Practical & High Efficient Seed Counting Machine

- Pneumatic Drive System

- Stable Temperature Control

- High-sensitivity Photoelectric Color Tracing

Allpack Seed Counting Machine

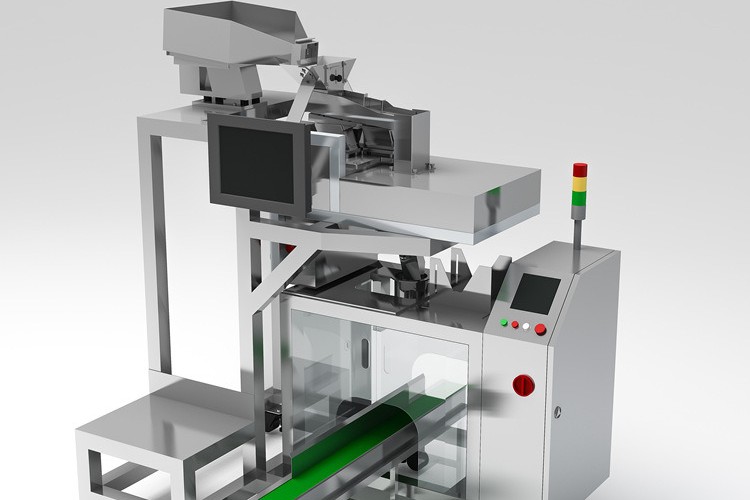

Allpack seed counting machine is a vertical form counting and packing equipment that can complete counting, bag forming, filling, sealing, cutting, coding operations, etc. This machine works by vibration and photoelectric. Equipped with a vibrating plate and a highly sensitive photoelectric sensor, the seed counting machine is able to count material accurately. The machine is also equipped with high-quality bag former, sealing, and cutting devices, which can provide perfect packaging and sealing effects. Allpack seed counting machine can make 3-side seal bags, 4-side seal bags, and back seal bags, and it is suitable for counting and packing various solid granules such as seeds, chemical fertilizers, electronic components, screws, nails, gummies, capsules, tablets, soft gels, etc.

Allpack Seed Counting Machines

Multi-purpose Automatic Seed Counting Machine

Allpack multi-purpose automatic seed counting machines can finish seed counting, bag making, filling, sealing, and cutting operations. This machine adopts an intelligent temperature control system which makes the temperature stable and provides excellent packaging and sealing effects. The seed cunting machine can pack 20-60 bags per minute without counting errors with high-speed and high production output. The machine is suitable for counting and packing all kinds of regular & irregular particle products such as vegetable seeds, candies, gummies, glass beads, screws, bolts, buttons, small batteries, etc.

High Power Motor

Emergency Stop Switch

Micro-computer Control

Vertical Form Seed Counting Machine For Solid Granules

Allpack vertical form seed counting machine is applied for various solid products such as toys, hardware, nuts, candies, diamonds, gems, nails, chemicals, and medicines. It sorts the material through its vibrating plate and uses a photoelectric sensor to count the amount. The seeds are filled into the bag which is made by the bag former, when the bag is full, it is sealed and cut. The whole working process is stable and smooth. This equipment has many advantages such as high precision, low power consumption, low maintenance, easy operation, and so on, which is an ideal packaging machine for industries.

No Product Alarm

Adjustable Bag Siz

Servo Film Transfer System

High Speed Fully Automatic Seed Counting Machine

Allpack fully automatic seed counting machine is constituted of three main parts including the lifting part, counting part, and bagging part. The seeds are delivered to the counting part by the lifter, and the machine counts seeds automatically, holding the pre-made bags, and fills products into pouches and bottles. This machine is controlled by PLC and human-machine interface which can monitor the whole working process. When there are abnormal situations such as empty bags and no bags, there will be a warning. Allpack fully automatic seed counting machine has a wide range of applications for packing seeds, capsules, tablets, soft gels, nuts, screws, buttons, etc.

Continuous Working

Adopt Anti-dust Technology

Overload Protection Function

Why Choose Us

Allpack is the leading manufacturer and supplier of seed counting and packaging solutions from China.

Our seed counting machine will make sure that seeds are counted in real-time with 100% count accuracy.

With years of experience in the industry, our team of experts understands your challenges and knows how to give you support.

As a leading seed counting and packaging manufacturer, we are committed to providing solutions tailored to your needs.

The Buyer's Guide

Seed Counting Machine:The Complete Guide In 2025

Do you know that seed counting machine is one of the most popular counting products now? This machine is to count seed, nuts, gems,mechanical parts and so on, it has high accuracy, the error is limited within 1%. As agriculture industry grows, the requirements for seed counting are higher, this is the reason why seed counting machines are put into use.

Perhaps that some of you are unfamiliar with seed counting machine, that doesn’t matter, you can learn it from now. Think about what you are curious about this machine and find the answer in this comprehensive buying guide of seed counting machine.

1. What Is A Seed Counting Machine?

Seed counting machine is a practical counting equipment which is mainly used in agriculture industry, it is used to count all kinds of seeds, grains, nuts, rice, wheat, corn and so on. As the picture shows, this machine has a compact design, you can easily operate it on desktop.

Seed counting machine can not only count seeds, it also plays a role in packaging, it counts the seeds and fills them into bags, and then seals and discharges the bags.

2. How Can Seed Counting Machine Benefit You?

As a trendy counting device, seed counting machine has its own characteristics and can benefit you a lot, however, how can it benefit you? Next you will learn some advantages of seed counting machine.

User Friendly

It is mentioned that seed counting machine is equipped with a smart control panel so that this machine is very simple to operate. You can click the buttons on the control panel and set up all kinds of parameters, thus you can say seed counting machine is user friendly.

High Accuracy

It is no doubt that seed counting machine has high accuracy, it is sensitive so that it can count products quickly and there are almost no error. With this advantage, seed counting machine can meet all high requirements and precise counting needs.

High Flexibility

Seed counting machine is applicable to seeds or other products of different sizes and shapes, it can quickly adapt to different particles and maintain high flexibility. Therefore, seed counting machine has a wide range of application, can count a variety of products.

High Speed

Seed counting machine can rapidly counts and packs large quantities of seeds because it has high degree of automation, it can count almost 1,000 seeds and pack 12 bags per minute.

3. What Are The Applications Of Seed Counting Machine?

Even though it is called seed counting machine, it isn’t only applied in agriculture industry, so, which industries can use this machine? Let’s discuss together.

Pharmaceutical Industry

Seed counting machine can be applied in pharmaceutical industry, to count capsules, tablets, softgels, it can count precise amount of pills, and then these pills are packed in bags.

Agriculture Industry

Agriculture Industry-Photo Credit:Cremer

The most common application of seed counting machine is in agriculture industry, the vegetable seeds, rices, wheat, corns, grains, beans and many other agricultural products, need to be count and packed, it is obvious that seed counting machine is a good equipment to deal with them.

Food Industry

Of course that seed counting machine is commonly used in food industry, it can count and pack nuts, candies, gummy, spices and many other granular food products. Because of its perfect performance, seed counting machine is very popular in food industry.

Jewelry Industry

Also, seed counting machine can be used in jewelry industry, you know that this machine has high precision, therefore, it is quite suitable for counting those previous jewelry materials such as gems, diamonds, rhinestones, natural ores, pearls, etc.

Manufacturing Industry

Manufacturing industry also has demand for seed counting machine since there are many mechanical parts during the production process, these objects are numerous and small so that they need to be counted by seed counting machine first.

Electronic Industry

Seed counting machine is commonly used to count all kinds of electronic components such as lithium battery, chip and other tiny objects. In the electronic industry, there are so many little components need to be counted so that seed counting machine is put into use.

4. What Is the Working Principle Of Seed Counting Machine?

To be honest, the working principle of seed counting machine is very simple, it counts seeds by using vibration and photoelectric sensor, can automatically complete counting, filling, sealing, cutting, coding and other processes.

Working Principle of Seed Counting Machine-Photo Credit:Cremer

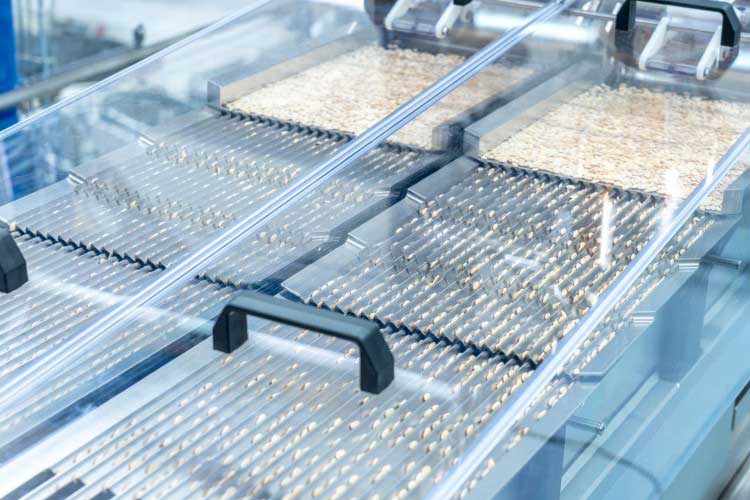

The first step is material feeding, the seeds are put into the vibrating plate, and then they are vibrated and fallen into the next station. The machine adopts photoelectric technology, when the seeds fall, the photoelectric sensor captures the seeds and takes pictures to complete the counting step.

Next step is bag filling, the counted seeds are filled into pre-made bags, and when there are enough amount of seeds filled into a bag, this bag will be sealed and discharged. Some models of seed counting machines have a printing function that will print the production date on the bags.

5. What Are The Functional Parts of Seed Counting Machine?

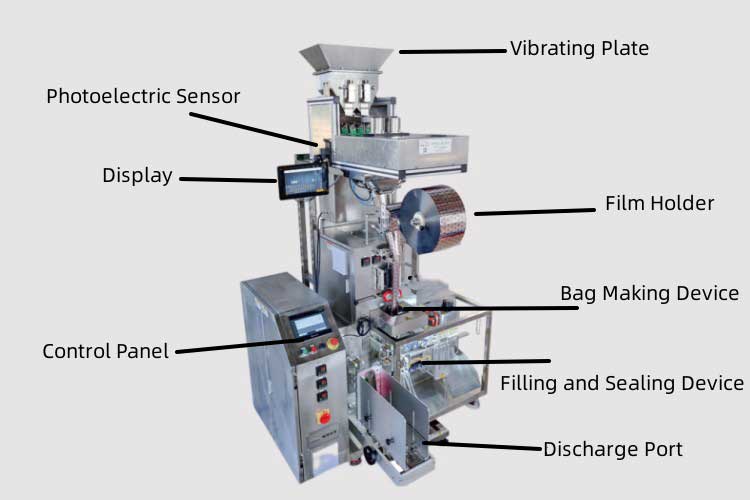

Now you have already known the working principle of seed counting machine, are you also curious about the structure of it, in the next part, you can see the main functional parts of this machine, such as:

Functional Parts of Seed Counting Machine-Photo Credit: Minpack

Vibrating Plate: The vibrating plate is to let the seeds distribute evenly by the function of vibration, which can avoid seeds overlapping and ensure counting accuracy.

Photoelectric Sensor: This part plays a role in counting, it scans the seeds which are fallen from the vibrating chute to obtain a full projection image of them and then count them.

Display: During the counting process, the number of seeds will be suggested on the display.

Control Panel: In this part, you can turn on/off the machine and set up all the parameters such as speed, amount, etc.

Film Holder: The film which is used to make packaging bags are rolled on the film holder, when the machine makes bags, the film is pulled from the film holder.

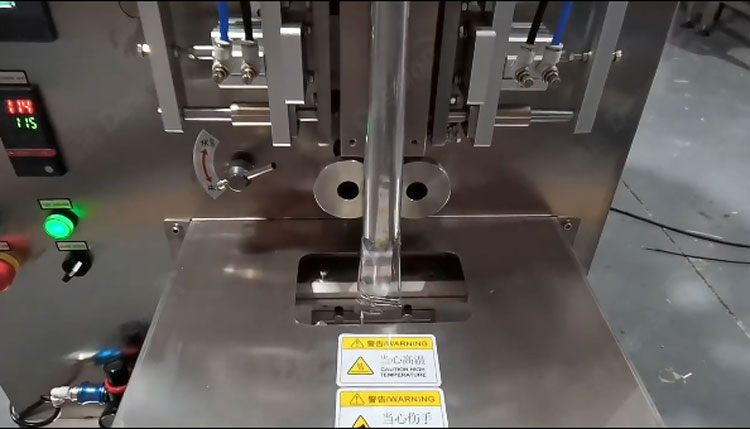

Bag Making Device: In this part, the thin film is folded and the bottom is sealed so that a packaging bag is made.

Filling and Sealing Device: After the bags are made, the counted seeds are filled into the bags, when the filling process is finished, the top of the bag is sealed and the bag is cut.

Discharge Port: After the bag is filled, sealed and cut, it will fall and slide out the discharge port.

6. How Many Types Of Seed Counting Machines Are Available On The Market?

In terms of the degree of automation, seed counting machines can be divided into three types: automatic seed counting machine, desktop seed counting machine and manual seed counting machine.

Automatic Seed Counting Machine

Automatic Seed Counting Machine-Photo Credit: Minpack

Automatic seed counting machine is produced for counting seeds, it has pretty high speed that can count thousands of seeds per minute. In addition, this machine has high accuracy rate which can reach 100%. Automatic seed counting machine is quite suitable for mass production and industries which have high precision requirements.

When using an automatic seed counting machine, the operator only need to click relevant buttons and then just wait for the counting result.

Desktop Seed Counting Machine

As the picture shows, this type of seed counting machine is small and compact, it can be easily assembled, because it doesn’t occupy too much space, you can use it on any desktop, isn’t it convenient?

Desktop seed counting machine consists of sample plates, display, control panel, frame, it is easy to operate, you need to put seeds into the sample plate, and turn on the machine, set up parameters, and then the machine will begin counting. This machine is suitable for small to medium scale production.

Manual Seed Counting Machine

Manual seed counting machine, also known as seed counting plate, there are many holes on the plate which are used to put seeds. The operator need to put seeds into the holes by hand, the speed is lower than that of automatic seed counting machine.

The size, shape and quantity of the manual seed counting machine are fixed so that it has many limitations. It can only count a certain amount of seeds for one turn, and a manual seed counting machine is not suitable for all kinds of seeds, if you have many different kinds of seeds to be counted, you should purchase several seed counting plates.

7. How Does Seed Counting Machine Differ From Tablet Counting Machine?

Are you curious about the difference between seed counting machine and tablet counting machine? The two machines are both used to count products, and in some case they are generic, however, there are also many differences between them, which are as follows:

| Seed Counting Machine | Tablet Counting Machine | |

| Appearance |  |

|

| Function | Seed counting machine is used to count the amount of products, and then it pack products into bags. | Tablet counting machine is also used for counting, and the counted products are filled into empty bottles. |

| Application | Besides seeds, seed counting machine can also used for counting pills, electronic components and even precious diamonds. | Tablet counting machine can be used to count capsules, tablets, softgels, candies, gummy, etc. |

| Classification | Seed counting machine can be divided into automatic type, desktop type and manual type. | There are different types of tablet counting machine on the market, which include fully automatic ones, semi automatic ones, manual ones and multi-channel ones. |

| Working Principle | As is mentioned that seed counting machine works by vibration and opto-electronics, it use photoelectric sensor to take pictures of products and then count them. | Tablet counting machine counts products by vibration and sensors, the products are vibrated by vibrating feeder and counted by sensors.Finally,the counted products fall into the empty bottles. |

8. What Kinds Of Products Can Be Counted By Seed Counting Machine?

As a matter of fact, seed counting machine is versatile, it can be used to count different products, such as:

Agricultural Products

Seed counting machine can be used to count various seeds such as flower seeds, vegetable seeds, fruit seeds. Besides seeds, there are other agricultural products such as wheat, rice, wheat, grain and all kinds of beans, all can be counted by seed counting machine.

Spices

Granular spices, such as sugar, sesame, pepper, mustard, prickly ash, star anise, cinnamon, etc, can be counted by seed counting machine.

Nuts

Less is known that seed counting machine can be used to count small particle size nuts, including melon seeds, peanuts, walnuts, pistachios, cashews, almonds, hazelnuts and so on.

Jewelry Accessories

Seed counting machine can count tiny diamonds, gemstones, rhinestones, drills and other jewelry accessories, its high precision can avoid waste of these precious objects.

Candies & Gummy

Candies and gummy are small sized objects and they can be packed in bags, therefore, seed counting machine is a proper equipment to count and pack them.

Nails

You can also use seed counting machine to pack nails and screws, it can count the amount of them accurately and fill them into bags, the process is convenient and safe.

9. Are There Any Expanded Functions Of Seed Counting Machine?

Even though the seed counting machine looks like a small and simple equipment, it has many expanded functions which can improve its performance, want to know them? Please keep on reading.

Modular Design

Seed counting machine adopts modular design, its components are easy to remove and install, which means that you can easily replace components by yourself, moreover, you can customize your own seed counting machine by using more advanced components.

Automatic Deceleration

Seed counting machine has a special automatic deceleration function, when you start operating this machine, you set up a counting number, during the counting process, if the machine detects that it is close to the setting number, the counting speed will be slow down gradually.

Self-stop

When there are no items on the vibrating plate to count, the seed counting machine will stop by itself, isn’t that function convenient for you? You don’t need to monitor the whole counting process of the machine because it is smart enough.

Fast Changeover

Seed counting machine has a one button clearing function, which means that you need to count and pack another type of seed, the machine can provide a fast changeover, more convenient for industries which need to produce various products.

Optimized Algorithm Software

Seed counting machine adopts a optimized algorithm software which can effectively distinguish overlapping objects and microscopic impurities, as a result, the precision of the machine is higher.

Intelligent Alarming System

Seed counting machine is equipped with an intelligent alarming system which will warn you when there are abnormal situations and shortage. If you find that are notice on the screen of the machine, there is something wrong with it.

10. Can Seed Counting Machine Work With Other Automatic Machines?

The answer is “Yes”, seed counting machine can work with other machines to form a production line. What are these machines? Next they will be introduced to you.

Vacuum Feeder

Vacuum feeder is widely used for material delivery application, it can deliver powders, granules and liquids from origin to destination. This machine works by suction, it sucks raw materials from origin and transports them through pipelines to the destination.

How can vacuum feeder help seed counting machine? It can work with seed counting machine to help it deliver seeds so that you don’t need to feed seeds by your hand.

Tablet Coating Machine

The tablet coating machine can work well with the seed counting machine, this machine uses spray nozzle to spray coating solvents on the raw materials, and then uses hot air to dry them. The purpose of coating is to remain the original property of the raw material and prevent them from being damaged.

So how can the tablet coating machine can work with the seed counting machine? Well, before the seeds enter the vibrating plate of seed counting machine, they need to be coated by tablet coating machine first. Why? This operation is to resistant to pests, prevent seeds from being eaten by bugs in the ground.

11. How Can You Operate A Seed Counting Machine?

As a matter of fact, seed counting machine is not s small machine, if you don’t operate it correctly, there is a possibility of damaging machine. However, how can you operate this machine, let’s learn together.

Generally speaking, seed counting machine can be divided into counting mechanism and packaging mechanism. Firstly, you need to connect the power supply of the machine so that it can start to work.

Then you need to find the control panel which is on the left side of the machine and turn on the counting and packing mode. Note, to set the quantity of seeds you need to count and how many bags you need to pack.

Next there is an essential step, you need to install the film on the film holder, pull it neatly, and adjust the film holder, and then, click the “start” button. The subsequent counting and packaging steps will be automatically completed by the machine, and you only need to monitor the entire workflow by the side.

12. Are There Any Precautions When Operating A Seed Counting Machine?

- Note that you need to clean the seeds before counting, ensure that there are not dusts attached on them, this is because that dust and other irrelevant substances will affect the judgment results and cause counting errors.

- Do not pour too many seeds for each time, feed according to the capacity of the vibrating plate.

- Be careful not to touch the buttons of seed counting machine with sharp objects or other hard objects, otherwise it may cause damage.

- Every time you press each function button to switch, remember to press the "Reset" button first to continue operating.

- After finish using the seed counting machine, you need to clean the vibrating chute and vibrating plate carefully.

- After finish using the seed counting machine, remember to turn off the power supply before leaving the site, otherwise it is easy to cause dangerous accidents of electric shock.

13. How Can You Solve The Common Problems When Operating A Seed Counting Machine?

When operating a seed counting machine, there might be some malfunctions, sometimes these problems are easy to be solved by yourself, next there are some common problems and their solutions shown.

Inaccurate Counting

When seed counting machine is working, if there are situations such as inaccurate counting or no counting, what should you do? You need to check whether there are large particles block the vibrating chute which influence the normal fall of seeds, if there are, remove them.

Machine crash down

If the machine crashes, or the buttons do not work, you can try to turn off the machine and restart it to check whether it can work normally. If the display does not light up after powering on, you need to check whether the plug, wire or switch fuse is normal, if not, replace the faulty parts.

Poor Sealing Quality

If you find that the bags have poor sealing quality, there might be several causes and solutions, first of all, check whether the bag sealing device is cleaned, and avoid sealing stains.Secondly, check whether the sealing temperature and sealing time are set appropriately.

Finally, check whether there is any abnormality in the operation of the sealing relay.Figure out the cause of this malfunction, and then prescribe the right medicine.

Conclusion

Overall, seed counting machine can be a good assistant for you, it can meet most of counting demands. Read by here, do you think you have a primary understand of seed counting machine? Have all your questions been resolved? If you have other puzzles about this machine, please contact us, you will get a reply at once.

Allpack Seed Counting Machine Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours