Your Premier Induction Sealer Machine

- Air Cooling System

- High Pressure Pumping Force

- Electric Current Overload Protection

Induction Sealer Machine

Allpack induction sealer is widely used for sealing aluminum foil on plastic and glass bottles or jars by induction sealing. This induction sealing way is the most advanced sealing way in dairy food, pharmacy, beverage, cosmetics, snacks, and chemical industries. It is not applicable for metal, threadless cap, gap shape caps. Full modular component design, can be against moisture, erosion, dust and magnetism, minimizes maintenance.With SUS304 stainless steel construction for use in harsh environments and easy to clean and maintenance, it can work with seals of various materials for bottles or jars, this induction sealer has a fast speed for bulk production and stable and reliable performance with long working life, its conveyor speed & sealing speed are variable. The machine is made of stainless steel, it’s durable and hascaps a long service life.

Induction Sealer Machine

APC-M1 Magnetic Induction Sealer

Allpack APC-M1 magnetic induction sealer is fully automatic and easy to operate. The machine adopts electro magnetic induction principle so that it can create instant heat to seal bottles firmly, to realize the purpose of mildew proofing. The machine is suitable for sealing bottles which are made of different materials, such as PP, PET, HDPE, etc. In addition, the machine is made of stainless steel, it’s durable and have long service life.

Electronic Magnetic Induction Principle

SUS304 Stainless Steel Construction

Air Cooling System

APC-M2 Water Cooling Induction Sealer

Allpack APC-M2 water cooling induction sealer is a semi automatic machine, it is suitable for sealing plastic bottle whose diameter is in the range of 10mm to 120mm, it has high speed and high precision, can seal up to 50 bottles per minute. This machine has a wide range of applications such as food, beverage, commodity, medical and chemical industries.

Water Cooling System

Electric Driven Device

Easy To Setup

LGYF-1500AI Continuous Induction Sealer

Allpack LGYF-1500AI continuous induction sealer is designed compact, it a type of table-top induction sealer, it is suitable for sealing plastic and glass bottles whose diameters are in the range of 20mm to 50mm. This machine is widely used in food, medical, chemical, agricultural and other industries since its flexibility and versatility. The machine is equipped with over-heat protection system and speed adjusting mechanism, it can ensure the safety during its working process.

Adjustable Speed

Continuous Sealing Operation

Magnetic Induction Sealing

LGYF-2000AX-I Continuous Induction Sealer

Allpack LGYF-2000AX-I continuous induction sealer adopts air-cooled system, it is used to seal plastic, glass and papery bottles. This machine takes advantages of easy operation, continuous conveyor, crystal conduit, digital circuit, air cooling fan, adjustable sealing speed and passing height, etc.An important function of this machine is that it can automatic stop working when there is a malfunction, to isolate sealed and unsealed products.

Electronic Stepless Speed Adjustment

Air Cooled System

Automatic Stop Function In Case Of Malfunction

LGYF-2000BX-I Continuous Induction Sealer

Allpack LGYF-2000BX-I continuous induction sealer is fully made of stainless steel, it has a hard construction, which makes it durable. The machine adopts the principle of electromagnetic induction heating, it is suitable for non-metallic bottles which has thread bottlenecks.The machine has stable performance and high sealing speed which can up to 100 bottles per minute, so it is suitable for large scale production.

Transistor Control Circuit

304 Stainless Steel Construction

Simple Operation

HL-3000A Continuous Induction Sealer

The HL-3000A continuous induction sealer of Allpack adopts heat sealing principle, it can quickly seal bottles when they go through it, it is suitable for sealing plastic and glass bottles. This machine is equipped with high level PLC control panel and overload protection system, thus it is easy and safe to use. Besides, the water cooling circulation system of the machine let it more stable.

Low Power Consumption

Water Cooling Circulation System

Full Stainless Steel Construction

HL-3000B Water Cooling Continuous Induction Sealer

Allpack HL-3000B continuous induction sealer is larger than other models, it has a high end and modern appearance, and it is fully made of stainless steel. The machine adopts water cooling principle, and it is equipped with over-voltage protection device and stadium-style magnetic heating ring, thus the machine is reliable and safe during the operation process. Also, with a simple construction and advanced control panel, this machine is easy to use and maintain.

Full Stainless Steel Enclosure

High Level Digital Display

Convenient Split Structure

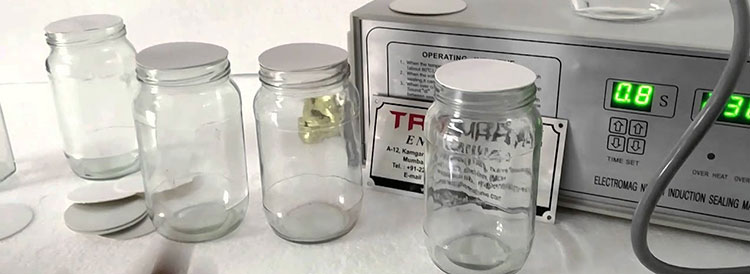

DGYF-S500A Electromagnetic Induction Sealer

The DGYF-S500A electromagnetic induction sealer of Allpack is designed compact, it is portable and space saving, it is a type of manual induction sealer, so it is suitable for small scale production. The machine consists of some main parts such as time display, voltage display, time setting, overheat indication, over-current indication, sealing switch and induction head, the operation of this machine is simple, but you need to seal bottles one by one by hands.

Instant Heat Sealing

User-friendly Control Panel

High Quality Components

DGYF-S500B Electromagnetic Induction Sealer

Allpack DGYF-S500B electromagnetic induction sealer is small in size and it has a low power consumption, it can seal plastic and glass bottles whose diameters are between 15 mm and 35mm. It is suitable for small scale production which don’t need continuous sealing operation.

Electromagnetic Capping Process

Simple Design&Construction

Overheating&Over-current Indication

DGYF-S500C Electromagnetic Induction Sealer

Allpack DGYF-S500C electromagnetic induction sealer is mainly used to seal and screw those bottles which are made of plastic and glass, the machine is flexible, durable, easy to operate, and portable. It is suitable for sealing bottles whose diameters are between 60mm and 130mm and bottles with large bottlenecks. The capacity of this model of induction sealer is not so high, so it can not adapt to large scale production.

Fast Ventilation And Cooling Device

Sensitive Switch Buttons

Independent Power Switch

DGYF-S50OD Electromagnetic Induction Sealer

Allpack DGYF-S50OD electromagnetic induction sealer is suitable for sealing plastic and glass bottles which have handles but don’t have metal bottlenecks, it can seal a variety of bottles whose diameters are in the range of 20 mm to 60mm. This machine can save much energy cause it will consume little power during its working process, it is generally used in small scale production.

Small&Compact Design

Low Power Consumption

Electromagnetic Induction Sealing

SF-1000 Handheld Electromagnetic Aluminum Foil induction sealer

The SF-1000 handheld electromagnetic aluminum foil induction sealer of Allpack can seal bottles whose diameters are from 30mm to 120mm, its maximum speed is to seal 30 bottles per minute. This machine is equipped with smart touch screen and high-brightness digital display, besides, it is operated by a handle, which makes it easy to use.

PLC Control System

Adjustable Sealing Duration And Power

Overload Protection System

SF-1010 Handheld Electromagnetic Aluminum Foil induction sealer

Allpack SF-1010 handheld electromagnetic aluminum foil induction sealer is suitable for sealing plastic bottles whose diameters are between 20mm to 100mm. The machine is semi automatic, it has control panel and can seal bottles automatically, but it also has a handle which need to be operated by human labor. The working principle of this machine is heat sealing, it take a use of high temperature, can realize instant sealing of the aluminium foil bottlenecks of bottles.

Adjustable Sealing Time&Power

Microcomputer Version Control

Tabletop Design

SF-1020 Handheld Electromagnetic Aluminum Foil induction sealer

Allpack SF-1020 handheld electromagnetic aluminum foil induction sealer is designed to seal small-diameter bottles, it is designed compact and portable. This machine is widely used to seal glass bottles, plastic bottles, jars and other products which has aluminium foil gaskets. The machine is equipped with a digital control circuit which makes it easier to operate, it is widely used in medicine, chemical, beverage, oil, cosmetic industries, etc.

Injection-molded Chassis Touch Screen

High-brightness Digital Display

Operation Memory And Data Saving Functions

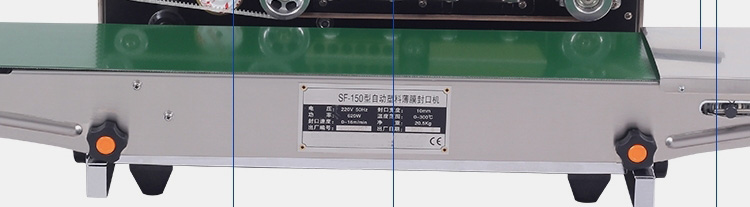

SF-1300 Desktop Automatic Electromagnetic Aluminum Foil Sealing Machine

Allpack SF-1300 desktop automatic electromagnetic aluminum foil sealing machine has a conveyor belt so it can realize continuous sealing operation, it has high production capacity and is suitable for large scale production. This machine adopts non-foil eliminating mechanism so that it is suitable for those products which has high sealing requirements. In addition, the height of this machine is adjustable, as a result, the machine can adapt to bottles of different heights.

304 Stainless Steel Appearance

Over Current Pressure Protection

Easy Operation

SF-1600 Desktop Automatic Electromagnetic Aluminum Foil Sealing Machine

The SF-1600 desktop automatic electromagnetic aluminum foil sealing machine of Allpack is a types of high speed continuous induction sealer, its maximum sealing speed can up to 200 bottles per minute. With such a high speed, the machine is suitable for mass production. This machine can seal bottles whose diameters are in the range of 15mm to 60mm and heights are in the range of 20-180mm, therefore, the machine can be used in a wide range of industries.

Digital Operating Voltage

No-foil Bottle Eliminating Mechanism

Automatic Protection Against Excessive Current

SF-1800 Desktop Automatic Electromagnetic Aluminum Foil Sealing Machine

Allpack SF-1800 Desktop automatic electromagnetic aluminum foil sealing machine adopts the most advanced electromagnetic sealing technology, it is suitable for sealing aluminum foil bottle mouth,glass bottles, plastic bottles, ceramic bottles, sharp-mouth bottles whose diameters are between 30mm to 121mm.

High Sealing Rate

Suitable For Large Scale Production

Unique Ultra-big-diameter Sealing Technology

The Buyer's Guide

Induction Sealer: The Complete Buying Guide in 2024

Sealing different sorts of bottles and vials in an effective way is a very tough task but there are some equipment that can help you with this.

Induction sealer is one of those convenient and extra ordinary working gadgets that can assist you in sealing different bottles in a non-contact way via fabrication and heat.

This blog post is going to explain many useful things about Induction sealer, explaining how it is used, how it works and much more. So keep reading.

1.What is induction sealer & explain its impactful sealing?

Aipak Induction Sealer

An induction sealer is a machine that uses inductive heating to seal containers. This type of machine is commonly used in the pharmaceutical, and food industries, as it provides a hermetic seal that can keep contents fresh for a longer period of time.

An induction sealer works by creating an electromagnetic field that generates heat when it comes into contact with a conductive material. When this happens, the heat creates a seal that bonds the lid to the container.

An Induction sealer is often used to seal containers that contain liquid or semi-solid contents. This type of seal is necessary in order to prevent leakage and maintain product freshness.

The Induction sealer is available in a variety of sizes and power levels. The size of the machine will depend on the size of the containers that need to be sealed. The power level will determine the speed at which the machine can seal containers.

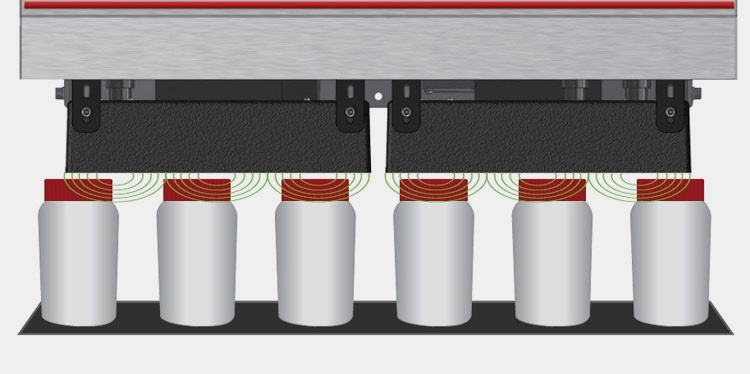

2.How an induction sealer works explain briefly?

Induction Sealer working

An induction sealer is a machine that uses induction heating to seal containers (usually bottles or cans) with aluminum foil or other materials.

Induction sealing is a non-contact heating process that uses electromagnetic induction to heat an inductor (coil) in close proximity to the container lid.

The inductor creates an oscillating magnetic field that induces an electric current in the conductive material of the container lid.

The electric current creates resistance heating that melts the aluminum foil, which then bonds to the container lip, creating a hermetic seal.

Induction sealers are used in a wide variety of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

They are also used for sealing containers that need to be sterile or have a tight seal, such as those used for medical purposes.

3.What are the different components of Induction Sealer?

1KW Induction Sealer

Induction sealers are present in different sizes and shapes in the market. That is why there some components are different from each other.

But also, some components are common in very induction sealers. These common components are the main components of the machine. These are as follows:

Power Supply

The power supply provides the electricity that is needed to generate the magnetic field. At the very first it provides the electricity to the inverter from the wall socket.

After that, the inverter helps the machine seal all the bottles by transforming electricity into the machine and make usable for sealing purposes.

The demand for electricity is varied from one induction sealer to other. So, it is up to your which sealer you want you. You just have to keep in mind to confirm the power rating of induction the sealer.

Moreover, the manual induction sealer needs a power supply of approximately 1 kilowatt. So, it starts working on this power supply.

But on the other hand, the automatic induction sealer almost needs a 6-kilowatts power supply, which is much more than the manual one.

So, this is how the main power supply of induction sealer works.

Sealing Head

The second main component of the induction sealer is the sealing head. The size of the sealing head mainly depends on the number of bottles that are required for sealing. It can be small or big.

The Sealing head has a sealing coil. The coil creates the magnetic field that heats the foil. Also, the coil is a great conductor of metal. But the coverage of coil is mostly done with plastic.

There are also two types of coils present in the market. You can use any kind of coin for your induction sealer. These two designs of sealing coils are as follows:

- Tunnel Coils

- Flat Coils

Tunnel sealing coils are basically used for caps like flip-top, dispensing, or spouted ones. This type of coil is not considered as much suitable for sealing solid material.

The flat sealing coils are considered suitable for sealing the flat caps because they have inner sealers.

So, it is up to you what type of material you require for sealing, and choose the sealing coil according to that material.

Controller

The third main component of the induction sealer is the controller. The main working of the controller is that it regulates the power supply and controls the heating process.

The Controller is considered a very critical component of the induction seal. Because all the heating process depends on it.

4.How many types of Induction Sealer are available?

Induction sealers have different types that are present in the market. These types are as follows:

Portable Sealers

Portable Induction Sealer

The very first type of induction sealing is portable sealers. The portable sealers have all the equipment that can be easily manipulated.

Also, this type of induction sealer is very flexible compared to the others. So, portable sealers are smaller and less expensive, but they’re still powerful enough for most sealing applications.

Portable induction sealers are easy to use. It has multi-functions in it. They can be easily moveable from one workplace to another.

These are also available in many designs in the market. Also, it is adjustable and very lightweight.

Working

A basic portable induction sealer contains a liner which holds the adhesive foil layer in it. A heating induction heats the foil and a cap threading happen in which foil is sealed on top of the bottle mouth then the induction sealer puts the cap on it.

Advantages

- Easy to carry in light weight.

- Less expensive and price efficient.

- Reliable for small business use.

Disadvantages

- You will face difficulties working with large production sealing.

- Sometimes it will cause unusual sealing because of high heating.

Working Components

Here are some working parts of the portable induction sealer.

Sealing Handle

A portable handle that you hold while performing the sealing it has a pipe that gives the power to it. On the sealing handle there is a button which gives you action permission.

Control Panel

You will see different buttons and a small display screen on the screen panel which gives you the power to perform multiple operations as well as give you visual display.

Tabletop Sealer

The second type of induction sealer is a tabletop sealer. Tabletop sealers are larger and more expensive than portable sealers, but they offer more power and features.

They are not easy to move as their size is larger. They are also easy to use.

Working

Tabletop induction sealer works in a different way as compared to some other induction sealer. When the product comes on the conveyor the metallic rode on both sides hold the product in a desired position.

After which the sealing induction assembly from top comes down on to the bottle and then seal the bottles with a induction film and puts the cap and seal it by applying torque.

Advantages

- Beneficial to induction seal large size bottles.

- Comes in a fully automation to achieve large production.

- Fast, reliable and effective for business use with handy actions.

Disadvantages

- A little noisy and expensive so, not environment friendly that much.

- Not reliable to work with metal caps induction sealing.

Components

Here are some tabletop induction sealer machine common working components.

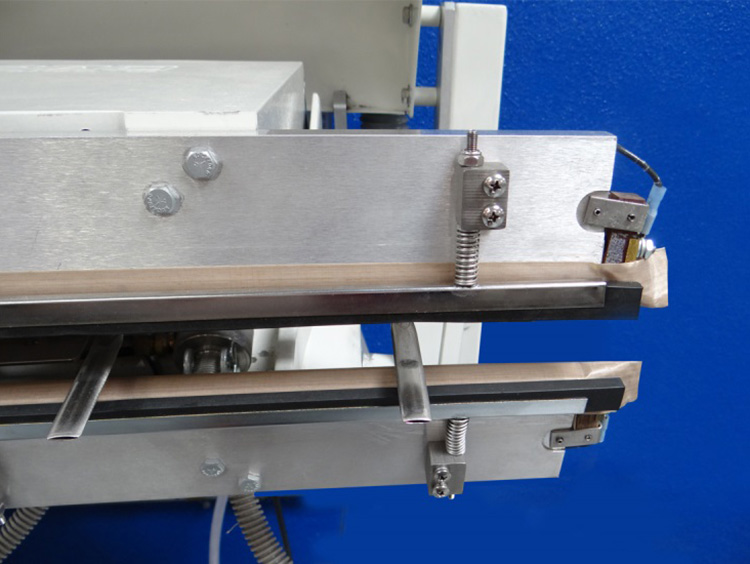

Conveyor Belt

This moving component in the induction sealing machine covers the baseline of the tabletop induction sealer to help control the forward movement of the bottles.

Metal Bars

One of the basic components and very important one in tabletop induction these metal bars are present on both sides of the machine that helps in controlling the products on the conveyor.

As well as, these metal bars also controls the induction assembly by holding it on top of the conveyor.

Power Motor

A powerful part works to provide power as the name suggests. Because it will be hard to control the induction assembly manually so a power unit must need to exists.

Manual Induction Sealer

The next type is the manual induction sealer. It is a fully manually driven machine. This machine is mainly used in small-scale industries.

Although the price of this manual induction sealer is comparatively low as compared to the others.

But also, this machine is not suitable for extensive manufacturing. And seals very less bottles as compared to the others. You cannot seal a metallic bottle from it.

It is also in very small size and has very less weight. Easy to use but required a worker that manually seals the bottles from it.

Working

A manual induction sealer works just like a portable induction sealer which comes with a portable handle. The only difference is that you have to perform the induction process manually by using an induction handler.

You need to adjust some settings manually like heating temperature before induction sealing any product in this machine.

Advantages

- Very flexible and user friendly for induction sealing multiple size vials.

- Hermatic seal in a perfect way with less errors chances.

Disadvantages

- Time consuming and slow in terms of achieving greater production rate.

Automatic Induction Sealer

The automatic induction sealers are very efficient in working. They are very smooth. It is very fast because of the technology that uses in it.

The machine gives very reliable performance. An Automatic induction sealer does not waste energy and uses very less energy during consumption.

This can be used in both small-scale and high-scale industries. It is very easy to use. But the price of this machine is very high.

You do not need human effort to work on it as it is fully automatic. Also, it can change direction and sealing diameters on its own.

Working

A fully automatic induction sealer works in a mysterious way that it can simply handle all the different working operations all by itself.

For instance, you just need to load your product into the machine then the ribbon will make a line of the empty bottles, these empty bottles then enter into the induction unit where an induction liner puts hot sealing film on the bottle mouth.

After that a cap holder puts the cap on top of bottle heads and seal the caps and then the final product came out.

Advantages

- Comprehensive to work with multiple size bottles.

- Much reliable and fast in terms of dealing large business needs.

- Ensure safety of the product and increase its shelf lifecycle.

- Preserve your food and other items from decay by making air free sealing.

Disadvantages

- A bit expensive as compared to all other induction sealers but much more effective.

Components

In a fully automatic induction sealer there are some unique components that work in a complete different way and they had different operations.

Visible Glass

This component helps you to look inside the induction process so, you can make sure that your production is going wee.

Moreover, it also protects the inside material from environment particles such as dust and other small particles present in air.

Heating Block

Mainly, a heating unit is utilized to melt the wax film which will later be given a desired shape to seal on top of the bottle. You can easily adjust the temperature according to your production needs.

Feed Port

A feeding port mainly feeds the bottle into the conveyor assembly in a sequence to make sure each product is sealed in a required manner.

It is helpful part for supporting your machine working in a quick manner.

5.What kinds of bottles can you seal using Induction Sealer?

The induction sealer can seal bottles of different kinds. These includes:

Plastic Bottles

Plastic Bottle Sealer

The induction sealer can seal plastic bottles easily. You can seal every type of plastic bottle from it.

Glass Bottles

Glass Bottle Sealer

You can also seal the glass bottles with the induction sealer. They are also very easily be sealed by it.

Metal Cans

The last kind of bottles you can seal from the induction sealer is metal cans. The best induction sealer that is used for sealing metal cans is the fully automatic one.

6.Explain the applications & uses of induction sealer?

There are lots of Induction sealer applications with many uses in each of these applications. Let me explain it to you in a sequence.

Chemical Industry

Chemical bottles sealing using Induction Sealer

An induction sealer is widely used in chemical industry to perform contact less sealing on different chemical filled bottles.

By using electromagnetic induction the induction sealer make sure that you will get contact-free sealing to keep the reactionary chemicals at ease.

Food & Beverage Industry

In our daily life routine we use different types of food products sealed inside a bottle, jar or a can to make your food safe & give it a longer life in terms of concatenation.

Safety of the product can not be compromised that is why induction sealer is used for better sealing without any flaw.

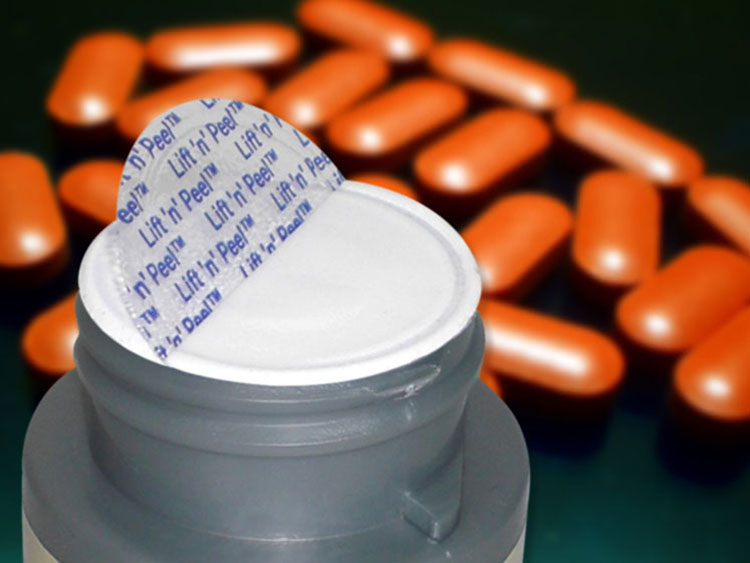

Pharmaceutical Industry

Tablet bottle sealed with Induction Sealer

When it comes to pharmaceutical and medical industry we often see different syrup bottles, bottles having liquid inside them theses are often sealed with induction sealer.

The induction sealing process helps to protect the contents of the container from tampering, leakage, and contamination.

Induction sealing is a very efficient and cost-effective way to package pharmaceutical products. It is a fast and reliable method of sealing containers.

Induction sealing is also a very versatile packaging method that can be used on a variety of different types of containers.

7.Why Induction Sealer is more beneficial as compared to other sealing machines?

An induction sealer is a type of sealing machine that uses induction heating to seal containers. This type of sealer is more beneficial than other types of sealing machines for several reasons.

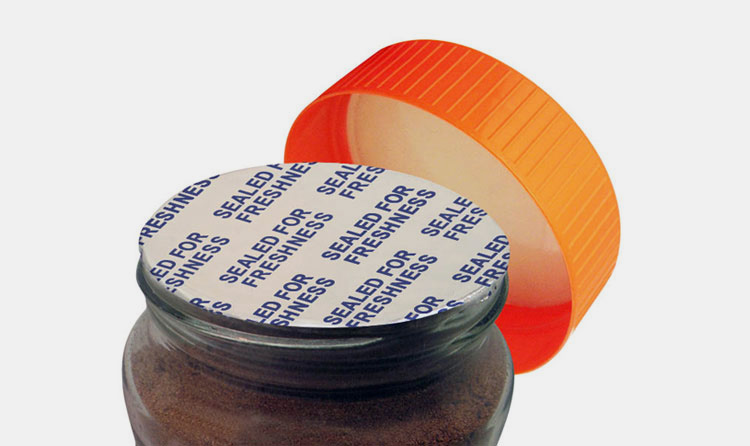

Prevents them from Leakage

One reason why induction sealers are more beneficial is that they provide a hermetic seal. This type of seal is necessary to keep products fresh and prevents them from leaking.

Prevents them from Tampering

Tampering

Induction sealers also provide a tamper-evident seal. This type of seal helps to ensure that products have not been opened or tampered with before they reach the customer.

More Efficient

Efficiency

Induction sealers are also more efficient than other types of sealing machines. They can seal more containers in a shorter amount of time. This makes them ideal for use in high-volume packaging operations.

Easy To Use

The induction sealer is very easy to use. So, there is no need for any special guide about the usage of this machine as this machine is user friendly.

Improves Durability

Sealed Jar

In induction sealer there is no chance of any external contamination. It improves the durability of the product you are sealing from it.

Fast Production Rate

The induction sealer has a very fast production as compared to the other sealers. The bottles are sealed very rapidly by this machine.

Increasing the Product Life

By using induction sealer for sealing purposes, you can increase your product life easily. As, it is a secured method of sealing bottes.

Overall, induction sealers are more beneficial than other types of sealing machines. They provide a hermetic seal, a tamper-evident seal, and are more efficient.

8.How to choose best Induction Sealer for your production line?

Aipak Induction Sealer

If you are in the market for an induction sealer, there are a few things you should keep in mind to ensure you choose the best possible option for your production line.

Size of the Unit

The first thing to consider is the size of the unit. Induction sealers come in a variety of sizes, so it is important to choose one that will be able to accommodate your specific needs.

Power Output of the Unit

Powerful output

Another important factor to consider is the power output of the unit. The higher the power output, the faster the unit will be able to seal your products.

However, it is important to make sure that the unit you choose is not too powerful for your particular application, as this could damage your product.

Price of the Unit

Finally, you will also want to consider the price of the unit. Units with higher power outputs and larger sizes will typically be more expensive than smaller units.

However, you should balance the cost of the unit against its benefits to ensure you are getting a good value for your money.

9.How to handle errors that can occur while working with induction sealer?

Induction sealer is a powerful tool but it might cause some problems when you do not set the requirements according to the instructions.

Temperature Problem

In this problem your induction bottles started heating up and it can also damage your product if the temperature is set high because induction sealer is more a kind of heating sealer.

So, you need to configure that heating temperature is set according to your product type and bottle type.

Bad Sealing

Most of the common problems in an induction sealing machine comes in the form of bad sealing such as cap is not sealed properly, induction film is not sealed or the cap is sealed very tightly.

The solution to these problems came in many ways in the bad cap sealing this happen because of torque level is very high and it may be happening because of low power coming from the sealer and the speed of your machine conveyor is high.

Sealing Film Melt Away

While working with induction sealer you might face sealing film problem like it melt away when you put it on top of the bottle top it did not get fit as you wanted it to be.

The reason behind this problem is you put the sealing film inside the induction unit for too long try to minimize the time of heating the film to solve this problem.

10.Can you explain the installation process of induction sealer?

Installation of the induction sealing machine is not that much complicated as compared to some other machines.

You just need to remember some common steps to deal with induction sealing machine as it comes in a built form like all its components are connected with each other.

Space Requirements

This step comes in a pre-planning installation process in which you make sure that you have the right space to set up your machine that you have selected for your production line.

Before purchasing the machine carefully measure the space that is required to set up the machine in this way you will get the right size machine for your needs.

Measurements

In this step you measure the size of different working parts and give them an adequate space so they can move and perform the required operation easily.

Fixing Conveyor & Sealing Coil

Right after when you set up your machine in the required area you need to fix the conveyor in a direction opposite to the sealing coil because sealing coil works in an opposite direction right after when the product came out of the conveyor.

Conclusion

In the conclusion, the induction sealer is the best machine for sealing different kinds of bottles. It is very beneficial for the industries and the benefits it has are enough for convincing you. You can easily start your business with the Aipak induction sealer because we are providing quality products. If you have any query regarding this you can contact us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586