High-Accuracy Fully Automatic Suppository Filling Machine

- Continuous Cooling Design

- High-precision Thermostatic Control

- Stable and Efficient Preheating Mold

Suppository Filling Machine

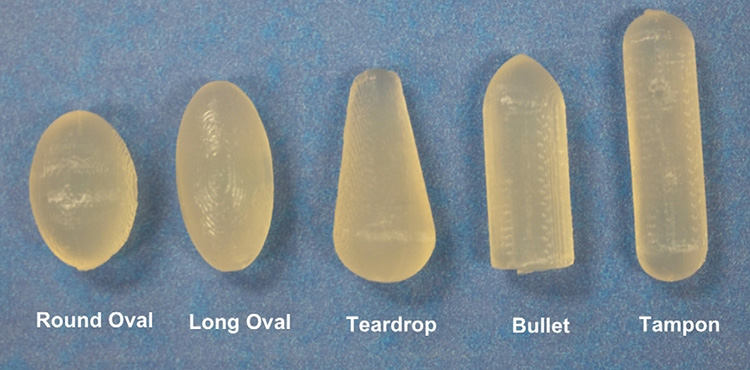

Allpack suppository filling machines are suitable for the production of special shapes such as bullet head shapes, duck mouth shapes, and other shapes, satisfying the production of various suppositories. Its main series of machines include Lab suppository packaging, middle-speed (linear or U type) suppository packaging, and high-speed satisfying linear type suppository packaging line. With PLC control system and middle-speed industry-grade person-machine interface operation, Aipak suppository packaging machine attaches features with a high degree of automatization, convenience in adjustment, high precise thermo-control reliability in action, and steady running. The equipment adopts PLC programmable control and man-machine interface operation, simple operation, convenient adjustment, accurate temperature control, and smooth operation. Its working is completely automatic, pneumatically based.

Suppository Filling Machine

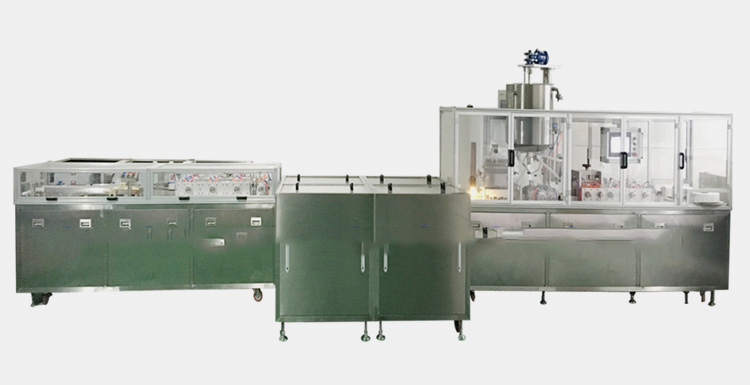

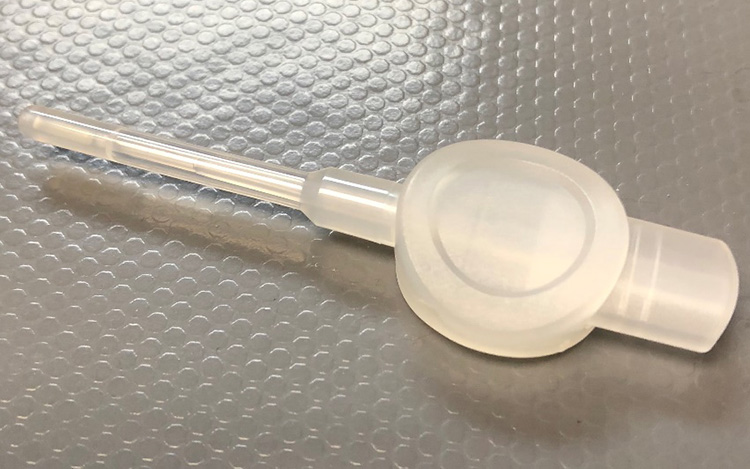

SJ-1L Lab Suppository Filling Machine Production Line

Allpack SJ-1L lab suppository filling machine production line is suitable for the production of suppositories with special shapes such as bullet heads, torpedo shapes, and duck's mouth shapes. Adopting the insertion type linear perfusion mechanism, it can locate accurately, not drop the medicine, and not hang the wall. With single grain measurement 0.5-5ml, filling error plus or minus 2%. It has a simple and reasonable design, with easy operation and maintenance.

Fault-self check

High precision&good sealing effect

The stable and efficient manufacturing process

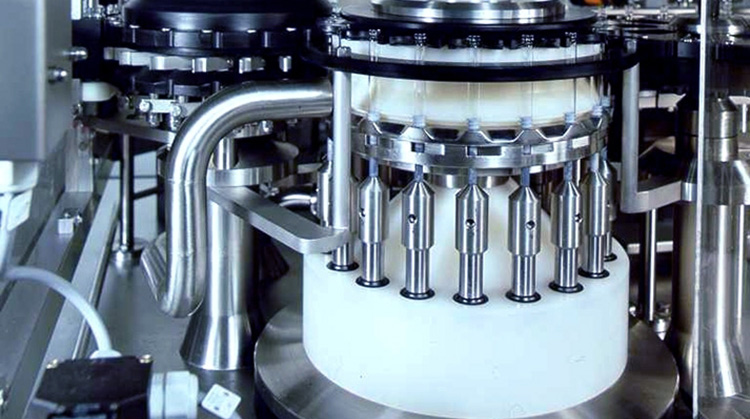

SJ-3L Automatic Suppository Filling Production Line

Allpack SJ-3L automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing, and other production processes to complete the whole process, and the production capacity is 5,000 grain/hour. The production line is welded flat, with no edge, slag, and splash. The whole machine is treated with reliable rust. The surface of the equipment is 304 stainless steel. It is smooth and easy to clean.

High accuracy of filling

Simple & reasonable design

Convenient operation & maintenance

SJ-7L High Speed Automatic Suppository Filling Production Line

Allpack SJ-7L high-speed automatic suppository filling production line using inset filling, accurate in position, non-dribbling drug, non-hanging wall, high-precision in counting. Be wide in suitability, and can be used to fill high gluing degree gelatin groups and traditional Chinese medicine ware. The machine also has a big volume storing fluid vessels, laying homoeothermic stirring, and fluid surface auto control assembly.

PLC inspection &control

Cooling speed adjustable system

Stirring barrel speed adjustable system

The Buyer's Guide

Suppository Filling Machine: The Complete Buying Guide in 2025

There are some special kinds of filling components that you have to work with in a pharmaceutical industry & suppositories are one of them.

Suppository filling machine is a unique and specially designed & manufactured filling equipment which is typically used to fill suppositories.

You are may be thinking like what are these suppositories and how a suppository filling machine works to fill them. Take a deep breath and start reading along because you will know everything once you are done reading this article.

1.What are suppositories & what is suppository filling machine?

Suppositories

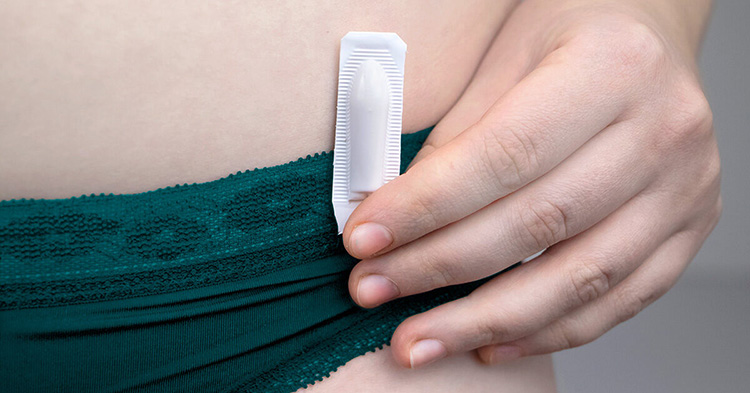

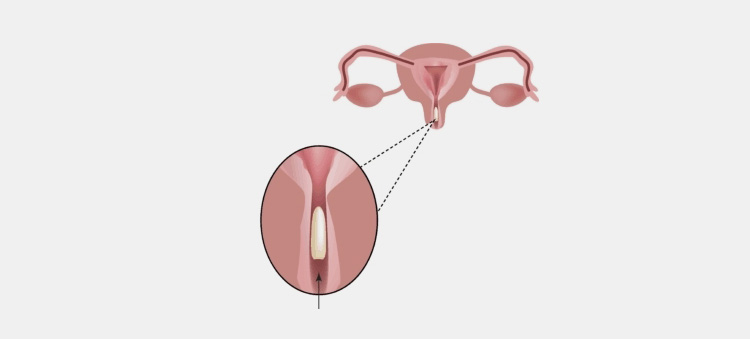

A suppository is an advanced dosage form intended for effective and efficient delivery of drug into the body of the patients.

This dosage form is given to the patient through the openings of the body other than mouth such as vagina, urethra or rectum. However, the most common type of suppository is the rectum one.

Suppositories are solid dosage forms and are made from such materials that melt when inserted into the body. In this way, the active pharmaceutical ingredient or the API gets delivered to the systemic circulation of the patient.

To help the patients that are abnormal or uncomfortable in taking drug orally then suppositories are very useful form of drug administration to help these types of patients.

Suppositories are also useful for the administration of drugs that have unpleasant taste or smell or that are prone to damage in the acidic environment of gastrointestinal tract.

The suppository filling machine is an innovation the field of pharmaceutical industry. It is an efficient machine that is used for preparing the shells of the suppositories and filling the drug material in them.

After that the next tasks of the suppository filling machine include cooling down the drug substances to solidify them, cutting them into your desired shapes and lengths and then finally sealing the shells, so that the suppositories are ready to be dispatched to the market for the patients.

2.Can you explain the working of suppository filling machine?

The working of the suppository filling machine depends on perfect coordination of different parts to perform the function of filling of suppositories.

The Unwinding Stage

In the unwinding stage, the material that you are going to use for making the shell of the suppositories gets unwind. The clamp action of the suppository filling machine transfers your material such as PE/PVC/PE + PVC towards the section of molding.

The Molding Stage

The guide wheels of the suppository filling machine guides the films of your material towards the molding section.

The Formation Stage

The next in the line is the formation stage. In thius stage, your material is made to pass through different sections of the formation section. These sections include steps such as pre-heating, heating, formation and blowing the casts.

Following the formation stage, the material you are going to use gets ready and in shape to hold the content of your suppository.

The Cutting Stage

Suppository

As the name indicates, the cutting stage involves precise cutting of the material of the suppository shell into suitable shape. The process of cutting is done by different types of cutters.

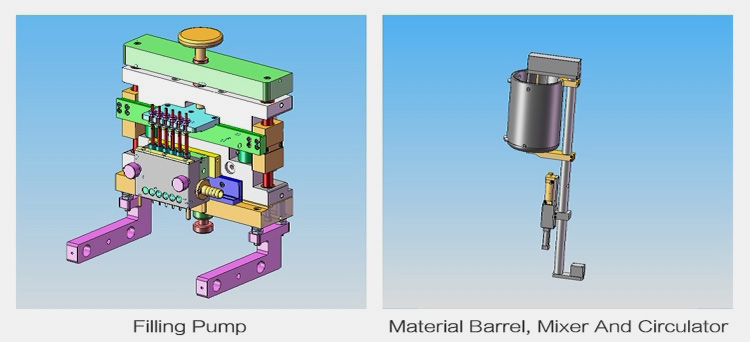

The Filling Stage

This is one of the most crucial stages of the formation of suppository in the suppository filling machine. In this step, the pharmaceutical material of the suppository is filled into the shells.

Note that the material that is being filled is pre heated at a temperature of around 80 degree Celsius. The number of filing terminals varies for different suppository filling machines. Mostly, the suppository filling machine has 3-6 of these filling terminals.

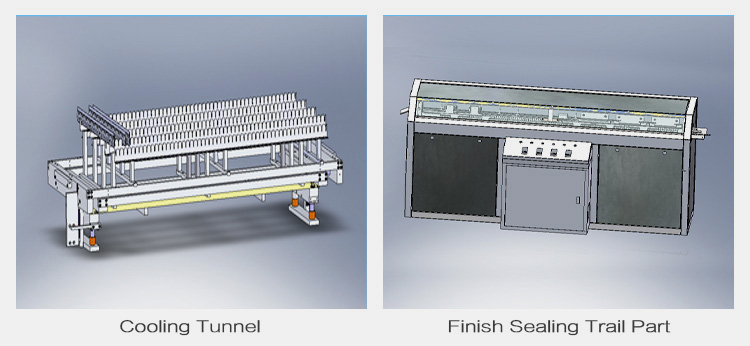

The Cooling Stage

The cooling stage involves the cooling of the suppository strips that come from the filling terminals. The suppository material is cooled down by using various methods of cooling.

A temperature of around eight to sixteen degree Celsius is maintained in this stage. This stage makes sure that the pharmaceutical ingredients of the suppository are cooled.

In this way, the suppository filling machine performs the function of filling the suppositories. The suppositories are then sealed and packed. After getting packed, the suppositories are ready to get dispatched.

3.How a suppository filling machine is beneficial for pharmaceutical industry?

The suppository filling machine is the primary tool for the formation of all the three types of suppositories. There are many cases in which the drug can not be administered to the patient through oral, parenteral, topical or the oral route.

In such cases, the drug is administered in the form of suppositories in rectum, urethra or vagina. That is why, the suppository filling machine is very important for the pharmaceutical industry.

Some of the advantages that make suppository filling machine a primary need for the pharmaceutical industry are listed below.

Precision and Accuracy

The suppository filling machine is a very accurate machine. You can adjust the quantity of the pharmaceutical ingredient to be filled in to the suppository shell via the control panel.

The machine will fill all the shells to the specified levels and the chances of error are almost zero. So you do not have to worry about over filling of the shells, incomplete filling of the shells or the spillage of your product during the process of filling of suppositories.

In this way, it can save you from financial losses.

Efficient

The suppository filling machine is very efficient when it comes to production rate. The suppository filling machine is fully automated and does its work at a quick pace.

The rate of production is also very high as suppository filling machine can make a great number of suppositories in a very short time. In this way, the suppository filling machine can save your time.

Versatile Device

The suppository filling machine is a very versatile invention as it has a huge application in different types of industries besides the pharmaceutical industry.

The versatility of the suppository filling machine makes it a very good option to invest your money as it can prove to be a very beneficial addition to your industry.

Easy to Instal

The suppository filling machine is very easy to install. You do not need a lot of floor space to instal your suppository filling machine. It only requires a small floor space for its installation.

Easy to Operate

The suppository filling machine is a user-friendly device that is very easy to operate. Any person with some training can become capable enough to operate the suppository filling machine.

This cuts down the need of hiring a highly paid professional to operate your suppository filling machine. In this way it can save your money.

Minimum Material Wastage

The suppository filling machine makes sure that the pharmaceutical ingredient or the packaging materials do not get wasted. It minimizes the wastage of these products and in this way saves you from financial losses.

Easy to Maintain

The suppository filling machine is very easy to maintain. You just need to make sure that the electrical supply to the machine is accurate.

Also keep looking after all the parts of the suppository filling machine and clean them regularly. This is the only maintenance that your suppository filling machine requires for its prolonged life.

4.What are the different types of suppository filling machine?

Suppositories

There are different types of the suppository filling machines that are used for the formation of different types of suppositories. The types of the suppository filling machine include rectal suppository filling machines, vaginal suppository filling machines and urethral suppository filling machines. These types are described below.

Rectal Suppository Filling Machines

The rectal suppository filling machine is a special type of suppository filling machines that is used for making the suppositories that are intended for rectal application.

The rectal suppository filling machine makes suppositories in such a shape that these can be easily administered into the rectum of the patient.

Working

In most cases, the machine will have either an adjustable nozzle or an automated pricking device to puncture the suppository and release the gel.

Once the gel is dispensed, it can be stored in a reservoir or released through the nozzle as needed. Many machines also have a cleaning function to ensure that all debris is swept away before the

Advantages

There are many benefits to using a rectal suppository filling machine.

- They are much faster than hand-filling.

- Machines are very accurate in terms of dosage of medication delivered will be exactly what the patient needs it to be.

- More comfortable than traditional forms of medication delivery.

- Machine help to minimize potential pain and discomfort when taking rectal medications.

Disadvantages

- They are expensive compared to hand filling.

- Rectal suppositories might not work as well as syringes and needles for some people because they take longer to reach the target area.

Components

There are many different types of components that make up a rectal suppository filling machine, and each one has a specific function.

Some of the most important components include the auger, piston, motor, and screw.

Auger

The auger is responsible for pushing the medication out of the cartridge and into the patient’s rectum. It typically has several blades that help it move quickly through the material.

Piston

This part is located in the center of the auger and helps to push and pull the medication along as it moves through the machine.

Motor

A motor powers both the auger and the piston, while the screw helps to keep everything moving smoothly.

Vaginal Suppository Filling Machines

The vaginal suppository filling machine is the type of suppository filling machines that is primarily used for the formation of the vaginal suppositories.

The vaginal suppositories are mostly oval shaped. These can be easily inserted in to the vagina for the pharmaceutical or cosmetic uses.

Working

Vaginal suppository filling machines are used to fill vaginal suppositories. A rectal applicator is inserted into the anus and a tube is inserted through the rectum into the vagina.

The applicator is then filled with vaginal suppository material and the tube is inserted into the vagina. The machine then pumps the suppository material into the vagina through the applicator.

Advantages

There are many reasons why people might want to use a vaginal suppository filling machine.

- These machines make it easy and fast to fill suppositories with a precise amount of medication.

- It helps to ensure that the suppositories are filled evenly and without any mistakes.

- Plus, these often come with features that make them easier to use, such as automatic dispensing and measurement tools.

Disadvantages

- The biggest disadvantage of using a vaginal suppository filling machine is the risk of complications.

- Additionally, if the device is not sterilized properly, it can cause an allergic reaction in the woman using it.

Components

Vaginal suppository filling machines use a variety of components to produce and ship the filled suppositories. These machines may include a robotic arm, a die-cutter and a filler device.

Robotic arm

The robotic arm typically uses a precision sensor to position the die-cutting machine over the desired area on the suppository.

Die-cutter

The die-cutter then cuts out the desired shape from the suppository. The filler device then inserts the shaped suppository into the vagina.

Filler Device

It typically performs the filling task by adding the equal amount of dosage into the suppositories.

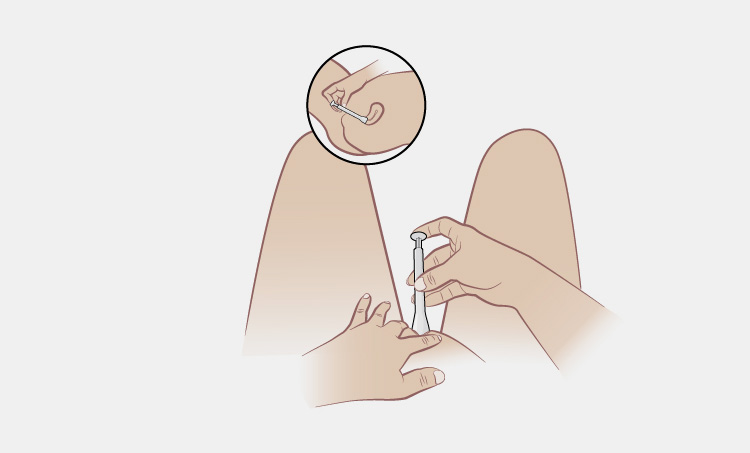

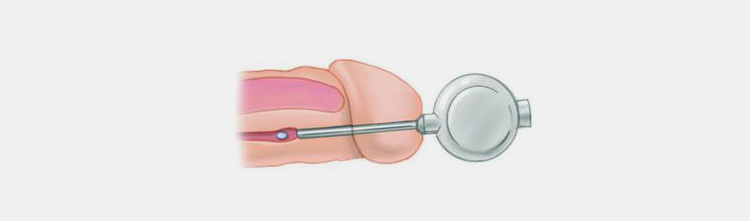

Urethral Suppository Filling Machines

The urethral suppository filling machine a type of suppository filling machines that is used for the formation of the urethral suppositories.

The urethral suppositories have a very small size which makes it easy to administer them into the urethra for different pharmaceutical purposes.

Working

Urethral suppository filling machines are devices that are used to fill urethral suppositories. They work by using a piston mechanism to push the suppository through a small opening into the patient’s urethra. This allows the patient to self-administer the medication without having to go through a healthcare professional.

Advantages

Some of the advantages of using a Urethral Suppository Filling Machine include:

- Efficient and accurate filling of suppositories.

- Reduced pain during and after use.

- No need for anesthesia or other forms of pain relief.

- Quick and easy filling process.

- Great for patients who are unable to give themselves injections.

Disadvantages

There are a few disadvantages to using urethral suppository filling machines.

- The first disadvantage is that the machines often use harsh chemicals to clean and sterilize the area before the suppositories are inserted.

- Many of these machines are quite expensive, making them out of reach for many people who could benefit from their use.

Components

There are three main parts to every urethral suppository filling machine: the pump, the cartridge, and the nozzle.

Pump

A pump present inside is responsible for transferring fluid from a reservoir to the cartridge.

Cartridge

The cartridge is filled with an appropriate suppository dosage and then inserted into the nozzle.

Nozzle

Nozzle is used for final step that activated the squirting fluid into the urethra.

5.Which industries can use the suppository filling machine?

The suppository filling machine a very versatile machine and has its application in different industries. Some of these industries are described below.

The Pharmaceutical Industry

The suppository filling machine finds its primary application the pharmaceutical industry where it used for the formation of suppositories.

Suppositories are very useful in treating the local diseases and infections at the site of their application.

Suppository is a very important dosage form especially in the cases when the drug can not be administered through any other route. Therefore, the suppository filling machine is a great asset for the pharmaceutical industry.

The Cosmetic Industry

The suppository filling machine finds its application in the cosmetic industry as well. Many of these products are made that are used for cosmetic purposes.

Examples include the vaginal suppositories that are used to minimise the feminine odour or other cosmetic purposes.

The Food Industry

The suppository filling machine has application in the food industry as well. Many nutritional suppositories are made that are used to make up for the deficiency of nutrients in the body.

These are the industries where suppository filling machines are extensively used.

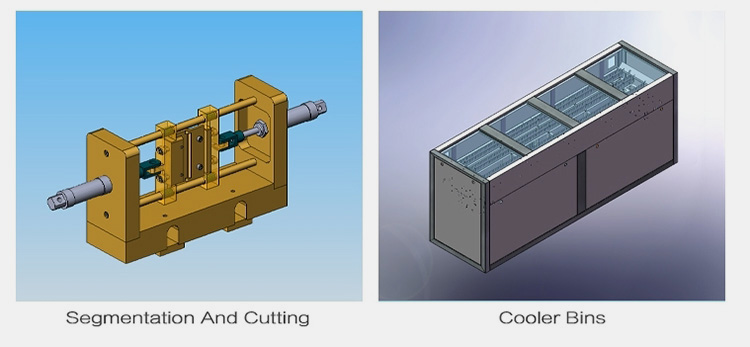

6.Explain the structure & working components of suppository filling machine?

The suppository filling machine works by complete coordination of its parts. Each part of the suppository filling machine performs its own function. All these functions collectively lead to a successful operation of the suppository filling machine.

Some of the parts of the suppository filling machine along with their functions are discussed below.

The Shell Forming Part

Suppository Filling Machine Part

The shell forming part of the suppository filling machine, as name indicates, is responsible for making the shells of suppositories.

The process starts with the unwinding and loading of the film roll that you are using. At the systemic position, two film rolls are placed above the poles.

The film is heated and formed into your desired shape. The shell is then shaped by blowing the air. In this way the shells are formed in the suppository filling machine.

The whole process is very quick and takes only around two seconds.

The Liquid Filling Part

The liquid filling part of the suppository filling machine is the most important part of the suppository filling machine because it is involved in the filling of the pharmaceutical ingredients in to the suppository shells.

The suppository filling machine has 2-4 fillers depending upon the size and type of machine you are using.

The accuracy of liquid filling part of the suppository filling machine is very important because errors in the filling may lead to toxicity and may cause adverse side effects to the patients.

The Cooling Part

Parts of Suppository Filling Machine

The cooling part of the suppository filling machine is the part that is used to cool down the filled suppository shells coming from the filling part.

The liquid pharmaceutical product is actually pre-heated before getting filled into the suppository shell. In this part, the liquid gets cooled at a temperature of about eight to sixteen degree Celsius.

The Sealing Part

Parts of Suppository Filling Machine

The sealing part of the suppository filling machine comes into action after the suppositories have been cooled. This part seals and cuts the suppositories.

The top of the shell is heat sealed with the help of heaters (in the form of heating blocks).

The Material Hopper

Material Hopper/barrel in Suppository Filling Machine

The material hopper of the suppository filling machine is a storage tank made of stainless steel. The main function of this tank is to hold and store the pharmaceutical material that needs to get filled in to the suppository shells.

This part has an agitator that rotates continuously for the sake of stirring the pharmaceutical ingredients to avoid sedimentation or solidification during the process of filling.

The size of the material hopper of the suppository filling machine varies and depends upon the type of the suppository filling machine you are using.

7.How you can do maintenance work on suppository filling machine?

Maintenance

Proper maintenance of the suppository filling machine should always be your top priority. The suppository filling machine does not require a very tough maintenance but there are some things that you should always take care of. These are described below.

Regular Cleaning

Make sure that you are cleaning your suppository filling machine regularly. This saves your machine parts to get rusty and ultimately non-functional.

Stable Electric Supply

Make sure that your suppository filling machine gets proper and stable power supply. Sudden changes in the power supply can damage your machine parts.

Regular Inspection

Inspection of the suppository filling machine must be done on regular basis. The parts of the machine are checked if they are working properly or not.

Repairing andReplacing Old Parts

Repairing and Replacing Old Parts

The parts of the machine that are not working properly should be repaired or replaced timely to avoid financial losses.

These are some simple steps that you can follow to maintain your suppository filling machine.

8.How to select a suitable suppository filling machine?

Suppository filling machines come in many different shapes and sizes, so it can be difficult to decide which one is right for you. There are a few things to consider when selecting a machine:

Capacity

Suppository machines come in different capacities, from small models that can fill just a few suppositories at a time to large models that can fill several hundred at a time.

Make sure you know the maximum capacity of the machine you’re considering before making your purchase.

Functionality

Suppository filling machines come with a variety of features, some of which are more important than others such speed, viscosity and hourly production.

The size of the suppository

Suppositories come in a variety of sizes, from small pills that can fit in the palm of your hand to larger suppositories that must be inserted into the rectum or vagina.

The size of the suppository will determine how much room the filling machine has to work with.

How many suppositories per batch

Suppository filling machines typically fill batches of 2-12 suppositories. The number of suppositories per batch will affect the price and speed at which the machine can fill batches. Machines that fill smaller batches may be cheaper, but they may take longer than machines that fill larger batches.

Filling method

Filling methods include manual (where you push each suppository individually into the filler tube with your hands), semi-automatic (where one person pushes all the suppositories into the filler tube at once), and automatic.

9.What is the main purpose of making suppositories?

Suppositories are a type of medication that is inserted into the rectum to be taken by mouth. Suppositories come in a variety of shapes and sizes, with different purposes. Some suppositories are used to treat conditions like diarrhea, while others are used to relieve pain from conditions like anal fissures or menstrual cramps.

Some suppositories even have additional uses, like treating urinary tract infections or reducing the risk of getting an STD. The main purpose of making suppositories is to provide a way for people to take medications without having to swallow them.

This can be helpful for people who have difficulty swallowing pills or for people who are unable to take medications by other means. Additionally, suppository medication is often more effective than taking medication orally because it reaches the area where it is needed most quickly

Conclusion

Over the years, suppository has become a popular dosage form for the cases when it is not possible to administer the drug product through any other route. These suppositories are efficiently made by the suppository filling machines. Suppository filling machine can prove to be a very healthy investment in your business due to its high efficiency so don’t hesitate & reach us for further inquiries.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours