Your Best Semi-automatic Capsule Filling Machine Manufacturer

- Fast&Safe Capsule Closing&Filling

- Highly Precise&Accurate

- Easy Clean&Maintain

Semi Automatic Capsule Filling Machine

Allpack semi automatic capsule filling machine adopts programmable control system, touch panel operation, stepless transduction speed shift, and electronic automatic counter. It can automatically complete the action of position, separation, filling, locking, etc. The dosage is accurate, and the operation is very convenient. The overall machine is made of good quality stainless steel, and the machine is suitable for capsules which filled with powder and pellet.Adopted frequency control system for changing the filling speed, which for adjusting the powder filling dosage accuracy.And with new type capsule loading system, which increased the capsule loading accurate and decreased the mold changing time. Mold changing time less than 5 minutes.With this semi-auto capsule filler, you are in a position to make capsules with different shapes and ingredients depending on your specifications.

Semi Automatic Capsule Filling Machine

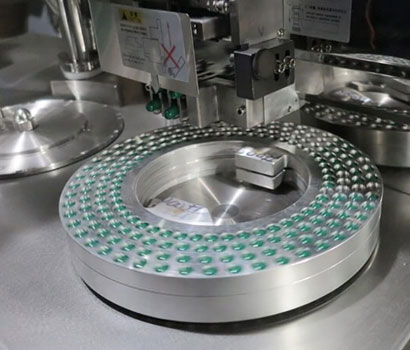

CGN-208D Semi Automatic Capsule Filling Machine

Allpack CGN-208D semi automatic capsule filling machine is a new type of semi-automatic capsule filling machine, which is an improved model from other previous models in the industry.The filling amount can be adjusted by the number of rotations of the dosing disk.The powder feeder also has a stirring feature to regulate the powder filling.This improvement results in faster production, meeting cGMP requirements, more accurate filling, safer operation, simple maintenance.

Low wear and tear

Frequency control

Fill 000#~ 5#capsule

CGN-208S Double Head Semi-Automatic Capsule Filling Machine

Allpack CGN-208S semi-auto capsule filling machine ,the design of the equipment adopts the double-head automatic capsule filling machine's dialing method. In terms of dialing speed, mold replacement, filling degree, maintenance, etc., it has made obvious progress compared with the old semi-automatic capsule filling machine. Become more fast, convenient, simple and stable. In terms of bag lock, the machine adopts pneumatic control and automatic bag lock method to save labor time.

High speed&accurate seeding with two heads

Accurate capsule locking mechanism

Safety guard

New Design Servo Control D3 Semi-Automatic Capsule Filling Machine for Powder

The new generation CGN208-D3 semi-automatic capsule filling machine is a new kind capsule filling machine which is deeply improved in the structure and attractive in the appearance. It adopts electrical equipment, pneumatic control, with the electronic automatic counting device, frequency speed controlling, and the actions such as capsule locating, separating, filling, and capsule locking which is accomplished respectively instead of manual. It reduces labor intensity, improves the filling efficiency and accurately, and compliant with pharmacy hygiene requirements.

Five-return capsule disengaging mechanism

Medicine expects filling mechanism

Frequency conversion speed controlling

Pharmaceutical CGN208-D1 Horizontal Semi Automatic Capsule Filling Machine

Allpack CGN208-D1 type semi automatic capsule filling machine is a new efficient equipment based on DTJ-C model (old type) after research and development: easier more intuitive and higher loading in capsule dropping, U-turning, vacuum separation in comparison with the old type. The new type of capsule orientating adopts columns pill positioning design, which shortens the time in the replacement of mould from the original 30 minutes to 5-8 minutes.

Electricity and pneumatic combined control

Automatic counting electronics

Programmable controller and frequency conversion speed regulating device

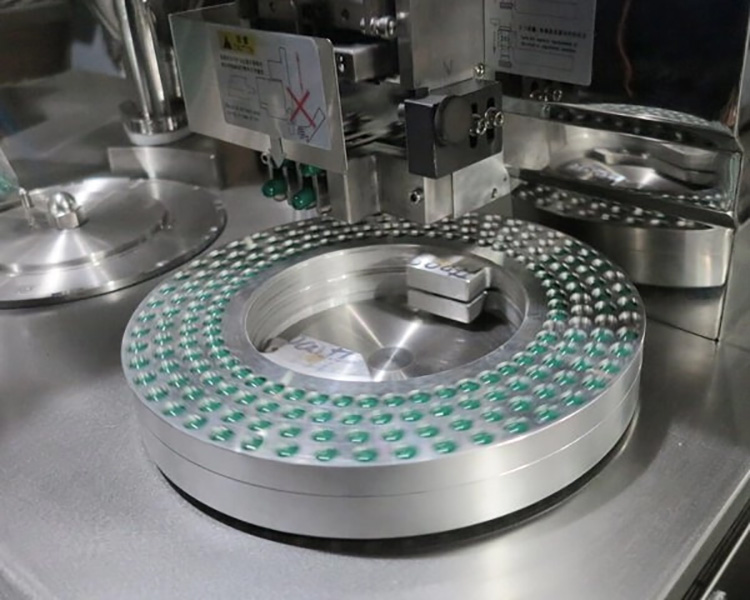

CGN208-D2 Pellet Semi Automatic Capsule Filling Machine

Allpack CGN208-D2 pellet semi automatic capsule filling machine combines with electricity and pneumatic power, it is suitable for filling international all size capsule, high output and easy for operating. The whole line equips with auto counting device and adjustable feeding device, can finish position action, separate action, filling action and lock action whole operating process.It meets GMP standard. The variable frequency stepless speed regulation is adopted to solve the weakness of large deviation of the weight of the head and tail of the traditional machine.

Mainly body 304 stainless steel

Touch screen parameter adjustable

Complete machine parts

The Buyer's Guide

Semi-Automatic Capsule Filling Machine: The Complete Buying Guide In 2024

Do you want a faster and more efficient way to do the tedious task of filling capsules? Well, the good news is that a semi-automatic capsule-filling machine can help with that. This kind of machinery has revolutionized the process – from manual labor to automated – allowing for greater accuracy and consistency in your final products.

Not only does it provide convenient operation and enhanced safety protocols, but it also ensures precise dosing as well as higher output rates than traditional methods. In this blog post, we’ll discuss semi-automatic capsule-filling machines: how they work, what benefits they offer, their key features and components, and much more! So let’s get started!

1.What Is A Semi-Automatic Capsule Filling Machine?

A semi-automatic capsule filling machine is a machine that is designed to fill pills and capsules with powders, granules, liquids, semi-solids, or combination products. The semi-automatic capsule filler automates the process of filling capsules quickly and accurately. It typically uses individual dosages for each capsule, which can be set to the desired amount.

The semi-automatic capsule filling machine is semi-automatic because it requires a semi-skilled operator to feed, align and monitor the filling process. It also has built-in safety features that ensure consistent quality in the capsules produced.

The semi-automatic capsule-filling machine is used in many industries, such as pharmaceuticals, nutraceuticals, and medical device manufacturing. This machine can also fill capsules with food products, vitamins, and supplements.

2.What Are The Components Of A Semi-Automatic Capsule Filling Machine?

A semi-automatic capsule-filling machine typically consists of the following components:

Capsule Hopper

This holds the empty capsules and helps transfer them to other parts of the machine.

Dosing Unit

This unit accurately doses a predetermined quantity of powder or granules into each capsule.

Sealing Unit

This component seals the filled capsules and prevents them from leaking.

Filling Tube

The filling tube is responsible for accurately transferring the powder or granule into the capsule according to the predetermined quantity set by the dosing unit.

Adjustable Plate & Tamper

This part helps compress the powder into the capsule, then seals it.

Control Panel

This accurately sets the dosage size and other specifications required for filling capsules.

Final Product Collection Tray

Finally, the semi-automatic capsule filling machine collects filled capsules on a collection tray for further packaging or storage.

3.What Are The Pros Of Semi-Automatic Capsule Filling Machines?

Increased Production Speed

Semi-automatic capsule filling machines can increase production speed by up to 25%-50% compared to manual capsule filling. This is because semi-automatic machines reduce the time and effort required for tasks such as counting, separating, transferring, and aligning capsules during the capsule filling process.

Improved Accuracy

Semi-automatic capsule filling machines also improve accuracy by using precise and consistent measurements when weighing, separating and transferring capsules. This eliminates the possibility of human error, resulting in higher-quality products that are ready for sale more quickly than manually filled capsules.

Lower Labour Costs

Semi-automatic capsule filling machines help to reduce labour costs. This is because semi-automatic machines require fewer workers when compared to manual capsule filling, freeing up staff to be able to focus on other tasks.

Reduced Risk of Contamination

With semi-automatic capsule filling machines, there is less risk of potential contamination during the capsule filling process. This is because semi-automatic machines reduce contact with the capsules, reducing the chance of any contamination entering them.

Flexibility

Semi-automatic capsule filling machines provide increased flexibility when compared to manual capsule filling. This includes being able to change settings and configurations quickly to accommodate different size capsules and volumes of production.

Cost-Effective

Semi-automatic capsule-filling machines offer an affordable solution for businesses and individuals looking to save money on their capsule-filling needs. Not only do semi-automatic machines provide a cost-effective solution for a range of production needs, but they also reduce labor costs since only one person is needed to operate the machine.

4.What Are The Applications Of Semi-Automatic Capsule Filling Machines?

Semi-automatic capsule-filling machines offer a range of applications. They include:

Pharmaceutical Production

Semi-automatic capsule-filling machines are widely used in the production of pharmaceuticals as they can quickly and accurately fill capsules with active ingredients, excipients, and other materials. This helps to reduce manual labor costs while also increasing productivity.

Nutraceutical Production

Semi-automatic capsule filling machines are a great asset in producing dietary supplements and nutraceuticals. They can precisely fill capsules with various ingredients, including vitamins, minerals, herbs, and other essential compounds. This helps ensure that every capsule contains the right amount of ingredients in the correct ratios.

Veterinary Care

Semi-automatic capsule-filling machines are increasingly used in veterinary care settings. They help quickly and accurately fill capsules with the right medication for pets and other animals.

Food Production

Semi-automatic capsule filling machines can also be used in food production applications, for example, in preparing powdered ingredients for ready-to-eat meals and snacks. The machines can accurately fill capsules with different powders or mixtures and can then be sealed using specialized tools. This helps to ensure consistent quality in the production process.

5.How Does A Semi-Automatic Capsule Filling Machine Work?

Semi-automatic machines generally have three stages: loading, filling, and closing. In the loading stage, the empty capsules are loaded into the machine for filling. Once loaded, the semi-automatic capsule-filling machine moves the capsules along a conveyor belt, filling them with the desired material.

The semi-automatic capsule filling machine then transfers the filled capsules to another belt where they are closed, either manually or by using a special closing tool. Once the semi-automatic capsule filling process has been completed, the finished capsules can be packaged and shipped out.

6.What Are The Different Types Of Semi-Automatic Capsule Filling Machines Available On The Market?

There are several semi-automatic capsule-filling machines available on the market, each with its own set of features and benefits:

Horizontal Semi-Automatic Capsule Filing Machine

Horizontal semi-automatic capsule filling machines are automated machines used to quickly fill capsules with precise amounts of powdered medication, supplements, and other substances.

These machines use horizontal hoppers which feed the material into a chamber where it is precisely weighed and cut into individual doses.

Components

Feeding Hopper

The feeding hopper is used for supplying and storing the powder or granules to be filled in the capsules.

Filling Station

This station consists of a dosing disc, cam & slider mechanism, filling plunger, and a filling control system that is used to fill the capsules accurately with the powder or granules.

Lower Turret

This component consists of empty capsule pockets and suction holes used for transferring empty capsules from Top to Bottom station.

Transfer Piston & Cylinder Assembly

This assembly helps in horizontal transfer of filled capsules from the top to bottom of the machine.

Sealing & Closing Station

It helps in sealing and closing of capsules by a die-punch mechanism.

Control Panel

This panel has all the switches and indicators used to control, operate, and monitor the horizontal semi-automatic capsule filling machine.

Safety Systems

Safety systems are necessary for ensuring a safe working environment in the horizontal semi-automatic capsule filling machine. These include safety switches for emergency stop, interlocks for preventing the accidental start of machines and shields for protecting the operator from potential danger.

Accessories

The horizontal semi-automatic capsule filling machine also comes with some accessories like dust collectors, compressed air lines, and a variety of other components that are used to improve efficiency and accuracy.

Working Principles

The horizontal semi-automatic capsule filling machine works by automatically positioning empty capsules in cavities of a die plate and then, using an automatic dosing system to fill each cavity with the desired amount of powder or pellet.

The machine is designed to accommodate different sizes and shapes of capsules as well as various dosages. Once all the capsules have been filled, the machine ejects them onto a conveyor belt and then they are collected in a container or tray.

Applications

Horizontal semi-automatic capsule filing machines are typically used in the pharmaceutical and nutraceutical industries for the filling, sealing, labeling and packaging of capsules. In addition, these machines can be used in small laboratories for carrying out tests and experiments.

Pellet Semi-Automatic Capsule Filling Machine

Pellet semi-automatic capsule filling machines are highly efficient machines that help to fill capsules with powders, pellets, granules and other products.

These machines are equipped with a semi-automatic system that is used to create the perfect capsule shape which helps to ensure accuracy in filling.

Components

The pellet semi-automatic capsule filling machine consists of the following components:

Pellet Hopper

This is where pellets are stored before they are fed into the machine. It is important to ensure that it is properly secured and sealed against dust and other contamination.

Pellet Feeder

This is a device that transfers the pellets from the pellet hopper into the filling chamber. The pellet feeder should be adjustable to ensure accurate and consistent feeding of pellets.

Filling Chamber

This is a cylindrical chamber where the pills are filled with powder or other material, depending on the capsule size. It should be designed to ensure accurate filling and should be easy to clean.

Pellet Separator

This is a device that separates the pellets from each other in order to prevent them from sticking together during the filling process. It ensures that each capsule contains the same amount of material.

Pellet Dispenser

This is a device that dispenses the pellets from the pellet feeder into the filling chamber. It should be adjustable to ensure accurate and consistent dispensing of pellets.

Pellet Sealing Plate

This is a device that seals each capsule after it is filled. It should be designed to ensure an air tight seal and should be easy to clean.

Pellet Cutter

This is a device that cuts the pellets into the desired size and shape before they are dispensed into the filling chamber. It should be adjustable to ensure accurate cutting of pellets.

Pellet Press

This is a device that presses the powder or other material inside each capsule to ensure that it is firmly packed. It should be adjustable to ensure accurate pressing of pellets.

Pellet Tray

This is a device used to collect the filled and sealed capsules before they are dispensed from the pellet semi-automatic capsule filling machine. It should be designed to prevent any spillage or contamination of the capsules.

Pellet Cleaner

This is a device used to clean the pellet semi-automatic capsule filling machine after it has been used to fill and seal capsules. It should be designed for easy cleaning and should be able to remove all dirt, dust, and other contamination from the machine.

Working principles

Pellet semi-automatic capsule filling machines use gravity and vacuum technology to fill capsules with pellets. The machine uses a hopper to store the pellets, which are then released into the capsule filling chamber by gravity. A vacuum is then used to collect the pellets and transfer them one at a time into each capsule.

Also, this device uses a rotating disc to ensure that pellets are evenly dispersed within the capsule. The pellet semi-automatic capsule filling machine then uses a tamper to compact and seal each filled capsule. After sealing, this machine ejects finished capsules for easy collection.

Applications

Pellet semi-automatic capsule filling machines are used in a variety of industries, including pharmaceuticals, nutraceuticals, and food. These machines provide an efficient way to fill capsules with pellets or granules for both manual and automated production lines.

c)Double Head Semi-Automatic Capsule Filling Machine

Double head semi-automatic capsule filling machine is a machine used in pharmaceutical and food production industries. This type of machine allows for the automatic filling of capsules with powder or granular material, while being operated by an operator. It is capable of filling up to double the speed compared to other manual capsule filling machines.

Components

Hopper

The hopper is used to store the raw materials, such as powder, pellets or liquid that will be encapsulated.

Filling Disc

The filling disc is where the powder/pellets are placed into the capsules. It can have different settings depending on the size and shape of the capsule.

Capping Disc

The capping disc is used to ensure that each capsule is sealed properly and keeps the contents secure.

Control Panel

The control panel is used to adjust the settings of the double head semi-automatic capsule filling machine, including speed and accuracy.

Tray

The tray is used to collect the finished capsules and can be easily removed for cleaning or transport.

Motor

The motor powers the double head semi-automatic capsule filling machine, ensuring that it runs smoothly and efficiently.

Safety Sensor

The safety sensor helps protect the operators by shutting off the double head semi-automatic capsule filling machine if it detects any danger.

Working principles

Double head semi-automatic capsule filling machines operate on the principle of filling pre-made capsules with a predetermined amount of powdered material. The double head semi-automatic capsule filling machine uses two separate heads, one for loading and one for unloading, to allow operators to quickly and accurately fill capsules.

These machines are typically fitted with a vibrator system, which helps to evenly spread the powder within each capsule. Once filled, the capsules are transferred from the double head semi-automatic capsule filling machine onto a conveyor belt or other material handling device for further processing.

Applications

Double head semi-automatic capsule filling machines are used in the pharmaceutical industry for filling capsules with powder, granules or pellets.

7.What Is The Difference Between Semi-Automatic Capsule Filling Machines And Automatic Capsule Filling Machines?

a) Semi-Automatic Capsule Filling Machine

b) Automatic Capsule Filling Machine

The semi-automatic capsule filling machine fills capsules with powdered, small granulated, or liquid medications. The semi-automatic capsule filler requires manual input from the user and has many adjustable parameters, such as speed and dosage accuracy. It is primarily used for low-volume pharmaceutical production and typically requires one operator.

On the other hand, automatic capsule-filling machines are fully automated devices that can continuously process semi-solid and solid materials with minimal human input. These machines typically feature automated sorting, dosing, and even sealing of capsules with greater speed and accuracy than semi-automatic machines. Automatic capsule fillers are well-suited for large-scale production and require less maintenance.

8.What Are The Different Types Of Capsules that Can Be Used With A Semi-Automatic Capsule Filling Machine?

Gelatin Capsules

These type of capsules are typically made from a combination of bovine or porcine gelatin and water, and are common for semi-automatic capsule filling machines as they are lightweight and easy to work with. They come in sizes ranging from 00 to 4.

Vegetarian/Vegan Capsules

These vegan capsules are made from plant-based cellulose (HPMC) and can be used by semi-automatic capsule filling machines. They come in sizes ranging from 0 to 5.

HPMC Capsules

These capsules are made from hydroxypropylmethylcellulose and are generally used for semi-automatic capsule-filling machines due to their strength and resistance to moisture. They come in sizes ranging from 0 to 5.

9.What Type Of Materials Can Be Filled In Capsuled By A Semi-Automatic Capsule Filling Machine

A semi-automatic capsule filling machine can be used to fill various materials into capsules of different sizes and shapes. These materials include:

Pellets

Pellets are the most common semi-solid form of active pharmaceutical ingredients that can be filled in capsules by semi-automatic capsule filling machines. These pellets come in a variety of sizes and shapes, from very small to large, depending on the requirements.

Tablets

Tablets are solid dosage forms that can also be filled into capsules using semi-automatic capsule filling machines. Tablets come in a variety of shapes, sizes and colors to meet the needs of different pharmaceutical products.

Powders

Powder is another semi-solid form of active pharmaceutical ingredients that can be filled in capsules with semi-automatic capsule filling machines. Powders come in many forms such as granular, semi-solid, or free-flowing.

Granules

Granules are small particles of semi-solid pharmaceutical ingredients that can be filled into capsules using semi-automatic capsule filling machines. Granules can be made up of various materials and come in a variety of shapes and sizes.

10.What Safety Measures Should Be Taken While Working With A Semi-Automatic Capsule Filling Machine?

Wear personal protective equipment (PPE)

When working with semi-automatic capsule filling machines, it is essential to wear appropriate PPE, such as safety glasses, face shields, and gloves. This will protect you from any potential hazards associated with the machine’s operation.

Read the user manual

Before operating semi-automatic capsule filling machines, it is important to read and understand the user manual. This will help you familiarize yourself with the operating instructions, safety features, and emergency shutdown procedures.

Be aware of potential hazards

Semi-automatic capsule filling machines may come with sharp or moving parts that can be dangerous if not handled properly. It is important to be aware of the potential hazards and take proper precautions.

Follow safety protocol

Semi-automatic capsule filling machines should only be operated following their respective safety protocols. This includes following all instructions for operating the machine and ensuring any necessary maintenance or repairs are carried out in a timely manner.

Ensure a safe work environment

Before operating semi-automatic capsule filling machines, it is important to ensure the surrounding area and equipment are free from any potential hazards. This includes checking for sharp objects, flammable materials, or other hazardous items that can interfere with the machine’s operation.

Keep an eye on the machine

Once the semi-automatic capsule filling machine is operating, it is important to monitor its performance. This includes checking for any malfunctions or signs of wear and tear. If any issues are noticed, the machine should be shut down immediately and inspected by a qualified technician.

Be aware of the safety switch

Semi-automatic capsule filling machines are equipped with a safety switch that must be enabled to ensure the machine is operated safely. All operators must be aware of this safety feature and its proper functioning.

11.What Are The Maintenance Procedures For Semi-Automatic Capsule Filling Machines?

Regular Cleaning

Before starting any maintenance procedure, it is important to clean the semi-automatic capsule filling machine thoroughly using a damp cloth or paper towel. This will eliminate any dirt and dust from previous use and ensure that no residue remains on the machine’s surface.

Inspection

Make sure all moving parts are working properly and free from any obstruction. It is important to check for any wear and tear, which may require repairing or replacing certain components.

Replace Worn Components

Any parts or components that have become worn out should be replaced as soon as possible to keep the semi-automatic capsule-filling machine running optimally.

Lubrication

It is important to lubricate any moving parts regularly with a suitable lubricant. This will help to reduce friction and wear and tear, prolonging the life of the semi-automatic capsule-filling machine.

12.What Are The Key Considerations When Choosing A Semi-Automatic Capsule Filling Machine For Your Pharmaceutical Production Line?

Output Capacity

The output capacity of semi-automatic capsule-filling machines is important as it determines the rate at which tablets and capsules can be filled. When choosing a semi-automatic capsule filling machine, ensure that its maximum output capacity matches the production needs of your pharmaceutical line.

Efficiency

The semi-automatic capsule filling machine’s efficiency should be considered to ensure that it can meet the required output rate and quality. When assessing a semi-automatic capsule filler’s efficiency, look at factors such as time to complete a cycle and possible jamming scenarios.

Durability

It is important to check the semi-automatic capsule filling machine’s construction material and mechanical design features to determine its durability. This will ensure that your semi-automatic capsule filler can run for extended periods without needing repairs or maintenance, thus keeping production costs low.

Cost

The cost of semi-automatic capsule-filling machines should also be considered. Check the machine’s features and functions, such as output capacity and efficiency, against its price tag to ensure you get the best value for your money.

Ease of Use

The semi-automatic capsule filler should be easy to use to accommodate different operators. Ideally, the semi-automatic capsule-filling machine should have features such as an embedded graphical interface, quick changeover functions, and automated calibration for easier operation.

CONCLUSION

The semi-automatic capsule-filling machine has made the capsule-filling process much easier. This versatile machine is perfect for any pharmaceutical, food, and nutraceutical industry. Also, this machine is very efficient in speed and accuracy, and it can be used for various products. If you are in the market for a high-quality and affordable semi-automatic capsule-filling machine, look no further than Allpack. Our team of experts will help you find the perfect machine for your needs and budget. Contact us today to get started!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours