Good High Accuracy Pill Counter Machine

- Dust Collection Device

- Special Electric Eye Protection Device

- High-Speed Photoelectrical Technology

Pill Counter Machine

Allpack pill counter machine is specially designed for laboratory production and small batch production. Desktop PC for tablet and capsule counting, but small and light. It starts from one bottle at a time, and automatically counts the next bottle after completion. This pill counter machine is convenient to pick and place bottles manually. Suitable for counting the number of capsules when filling capsule bottles and capsule packaging. Accurate, fast, healthy, and avoid touching capsules, it is the most suitable counting tool. According to the shape design of capsules, pills, and honey pills, the counting disc is used for counting. The pill counter machine can be assembled with a conveyor belt and PLC control system, and it can also be part of the automatic production line. The rotation speed of the grain number can be adjusted according to the speed of the manual bottle.

Pill Counter Machine

YL-2 Semi-automatic Rotary Electronic Pill Capsule Tablet Filing Counter Machine

YL-2 semi-automatic rotary pill filing counter machine is mainly applied for counting and filling capsules, tablets, soft gel capsules, and pills. It is mainly used in the pharmaceutical, herbal, food, and chemical industries. The particle number can be set arbitrarily from 0 to 9999. The whole machine is made of stainless steel and complies with GMP requirements. It is easy to operate without special training. Equipped with a special electric eye protection device, the coding can be stored. The rotation speed of the grain number can be adjusted according to the speed of the manual bottle.

Dust Collection Device

Complies With GMP Requirements

Equipped With Special Electric Eye Protection Device

YL-2A Semi-automatic Vibrating High Speed Capsule Pill Counter Machine

YL-2A semi-automatic vibrating high-speed capsule pill counter machine is a semi-automatic counting and bottle-filling machine for capsules, tablets, soft gel capsules, and pills. It is mainly used in the pharmaceutical, herbal, food, and chemical industries. The number of counts can be set freely within the range of 0-9999. The whole machine is made of stainless steel material that complies with GMP requirements. The operation is simple and no special training is required. The rotation counting speed can be manually adjusted steplessly according to the bottle releasing speed.

Dust Collector

Made Of Stainless Steel Material

Complies With GMP Requirements

YL-4 Semi-automatic Desktop High Quality Vibrating Pill Filling Dispensing Counter Machine

YL-4 semi-automatic desktop high-quality pill filling dispensing counter machine is specially designed for capsule and pill counting and filling. The high-quality pill counter machine adopts high-speed photoelectric technology, and the counting and filling are fast and accurate. This counting machine is small in size, easy to use, clean, and maintain. Count by numbers/digits, the counting range can be set to 0-9999. The pill container is equipped with a vibrating device for automatic feeding, and the feeding speed is adjustable. This pill counter machine can be assembled with a conveyor belt and PLC control system, and it can also be part of the automatic production line.

PLC Control System

High-speed Photoelectric Technology

Vibrating Device For Automatic Feeding

The Buyer's Guide

Pill Counter Machine: The Complete Buying Guide In 2025

We all know how important it is to take the right medications on time and in the right dosage. However, pharmacies, hospitals, and other healthcare facilities face the challenge of safely dispensing a multitude of prescription of drugs each day. Fortunately, by investing in a pill counter machine, you can streamline the process while reducing errors.

In this blog post, we will discuss how using a pill counter machine can help ensure that medications are properly tracked and documented. Also, we will explore why using a pill counter machine is beneficial as well as some features to consider when selecting one that can suit your needs. Let’s dive in!

1. What Is A Pill Counter Machine?

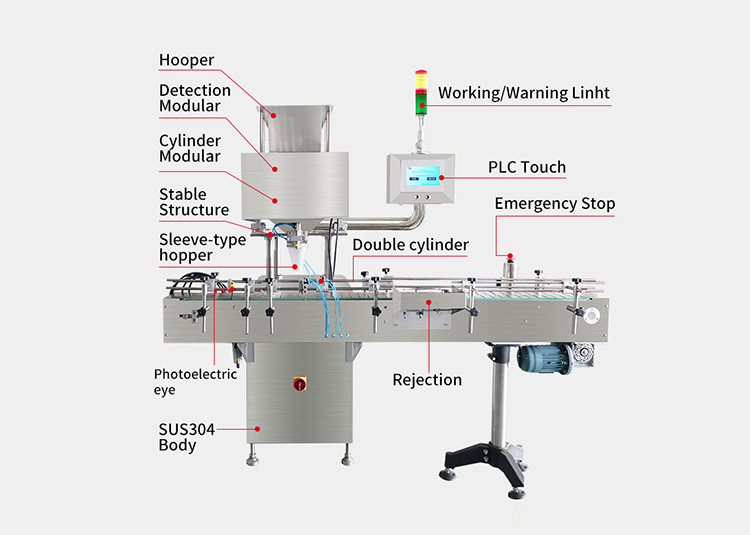

A pill counter machine is a device that helps users to accurately count and dispense pills. It typically consists of two main components: a hopper, which holds bottles of medication, and a counting tray or plate, which allows the user to manually count tablets or capsules.

The pill counter machine is designed with accuracy in mind, as incorrect pill counting can cause severe medical complications. For this reason, pill counter machines are used in hospitals, pharmacies and other healthcare facilities to ensure that each pill is dispensed with precision and accuracy.

In addition to counting pills accurately, pill counter machines also help users save time by quickly counting out the required amount of medication needed for a patient or customer. This enables pharmacists, nurses and other healthcare personnel to efficiently provide the medications they need while ensuring accuracy and safety.

2. What Are The Components Of A Pill Counter Machine?

The components of a pill counter machine include:

Hopper

This is the part that holds the pill bottles so they can be dispensed one pill at a time. The hopper has sensors to determine when all pills have been counted, and it is adjustable to accommodate different pill bottle sizes.

Dispensing Chute

This part of the pill counter machine is used to dispense the pill into a designated cup or tray. It has adjustable guides to ensure that each pill is dispensed correctly and in an orderly fashion.

Counter

This component is used to count the pills being dispensed and keep track of the number of pills dispensed. It has an lcd display that shows the pill count and can be programmed for different pill sizes and counts.

Separator

This part of the pill counter machine is used to separate the pill from its container, allowing it to be dispensed into the designated cup or tray without any mess.

Recycler

This component is used to store pill bottles that cannot be counted by the pill counter machine. It has a revolving door, allowing pill bottles to be accepted and dispensed from one side, while the other side is used for storing and disposing of pill bottles that have been counted.

Controls

These components are used to control all the operations of the pill counter machine. They include buttons, switches, and a display that can be programmed for different pill sizes and counts.

Safety Features

These components are essential to ensure the pill counter machine is operating safely and correctly. These could include emergency stops, sensors, alarms, or other safety features.

3. What Are The Merits Of A Pill Counter Machine?

Accurate Counting

A pill counter machine can provide highly accurate pill counting, eliminating the time and effort it takes to manually count pills. This ensures that all medications are correctly counted, reducing the risk of errors or other safety issues.

Efficiency

A pill counter machine offers significant efficiency gains over manual pill counting. It can accurately count pills in a fraction of the time, allowing pharmacists to spend more time on other tasks.

Cost Savings

By reducing the amount of time it takes to count pill bottles, pill counter machines can save pharmacies money in labor costs. This is especially beneficial for large-scale pill-counting operations that require multiple people to complete.

Reduced Human Error

Mistakes can happen when counting pill bottles by hand, but pill counter machines are designed to virtually eliminate human errors. By using automated pill-counting technology, pharmacies can ensure that all medications are accurately counted every time.

Easy to Use

Pill counter machines are surprisingly easy to use and require minimal training for operators. With just a few simple steps, pill bottles can be quickly and accurately counted with the machine.

4. Are There Any Demerits Of A Pill Counter Machine?

The pill counter machine is a highly accurate and efficient way to count medication. However, pill counter machines do have some drawbacks.

For one, pill counter machines can be expensive to purchase and maintain. In addition, pill counters require manual intervention to adjust pill counts when pill sizes or shapes are different from the standard. Finally, pill counter machines can be complex to operate and require staff training for accuracy and proper operation.

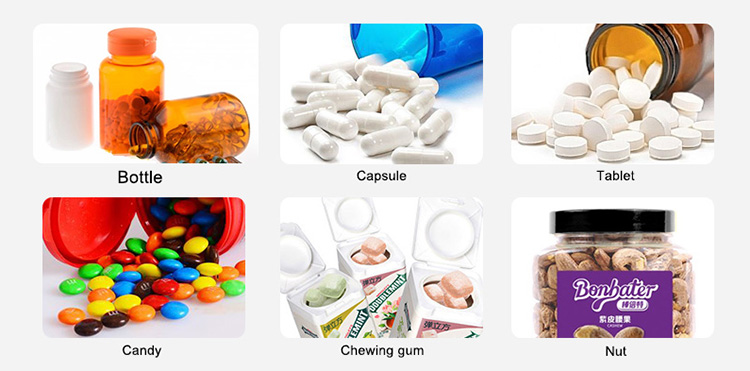

5. What Are The Applications Of A Pill Counter Machine?

Food Industry

Pill counter machines are often used in the food industry as a method of packaging and counting products. They can accurately count how many of each pill or capsule are in a container, which makes it easier to create consistent product batches and ensure packaging consistency.

Pharmaceuticals Industry

Pill counter machines are useful in pharmaceuticals where they provide a fast and efficient way to count and sort pills and capsules. They can help in the accurate and rapid distribution of medications, reducing the risk of errors.

Medical Research

Pill counter machines can be used to count a variety of pill sizes in scientific studies or medical research, ensuring that the exact amount is measured and distributed correctly.

Veterinary Use

Pill counter machines can be used for counting pill volumes in veterinary medicine, as well as for administering medications to animals. This helps reduce the risk of errors and ensures a more accurate dosage is given.

Chemical Industry

Pill counter machines are used in the chemical industry for counting pill volumes and ensuring that materials are accurately distributed.

Retail Industry

Pill counter machines can be used in retail stores to accurately count pill volumes for customers, reducing the chance of error and providing an accurate and efficient way to serve their needs.

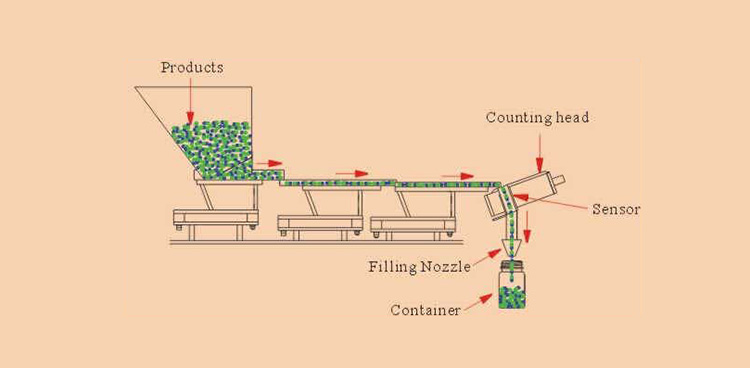

6. What Are The Working Principles Of A Pill Counter Machine?

A pill counter machine uses a combination of sensors and automation to accurately count pills. It operates by passing pill bottles, trays, or other containers through an opening in the machine where a scanning light is passed across the pill bottle surface.

The pill inside is then assigned a unique identification code based on its shape, size, color, and unit weight. This code is then used to count the pill and ensure accuracy.

7. What Are The Different Types Of Pill Counter Machines?

a) Automatic pill counter machines

These pill counters use an automated process to accurately and quickly count pills. The machine has a hopper or chute where the pill bottles are placed which then gets scanned by sensors, counted, and dispensed into pill trays. This type of pill counter is ideal for pharmacies that need to fill high volume pill orders quickly and accurately.

Components

Here are the main components of an automatic pill counter:

Motor

Automatic pill counter machines usually require a motor to run the machine and drive any functions such as moving pills into position for counting or vibrating the pills when being filled.

Dispensing mechanism

Automatic pill counters typically have a dispensing mechanism that can move individual pills from their container into the counting area.

Counters

Automatic pill counters often integrate multiple counters with different capabilities such as counting pills, weighing them, or measuring dimensions.

Sensors

Automatic pill counter machines often incorporate sensors such as optical or mechanical sensors to detect the presence of pills and determine their size, shape, or weight.

Display/Control Panel

Automatic pill counters also feature a display or control panel that allows users to view the results of their count and interact with the machine.

Interface

Automatic pill counter machines may also include interfaces such as a USB or Ethernet port for connecting to other computers or devices and transferring data.

Working principles

The automatic pill counter machine is first loaded with the required number of pills into its hopper. As pills are released from the hopper, an automatic weighing mechanism measures the weight of each pill and records it on a tally board.

The automatic pill counter also uses a counting disc system to accurately count each pill as they travel along its conveyor belt. Finally, at the end of the line, pills are sorted into their respective containers and sealed with packaging tape for safe storage.

Applications

An automatic pill counter can be used for a variety of applications, such as counting and sorting medicines in pharmacies or hospitals. It can also be used to help streamline processes for home health care providers, such as nursing homes or long-term care facilities.

Also, automated pill counters can be used to track inventory in a medical facility, ensuring that there is enough stock on hand when needed. Finally, automatic pill counters can be used for research purposes in drug development or clinical trials to help track patient intake and dosage.

b) Manual pill counter

Manual pill counters require a person to manually count the pills, one by one. These counters are typically used in smaller pharmacies that don’t require the high-speed accuracy of automated pill counting machines.

Components

Tray

A manual pill counter typically has a shallow tray with dividers or an adjustable track to evenly disperse the pills. The tray also allows for easy cleanup and is designed to optimize counting accuracy and minimize spills.

Compartments

There are usually multiple compartments within the manual pill counter that store the pills being counted. Depending on the manual pill counter type, the compartments can be removable or fixed in place.

Counting Wheel

This is used to count and measure the quantity of pills within each compartment. The wheel typically has a number of slots that correspond with the amount of compartments in the manual pill counter tray.

Cover

The manual pill counter often has a cover that is designed to prevent any dust or debris from entering the system and affecting the accuracy of the count. The cover also provides additional safety for the user, keeping them safe from potential inhalation of airborne particles.

Counter Control Knob

This knob is used to rotate the manual pill counter’s counting wheel and accurately count the pills in each compartment.

Display Screen

The manual pill counter often has a display screen that shows the user the number of pills counted and any discrepancies between the expected number and actual count.

Spill Tray/Container

Some manual pill counters include a spill tray or container that collects any dropped or spilled pills. This allows you to accurately track and collect any mistakes in order to avoid inaccurate counts.

Battery/Power Source

The manual pill counter typically needs some form of power source, be it battery or manual winding, to operate correctly. This ensures that the manual pill counter runs consistently and accurately no matter how long it is used.

Dispensing Plate

This plate is used to dispense pills from the manual pill counter into a container for further use or storage. The dispensing plate can be adjustable depending on the manual pill counter model, allowing for more accurate counting in larger batches.

Working Principles

Manual pill counters work by placing the pills in a tray, then turning a manual dial or lever which moves the pills along a counting track. The manual pill counter counts each pill as it passes through the track, tabulating the total number of pills counted at the end. Once the pill count is complete, the manual pill counter can be reset and used for another count or a new set of pills.

Applications

A manual pill counter is often used for counting pharmaceuticals in hospitals, pharmacies, long-term care facilities, and other medical facilities. It can also be used for home pill storage and dispensing for individuals who need to take medications regularly.

In hospitals and other medical facilities, manual pill counters are essential for accurate prescription filling and medication administration. In-home care settings, manual pill counters can be used to conveniently store and dispense medications on a daily basis.

c) Semi-Automatic Pill Counter

A semi-automatic pill counter is a device used to quickly and accurately count pills or tablets (or both) in bulk. It can be used for inventory, prescription filling, clinical trials, and other purposes where accuracy and speed are important factors.

These devices typically use advanced imaging technology and algorithms to identify the size and shape of each pill, ensuring precise counting. Many semi-automatic pill counters can operate at speeds of up to 600 pills per minute, making them ideal for high-volume applications.

Components

The components of a semi-automatic pill counter include:

Tablet Dispenser

This is the part of the semi-automatic pill counter which actually holds and dispenses the pills or tablets. It typically consists of an acrylic chamber with multiple compartments to hold different types of medication.

Counting Tray

This is a lightweight, flat surface tray that is used to hold tablets or pills in large batches for counting. It is typically lined with a non-slip material to ensure the tablets do not move around when being counted.

Counting Port

This is a small opening at one end of the semi-automatic pill counter where the pills are dispensed. The user places a batch of pills into the counting tray, and then inserts it into the counting port to begin the counting process.

Counting Mechanism

This is responsible for accurately calculating the number of tablets or pills in each batch. It typically consists of a counting wheel that rotates when the pills are placed in the counter and a counter that keeps track of the total number.

Display Screen

This is the part of semi-automatic pill counter which displays the results of the counting process. It typically consists of a digital display which provides information such as the number of tablets or pills counted and total count.

Control Panel

This part includes buttons and dials which are used to control the semi-automatic pill counter. The control panel allows you to set parameters for the counting process such as the time interval, batch size and total number of tablets or pills.

Working Principles

A semi-automatic pill counter machine works by first dispensing the desired number of pills into a hopper. From there, an internal belt system moves the pills along the conveyor for counting.

A sensor picks up each individual item as it passes through and into the counting chamber, where a counter keeps track of the number.

The semi-automatic pill counter is then able to deliver an accurate count at the end of each cycle and alert users when it reaches the desired amount.

Applications

A semi-automatic pill counter can be used for a variety of applications, such as accurately and quickly counting pills in pharmacies, hospitals, nursing homes, and other healthcare settings.

Semi-automatic pill counters are also commonly used in research and development laboratories, veterinarians, and pharmaceutical manufacturing facilities.

In addition, semi-automatic pill counters can be utilized in medical and healthcare settings for inventory management and compliance.

Finally, semi-automatic pill counters are used to package bulk medications into unit doses for easy dispensing by medical professionals.

8. What Is The Difference Between Manual Pill Counter And Automatic Pill Counter?

a) Manual Pill Counter

b) Automatic Pill Counter

The main difference between manual and automatic pill counters is the speed and accuracy. Manual pill counters are manual devices used to count pills by hand. They involve a manual process of sorting, counting and pouring the pills. Also, manual pill counting requires manual dexterity and is time consuming which can lead to errors if not done correctly.

Automatic pill counters, on the other hand, are electronic devices that use either mechanical or optical scanners to quickly identify and count pills. Automatic pill counters are usually much faster and more accurate than manual pill counters as they can accurately identify and count pills in a fraction of the time manual counting would take.

Additionally, automatic pill counters allow for precise record keeping which manual pill counting does not provide. This makes automatic pill counters ideal for hospitals or pharmacies where accuracy and speed are paramount.

9. What Is The Difference Between The Automatic Pill Counter And Semi-Automatic Pill Counter?

a) Automatic Pill Counter

b) Semi-Automatic Pill Counter

The main difference between an automatic pill counter and a semi-automatic pill counter is the amount of human intervention needed to count pills. An automatic pill counter is fully automated, requiring no manual input from a user. The automatic pill counter uses advanced technology such as sensors and cameras to accurately count the number of pills in a container.

On the other hand, semi-automatic pill counters require more user involvement, as a user must manually input the number of pills into the machine for it to accurately count.

While automatic pill counters are more efficient and accurate than semi-automatic pill counters, they tend to be much more expensive. Semi-automatic pill counters are less costly but also less effective in terms of accuracy.

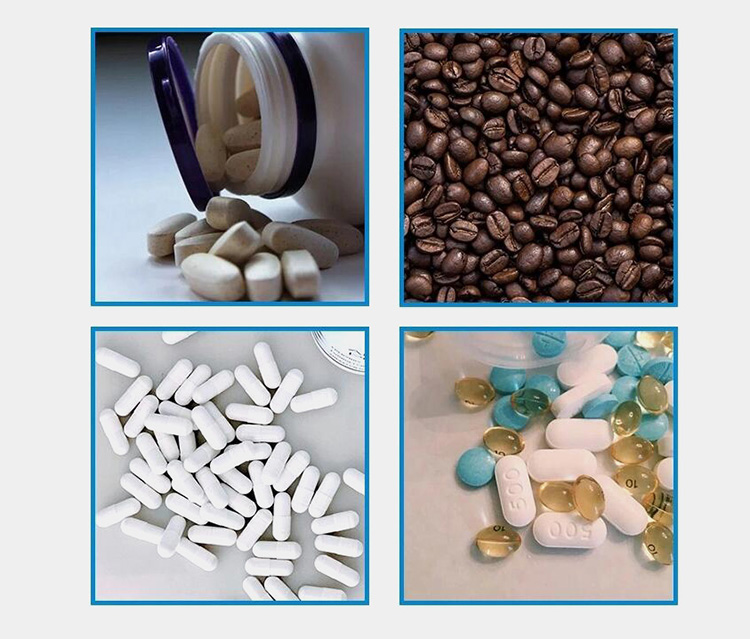

10. What Can Be Counted Using A Pill Counter Machine?

Capsules

A pill counter machine can help quickly and accurately count capsules of different sizes, shapes and colors. It does this by utilizing a vibrating hopper to separate the pills so that they can be counted individually.

Tablets

Tablet counting is also possible with pill counter machines as it has specialized chutes which guide the tablets and help them pass through counter detectors. This ensures that all tablets are accurately counted.

Soft gel

Soft gel pill counting is possible with pill counter machines as it has a gravity-fed hopper system. This helps to ensure that each soft gel pill is fed into the machine without damaging or bending them.

Beans

Pill counter machines can also count beans by using a vibrating hopper. The pill counter is able to accurately measure the number of beans in each pill so that it can be counted correctly.

Sweets/Candy

Pill counter machines can be used to count sweets and candies. The pill counter machine is able to accurately measure the size and weight of each sweet or candy so that it can be counted correctly.

11. Which Quality Standards Should A Pill Counter Machine Conform To?

Accuracy

A pill counter machine should be able to accurately count and dispense pills to ensure the correct dosage is being taken.

Durability

A pill counter machine should be built with durable materials that can withstand heavy usage and extreme conditions over time without breaking down or malfunctioning.

Ease of Use

A pill counter machine should be easy to use, taking into consideration different abilities of its users. The controls should be intuitive and locatable, and the user feedback should be clear and concise.

Reliability

A pill counter machine should have a reliable mechanism to ensure that it dispenses the correct number of pills at all times, without fail. It should also have an uninterrupted power supply to keep it running even in cases of power outages.

Data Security

A pill counter machine should be equipped with secure data handling systems to prevent any unauthorized access or manipulation of the pill counting process.

Quality Assurance

A pill counter machine must conform to stringent quality assurance and control standards, such as those outlined by ISO 9001, to ensure consistent performance and operation.

12. What Are The Best Practices When Using Pill Counters To Reduce Pill Counting Errors?

Ensure pill counter machine is routinely calibrated

A pill counter machine should be regularly and accurately recalibrated to ensure accurate pill counting. This will help reduce errors associated with dosage calculations and pill counts.

Utilize a double-check system

The use of two independent individuals to check the accuracy of pill counts and dosage calculations can help to reduce pill counting errors.

Use the correct pill shapes and sizes

Pill counter machines should be used with pill shapes and sizes that are compatible with them. Allowing the pill counter machine to only accept certain pill shapes and sizes will help prevent incorrect pill counts due to incorrect pill shape or size recognition by the pill counter machine.

Monitor pill counts manually

Monitoring pill counts manually will help to spot errors early and prevent incorrect pill counts from occurring in the first place.

Utilize pill counting logs

Pill counting logs can provide an additional level of accuracy for pill counting, helping to ensure that the correct number of pills are being dispensed for each patient.

Store pill counting logs electronically

Storing pill counting logs electronically ensures that all pill count records are securely stored and easily accessible for future reference. This will help to prevent discrepancies between pill counts across different groups or locations, reducing the risk of pill counting errors.

Utilize barcode scanning

Utilizing pill counter machines with barcode scanning capabilities can help to ensure that the pill counts are being accurately read and entered into the system, reducing potential pill counting errors.

Follow-up on discrepancies between pill counts

If there is a discrepancy between pill counts, it is important to investigate the cause of the discrepancy and address it immediately. This will help to prevent any potential pill counting errors from occurring in the future.

13.What Are The Maintenance Procedures For A Pill Counter Machine?

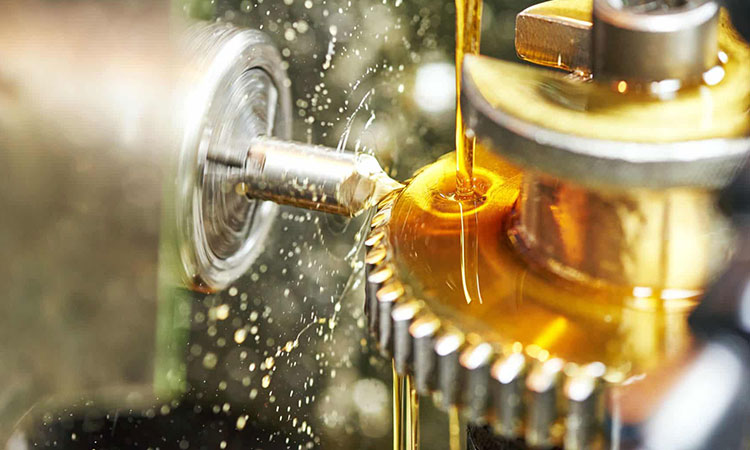

Lubrication

Use a lubricant to maintain pill counter machine parts like gears and conveyor belts so they run smoothly and don’t cause excessive friction or wear.

Cleaning

Clean the pill counting bowl, chute, hopper, and other pill counter machine components with a damp cloth to remove any dust or dirt.

Adjust Settings

Adjust the pill counting speed and accuracy levels based on your pill sorting requirements, such as pill size and pill shape.

Testing

Test pill counter machine accuracy by running a few batches of pills through the pill counting process to make sure it is working as intended.

14. What Are The Common Pill Counter Machine Problems And How Can You Troubleshoot Them?

Jammed pill hopper

A pill hopper can become jammed when pill shapes, sizes and/or textures vary significantly.

Solution

To troubleshoot this problem, inspect the pill hopper for debris and dislodged pills, then remove them before attempting to use the pill counter machine again.

Incorrect Pill Counting

If pill counting is off, it could be due to errors in the pill size settings or pill shape inconsistencies.

Solution

To troubleshoot this problem, double-check that pill sizes are set correctly, and inspect pills for any irregularities before use.

Incorrect Pill Count Dispenses

This could happen if a pill counter machine has been set for incorrect pill sizes or pill types.

Solution

To troubleshoot this problem, check pill counting settings and verify pill type is correctly set.

Poor Pill Filling Accuracy

This could happen if pills are sticking together when placed in the pill hopper.

Solution

To troubleshoot this problem, inspect pill-filling area for any debris and pill residue, then clean as necessary.

Poor Pill Counting Accuracy

This could happen if pill counter parameters are not set correctly or because pill types vary too much.

Solution

Check pill size settings and inspect pills for any irregularities before use. Additionally, consider using a pill counter machine that has different speed settings to get more accurate pill counting results.

Error Codes

Pill counter machines will display error codes when there is an issue with pill counting accuracy or pill filling accuracy.

Solution

Look up the error code in the pill counter machine manual and follow any instructions that are provided to resolve the issue. If needed, contact a pill-counting machine technician for additional help.

15. What Regulatory Compliance Measures Should Be Taken Into Account When Purchasing Pill Counters?

Regulatory compliance measures to consider when purchasing pill counters include:

Ensure the pill counter machine is FDA approved

All pill counters should be certified and listed by the FDA to ensure they meet all applicable standards for accuracy and safety.

Ensure the pill counter is compliant with USP <797> standards for sterility assurance

These are standard outline requirements for pill counting machines that help maintain the sterility of medication, including pill counter systems that use sonic or electrical pill counting technology.

Ensure the pill counter is compliant with Good Manufacturing Practices (GMP).

GMP lays out a set of guidelines to help manufacturers ensure their pill counters are manufactured, stored and used in a safe and effective manner.

Ensure the pill counter machine has been tested and certified by an independent testing laboratory.

Having pill counters tested and certified by a third party creates more confidence in the accuracy of the pill counter machine, as well as its durability over time.

Conclusion

As the global population continues to grow, so does the demand for medications. With that in mind, hospitals and pharmacies are looking for ways to dispense pills more efficiently. The Allpack pill counter machine is a great option if you want to increase efficiency and accuracy. Therefore, if you are looking for a machine that can help you count pills, please do not hesitate to contact us. Our team of experts will be more than happy to help you with your needs and answer any questions that you may have. So what are you waiting for? Contact Allpack today to learn more about this amazing tool and we’ll help you find one that suits your needs.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours