Your Best Tape Dispenser

- Intelligent CNC Operation Interface

- Corrosion-resistant Body

- Infrared Sensor Function

Tape Dispenser

Tape dispensers are devices which hold, dispense and cut tape. They are designed to help make tape dispensing quick and easy, especially for applications where tape is used regularly. Tape dispensers help to increase efficiency and reduce tape waste. Allpack tape dispenser is designed compact and simple, it has small size and it is easy and convenient to operate. Although it is small, it has large capacity, is suitable for different types of tapes. Allpack tape dispenser can be used to pack all kinds of objects such as cartons, pouches, books, etc, it is widely applied in various industries, especially in express industry. Allpack provides different types of tape dispensers, which include gummed tape dispenser,electric tape dispenser and manual operated tape dispenser.

Tape Dispenser

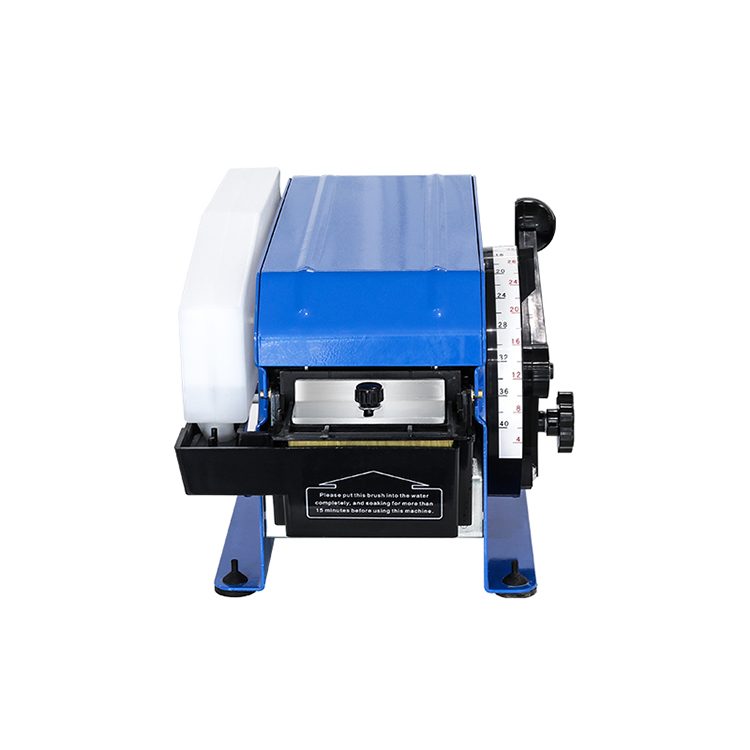

FX-800 Small Sized Gummed Tape Dispenser

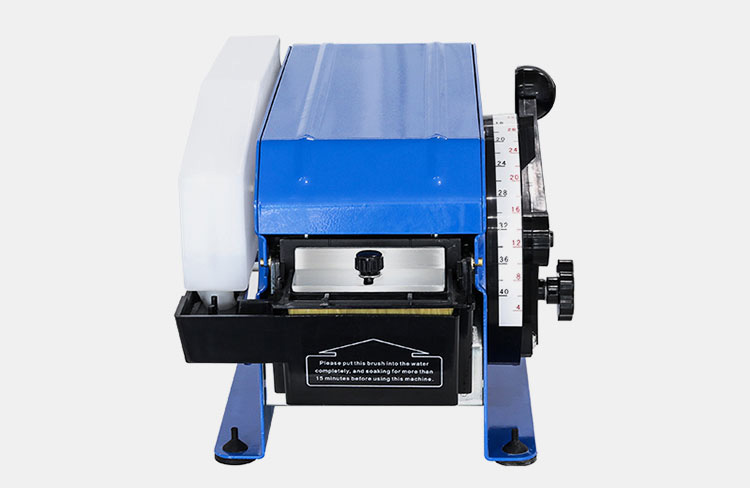

Allpack FX-800 small sized gummed tape dispenser is suitable for paper tape, and the length of tape can be adjusted according to real requirement. This tape dispenser is semi automatic mode, it is equipped with ruler, which is used to custom tape length. The machine can dispense paper tapes continuously so it has a high production efficiency. This gummed tape dispenser can adapt to tape whose length is between 100-1000mm and width is between 20-100mm.

Large Storage Capacity

Free Choice Of Cutting Length

Flexible Width Adjustment

FX-800B Practical Semi Automatic Tape Dispenser

The FX-800B practical semi automatic tape dispenser is a type of kraft paper tape dispenser, it is suitable for tape whose width is between 20-80mm and roll diameter is 220mm. This tape dispenser is compact,portable and durable, it has long service life. It can feed paper automatically and dispense paper accurately, the speed of it can up to 600mm per second, which can largely increase the production efficiency.

Environmental Protection

Automatic Coat Of Water

Adjustable Length Of Paper

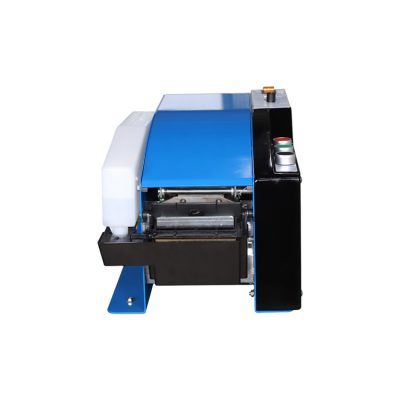

FX-800P Electric Tape Dispenser

Allpack FX-800P electric tape dispenser is suitable for assembly line operation of high speed packaging, it takes advantages of dual motor driven, intelligent operation, durable, safe, stable performance, environment friendly and easy to operate. The width of paper is adjustable, the maximum width is 80mm, besides ,the tape dispenser is equipped with uniform wet water brush which increases the durability of it.

Automatic Paper Dispensing Function

Digital Touch Screen

Self-lubrication Blade

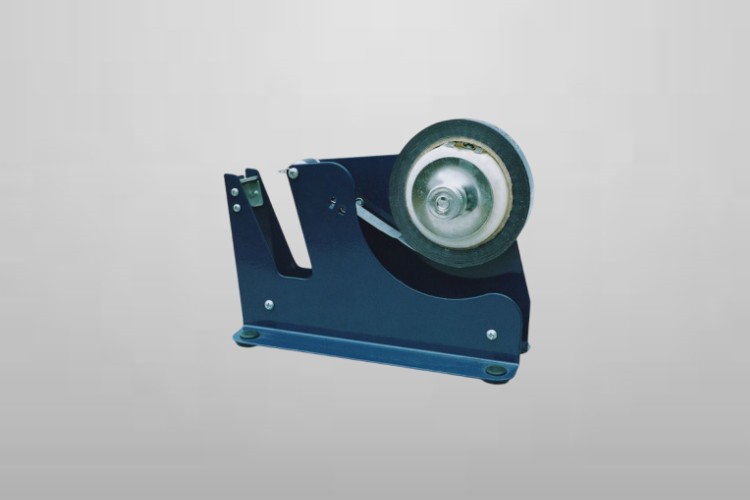

TD-A Manual Type Tape Dispenser

The TD-A manual type tape dispenser has a simple structure, it is a manual type tape dispenser which is very easy and convenient to use. It is equipped with a tape holder to storage tape and it also has a blade to cut off tape, it is suitable for family use, express industry,small shops, supermarkets and so on. This manual tape dispenser is durable since it has a hard metal construction, moreover, it is multi-functional so that is is recognized by many people.

Heavy-duty Metal Frame

Compact Design Desktop Tape Dispenser

Ease Of Use

TD-C Manual Type Tape Dispenser

Allpack TD-C manual type tape dispenser is designed compact and lightweight, it is portable and convenient to use, it consists of three main parts: metal frame, tape holder and cutting blade. With such a simple structure, this manual tape dispenser is easy to operate by everyone, it can adapt to various tapes which are different in width, diameters and materials, in a word, this is an equipment which brings large convenience for people no matter they use it for family or industrial.

Safe To Operate

Quick&Accurate Cutting

Adjustable Tension

The Buyer's Guide

Tape Dispenser: The Complete Buying Guide In 2025

Have you ever wondered how the cartons are sealed by tapes? The machines we daily use for sealing cartons are called tape dispenser. Those tape dispensers are put into packaging industrial production in large numbers especially for cartons. Let’s take a look at this machine together!

Let’s get started now!

1.What Is The Tape Dispenser?

Tape Dispenser

Tape dispenser is a device that holds the tape and has the ability to cut the tape. Tape dispensers come in different models and sizes. And it varies according to the size of the matching tape. The tape dispenser is made of plastic. And are usually single-use items.

The tape cutting machine is a device used for tape cutting, and the cutting width of the tape cutting machine is 6 – 60 mm.

Tape dispenser is widely used for sticking the reinforced gummed tape,which can lower packaging cost.

Tape dispensers have various functions including high appearance and precise length, safety switch, multiple selection operating mode, improve packaging efficiency, easy to use, sensor function and so on.

2.How Many Types of Tape DispensersAre There?

There are many types of tape dispensers. From the first aspect, there are the manual type and the automatic type of tape dispenser. The manual type includes handheld tape dispenser. The automatic type includes electrical tape dispenser and the pneumatic tape dispenser.

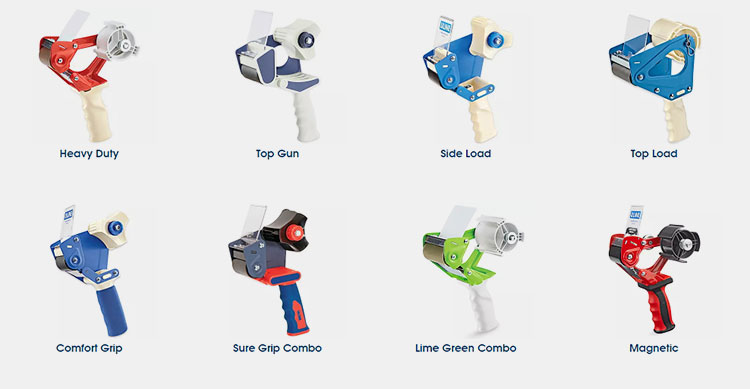

Handheld Tape Dispenser

The Handheld Tape Dispenser is a device that simply cuts tape. This device is fitted with a roll of self-adhesive packaging tape. With one handle, apply the desired length of tape to the package. This device is specially used for small amount or individual carton packaging.

There are many types of Handheld Tape Dispenser including heavy duty tape dispensers, top gun tape dispensers, side load tape dispensers, comfort grip tape dispensers, sure grip tape dispensers, lime green tape dispensers, and magnetic tape dispensers.

ElectricalTape Dispenser

Electrical Tape Dispenser is mainly driven by electricity. It has the advantage of being faster and easier to operate than a manual dispenser. But the Electrical Tape Dispenser is more expensive.

Electrical Tape Dispenser is suitable for commercial or factory use. Because the Electrical Tape Dispenser is more efficient. Suitable for large events and projects. It is a powered machine and does not require any manual operation to cut the tape.

Electrical Tape Dispenser has many functions, and the functions can meet most commercial needs.

Pneumatic Tape Dispenser

Pneumatic Tape Dispenser is the most expensive of the three tape dispensers. Pneumatic Tape Dispenser is the most efficient and fastest tape dispenser among the three tape dispensers.

Pneumatic Tape Dispenser is best suited for industrial applications. Pneumatic Tape Dispenser is most suitable for encapsulating large cartons.

Different types of tape dispensers have different applications, and do you know what’s their applications and components?

3.Which Industries Are Tape DispensersMostly Applied?

A Tape dispenser is a device that is used to hold and dispense adhesive tape. A Tape dispenser is an essential tool in many industries. It is strong and durable and can be reused many times.

It is widely used in many industries, such as packaging, printing, and food processing.

Packaging Industry

Packaging Industry

The tape dispenser is often applied in the packaging industry, such as express packaging, gift packaging and large luggage packaging, which are often used in this machine, which is very convenient, and can be put into use on a large scale, which can bring very high efficiency.

Printing Industry

Printing Tapes

Many tape dispensers are often applied in the printing industry. Because many tapes are now made into tapes with many patterns or colors. This makes it possible to distinguish between different packaged items and to attract more attention.

Food Processing Industry

Food Packaging

In the food processing industry, a tape dispenser is used to seal food containers. By sealing them from a tape dispenser the food can be preserved for a longer period of time. For example, different foods need to be packaged with different tapes.

Some tapes may cause certain harm to the human body if they are directly used for food packaging due to different materials. Some materials are very environmentally friendly, so they can be directly used to package food without any harm to the human body.

4.What Are The Components Of The Tape Dispenser?

Different type of tape dispenser have different parts. Do you know how many parts they have and what is there part differences?

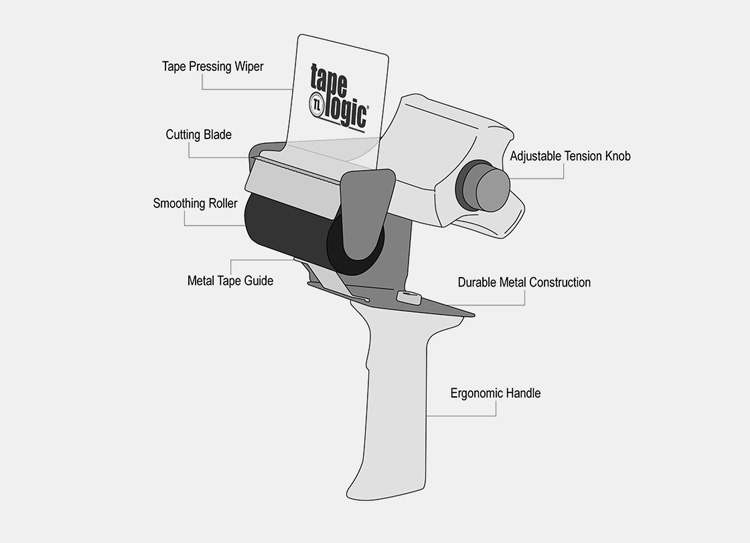

Components of Handheld Tape Dispenser

There are 7 parts of the manual type tape dispenser including: Tape Pressing Wiper, Cutting Blade, Smoothing Roller, Metal Tape Guide, Adjustable Tension Knob, Durable Metal Construction, Ergonomic Handle.

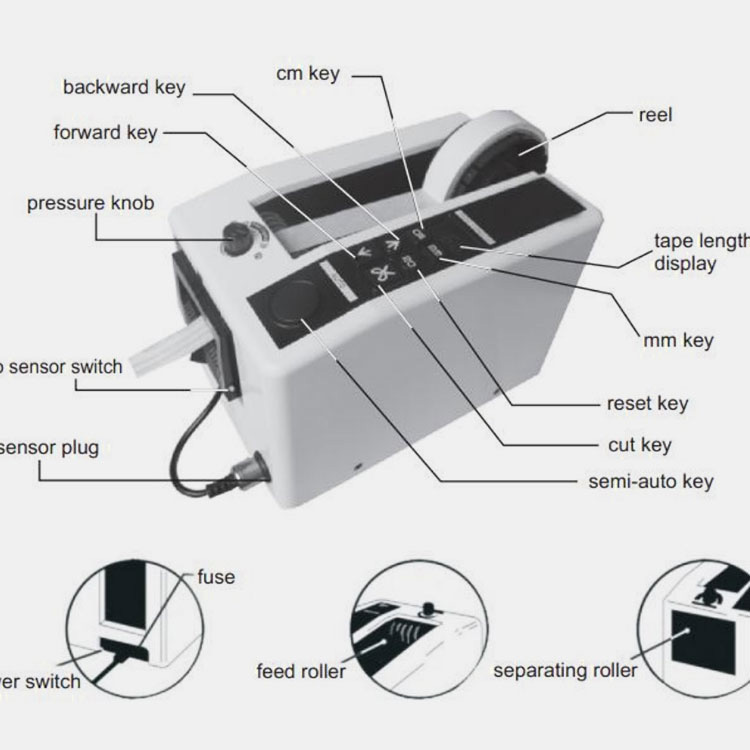

Components of Electrical Tape Dispenser

Automatic Tape Dispenser

There are 12 parts of the automatic tape dispenser including: CM Key, Backward Key, Forward Key, Pressure Knob, Sensor Switch, Sensor Plug, Semi-auto Key, Cut Key, Reset Key, MM Key, Tape Length Display, Reel.

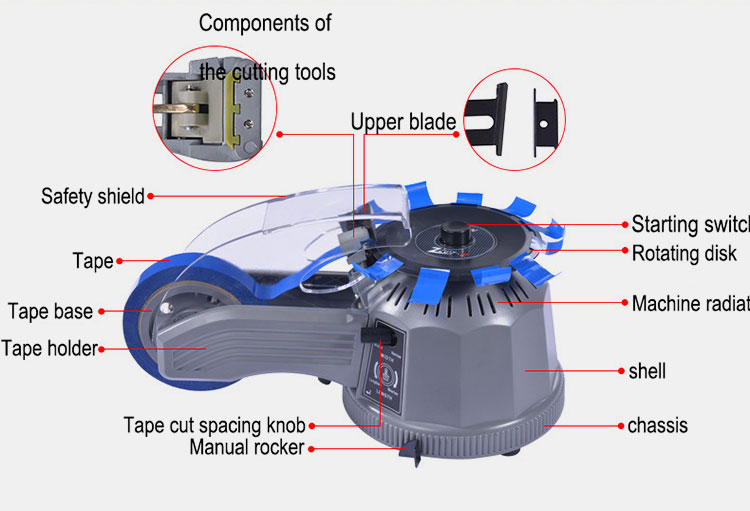

Components of Pneumatic Tape Dispenser

There are 13 parts of the pneumatic tape dispenser including: Safety Shield, Tape, Tape Base, Tape Holder, Tape Cut Spacing Knob, Manual Rocker, Chassis, Shell, Machine Radiate, Rotating Disk, Starting Switch, Upper Blade, Components of the Cutting Tools.

The parts composition of Pneumatic Tape Dispenser is the most complex and the most parts tape dispensers among the three styles. This needs to be more maintained and monitored. When put into use, you need to pay more attention to the way you use it.

5.What Are The Features Of The Tape Dispensers?

The features of the different types of the tape dispensers are different. Here are the differences:

Features of Handheld Type Tape Dispenser

Serrated blade cuts tape cleanly.

Easily tear the tape.

The blade of dispenser in sharp but safe.

Features of Electrical Tape Dispenser

Automatic paper releasing function.

High speed of feeding tape (1.1m/s).

Intelligent operation.

Adopting step motors for paper feeding and cutting.

One-way valve on the water tank.

Using a self-lubricating blade.

Optional laser range finder.

Features of Pneumatic Tape Dispenser

The tape cutting machine is mainly used for cutting various tapes, cutting them into the width and length required by customers. The maximum cutting width without roller design is 60mm.

Memory function (six groups of different lengths can be freely set for supply and application before operation). The film can be easily fixed through the elastic film auxiliary shaft.

Preset, cycle and job count functions allow two rolls of tape to be used at the same time. Protection device, a safety protection baffle is added at the knife edge. Precise digital control of cut length.

There is no need to adjust due to the thickness of the tape. Built-in pliers, lubricating oil, partition for easy operation Anti-static ABS material.

To improve safety, when the warning device operates and the tape machine is suspended, even if the blockage is cleared, the tape machine will stop.

It will not work immediately, and it can be used normally only after pressing the start button again.

6.What Are The Working Modes Of The Tape Dispenser?

For the handheld tape dispenser, there is only 1 working mode and it is suitable for own use.

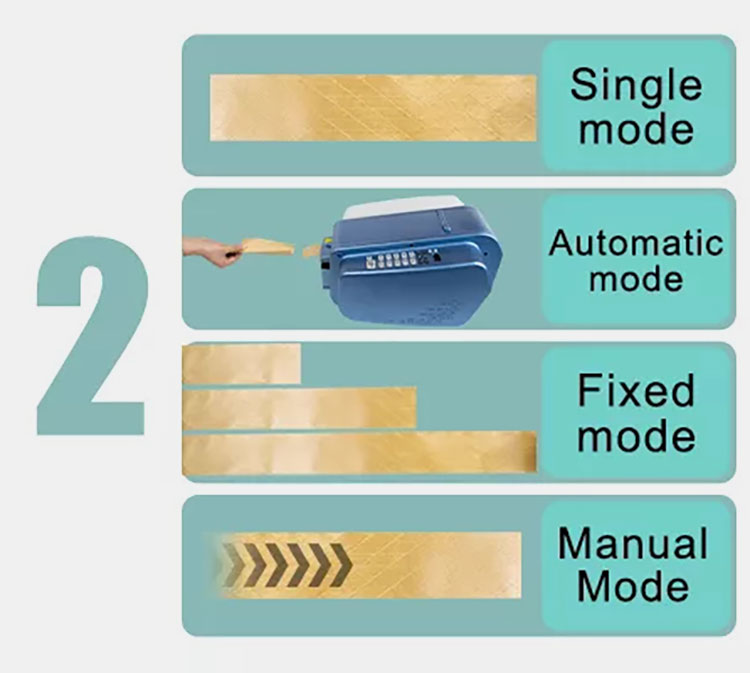

There are multiple working mode of the automatic tape dispenser including electrical tape dispenser and pneumatic tape dispenser, and the main working mode are 4.

The Working Mode of the Automatic Tape Dispenser

Single mode: Select different length to produce the selected length tape.

Automatic mode: Select one length and all the rest with same length to be produced automatically.

Fixed mode: Select several different sizes and produce the tapes as per the

setting order.

Manual Mode: Long Press Production Tape

The Characteristics of the Working Mode of the Tape Dispenser

High Safety Level

Safety interlock switch disables cutting mechanism when cover is open,prevents worker injury.

Multi Working Mode

Including single mode, automatic mode, fixed mode, manual mode.

Fast And Efficient

Tape output at 30 cm per second.Offer one-touch dispensing of tape lengths from 15 cm to 210 cm.Brush position with heating function to enhance brushing effect.

Quality Assurance

The cutter, brush, motor and LCD display of the tape machine are all tested in the laboratory. Our machine is guaranteed for 2 years.

From applying different types of working mode of tape dispenser, you can realize your various tape dispensing purposes.

7.What Are The Operations Of Tape Dispensers?

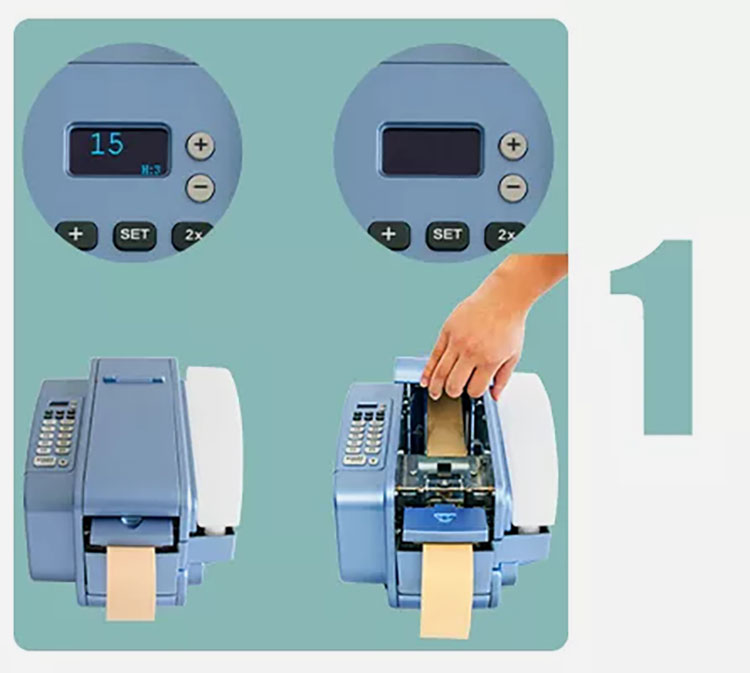

The handheld tape dispensers are simple to operate so we are mainly learning about the automatic type operation here.

The operation of the automatic tape dispenser is quite simple and you can learn it easily by reading the steps below.

The tape dispenser is a very simple, but essential, office tool. It is used to hold and dispense adhesive tape. Most tape dispensers have a cutting blade built into them so that the user can cut the tape to the desired length. And there are 4 steps for you to use the tape dispenser.

There are 6 steps to work the automatic tape dispenser. When you are using this type of tape dispenser, please follow the following steps.

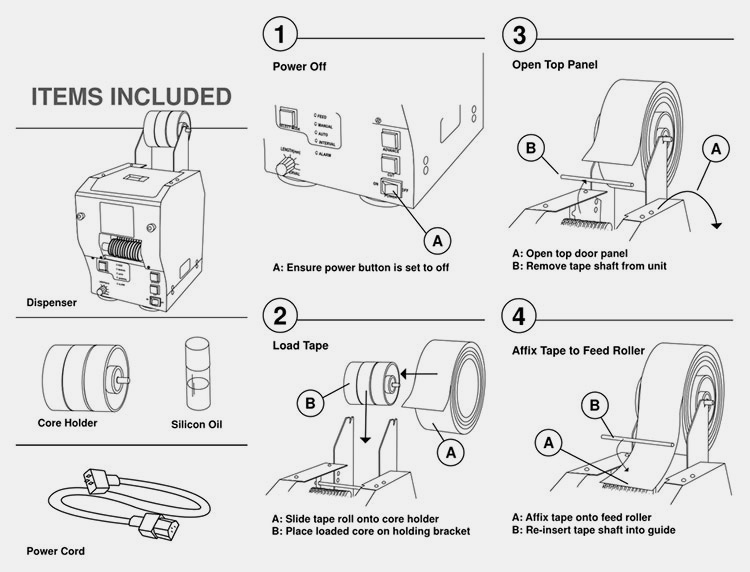

Power Off

Please ensure the power button is set to off then taking the following steps.

Load the Tape Into the Dispenser

- Slide tape roll onto the core holder

- Place loaded core on holding bracket

The first thing you need to do is load the tape into the dispenser. To do this, you will need to remove the top cover.

Open the Panel

Open top door panel

Remove tape shaft from unit

Once the top cover is removed, you can feed the end of the tape through the slot in the dispenser base and then wind it around the spool inside the dispenser.

Affix Tape to Feed Roller

Affix tape onto feed roller

Re-insert tape shaft into guide

Once you have wound enough tape around the spool, replace the top cover and you are ready to use your dispenser.

Pull the Tape Out

To use the dispenser, simply hold it in one hand and pull the desired amount of tape out with the other hand. The cutting blade will automatically cut the tape at the correct length.

Peel Off the Backing Paper

You can then peel off the backing paper and apply the adhesive tape to whatever surface you need it on.

The next time you need to use adhesive tape, make sure you have a trusty tape dispenser by your side!

8.What Are The Advantages And Disadvantages Of The Tape Dispensers?

There are a lot advantages both for manual tape dispenser and automatic tape dispenser.

Tape Dispenser

Advantagesfor Handheld Tape Dispenser

- It has a very low cost as compared to the electric dispenserand the pneumatic tape dispenser.

- It increases the efficiency level while packaging.

- It is made for low and middle-scale industries.

- It does not require any special training before using.

Advantages for Electrical Tape Dispenser

It is more efficient than the manual one, and it is customizable.

It does not require any manual working and extremely fast.

Improve operational efficiency, productivity and throughput. Reduce labor costs. Save material cost and reduce material waste.

Improve working pressure and provide operators with a good working environment.

It also risks free to use.

Advantages for Pneumatic Tape Dispenser

The pneumatic tape dispenser machine works very fast. It cuts the tape more quickly than cutting it by hand. In just one minute you can seal a great number of packages due to its fast speed.

Pneumatic tape Dispenser is very easy to use and you can get the perfect seal every time. It does not require any special education before starting working.

It is a great way to show your customers that you care about their satisfaction by providing them with a high-quality seal.

Also, it is very efficient and smooth in working. The efficiency level of the tape dispenser is very high. It smoothly packages all the packs.

Disadvantage:

For manual tape dispenser, there is a disadvantage including:

- It requires some human effort to cut the tape.

For automatic tape dispenser, there are disadvantages including:

- It is expensive to purchase.

- It requires electricity to work.

For pneumatic tape dispenser, there is a disadvantage including:

- The price is a little high.

9.How Many Types Of Tapes Are ThereApplied To The Tape Dispenser?

Kinds of Tapes

There are many different types of tape that can be used for packaging, but not all tapes are created equal.

Some tapes are stronger than others, and some are better suited for particular applications. Here is a rundown of some of the most popular types of packaging tape:

Clear packing Tape

Clear Packaging Tape

This is one of the most commonly used types of packing tape. It is strong and versatile and can be used on many different types of surfaces.

Brown packing Tape

This type of tape is often used for heavy-duty packaging. It is very strong and resistant to tearing.

Masking Tape

This type of tape is not as strong as packing tape, but it is useful for sealing lighter packages. It is also easy to write on, which makes it ideal for labeling packages.

Scotch Tape

This type of tape is not as strong as packing tape, but it is useful for sealing lighter packages. It is also easy to write on, which makes it ideal for labeling packages.

Duct Tape

This type of tape is very strong and can be used for a variety of applications. It is often used for repairing damaged packaging or sealing leaky packages.

10.What Are The Suitable Tapes For Different Types Of Tapes Dispensers?

The different model tape dispensers are matching with different tapes. When you are applying the tape dispensers, you may consider what’s the matching tapes. With the table below, you will understand how to choose the right tapes for your tape dispensers.

Here is the list below:

| No. | Model | Cutting Length | Cutting Width | Maximum External Diameter | Suitable Tape | Dimension | Weight |

| 1 | M-1000 | 20-999mm | 7-50mm | 180mm | Adhesive Tape | 137*218*150 mm | 2.5 Kg |

| 2 | M-1000S | 5-999mm | 3-50mm | 180mm | Adhesive Tape | 137*218*150 mm | 2.5 Kg |

| 3 | ZCUT-2 | 11-59mm | 3-25mm | 130mm | Adhesive Tape | 130*165*170 | 2.8Kg |

| 4 | ZCUT-9 | 5-999mm | 6-60mm | 300mm | Both Adhesive and No Adhesive | 116*140*213mm | 2.5 Kg |

| 5 | ZCUT-10 | 8-70mm | 3-25mm | 300mm | Adhesive Tape | 126*150*250mm | 2.5 Kg |

| 6 | ZCUT-870 | 8-70mm | 3-25mm | 300mm | Adhesive Tape | 126*150*250mm | 2.5 Kg |

| 7 | RT-3000 | 9-61mm | 5-25mm | 150mm | Adhesive Tape | 120*150*250mm | 2.2Kg |

| 8 | RT-5000 | 5-999mm | 6-50mm | 300mm | Both Adhesive and No Adhesive | 115*140*215mm | 2.8Kg |

| 9 | RT-7000 | 5-999mm | 6-60mm | 300mm | Both Adhesive and No Adhesive | 116*140*213mm | 2.5Kg |

| 10 | ED100 | 5-999mm | 7-55mm | 180mm | Adhesive Tape | 140*157*240mm | 3.0Kg |

After knowing the matching tapes for different tape dispenser models, you will know how the choose the matching tapes for your own dispensers and know how to apply those tapes.

11.How To Refill The Tapes For The TapeDispenser?

Refilling of Tape Dispenser

If you’re like most people, you probably use a lot of tapes. Tape is great for packaging, sealing envelopes, and a variety of other tasks. But what happens when you run out of tape?

The good news is that it’s easy to re-fill your tape dispenser. All you need is some tape and a little bit of time.

Refill the tapes

First, remove the empty roll of tape from the dispenser. Next, take the new roll of tape and thread it through the dispenser. Be sure to leave enough slack so that the dispenser can grip the tape.

Finally, pull the end of the new roll of tape until it’s tight. You may need to use a pencil or other object to help feed the end of the tape through the dispenser.

That’s it! You’re now ready to continue using your tape dispenser.

12.What Are The Recommended Type Tape Dispenser?

There are various excellent tape dispensers including handheld one and automatic one. The list below are the recommended type tape dispenser for your future use and hope it can help you.

Recommended type 1- Gummed Tape Dispenser

If you want a high efficiency tape dispenser but only for own use then we highly recommend this one.

This is a type of tape dispenser with the semi-automatic mode which can make your work more efficient.

This tape dispenser is equipped with ruler, which can custom cut length output paper continuously and increase of the efficiency.

Large capacity water tank can hold with large storage capacity, one-time water lasting use, and simple disassembly.

Recommended type 2- Tape Dispenser / Zcut 9

If you want a high efficiency with electrical supplying working and without labor work, we are highly recommended this one.

It is built-in double sensors,pliers, lubricating oil, partition for simple operation.

It can be applied in protective film, aluminum foil and copper foil, insulation material.. etc

It can be used to cut fiber sericin belt, hard tape, acetate, glass wall paper, double-sided adhesive, nomex, sealing glue.

These two types are the best that we high recommended you to have a try. And if want to know more about other types of tape dispensers, that you are welcome to come to us, and choose the best type for your own.

Conclusion

In conclusion, the tape dispenser is the dream machine for packaging cartons and so on. It makes the work easier and saves a lot of time with high efficiency. It also reduces human effort. After knowing all the things about the tape dispenser you may know how to choose the prefect tape dispenser for yourself. If you have any questions regarding the tape dispenser, you are welcome to us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586