Thermoforming Machine:The Complete Buying Guide In 2025

Product and material safety has been the first priority of manufacturers globally. Thermoforming is one of the processes which are used in this regard. Plastic sheets are heated at a certain temperature and placed on the top of packing. This helps the product remain safe from the atmospheric conditions and microorganism.

But what is the process of thermoforming and how it helps to keep the product safe? What are thermoforming machines and components present in it. This article will resolve all your queries regarding thermoforming machines and their applications. What are the benefits of thermoforming machine to global world and their selection procedure? So, take the most of it.

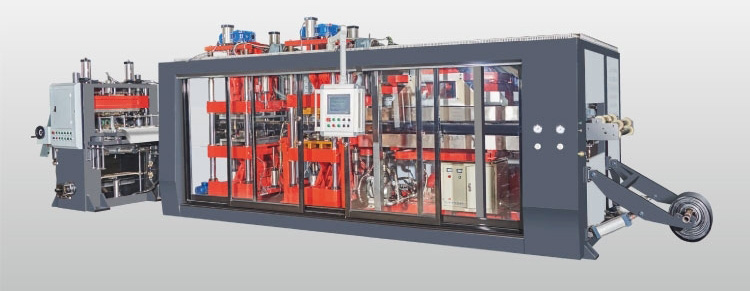

1.What is a Thermoforming Machine?

Thermoforming is a process in which a plastic sheet or film is applied on products through proper heating and molding procedure. The machine ensures proper placement of film to cover the product and with high precision and accuracy.

Manufacturers are using thermoforming machines to secure their products so that any cross-contamination or microbial attack may be avoided. A thermoforming machine itself carries all the processes which make it more economical. It is a versatile machine and has enough capability to reach higher productivity.

Plastic, medical, food, agriculture, domestic goods, retail, automobile interior, chemical, electronic and other industries are using thermoforming machines to ensure proper lid or cover on products.

2.What are the applications of a Thermoforming Machine?

Thermoforming machines are used in variety of industries. There common applications are

Packaging

Mostly thermoforming machines are used for making packaging materials. Packaging of eggs, fresh meat and fruits etc in thermoformed plastic trays and containers is done in these disposables units. Other that food items, medical, shipping and electronic equipments is also done in these products.

Transportation

Seats, covers, folding and other transportation components are made using thermoforming machines.

Trays and Covers

Thermoforming machines are also used to make trays, covers baskets for food, cosmetic, chemical and other products replacing the traditional procedures.

Appliances

Appliances in modern also have several parts that are thermoformed using thermoforming machines. Cloth dryers, computer television appliances and others are made through these machines.

Horticulture

Trays used for seeding plants are made from thermoforming machine. They are reusable and allow better production of plants.

3.Which industry prefers Thermoforming Machine for their products?

Industries that prefer thermoforming machine for their products are

Food Industry

Most of the food items are packed and protected using thermoforming machines and its products. It restricts the atmospheric elements, ultraviolet radiations and other corrosive material to enter the product and increases the shelf life of products. No matter what type and size of product it is, these thermoforming machines are reliable for all of them.

Medical Industry

Covers and protections of medical equipments are made using a thermoforming machine. These machines are used for high resistance impact of instruments, heat deflection, radiation blockage and low cost covers for medical things.

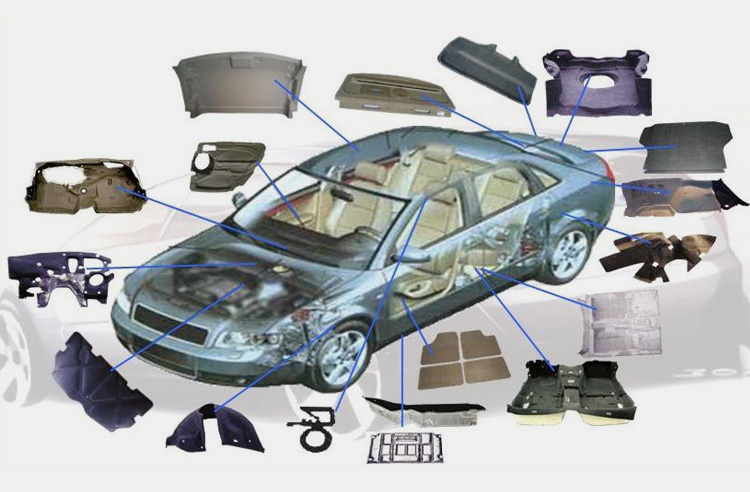

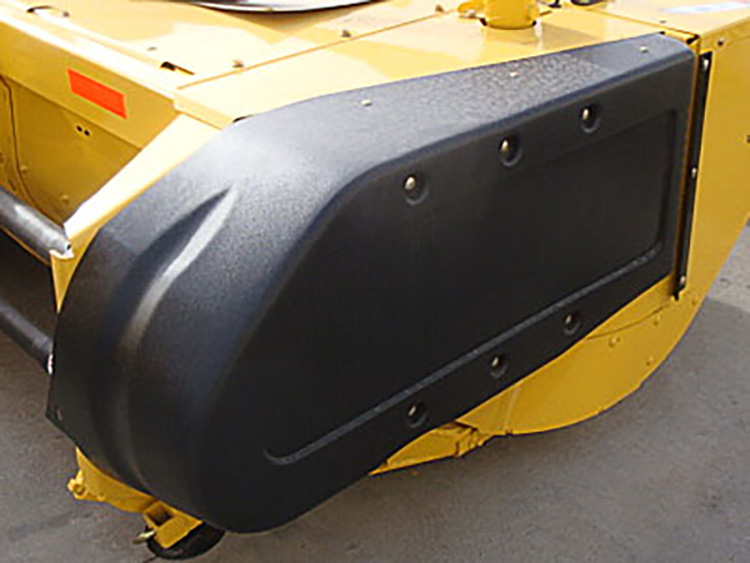

Automobile Industry

Panels, seating parts, bumpers, bed liners, air ducts, mats and doors are made using thermoforming machines. Both vacuum and pressure technology is ideal to form precise and high quality materials for automotive industry. Parts are made using acrylonitrile butadiene styrene and thermoplastic olefin as material of thermoforming.

Agriculture Industry

Agriculture equipments and components including roofs, pots, trays and frames are made up through these machines. These components are ultraviolet resisting and also avoid any type corrosion.

Construction Industry

Thermoforming machines are also highly applicable in construction industry as they are used to produce tool boxes and cases where construction instruments are kept. The polyethylene and polycarbonate materials are used for manufacturing such industrial casings.

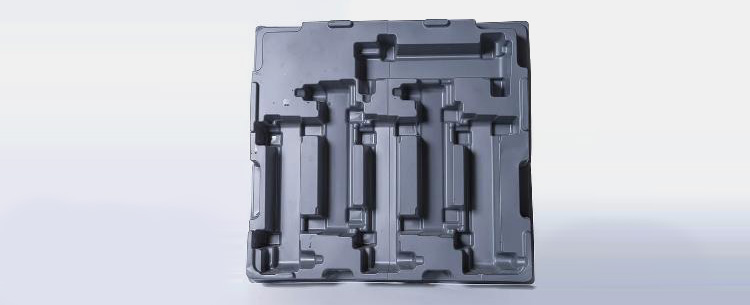

Electronic Industry

Electronic components that are small in size are difficult of handle and control. These components are kept in special type of thermoformed trays or covers where they are secured for longer period.

Electronic industry also uses thermoforming machine in manufacturing of casings for components like PC, mouse, keyboards, cables, gadgets, and drives. The transparent film also assists in easy monitoring of these components.

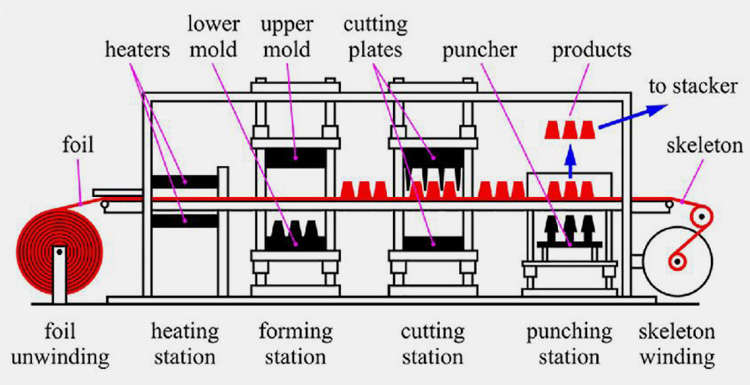

4.What is the working principle of a Thermoforming Machine?

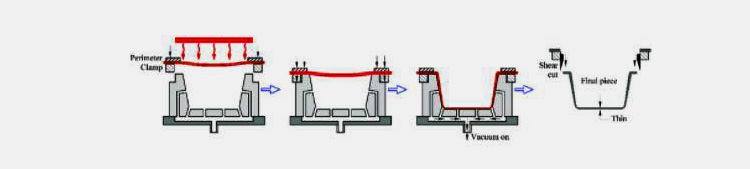

The working principle of a thermoforming is quite simple. Following are the steps involved in a thermoforming process.

- Initially the sheet or foil present on the roller is feeded using a feeding unit to the oven or preheater.

- Here the sheet is heated to a certain temperature that accurate molding of material can be performed.

- The sheet is then sent to the molding unit where the sheet is stretched either mechanically or through vacuum or air pressure. The sheet gets adjusted to the shape of mould and then both the male and female parts force it to achieve the desire shape.

- The product is then supplied to the output unit through a conveyer system where it the cropping of extra mould is done and after then the packing process is carried out.

- The process is too fast that thousand of products are formed in a day and also recycling of waste material is done.

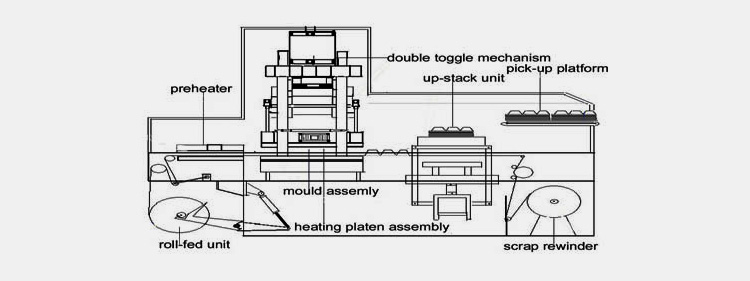

5.What are the components used in a Thermoforming Machine?

Main components of a thermoforming machine are

Main Control Panel

The control panel allows us to monitor, control and regulate all the parameters involved in thermoforming process like power supply, temperature, pressure, vacuum pressure and conveyer speed etc. It is present on the body of a thermoforming machine and can easily be seen there.

Roller Feeding Unit

The foil or packing material is supplied from this roller feeding unit and it is adjusted according to the material width. It is essential to note the movement of this roller as it can cause poor thermoforming if not supplied properly.

Oven or Preheater

Preheater or an oven is the initial component in a thermoforming machine. It heats the sheet and stretches it according to the shape of product to ensure easy molding.

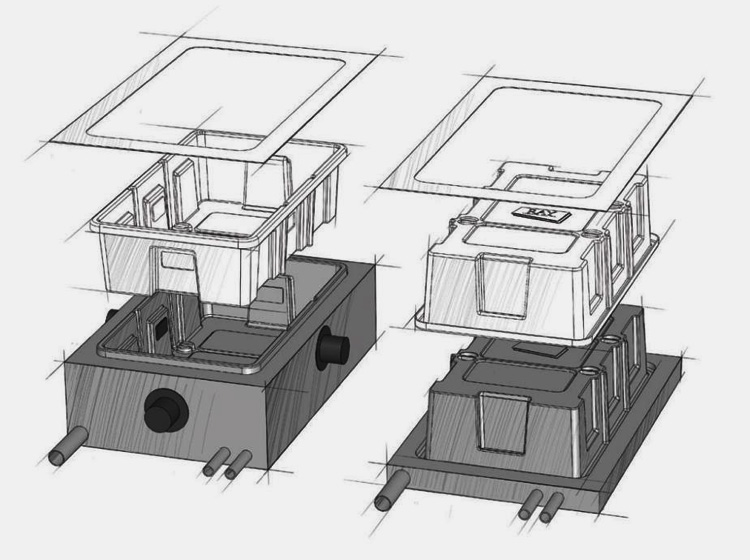

Mold Assembly

When the sheet or film gets heated it enters the second stage where thermoforming molding units are present. These units are responsible for easy manipulation of plastic sheet according to the size of product. Both the male and female molds press the sheet and make the desire lid, tin or cover.

Pickup Platform

As the material is completed the products are then taken off by a pickup platform and collected at the end.

Scrap Removal

During the thermoforming process the sheets that are of no use or are scrap are removed by the scrap removal unit. The scrap is then recycles and used as a thermoforming material.

6.What are the advantages of using a Thermoforming Machine?

Some of the benefits that we can get from a thermoforming machine are

Durability

A thermoforming machine is mostly made-up of stainless steel which makes it highly durable and reliable. The machine lasts for a longer period and can easily be moved from one place to another due to its light weight.

Product Shelf life

The most important factor of a thermoforming machine is that it extends the product shelf with keeping its nature same. The shelf life of product increases and all the external microorganisms are blocked to enter which can contaminate the product.

Low Setup Cost

Thermoforming machines have a low setup cost which makes it so beneficial for the manufacturers to afford. The machine gives high productivity that it returns its investment in a very minimum duration of time.

Quality

The quality of packaging stands the most important benefit of a thermoforming machines. Each product is packed identical and in a highly precise manner.

Compatibility

Different sizes of film can easily be adjusted in a single thermoforming machine. There is no restriction of size, material and width which makes the machine unique in nature.

External Parameters

Thermoforming machine requires no extra external parameters for its operation like temperature, pressure or electricity. It can easily operate on low pressure and achieves its desire temperature on which it is set to be

Productivity

High level of automation is there in a thermoforming machine. Machine can give an output from 20 to 200 packets in a minute which makes it so efficient. Manufacturers can easily purchase their desire machine according to its production requirement as there are number of options available.

7.What types of Thermoforming Machines are available globally?

Thermoforming machines are available in global market depending upon its level of automation, machine and material filling methods. The classification of thermoforming are as below.

Thermoforming Machine According to Material Filling Method

Horizontal Liquid Filling Type

Horizontal thermoforming liquid filling machines are ideally used in pharmaceutical industries to fill tablets, capsules, pill, syringes and bottles. These machines have also incorporated separate sealing level where these products are sealed properly.

Suppository Type

Suppository typThe thermoforming machines are used to fill active ingredients into pharmaceutical drugs. The material gets melt in its initial stage and then is dissolved into the drug as an active ingredient.

A cooling system is there in a thermoforming machine to maintain the quality of active ingredient for a longer period.

Thermoforming Machine According to Automation

Manual Thermoforming Machine

A manual thermoforming machine is the simplest type of thermoforming machine in which maximum tasks are performed by the operator itself. The moulds according to the material is also set by the operator.

The operator feeds the thermoforming sheet into the system and maintains its temperature accordingly.

Semi-Automatic Thermoforming Machine

Semi-automatic thermoforming machine divides the process equally between operator and machine. These are ideal for low scale and medium scale industry. Molding and thermoforming processes are done by the machine itself whereas feeding of material is each interval is carried out by the operator.

Fully Automatic Thermoforming Machine

Process from start to end and even in batch form is performed by the machine itself. These machines are used in medium and large scale industries where the productivity remains higher.

A fully automatic thermoforming machine performs each step itself and reduces human efforts to a distinct level.

Thermoforming Machine According to Machine Filling Method

Vacuum Filling Models

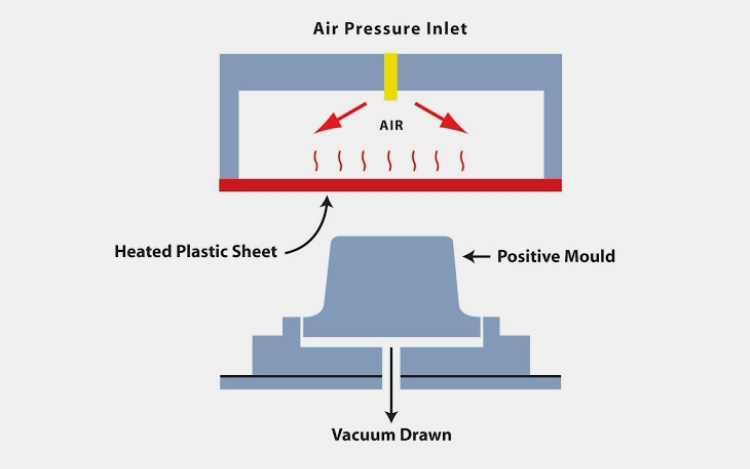

In a vacuum thermoforming machine, the stretching of thermoforming plastic is done using a vacuum system on molds. Air is evacuated from the surface to achieve vacuum effect. This also is a great advance form of thermoforming but limits where the vacuum pressure is not obtained.

Pressure Filling Models

As the name explains, pressure is used for stretching of material in this type of thermoforming machine. The upper and lower side of the mold contains air pressure that stretches the heated material to achieve high quality and precise design. The heating system maintains the heat of sheet and helps in shaping the thermoplastic material.

Blister Filling Models

In this type of thermoforming machine, the forming film is heated until it gets soft. The blister is created by this soft thermoforming film in presence of compressed air. The process is further carried until all the products are efficiently filled into this blister film.

8.What Are Some Of The Materials That Are Used In Thermoforming Machine?

Some of the materials used in thermoforming machines are

Polyethylene Terephthalate (PET)

Efficient barrier to products like alcohol, oil and chemicals is provided by polyethylene terephthalate material. PET is a tensile and impact resistance mostly used for manufacturing of food products packaging.

Polypropylene (PP)

Most popular material that is used for mass production thermoforming machine is polypropylene Because of its innate properties, PP is used for chemical and heat resistive packaging.

Polyethylene

Low and High density polyethylene are used in thermoforming processes because it resists chemical and ultraviolet rays. Manufacturing of thermoformed cables, packaging films, bottles, pipe and plastic bags is done using LDPE and HDPE.

Polyvinyl Chloride (PVC)

Polyvinyl chloride after polypropylene are the most popular thermoformed material used worldwide. Polyvinyl chloride is highly resistive to water and moisture and used mostly in packaging of automotive, home, packaging, food and chemical products.

Polycarbonate (PC)

Polycarbonate is tough, rigid, crack resistive and strong materials that is resistive to both water and heat. The most beneficial thing of using a PC is that there are variety of grades available that can be used according to its necessities.

9.What Are The Differences Between Thermoforming Machine And Vacuum Forming Machine?

Thermoforming and vacuum machines are always related with each other as heat is the basic necessity for both of them. The basic difference arises that a thermoforming process is carried out under extreme heat and pressure whereas a vacuum forming process occurs when plastic products are heated at a certain heating temperature.

Some of the other differences between both machines are

Definition

A thermoforming process includes application of thermoplastic film that has been heated at a high temperature. A single sided mold is responsible for its handling and after cooling down it acquires the shape of mold. A Thermoforming machine has a unique feature that they can adapt wide range of materials in its operational procedure.

Vacuum forming process is one of the most ancient methods for treating plastic materials. Plastic material is molded for forming permanent shapes. The sheet first gets soft and then wrapped over a mold.

Procedure

A thermoforming machine heats the film to its melting points and pours into the mold. The mold then releases the final product once the system is cooled down.

While in a vacuum forming machine, the plastic is clamped according to the position of frame and then heat is applied. It softens the plastic and makes it pliable. The frame is then combined together and as a result the final, shaped plastic product is received.

Mold Tooling

Shape edges, roughness, clear cutting and proper shape can only be achieved if correct mold according to the machine and material is used.

A thermoforming machine is highly versatile that its tools can easily be replaced and updated whenever required. This allows the manufacturer to make variety of materials using a single machine

A vacuum forming machine uses a single mold for a single type of forming. Suction and heating parameters are more important to ensure appropriate molding. Pressing in desire mold shape gives desired shape.

Application

Wide range of production setups is now using thermoforming machines in their processes. Thermoforming machines are used for following setups

- In automotive industry for dashboard, handle, holder manufacturing.

- Parts of business equipment

- Parts of aerospace and aviation industry

- Interior and seating panels of transportation industry

- Equipment and devices for medical industry

- Construction machines cover and cases

- Equipment for fitness centers

Likewise, vacuum forming machines are used in

- Packaging industry uses plastic that is formed by vacuum forming process.

- Trays, pads and other consumables for medical setups.

- Plastic components of heavy duty machines that are used in agriculture business are also made using a vacuum forming machine.

Pros and cons

| S.No | Advantages | |

| Thermoforming Machine | Vacuum Forming Machine | |

| 1 | High speed manufacturing | Low manufacturing cost |

| 2 | Faster setup | Timely production sequence |

| 3 | Large and complex designs can easily be formed | Adjustable and adaptable mold sizes |

| 4 | Low tooling cost | Low molding cost |

| 5 | Low cost material prototype designing | New components can be used and replaced |

| S.No | Disadvantages | |

| Thermoforming Machine | Vacuum Forming Machine | |

| 1 | Non-uniform stretching gauge | Wrapping of thick plastic sheet |

| 2 | More usage of Plastic | Single production setup at a time |

| 3 | High Part Cost | Additional Expense on parts |

| 4 | Possibility of undercut pieces | No complex design can be formed |

10.What Are The Common Errors And Their Remedies While Using A Thermoforming Machine?

| S.No | Problem | Problem Cause | Problem Remedy |

| 1 |

Blisters |

Excess Moisture | Pre heat sheet

Heat from both sides |

| 2 | Uneven Heating | Check output power of heat

Usage of pattern heating |

|

| 3 | Heating too Rapidly | Distance between heater and sheet should be increased.

Decreasing heating temperature |

|

|

4 |

Incomplete Forming |

Insufficient Vacuum | Increasing number of holes in vacuum chamber

Diameter of vacuum holes if increased can resolve the problem. |

| 5 | Cold Sheet | Heating temperature should be raised.

Increasing number of heaters |

|

| 6 | Too low applied pressure | Increasing pressure of air. | |

| 7 |

Change in Color Intensity |

Excess Heating | Reducing temperature of heater.

Short the cycle of heater |

| 8 | Insufficient Heating | Raising temperature of heater

Purchasing more efficient heater |

|

| 9 | Surface Blemishes

|

Hot mould | Reducing temperature of mould |

| 10 | Scratching of Sheet | Using polished sheet

Inspecting the handling of sheet |

|

| 11 | Poor Vacuum | Increasing hole area of vacuum

Checking inlet of vacuum |

|

| 12 | Rough Mould Surface | Polishing of mould to be done

Using aluminum mould can reduce this |

11.What Are Some Of The Safety Measures Taken While Operating A Thermoforming Machine?

It is always recommended that proper safety procedures should be read before operating a thermoforming machine. Few basic steps should be taken before operating a thermoforming machine to prevent man and machine accidents. Those are

- Only trained operator should be allowed to operate a thermoforming machine who holds expertise in performing tasks.

- All the electrical connections and mechanical equipment should be checked properly before operating thermoforming.

- Proper elevating devices should be used to raise tools and plastic raising off the floor.

- The operator should be bounded to wear personal protective equipment (PPEs) like footwear, helmet, glasses and gloves.

- The working zone should be cordon off to prevent entrance of any unauthorized person.

- Doors of thermoforming machine should be opened after the temperature of machine is maintained.

- Performing proper cleaning of wet surfaces around the machine.

- Machine with proper ventilation are ideal to be used in closed working areas.

Conclusion

Thermoforming machines are highly beneficial in food, packaging, medical, automotive and other industries. These machines have brought a revolution in preserving food items and manufacturing reliable household items. You can go through this article and know all about thermoforming machines. Feel free to contact us anytime or visit our website http://www.allpackchina.com/ for complete details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours