Affect the Filling Speed:

- Cream Viscosity

Material viscosity will greatly affect the filling speed. Different material has different viscosity. The more viscous the material, the poorer its fluidity, and the slower the filling speed will be. Conversely, the more fluid the material, the faster the filling speed will be.

- Hopper Sizes

Hoppers are applied for uploading the filling materials. If the hopper sizes are smaller, the materials filling speed will be slower. Conversely, the larger the hopper sizes, the faster the materials filling speed will be. If you have high requirements for filling speed, then we suggest that you try to choose bigger sizes of hoppers when configuring the machine.

- Filling Head Sizes

Filling heads are applied for filling the materials into the containers. If the filling heads are smaller, the materials filling speed will be slower. Conversely, the larger the filling heads, the faster the materials filling speed will be.

- Labor Work

Machine filling is divided into two modes: automatic and manual modes. The automatic mode is for the machine to fill continuously. Manually use foot-operated filling materials for workers according to their own experience.

In manual mode, material filling accuracy and speed will greatly affected by the labor work. Therefore, in order to ensure the filling accuracy and filling speed, you need to choose the automatic cream filling machine.

If you figure out all the above problems, the filling speed and accuracy of your machine will not be greatly affected.

8.What Are the Filling Speed of Different Types of Cream Filling Machines?

Different types of cream filling machines have different filling speed. There are a lot factors can affect the filling speed, too. So you can learn from the types of manual, semi-automatic, and fully automatic.

- Filling Speed of Manual Cream Filling Machine

The filling speed of the manual cream filling machine is the lowest one in semi-automatic ones and fully automatic ones.

Manual cream filling machine mainly controls the filling speed through the handle. Usually slower. This model is suitable for small businesses or personal use.

Manual cream filling machine can hold the max material weight of 15KG at one time, with the hopper volume of 10L. The filling speed is completely manual.

- Filling Speed of Semi-automatic Cream Filling Machine

The filling speed of the semi-automatic cream filling machine is the medium one in manual ones and fully automatic ones.

Semi-automatic cream filling machine mainly controls the filling speed by pedaling. Usually the speed is faster than the handle control speed, and the operation is more comfortable. This model is suitable for medium-sized businesses or small workshops.

Semi-automatic cream filling machine can hold the max material weight of 40KG at one time, with the hopper volume of 35L, with the filling speed of 10-50 bottles per minute.

- Filling Speed of Fully Automatic Cream Filling Machine

The filling speed of the fully automatic cream filling machine is the most fast one in manual ones and semi-automatic ones.

Fully automatic cream filling machine uses fully automatic machine control to control the filling speed. The speed is faster than the speed of the handle and the foot, and the filling accuracy is the highest. This model is suitable for large businesses or assembly lines.

The filling range can be 100-1000ml and can be customized. Fully automatic cream filling machine can hold the max material weight of 600KG at one time, with the filling speed of 1000-2000 bottles per hour.

You can choose the right cream filling machine according the filling speed and filling productivity of different types.

9.What Are the Differences Between Cream Filling Machine and Liquid Filling Machine?

- Filling Materials

Cream filling machines are mostly applied for filling cream products with high viscosity and less fluidity like pastes, creams, lotions, cosmetics, sauces, etc.

Liquid filling machines are mostly applied for filling liquid products with low viscosity and high fluidity like oils, beverages, liquors, alcohols, etc.

- Filling Methods

Cream filling machines are mostly applied for filling cream products with high viscosity and less fluidity. So it adopts the syringe (pressurized) filling. Because materials with poor fluidity require greater pressure for filling.

Liquid filling machines are mostly applied for filling liquid products with low viscosity and high fluidity. So liquid filling machines adopt atmospheric (isobaric) filling or vacuum (negative pressure) filling.

- Application Range

Cream filling machines are mostly applied in daily chemical, pharmaceutical, food, pesticide and other industries. The products mainly include cosmetics, lotions, creams. Liquid filling machines are mostly applied in food industry. The products mainly include oils, beverages.

- Filling Heads

Cream filling machines adopt bigger sizes of filling heads. Cream filling machines are mostly applied for filling creams and lotions with high viscosity and less fluidity. So the cream filling machines need bigger sizes of filling heads

Liquid filling machines are mostly applied for filling liquid products with low viscosity and high fluidity. So liquid filling machines adopt smaller filling heads.

There is not much difference between Cream filling machine and liquid filling machine in essence. Different materials can also be filled with each other. However, there will be a huge difference in accuracy and speed from the adapted materials. Cream filling machine can also fill liquid materials. But liquid filling machine cannot fill cream material.

With all the differences, you can differ from the cream filling machines and liquid filling machines. But cream filling machine is also a type of liquid filling machine. If you want to know more, you are always welcome to us.

Conclusion

Cream filling machines also can replace liquid filling machines with various functions and applications. Low failure rate, high stability, long service life, cream filling machines are your best choices. If you are interested in more machines related or have the consideration for this type machine, please kindly come to us anytime.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide