Two Common Packaging Methods-Shrink Packaging VS Vacuum Packaging

As a fact,there are two common packaging methods in the market-shrink packaging and vacuum packaging,if you always go to the supermarket,maybe you will find that some products are respectively packaged by these two different packaging methods.

But,have you really thought about the two packaging methods?Why some products are shrink packaged while others are vacuum packaged?What are the differences between them?Which one is suitable for your demand?Now please explore the answers from this article.

1.What is shrink packaging VS vacuum packaging?

At the first part,we need to resolve the basic problem,what is shrink packaging and what is vacuum packaging,in other words,what are the definitions of them.

Shrink Packaging

Shrink packaging is to wrap product with a plastic film which is accord with the size of it,then begin the operation of heat-sealing,under the influence of the heat,plastic film is shrinking constantly until it fit tightly to the surface of product.

Shrink packaging originated in the mid-1960s and developed rapidly in the 1970s,it is widely used by some economically developed countries.

Vacuum Packaging

Distinct from shrink packaging,vacuum packaging is to extract the air from the container of product,to make it under a low-oxygen condition in which microorganism can not survival and reproduce.

The appearance of vacuum packaging is earlier than shrink packaging,it first appears in the 1940s,and after 1950s,it has developed in a fast speed.

2.What are the effects of shrink packaging VS vacuum packaging?

In the basic case,the purpose of shrink packaging and vacuum packaging is to storage products for longer time,and besides,they also have other effects,which are as follows:

Effects of Shrink Packaging

Moistureproof and Waterproof

Because of the leakproofness of shrink packaging,you can ensure that there is no moisture inside the packaging film,therefore,shrink packaging is moistureproof and waterproof.

Anti-pollution

Through shrink packaging,the products are sealed in plastic films so they will not contact with dust in the air or other environmental elements,as a result,shrink packaging achieves the function of anti-pollution.

Avoid Shock

In fact,when the product is stuck, the plastic film which is wrapped around it can plays a role in buffer,protects the product to a certain degree.Moreover,if the product which is shrink packaged is a fragile object,the film can prevent splashes when the product is broken.

Effects of Vacuum Packaging

Prevent food oxidation

Sometimes,there are some fatty foods,they contain a lot of unsaturated fatty acids,which are easy to influenced by oxygen and come to oxidation.Vacuum packaging extract the air,so it can effectively avoid food oxidation.

Prevent Pollution

The reason why vacuum packaging can prevent products from pollution is that,by using vacuum packaging,the products is wrapped in the packaging pouch and don’t touch outside environment,so possible pollution is avoided.

Keep a Good Appearance

The same as others,principle of this is also because vacuum packaging can keep food in a low oxygen condition,which inhibits the survival and reproduce of the microorganism,so that the food can keep in a original appearance.

Crush Resistance

During the vacuum packaging,after extracting the air, there are other gases filled into packaging pouch,then the air pressure in the pouch is greater than the air pressure outside the pouch, which can effectively prevent the crushing deformation of the food and does not affect the appearance of the pouch.

3.How many types of shrinking films and vacuum packaging pouches there are?

In general,there are different types of shrinking films and vacuum packaging pouches,which are made of different materials and are adapted to different products.

Shrinking Films

PE Film

This kind of film is suitable for wine, cans, mineral water, all kinds of beverages, cloth and other products of the whole collection packaging,it takes advantages of flexibility and tear resistance ability.

In addition,the PE film is hard to be damaged and the shrinking percentage of it is high.

PVC Film

The PVC film has features of high transparency,high glossy and high shrinking percentage.

POF Film

POF refers to multi-layer co-extruded polyolefin thermal shrinkage film,it has high surface gloss, good toughness, high tear strength, uniform thermal shrinkage.

OPS Film

OPS film is type of shrinking film which is standard to the environmental protect requirements,it has high strength, high rigidity, stable shape, and has good gloss and transparency.And the OPS film is convenient in processing,coloring and printing.

Pet Heat-shrinkable Polyester Film

This film is stable under normal temperature,but while the temperature up to glass transition temperature,it starts to shrink.It has many advantages,and the most special one is that there is no renaturation of it, which makes it has a certain anti-counterfeiting function.

Vacuum Packaging Pouches

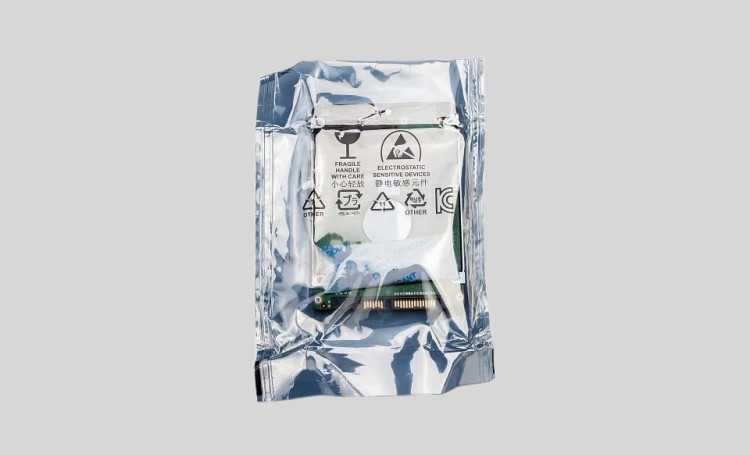

Aluminum Foil Vacuum Pouch

The material of this vacuum pouch is generally PET/AL/CPE or PET/NY/AL/CPE,This product has good performances such as anti-static, oxygen, shielding, moisture-proof, shading function and excellent heat sealing.

Aluminum foil vacuum pouch is widely used in food, electronics, chemical and other industries. Because the raw material of aluminum foil itself is expensive, the cost of vacuum will be relatively high.

Nylon Co-extrusion Vacuum Pouch

Nylon co-extrusion vacuum pouch is made of PA, EVOH and PE, PP, TIE and other resins.It has the characteristics of pollution-free, high barrier,low cost, small capacity ratio, high strength, flexible structure and so on,and it makes the production process of food packaging materials realize pollution-free.

Nylon Composite Vacuum Pouch

The material of nylon composite vacuum pouch is similar to nylon co-extrusion vacuum pouch,the difference between them is the technology,the composite pouch is made up of multiple layers of materials.

PE Vacuum Pouch

PE vacuum pouch is the most widely used vacuum pouch in the market because the price is cheap,that is,high cost performance.But,it has disadvantages of high breathability and low leakproofness,as a result,it’s easier to be broken.

4.What are the pros and cons of shrink packaging VS vacuum packaging?

Certainly,nothing in the world is perfect,both the two packaging methods have their own pros and cons,which will be explained in detail to the below.

Pros of Shrink Packaging

Adaptable

As is mentioned above,shrink packaging to heat the film which is cover around the product,then it is wrapped tightly to the products,so that it is adapted to products of various shapes and sizes.

Transparency

The film which is around the product is transparent,so people can directly see the appearance of the product,which is convenient for purchase.

Stable

The close and tight contact between the film and the product can increase the stability of the product,prevent it from moving position.

Save Labor

Both the packaging technology and packaging equipment of shrink packaging are simple,which makes it convenient for shrink packaging realizes automatically production,save the investment of labor.

Cons of Shrink Packaging

Can Not Be Recycled

One of the cons of shrink packaging is that it is hard to recycle,as the shrink packaging is to tightly wrap the product itself,the recovery rate is relevantly reduced.

Not suitable For Heat Sensitive Products

If there are some heat sensitive products,shrink packaging is not appropriate for them.So,in fact,shrink packaging isn’t suitable for all kinds of products.

Energy Consumption

In addition,the precondition of shrink packaging is heat,to reach the required temperature,there is much energy that consumed.

Pros of Vacuum Packaging

Retain the Original Taste

Vacuum packaging can make sure that food is sealed in packaging pouch,it will not contact with air,so it can keep the same condition as when it is packaged.As a result,the taste of food is also retained.

Save Space

Vacuum Packaged products are compact and organized,when you put them into your refrigerator or other places,they will not occupy too much space,in other word,vacuum packaging can save your space.

Reduce Cost

By the way,vacuum packaging can reduce the cost which you spend in packaging food or other products because its packaging procedure and raw material are simple.

Convenient

Similar to the last point,the whole operation process of vacuum packaging is more simple than shrink packaging,it doesn’t have so many complex procedure,so vacuum packaging is convenient.

Cons of Vacuum Packaging

Not Environmental Friendly

Generally,vacuum packaging uses disposable packaging pouches,which are unfriendly to the natural environment.

Easy to be Affected by Temperature

Although vacuum packaging can lengthen the shelf life of food,it often thanks to the help of refrigerator,if food is exposed to the high temperature condition,it still be affected.

Not Adapt to Liquid

There are a few kinds of liquid such as beverage and milk can be vacuum packaged,but when it comes to soup or congee,it seems not so convenient to operate.

5.What is the application range of shrink packaging VS vacuum packaging?

Even if both shrink packaging and vacuum packaging are suitable for many fields,they also have their own applications.

Application Range of Shrink Packaging

Food Industry

Shrink packaging is always used to package food,you will find shrink packaged food in supermarket,fruit store,bread store and so on.

Beverage Industry

The application range of shrink packaging in beverage industry is also wide,shrink packaging can make the packaging film fit the beverage product perfectly,so it is widely used in beverage industry.

Medicine Industry

Furthermore,shrink packaging is also used in pharmaceutical industry,the outside package films of medicine bottles and medicine cases are shrink packaged.

Commodity Industry

Actually,shrink packaging is also used in commodity industry,such as shampoo,shower gel,facial cleanser,toothpaste, detergents and so many other commodities.

Stationery Industry

And,stationery can also be shrink packaged,for instance,look at the picture,the notebook uses shrink packaging.

Express Transportation Industry

If you always shop online,this is not strange to you,sometimes,the carton package that you receive will also have a shrink film on the outside,this can reduce some shock to the cartons.

Cosmetic Industry

Maybe ladies are not unfamiliar with this,generally,cosmetic or skin care products all have a layer of plastic film packaging to cover their packaging cases.

Application Range of Vacuum Packaging

Food Industry

The most basic application of vacuum packaging is the food field,you can say that it is mostly widely used in this industry.Vacuum packaging is used to pack meat,vegetables,fruit,snacks,etc.

Medicine Industry

Vacuum packaging is also widely used in medicine industry,its function is to protect drugs from environmental affects,keep the property of drugs and lengthen the shelf life of medicines.

Electronic Component Industry

Vacuum packaging applied in electronic components industry,to prevent the components from being damaged by statics.

The all above is the main applications of shrink packaging and vacuum packaging,of course that these are not the whole application range,the applications of shrink packaging and vacuum packaging is large more common than you can image.

6.What is the working principle of shrink packaging VS vacuum packaging?

After reading the all above content,I believe that you have a general understand of the two packaging methods,the next part is to tell you the working principle of them.

Working Principle of Shrink Packaging

In detail,the working principle of shrink packaging is that,heating the shrinking film at a high temperature, the irregular arrangement of atoms has undergone drastic changes.

Then under the use of infrared radiation light, plastic molecules move again, the arrangement changes, so that through atomic rearrangement, resulting in a large reduction of the area of the film.

In this way, it can more closely fit the finished products to be packaged and processed by the manufacturer, that is the working principle of shrink packaging.

Working Principle of Vacuum Packaging

The working principle of vacuum packaging is simple,it solves the problem from the origin.At first,you need to consider,why does food go bad?The chief culprit is microorganism,it is because of the survival of microorganism that the food would be mildewed,however,what if microorganism disappears?

Vacuum packaging achieves this,the survival of microorganism depends on oxygen,so we extract the oxygen of the packaging pouch,means that the microorganism loose its survival condition,it can not survive and multiply,so the function of vacuum packaging is realized.

7.What is the technologicalprocess of shrink packaging VS vacuum packaging?

Besides the working principles,you also need to know the technological process of shrink packaging and vacuum packaging,that is,how does a shrink package or vacuum package create.

Technological Process of Shrink Packaging

There are two types of shrink packaging method:manual shrink packaging and mechanical shrink packaging.

If you choose manual shrink packaging,you need to wrap the product with film by hand,and then use heater blower gun to blow hot air on the product to complete the shrink packaging process,but this method consumes too much time and energy,so it just suitable for family needs.

On the contrary,the mechanical shrink packaging is to assist the help of shrink packing machines,process of this shrink packaging method is also simple,just divided to two steps:wrap in advance and heat shrink.

The first step,you need to wrap the products with plastic film,and leave the necessary seam for the heat shrink step.And then is the next step,put the wrapped products on the heat shrinking equipment,when the heating starts,the film begins to shrink until it closely fit the product.

Technological Process of Vacuum Packaging

Vacuum packaging needs to use vacuum packaging machines,although there are many types of vacuum packaging machines,their working process is similar.The whole packaging process can be divided into three parts:extracting out air,filling into other gases,hot-sealing.

At the beginning,put product into the chamber of vacuum packaging machine,then the machine start work,extract the air of the packaging pouch until the vacuum index in the pouch is up to requirement.

After this step,the machine fills other gases such as nitrogen, carbon dioxide, rare gas and other single gas or a mixture of two or three gases into the packaging pouch,to guarantee that the pouch is under the positive pressure,which makes the product hard to be damaged.

The final step is hot-sealing,the chamber inflates and the hot pressure frame presses the mouth of packaging pouch to complete the hot-sealing operation.Until now,vacuum packaging process is finished.

8.What are the similarities of shrink Packaging VS vacuum packaging?

Even though shrink packaging and vacuum packaging are two different type of packaging methods,they also have some similarities,which are to the below:

Transparency

In common,either shrink packaging or vacuum packaging uses transparent films or pouches to package products,this is one of their similarities.

Heat-sealing

During the packaging process,both shrink packaging and vacuum packaging have a heat-sealing step to ensure the products are sealed into the package.

Neat Packaged Appearances

Moreover,products which are shrink packaged or vacuum packaged all kept in a good and neat appearance,they looked compact,clean,exquisite and beautiful.

Widely Used in Food Packaging

The most similar point of shrink packaging and vacuum packaging is that both of them are widely used in food packaging field because they can make food keep fresh.

9.What are the differences between shrink packaging and vacuum packaging?

Certainly,when there are similarities,there are differences,now lets start to explore the differences between shrink packaging and vacuum packaging.

Thickness of Packaging Material

As is known,the packaging material of shrink packaging is plastic film while vacuum packaging uses packaging pouch,in many cases,the packaging pouch maybe a little thicker than plastic film.

Packaging Machine

It is mentioned a little bit in the previous article that the two packaging methods all have their own packaging machines:shrink packing machine and vacuum packaging machine,the two types of packaging machines have different function and working process.

Presence of Oxygen

The most essential difference is the presence of oxygen,shrink packaging uses high temperature to realize heat-sealing,it doesn’t affect by whether there is air,on the contrast,vacuum packaging needs low oxygen,it has a high requirement of vacuum.

That is the most obvious distinction of shrink packaging and vacuum packaging.

10.Which one is better-shrink packaging or vacuum packaging?

After reading all above text,you may find that the shrink packaging and vacuum packaging have their own advantages and disadvantages separately,you can not absolutely say which of them is better,how about just say which one is better in specific situations?

When you need to pack liquid product,it is better to put the product in proper container and use shrink packaging cause vacuum packaging isn’t suitable for all kinds of liquid products.

When you need to pack products which is in a large size,such as furnitures,cartons,or even larger objects,it seems hard to find packaging pouches in such a large size,in this case,shrink packaging is a better choice.

If you need to pack products which are sensitive to high temperature,choose vacuum packaging is better,the reason is that the process of shrink packaging is in a high-temperature condition,may cause damage to this type of products.

And there are some products which will release toxic substances when they are under high temperature,it is obviously you can not use shrink packaging to pack them,vacuum packaging is better in this situation.

Of course that there are many other situations,you need to consider the real condition,choose more proper one of the shrink packaging and vacuum packaging.

Conclusion

Totally speaking,both shrink packaging and vacuum packaging are useful and convenient for your daily life,you can choose each of them according to your actual requirement.After reading this article,if you still have some confusions,welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours