Direct Factory Price Automatic Capsule Filling Machine

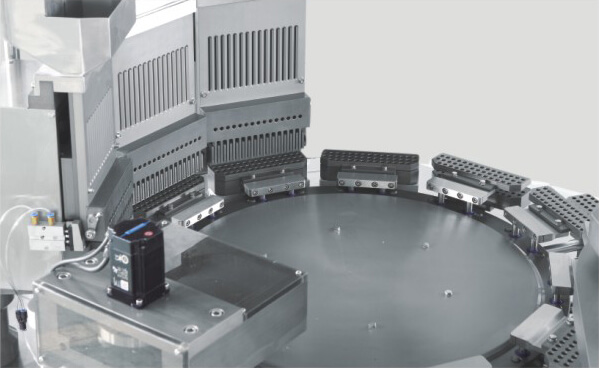

- Closed Rotary Table

- Butterfly Valve-type Powder Feeding

- Intermittent Full Automatic Capsule Filling

Full Automatic Capsule Filling Machine

Allpack full automatic capsule filling machine is widely applied to the powder, grain, tablet and pellet filling and widely used in pharmaceutical, medicine, and chemicals industry for filling powder, pellet, granule and pill,it also can be used to fill vitamin, foodstuff and animal drug, etc.The full automatic capsule filling machine can feed, separate, fill and lock capsules, clean wastes, discharge end products and clean molds synchronously.With compact structure, small size, low noise, accurate filling, perfect functions and stable operation. All Allpack capsule filling machines have perfect functions since it is equipped with HMI. When material or capsules are lack or material channel is faulty, the machine will alarm and stop automatically. Besides, it can display the counting value of every capsules and the cumulative output.

Full Automatic Capsule Filling Machine

NJP-200C CE Pharmaceutical Hard HPMC/Gelatin/Halal/Vegetarian Automatic Capsule Filling Machine

Allpack NJP-200C automatic capsule filling machine is small in size, light in weight, energy savings, easy to operate and clean.Equipped with inching control system, which makes this automatic capsule filler easy and convenient for cleaning, loading and unloading of upper and lower dies.The machine will automatically alarm and shutdown when lacks empty capsule or powder.The plane cams are running in the mode of double rails, where the two axes run out separately. It can improve the operation accuracy and meanwhile eliminate the possibility of collision between the lower die and the dosage disc.

High precision filling

Safe and convenient

Good suitability

NJP-400C High Productive/Automatic Capsule Filling Machine

Allpack NJP-400 automatic capsule filling machine runs as per automotive separating revert interval, feeding, removing useless cap less, clipping and coming capsule, cleaning mould are completed at same time, which has reached high precision and low noise levels.With the automotive controlled, stepless speed adjusted, digit display, this automatic capsule filler machine is easy to operate. With advance technology, fully automatic capsule filling machine gives you extremely effective and accurate filling results that is exactly in accordance with your demands. Moreover, due to the high degree of automation it possess, many capsule processing industries are constantly utilizing this machine to better enhance their production level such as pharmaceutical, nutraceutical and healthcare Industries etc.

Good suitability, high frequency

Equipped with safety-protection

Automatically stopped when the material used up

NJP-800C Automatic Capsule Filling Machine

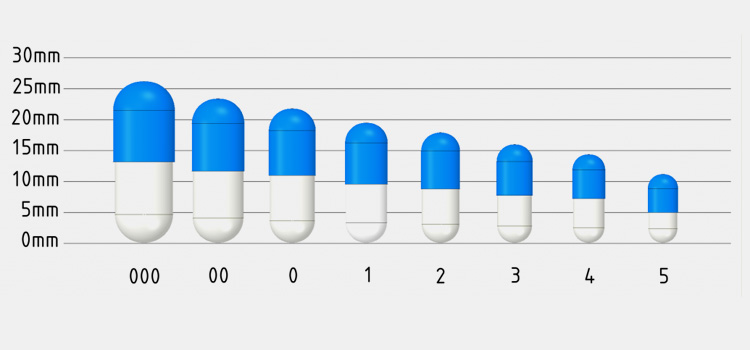

Allpack NJP-800 fully automatic capsule filler filling machine is used for Pharmaceutical, medicine, and chemicals (powder, Pellet, granule, pill),also can be used to fill vitamin, foodstuff and animal drug, etc. It adopts intermittent motion and multi-position tamped dosing method to complete capsule orientation, separation, filling, closing and ejection etc. With different size parts the machine is suitable for size 00 to size 5 of empty capsules.The production speed can be controlled by means of a frequency converter.This automatic capsule filler machine is designed in accordance with GMP standard. All parts in contact with product are made of stainless steel or GMP approval material. Advantage of the machine is advanced designing, novel structure, precise dosing, safe and reliable, high filling rate etc.

Reliability and low wear rate

Can fill No.00-No.5 gelatin capsule

PLC control system

NJP-1200C Automatic Capsule Filling Machine

Allpack NJP-1200C automatic capsule filling machine is an intermittent motion and hole plate type filling full automatic capsule filling equipment. It adopt optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stable running etc. Due to the high degree of automation it possess, many capsule processing industries are constantly utilizing this machine to better enhance their production level such as pharmaceutical, nutraceutical and healthcare Industries etc. It can finish the following motion at same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge.

Quick and accurate part changing system

PLC program control pane

Easy speed selection

NJP-1200D Automatic Capsule Filling Machine

Allpack NJP-1200d automatic capsule filling machine has made through some significant minutes minute on the original 1200C automatic capsule filling machine. This automatic capsule filler machine adopts improvements in the minute cam dividing configuration of 100DS, which the filling speed to about 1000 per minute. A fully automatic capsule filling machine gives you extremely effective and accurate filling results that are exactly in accordance with your demands. Although the production cost increases, we have significantly enhanced the device's production efficiency and service life. Its filling speed has been raised up to about 1100pcs capsule per minutes. Due to these advantages, it has been widely received by customers at home and abroad.

100DS cam dividing

New closed-working table

High efficiency&precision

NJP-2500C Automatic Capsule Filling Machine

Allpack NJP-2500C automatic capsule filling machine uses the lower plane of the dosing tray as the benchmark with three-dimensional adjustment and even gaps to reduce the filling differences effectively and clean the machine conveniently. This machine can fill various types of material into the capsules such as powder, granules or pellets, etc. Applying HMI with complete functions. When capsules are not filled or the material channel is faulty, the machine will alarm and stop automatically. Besides, the machine can function to display the value of filling volume of every capsule and cumulative output. many capsule processing industries are constantly utilizing this machine to better enhance their production level such as pharmaceutical, nutraceutical and healthcare Industries, etc.

Fully closed rotating table

Removable powder hopper

Large cam mechanism

NJP-3800C Automatic Capsule Filling Machine

Allpack NJP-3800C automatic capsule filling machine is designed and further improved on the base of original full automatic capsule filling machine from both home and aboard. This machine can fill various types of material into the capsules such as powder, granules or pellets, etc. With high technology and exclusive performance, it has reached the international leading level. It is an ideal equipment for capsules and medicine in the pharmaceutical industry which is in full compliance with GMP requirements. It adopted PLC programmable controller, stepless frequency inverter, man-machine interface to operate, and touch screen display (Type A&B is a Touch Panel operation).

Simplicity and convenience of dismantling

Quick and accurate part-changing system

Easy to remove rotary table

NJP-5500C Fully Automatic Capsule Filling Machine

Allpack NJP-5500C fully automatic capsule filling machine is an intermittent full automatic capsule filling machine with multiple tamping stations, precise design and stable performance. It can complete the following process: feeding the capsule, separating the capsule, filling, rejecting the defective capsule, closing the capsule, and the discharging finished capsule automatically. It adopts a closed rotary table with twelve stations. There are 38 holes in four rows of the module. This machine can meet the international advanced standard, and also meet the requirement of GMP and FDA standards. It's absolutely the most ideal machine for the pharmaceutical industry.

Compact body, low power consumption

Powder collecting device

Easy to operate and clean

NJP-7500C Fully Automatic Capsule Filling Machine

Allpack NJP-7500C automatic capsule filling machine produced by our company is an innovative product of the third generation. Fully automatic capsule filling machine is mechanical equipment integrated with several parts to perform the task of filling hard gel capsules. It not only covers all the functions and effects of the domestic capsule-filling machine of the same model but also has four innovative technologies. The new hopper adopts butterfly valve-type powder feeding, and is very suitable for drug powder with poor liquidity, including Chinese herbal medicine and Chinese patent drug, that its vibration unit equipped will force the powder to run down.

Fully enclosed new turntable

Transmission of guide rail

High precision and longer service life

The Buyer's Guide

Fully Automatic Capsule Filling Machine: The Complete Buying Guide In 2025

Have you ever thought about how automation technology was introduced? What were the main objectives behind it? Why every industry is keen to incorporate this technology into its business sphere? And what is the importance of automation in capsule making process?

Are you curious to know about it? Take it easy! This informative review is basically drafted to respond all of your queries and enable you to acknowledge the significance of a fully automatic capsule filling machine in diverse sectors. How this machine works, how it can benefits you and how to solve the problems if faced during operation is all explained in detail. Stay hooked to know everything about it!

1.What Is A Fully Automatic Capsule Filling Machine?

Fully automatic capsule filling machine is mechanical equipment integrated with several parts to perform the task of filling hard gel capsules. This machine can fill various types of material into the capsules such as powder, granules or pellets etc.

With advance technology, fully automatic capsule filling machine gives you extremely effective and accurate filling results that is exactly in accordance with your demands. Moreover, due to the high degree of automation it possess, many capsule processing industries are constantly utilizing this machine to better enhance their production level such as pharmaceutical, nutraceutical and healthcare Industries etc.

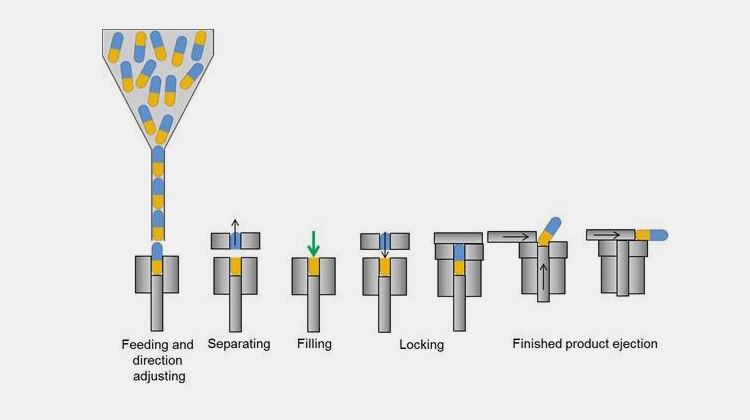

2.Elaborate The Working Principles Of A Fully Automatic Capsule Filling Machine?

A fully automatic capsule filling machine has pre-determined mechanism for its operation. To better know the principles on which this machine runs consider the underlying steps:

Rectification

In the very first step, all empty capsules are loaded into capsule hopper from feeding tank through vacuum pump which. Once hopper gets capsules, these capsules are sequentially delivered to the narrow tube where capsule block-shelf drives the capsule block slide and a capsule dropped down from the tube. Now, here the direction of capsules may be in false position. To correct them, guide slot adjusts the direction of capsule by pushing it forward through its edge into the capsule conveying comb. Here the process of capsule rectification ended.

Capsule Splitting

Now in second stage, cap and body of capsules are separated. When empty capsule gets into the mold hole it is adjusted inside the lower mold. Lower mold tightly attached to the capsule body and cap is separated from it through vacuum sucking which is then held by upper mold.

Capsule Filling

In this stage, capsules are filled with material that is conveyed by the powder hopper. After that, cap of capsule is tightly pressed over its body and the capsule is locked by the dose plate in mold hole.

Discharge of Capsule

The final step takes place here, when capsules are discharged by the discharge ejection device, which constantly moves in upward and downward position. When the locked capsule is placed in discharging station the ejector pushed it out from mold hold and capsule is released into the barrel.

Station Cleaning

All the waste particles including filling powder, powder residue or broken capsules are blown out of the mold hole after completion of each cycle.

3.Which Type Of Material Can Be Filled By A Fully Automatic Capsule Filling Machine?

You might be interested in knowing that which type of material a fully automatic capsule filling machine can fills into capsules. For this we have presented you some items along with their pictures which would clearly demonstrate these materials. They are:

Powder

Powder is one of the essential and most commonly used materials that is filled inside the capsules. It helps in quick absorption of the material which it contains and is easy to swallow. Various minerals and herbs are transformed into powder so they can be actively consumed through capsules. Moreover, it can be used with granules, pellets or powder alone.

Granules

Another type of capsule filling material is granules which come in round shape but they are too little in size than any other granules like sugar. Different vitamins and nutritional sources are often delivered in form of these granules. They can be single, double or multi color depending upon the content of dosage. You can also use the combination of granules with powder or pellets.

Pellets

Now comes the pellets, having cylindrical shape and are small in size. Here you can adopt the mixture of two substances like half amount of pellets and of powder for rest. Using these types of material in your capsules enhance the flexibility of capsules in designing and development of attractive manifestation.

4.What Are The Essential Attributes Of A Fully Automatic Capsule Filling Machine?

A fully automatic capsule filling machine comes with immense degree of versatility, flexibility and efficiency. It has been praised with lots of features associated with its design and functions as well. Here we would take all of these attributes so you can get benefits from using it. These features include:

Upgraded Machinery

A fully automatic capsule filling machine has upgraded machinery. Although, it functions through pre determined limits but you can also modify the cutoff limits for filling material. It is also integrated with many devices like capsule feeder, vacuum feeder, industrial cleaner and metal detector etc.

High Production Capacity

One of the essential contributions of a fully automatic capsule filling machine is the high level of production which it can produce. This fact can be acknowledged by the figure which it produces every hour and that is 91000 capsules.

Flexible

This machine comes with good flexibility ratio and enables you to fill different materials at same time in a single capsule like powder, granules and pellets etc.

Fill Different Sizes

Do you know that different capsule filling machines are designed to fill the capsules of particular size? That’s why their processing remains confined to few sizes of capsules. While as, a fully automatic capsule filling machine can fill the capsules of every size.

Hygienic

With anti-acidic and corrosion resistant surface this machine preserves the hygiene and sterility of capsules. It also removes the dust and waste that is left during the process.

Safety

This equipment has improved safety because of stainless steel frame having soft edges and all electric connections are safely fitted inside the machine. Operator can also deal with all parts of machine without being affected physically.

Complying GMP’s Prerequisites

Good Manufacturing Practice (GMP) is a platform that works for checking the production of industries that whether the products they use is of good quality or not. Currently, the technology of fully automatic capsule filling machine has been constantly acknowledged by the GMP.

Self Reliant & Consistent

This advance equipment is designed in such a way that it performs its entire tasks independently without any manual intervention and in consistent manner.

Accuracy

Regardless of the fast processing it shows, the machine does not compromise on the accuracy of capsule filling as well as its closing which is mostly neglected by manual filling. This is what makes it the best solution among other machines.

5.What Types Of Capsules Can be Processed By A Fully Automatic Capsule Filling Machine?

A fully automatic capsule filling machine is capable of processing different types of capsules with varying nature and size such as:

Hard Gelatin Capsules

Hard gelatin capsules are made up of protein that is usually taken from animal sources. This is one of the popular kinds of capsule which is used for filling material. Around 94% of hard gel capsules are used in different medicine industries due to its strong cover which is very reliable for mobilization and cannot easily tear.

HPMC Capsule

HPMC stands for hydroxypropyl methylcellulose or hypromellose and these capsules are comprised of water and vegetable sources. They have no taste and are taken as supplements. A fully automatic capsule filling machine is sometimes used to fill these capsules but due to their soft nature, they are often preferred to be processed by automatic machine with moderate speed.

6.Describe The Major Components Of A Fully Automatic Capsule Filling Machine?

A fully automatic capsule filling machine consists of various parts each play a crucial role in the accomplishment of capsule filling task. What are these components can be known by the details explained below:

Control Panel

This part of machine works as a head because all the parameters required for executing machine are fixed here. With touch screen display it enables you to communicate and command the machine accordingly.

Hopper

This is another part of machine and each automatic capsule filling machine has two hoppers one for holding empty capsules and another for material loading.

Vacuum Feeder

Like hopper, vacuum feeders are also two in numbers because separate vacuum pumps are used for loading capsules and filling material into hopper.

Turret

Turret is the place which takes capsules from hopper and transports them from one dosing station to another.

Material Pump

The task of material pump is simple but essential as it transfers the filling material from hopper into the infusion wedge. If the amount of material taken is greater than required, it then returns material back to hopper.

Infusion Wedge

It is another component of a fully automatic capsule filling machine which undertakes the task of infusing filling material. It warms the filling material until it reaches to exact temperature.

Material Filling Mechanism

This is the core component of machine where actual filling of material is occurred. When cap of capsule is removed from the body, filling rod fills the body of capsule with required amount.

Rectifier

It positions the capsules in right direction.

Tooling System

Tooling system covers various parts of machine which separately performs many functions. They are namely two-pass roller which are consistently in turning position with constant speed, another is turntable that keeps the dust away from getting into equipment parts and the dosing station which play eminent role in filling accurate amount of material.

7.Can Liquid Capsules Be Filled By A Fully Automatic Capsule Filling Machine?

A question may arise in your mind that whether a fully automatic capsule filling machine can process the liquid capsules or not. So the answer is no, because it can only process dry and solid material like powder or granules.

If you want to fill capsules with liquid then you have to remove the existing feeder of machine and integrate the band sealing machine with it.

8.Compare And Contrast Between Fully Automatic Capsule Filling Machine And Semi-Automatic Capsule Filling Machine?

There are many apparent differences between a fully automatic capsule filling machine and semi automatic capsule filling machine like:

| No | Machine Type | Fully Automatic Capsule Filling Machine | Semi Automatic Capsule Filling Machine |

| 1 | Definition | It is automatic machinery designed to fulfill capsule filling task with good accuracy without any need for user involvement. | In contrary, this machine refers to the process of filling capsules through human help. |

| 2 | Process | Its process is quite lengthy and difficult that can be understood by an expert. | It has simple process which any user can understand easily. |

| 3 | Structure | Its structure is too long and complicated. | It is having precise make up of parts. |

| 4 | Speed | It runs faster than other machines. | It is low process due to human involvement. |

| 5 | Capacity | Its capacity is of optimum level. | The figure if capsules processed by this equipment are limited and less than fully automatic machine. |

| 6 | Size | It is having big size and need more space for installment | It occupies less space compare to fully automatic capsule filling machine. |

| 7 | Application | This machine has been employed in large scale industries like pharmaceutical, nutraceutical, veterinary etc | It is used in medium scale production firms such as laboratories, healthcare and herbal industries etc. |

| 8 | Machine |  |

|

9.How Many Sectors Are Being Influenced By The Use Of A Fully Automatic Capsule Filling Machine?

This machine is employed to assist various sectors linked with capsule manufacturing and now many of them are constantly admiring its use some of which are considered below:

Pharmaceutical Industry

It is one of the broadest manufacturing firms involved in medicine production. It is the pharmacy sector, whose contribution and research has made all the chronic diseases curable today. In such condition, when you are responsible for the production of huge amount of pills everyday day, a fully automatic capsule filling machine is always the first choice of every pharmaceutical industry.

Cosmetic Industry

The growing advancement in technology of capsule making has gripped over every capsule manufacturing industry among which the cosmetic industry is also on top list. Different capsules are now available for glowing skin, reducing dark spots and for healthy hairs treatment. These capsules are also prepared by a fully automatic capsule filling machine.

Nutraceutical Industry

Nutraceuticals can be also referred as supplements which are prepared from food items like vegetables, fruits or cereals containing good amount of vitamins and minerals. These nutraceutical capsules are formed by a fully automatic capsule filling machine which helps in health augmentation and prevention of various diseases.

Herbal Industry

Herbal medicines are becoming popular now a day. These herbal capsules are naturally obtained from different types of leaves, roots or flowers etc. To meet the demands, all these raw material is first properly pulverized and then filled by a fully automatic capsule filling machine as a ready mixture.

Healthcare Industry

Healthcare support is of the prime importance for every person that’s why most of the countries around world prefer to provide their nationals with good healthcare in order to promote health give treatment and enhance life expectancy resultantly. Under these services, they facilitate people with free medication and for such large amount of subjects only a fully automatic capsule filling machine is the best solution every owner looks for.

Veterinary Industry

Similar to other industries, veterinary industry is also in great need for using such highly innovative and efficient equipment like fully automatic capsule filling machine. Instead, most of the capsule manufacturing firms who use to prepare pills for animal diseases are utilizing this machine on large scale.

10.What Are The Auxiliary Devices Required For Operating A Fully Automatic Capsule Filling Machine?

Whenever you are intending to make capsules, you should have an idea that only a single machine is not sufficient. You will require much other equipment to integrate with the main machine so that your process will run smoothly and results in accurate output manifestation. For that we have described the devices which you will need during your process such as:

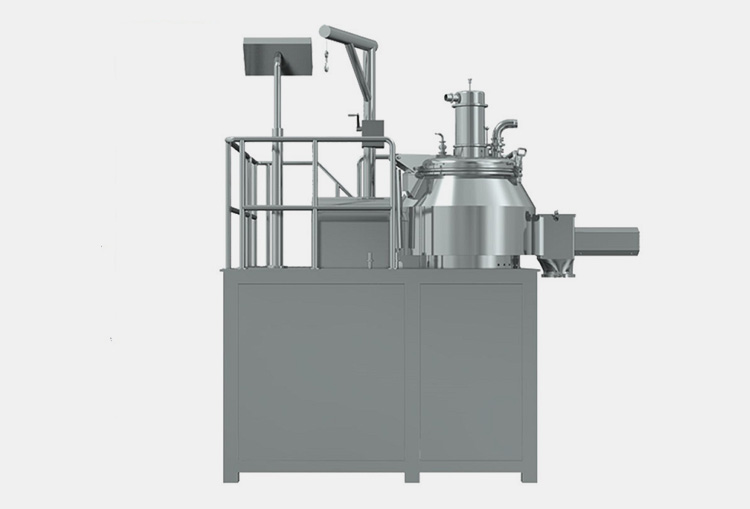

High Shear Granular Machine

This machine is an inevitable part of processing capsules as it performs the basic role of preparing granules for solid dosage. It comprised of three conical blades, a motor for rotating these blades and a chopper. Together they mix the powder and liquid to form granules for capsules.

Crushing Machine

A crusher machine contains hammer inside and break down all the material that is poured in it. Thus, it is crucial in grinding any type of stuff that is used for filling capsules

Vibratory Sifter

This machine is basically incorporated for screening and scaling the filling material. It revolves in circular motion and separates the granules according to their size.

Fluid Bed Processor

Fluid Bed processor is effective equipment designed to take multiple tasks for capsule granules like spraying them from top side and coating these particles from bottom side. It completely removes the moisture from capsule filling granules

Capsule Sorting Machine

It is one of the best equipment praised with the quality of separating capsules on the basis of their size and it also apart the capsules which remain unfilled during process.

Capsule Polishing Machine

Sometimes when capsules are discharged after getting filled, they may be found with residual particles left during filling process. This can cause bad impression of your production. Thus, to fully purify these capsules from dust and contamination a capsule polishing machine is perfect instrument.

Blister Packaging Machine

Now, when you have finally achieved the desired amount of capsules there arise a question how to store or pack these capsules in a way that they do not lose their quality, hygiene and originality? The answer is a blister packaging machine, which can create unit-dose form of your capsules either in plastic or aluminum foil blister packaging.

11.How To Find The Quality Inspection And Verification Of A Fully Automatic Capsule Filling Machine?

This question is carrying great importance because you should be aware of the inspection criteria for a machine you are intending to purchase. A fully automatic capsule filling machine should conform the following quality standards such as:

International Organization for Standardization (ISO)

ISO is the first and foremost non-governmental organization aims at promoting the manufacturing of high standard quality products and supporting trade by drafting common standards. If a company producing fully automatic capsule filling machines is ISO certified it indicates that the firm is meeting the international standards.

Current Good Manufacturing Practices (cGMP)

Current Good Manufacturing Practices is an agency that has made some regulations necessary for ensuring products safety. Through these regulations, it administers whether the firm is complying these rules and assures the essence and presence of ingredients which the firm claims to have.

Chartered Engineers (CE)

CU can be short abbreviated for Chartered Engineers. It is mandatory mark for all the goods that has to be exported in European countries because it reveals the compliance with strict directives for safety.

12.Are There Any Disadvantages Of A Fully Automatic Capsule Filling Machine?

Do you expect that a fully automatic capsule filling machine is only having lots of benefits without any drawbacks? Your assumption might be proved wrong when you get to know the underlying defects of this machine like:

Expensive

As the machine is fully automatic, it has been constructed with quality stainless steel, having heavy tooling system and requiring dual devices one for capsules and another for filling material like hoppers and vacuum pump. Together, these all make the machine expensive.

Big Size

Although, a fully automatic machine is separately not that much big in size but as it is automatic so it requires entire system for making capsules, filling material and additional devices like crushing machine and sorting machine etc. So, it will occupy huge area.

13.What Are The Safety Features Of A Fully Automatic Capsule Filling Machine?

Fully automatic capsule filling machine relieves you in so many ways, which you may not enjoy when using any other capsule filling machine. They are highlighted as under:

Automatic Cleaning System

Every equipment is in need of proper cleaning due to the items they process. Similar is the case with fully automatic capsule filling machine, but here this function is performed by the machine itself. You just have to click on the button for beginning the process.

Automatic Lubrication System

This machine is the combination of so many parts among which small parts are more in number. They need proper lubrication system for continuing their functions in smooth manner. Now, it gets difficult to lubricate these gadgets by hands but this is done automatically by a fully automatic capsule filling machine.

Assures Data Security

One of the greatest features this machine possesses is the security of your organizational data. Due to the reason that data you enter in control panel is in computerized form so it reduce the chances of errors.

Advance Technologies

This machine is designed with modern technologies and has integrated systems of sensors, printing capsules, emergency button and alarm that ring in case of insufficient filling material.

Shock Proof

All the electrical parts of machine are fully enclosed inside the machine. You cannot use this equipment during operation and if you do so, it will automatically turn off. It also beeps an alarm in case of electric current.

14.How Would You Tackle The Issues If Confronted When Using A Fully Automatic Capsule Filling Machine?

To tackle the issues which arise when using a fully automatic capsule filling machine you need to understand the following steps:

| No | Issues | Causes | Remedies |

| 1 |

Problem of capsule entering the mold hole |

This usually occurs when small baffle plate is improperly fixed | Correct it by approved setting of baffle plate for smooth flow of capsules |

| 2 | The mold hold may be damaged | Replace the damaged magazine with new one | |

| 3 | The presence of dust particulates is creating hindrance | Clean the area via compressed air | |

|

4 |

Capsules get damaged during process | It indicates the improper alignment of rectification block | Solve this issue by aligning the rectifier exactly |

| 5 |

Problem of abnormal splitting of capsules |

Mold holes are not tightly attached to the capsule body and cap | Sort it out by adjusting the concentration of mold holes through regulating rod |

| 6 | Another reason can be the jammed pipeline of vacuum | Decontaminate the vacuum pipeline | |

| 7 |

Desired weight of capsules is not achieved |

The capsules you have taken are either too small or too large | Take the capsules with capacity of holding exact amount |

| 8 | Flow rate of filling material is feeble | Adjust the speed for conveying material also check its amount | |

| 9 |

Capsule cap is lost during process |

This usually happens when pressure of vacuum is high | Reduce the air pressure by modifying throttle |

| 10 | The alignment of capsule cap and body is disturbed | Make sure to examine the proper alignment of both cap and body before starting mechanism |

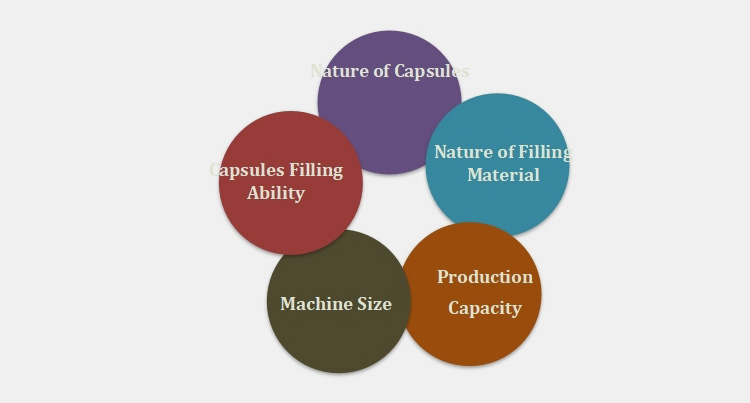

15.What Factors Play Significant Role When Selecting A Fully Automatic Capsule Filling Machine?

Last but not the least, this question would be helpful for you in choosing ideal solution for your capsules filling. Just start reading the below factors to know which type of factors should you consider:

Nature of Capsules

Which type and size of capsules you are wishing to fill should be kept in mind so you can get better machine that exactly suits your needs.

Nature of Filling Material

Now this is another question which is important to know. There are various machines with the ability to fill single, double or multiple items in same capsules. So, you should choose one according to your requirements.

Production Capacity

The machine you are considering has enough capacity to reach the production level which you marked ideal? Look into this aspect because it will play major role in determining the success or failure of your business.

Machine Size

Some machines have precise structure and they can be easily handled. It depends upon you and your place in which you would install it. So, never overlook this factor.

Capsule Filling Ability

There are different fully automatic capsule filling machines available in market. But which one you do need? Is it for filling granules, powder or pellets? This question will assist you in exploring the ability of machine in processing various materials.

Conclusion

To sum up, we are hoping that you have thoroughly understood a fully automatic capsule filling machine. You may also want to take advantage of this innovative technology by bringing it into your production unit. If yes! Then don’t show any delay and take step forward by contacting Allpack. Our help is just one step away, click on the given link http://www.allpackchina.com/ and get every type of assistance without any hesitation.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586