Vacuum Sealed Food Shelf Life Chart

Vacuum Sealed Food Shelf Life Chart

Ever wondered how vacuum sealed foods have an improved shelf life? No? Possibly, we have knocked your brain to think about it. But don’t worry! Along with this riddle, we have already described many clues, expert discussions, and reasons behind the significant role of vacuum sealing in a product’s packaging and considered a ‘super-hero’ in the packaging industry.

However, understanding how long it will preserve your food? For that, we have created this blog which is composed of various vacuum sealed food shelf life charts. The purpose of this article is to make you well aware of the standard shelf lives of your product that you can claim when offering a vacuum sealed food product. Without further ado, let's get into an interesting article, do not forget to see our amazing range of vacuum sealed equipment and share the post.

1.What Exactly a Vacuum Sealed Food is?

Vacuum Sealed Food- Picture Courtesy; Oilso

The vacuum sealed food is a significant way of packaging your eatables to extend their shelf life and obtain unlimited health benefits in any season. This method is achieved by removing the presence of oxygen molecules inside the packaging.

The different kind of food have different affinities to react with oxygen and moisture and starts the reaction of rancidity and contamination in a defined period. For instance, certain food goes bad in twenty-four hours while some in forty- eight hours etc.,

However, vacuum sealing is a standard way to enclose your food that generally lasts for weeks to months, and sometimes till a year. That’s why this way is strictly and preferably followed by manufacturers and businesses to save money, improve food protection, retain taste, texture, colour, flavour, and much more.

So, now you don’t need to worry about consuming unwanted preservatives or additives in many organic foods if they’re vacuum sealed.

2.What do you understand by Vacuum Sealed Food Shelf life?

A vacuum Sealed foods- Picture Courtesy: nationalproductreview

Keeping food products in the original packaging is a failsafe way to increase their consumption period but manufacturers can extend the expiration date of their food products even further by vacuum sealing it.

It is the ideal way to protect and preserve food products as during vacuum sealing the oxygen is eliminated from the packaging. after oxygen removal packaging is tightly closed and air sealed.

So, vacuum sealed food shelf life is considered as multiple times greater than storing foods using a conventional method. The reason behind its extended shelf life is due to:

Minimize the process of oxidationand reduce the generation of reactive oxidative species which is a liberating and fast-reacting moiety to deteriorate your food and nutrition.

Preventing Progression of Bacterial and Fungal Growthby reducing aerobic bacterial development, fungus and yeast which rapidly spoil your food and make one’s ill.

Stabilize your food by protecting it against humidity, oxygen, and light, and maintain the integrity of food and keep it fresh for a longer period.

High Nutritional Value can be maintained with vacuum sealed food shelf life.

Texture and Flavour ofvacuum sealed food are kept mouth-watering till their shelf life and thus you can enjoy the cuisine experience anywhere.

Good for Storage for a Longer Time as vacuum sealed food shelf life is higher which ensures their storage in bulk and delivery anywhere in the world.

Vacuum sealed food stuffs last longer than food without a vacuum. The average increase in the shelf-life of foods with vacuum sealing is about 1-2 years.

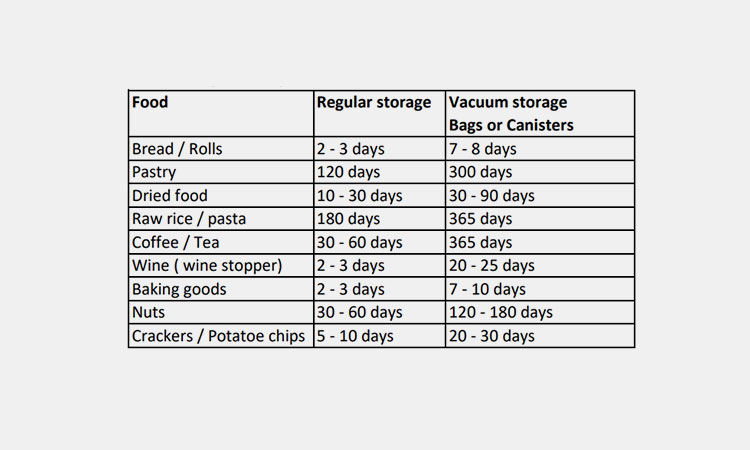

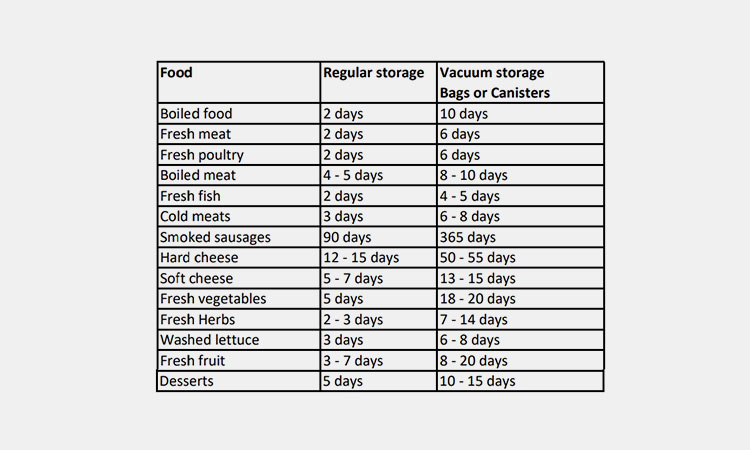

Vacuum Sealed Food Shelf Life Chart-Picture Courtesy: FoodSaver

The estimation of vacuum sealed food shelf life is done by comparing various research studies.

The above-mentioned graph illustrates the sustainability and intact quality of food with stable shelf life, which means you can enjoy beef and poultry for over two to three years with vacuum sealed as compared to ordinary food storage.

Similarly, if you see other items such as fish, soup stock stew, etc you can easily understand their shelf life is extended by 1-2 years with vacuum sealing.

3.How Do Find Vacuum Sealed Food Shelf Life Chart?

Firstly, you need to understand what is vacuum sealed food shelf life chart; it begins with your vacuum sealed food packaging which is packed with vacuum sealing offered by the packaging company. The manufacturer examines and coins an expiry date which is mentioned in the product’s label for your ease. These values or dates are well-documented and accompanied by the manufacturer's website and official documentation as well.

So, we have exemplified the following information and readily available charts with particular details below so learn more about vacuum sealed food shelf life chart.

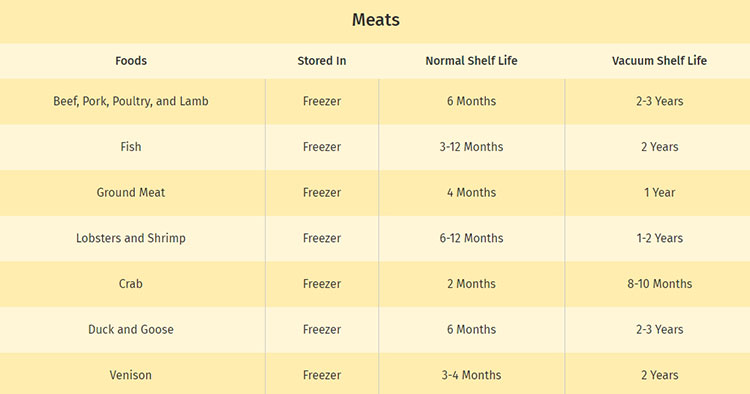

Vacuum Sealed Food Shelf Life Chart of Meats

Vacuum Sealed Meat- Picture Courtesy: Mountain America Jerk

Meat products are packed with proteins and other nutrients. In old times, people use salt as a means of extending shelf-life of the meat products. The salt forces water content out of the meat and prevent growth of microbes.

| MEATS | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Beef, Pork, Poultry, and Lamb | Freezer | 6 Months | 2-3 Years |

| Fish | Freezer | 3-12 Months | 2 Years |

| Ground Meat | Freezer | 4 Months | 1 Year |

| Lobsters and Shrimp | Freezer | 6-12 Months | 1-2 Years |

| Crab | Freezer | 2 Months | 8-10 Months |

| Duck and Goose | Freezer | 6 Months | 2-3 Years |

| Venison | Freezer | 3-4 Months | 2 Years |

Nowadays, vacuum sealing meat products is standard way to prolong expiry period of meat. With vacuum sealing meat products, the beef and other red meat have a shelf life of 2-3 years in freezer but with normal packaging, these products can last around 6 months. With vacuum sealing, the shelf life of every meat product is extended over 8 months.

Here is a chart detailing the comparison of shelf life of meat products packed under normal packaging and vacuum sealed packaging.

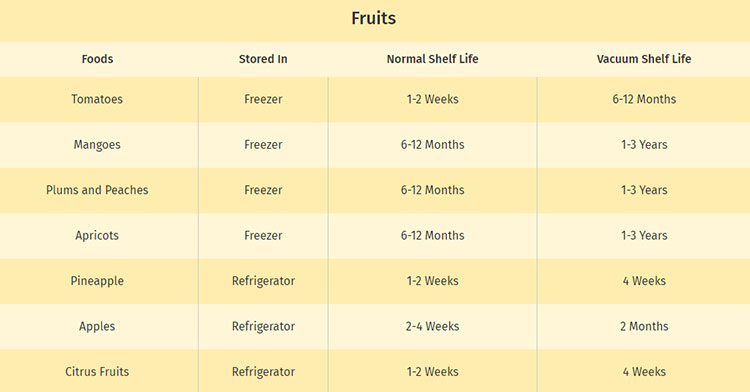

Vacuum Sealed Food Shelf Life of Fruits

Vacuum Sealed Fruits

Fruits are rich sources of all essential nutrients, especially vitamins and minerals. By eating fruits, you are guaranteed body health. Drying, curing, and fermenting are a few ancient ways to preserve fruits.

With innovation, vacuum sealing is introduced to extend the shelf-life of fruits. Below mention chart discusses about expiration period of normal packaging and vacuum sealed fruits.

| Fruits | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Tomatoes | Freezer | 1-2 Weeks | 6-12 Months |

| Mangoes | Freezer | 6-12 Months | 1-3 Years |

| Plums and Peaches | Freezer | 6-12 Months | 1-3 Years |

| Apricots | Freezer | 6-12 Months | 1-3 Years |

| Pineapple | Refrigerator | 1-2 Weeks | 4 Weeks |

| Apples | Refrigerator | 2-4 Weeks | 2 Months |

| Citrus Fruits | Refrigerator | 1-2 Weeks | 4 Weeks |

It is estimated that vacuum sealed fruits stored in refrigerators like, pineapples, apples experience an increase of 2 weeks on average in their shelf-life, whereas, the consumption period of freezer-stored fruits, for instance, mangoes, plums, and many more are boosted by about 6-12 months with the use of vacuum sealed packaging.

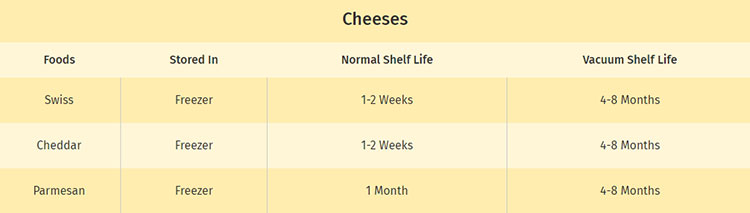

Vacuum Sealed Food Shelf-Life Chart of Cheese

Vacuum Sealed Cheese- Picture Courtesy: Modified Atmosphere Packaging

Cheese is a dairy product that is rich in protein and minerals. Cheese pots are buried deep underground for storage and to prevent their spoilage in ancient times. Vacuum sealing a whole block or even just a slice of cheese keeps its freshness and nutritional value longer.

Here is a chart detailing the shelf life of normal and vacuum cheese.:

| Cheese | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Swiss | Freezer | 1-2 Weeks | 4-8 Months |

| Cheddar | Freezer | 1-2 Weeks | 4-8 Months |

| Parmesan | Freezer | 1 Month | 4-8 Months |

Cheese products are typically stored in the freezer and comparative studies of vacuum sealing cheese products showed that these products have a higher expiration time of about 4-8 months while normal cheese packaging has a shelf-life of only 1-2 weeks.

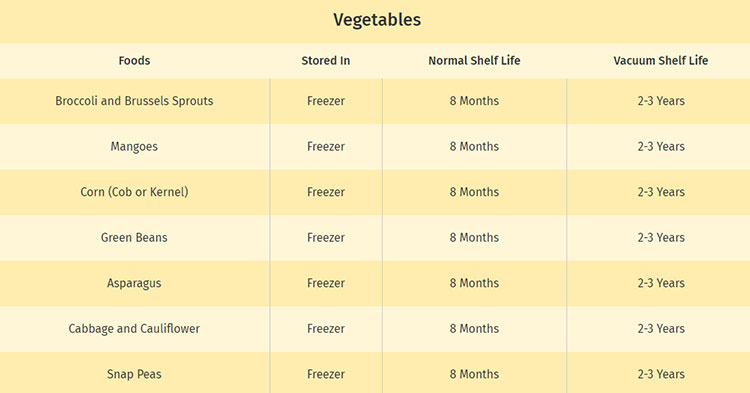

Vacuum Sealed Food Shelf-Life Chart of Vegetables

Vacuum Sealed Vegetables- Picture Courtesy: Weston Brand

Vegetables are good sources of fibre, vitamins, minerals, and, proteins. Daily consumption of vegetables is best for the well-being of humans. Pickling vegetables was the popular way of maintaining their nutritional quality in the old days.

Below is the comparative chart of normal packaging and vacuum seal packaging of vegetables.

| Vegetables | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Broccoli and Brussels Sprouts | Freezer | 8 Months | 2-3 Years |

| Mangoes | Freezer | 8 Months | 2-3 Years |

| Corn (Cob or Kernel) | Freezer | 8 Months | 2-3 Years |

| Green Beans | Freezer | 8 Months | 2-3 Years |

| Asparagus | Freezer | 8 Months | 2-3 Years |

| Cabbage and Cauliflower | Freezer | 8 Months | 2-3 Years |

| Snap Peas | Freezer | 8 Months | 2-3 Years |

The latest vacuum sealed packaging is the easiest way to increase the longevity of vegetables. Studies have estimated that vacuum sealing has a significant impact on the shelf-life of vegetables. Vacuum sealed vegetables typically are good for 2-3 years in the freezer, whereas, vegetables in normal packaging can only stay fresh for 8 months.

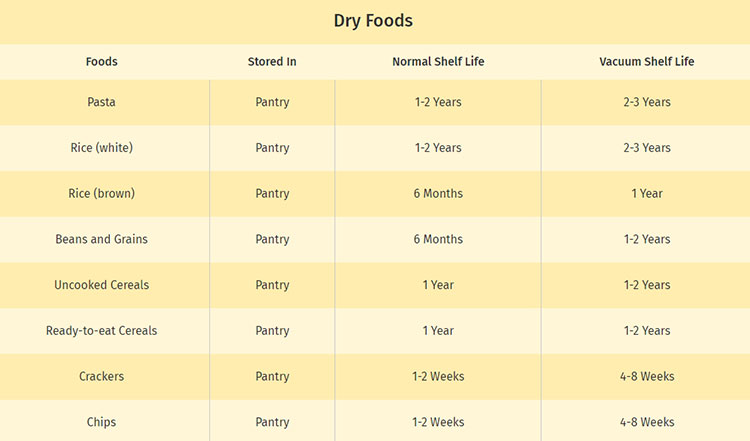

Vacuum Sealed Food Shelf-Life Chart of Dry Foods

Vacuum Sealed Dry Food

Dry foods such as pasta and rice can be vacuum sealed to maintain their quality.

Following is the chart comparing the shelf-life of dry foods in normal and vacuum sealed packaging.

| Dry Foods | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Pasta | Pantry | 1-2 Years | 2-3 Years |

| Rice (white) | Pantry | 1-2 Years | 2-3 Years |

| Rice (brown) | Pantry | 6 Months | 1 Year |

| Beans and Grains | Pantry | 6 Months | 1-2 Years |

| Uncooked Cereals | Pantry | 1 Year | 1-2 Years |

| Ready-to-eat Cereals | Pantry | 1 Year | 1-2 Years |

| Crackers | Pantry | 1-2 Weeks | 4-8 Weeks |

| Chips | Pantry | 1-2 Weeks | 4-8 Weeks |

Additionally, it prevents pest and bug infestations. Vacuum sealed technique in dry food packaging exceedingly uplifts their expiration date, for instance, the shelf-life of pasta, white rice, etc is increased by about 2-3 years as compared to 1-2 years in normal packaging.

Crackers and chips that are vacuum sealed are good to eat for up to 4-8 weeks while vacuum sealed cereals can be consumed in 1-2 years after their purchase.

Vacuum Sealed Food Shelf-Life Chart of Spices

Vacuum Sealed Spices

Spices bring tanginess to culinary. Yes, in old times, spices were preserved with air-drying which often resulted in mould infestation. Fortunately, vacuum sealing prevents mould, fungus, and bacterial growth on spices by eliminating air. This ensures your spices are clean, safe, and ready for cooking.

Here is an impact chart of vacuum sealing on the shelf-life of spices.

| Spices | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Herbs / Spice Blends | Pantry | 1 Year | 1-3 Years |

| Spices (ground) | Pantry | 6 Months | 1 Year |

| Spices (whole) | Pantry | 1-2 Years | 2-3 Years |

It has been determined by the studies that the serviceable life of herbs and spices blend is improved to 2-3 years with vacuum sealing than 1 year in normal packaging. Ground and whole spices preserved with vacuum sealing are good for 1 and 2-3 years, respectively.

Vacuum Sealed Food Shelf-Life Chart of Condiments

Vacuum Sealed Condiments- Picture Courtesy: Mountain America Jerk

Condiments serve various purposes like dip or dressings. They are also used in cooking to prepare sauces. They improve the taste, texture, and aroma of food.

| Condiments | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Tomato Sauces | Pantry | 1-2 Years | 6 months-3 Years |

| Olives | Pantry | 6 Months | 1-2 Years |

| Mayo | Pantry | 2 months | 1 Year |

| BBQ Sauce | Pantry | 6 months | 1 Year |

| Salad Dressing | Pantry | 1-2 Weeks | 1 Year |

Vacuum sealing adds to the expiration period of the condiment. By vacuum sealing, manufacturers can improve the consumption time of mayo, BBQ sauce, and salad dressing to 1 year, whereas, their normal shelf-life in the pantry is only 2 months, 6 months, and 1-2 weeks, respectively.

Tomato ketchup with vacuum sealing is good for consuming for 3 years when stored in the pantry.

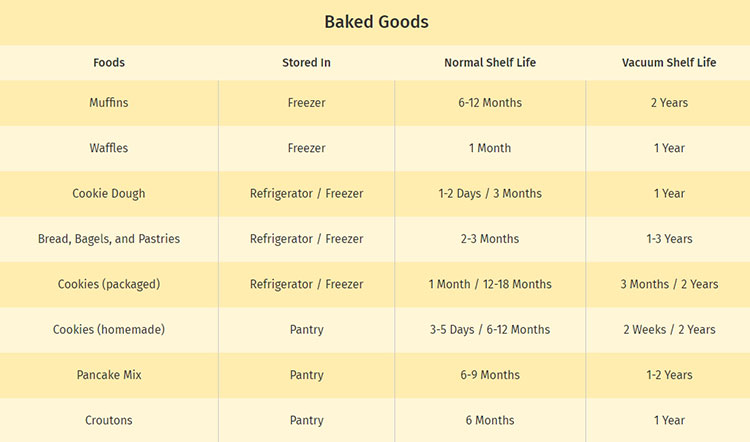

Vacuum Sealed Food Shelf-Life Chart of Baked Goods

Vacuum Sealed Baked Goods

Baked goods are an instant source of carbohydrates. Innovative vacuum sealing is also used in baked goods packaging.

| Baked Goods | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Muffins | Freezer | 6-12 Months | 2 Years |

| Waffles | Freezer | 1 Month | 1 Year |

| Cookie Dough | Refrigerator / Freezer | 1-2 Days / 3 Months | 1 Year |

| Bread, Bagels, and Pastries | Refrigerator / Freezer | 2-3 Months | 1-3 Years |

| Cookies (packaged) | Refrigerator / Freezer | 1 Month / 12-18 Months | 3 Months / 2 Years |

| Cookies (homemade) | Pantry | 3-5 Days / 6-12 Months | 2 Weeks / 2 Years |

| Pancake Mix | Pantry | 6-9 Months | 1-2 Years |

| Croutons | Pantry | 6 Months | 1 Year |

A major increase in the shelf life of baked goods is seen with vacuum sealing, Normally, these food products can last only about days in the pantry and some months in the freezer.

But with vacuum sealing, their lifetime is increased to 1-2 years. Shelf-life of different baked goods is discussed below for your information.

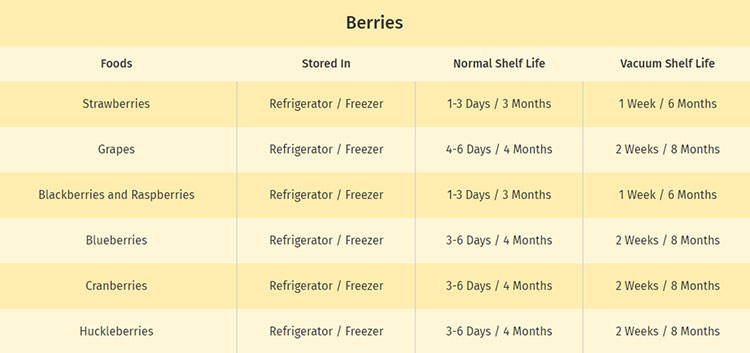

Vacuum Sealed Food Shelf Life Chart of Berries

Vacuum Sealed Meat Berries

Berries are immunity-boosting food and are rich in vitamin C. You can consume vacuum sealed berries even after their end season. Because this technique retains the nutritional quality of berries.

| Berries | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Strawberries | Refrigerator / Freezer | 1-3 Days / 3 Months | 1 Week / 6 Months |

| Grapes | Refrigerator / Freezer | 4-6 Days / 4 Months | 2 Weeks / 8 Months |

| Blackberries and Raspberries | Refrigerator / Freezer | 1-3 Days / 3 Months | 1 Week / 6 Months |

| Blueberries | Refrigerator / Freezer | 3-6 Days / 4 Months | 2 Weeks / 8 Months |

| Cranberries | Refrigerator / Freezer | 3-6 Days / 4 Months | 2 Weeks / 8 Months |

| Huckleberries | Refrigerator / Freezer | 3-6 Days / 4 Months | 2 Weeks / 8 Months |

Normally packed berries, for instance, strawberries, grapes, and blackberries, persist 1-6 days in the refrigerator and 3-4 months in the freezer. However, with the use of vacuum sealing, a notable increase in their shelf-life is observed, with vacuum sealed berries lasting 1-2 weeks in the refrigerator and 6-8 months in the freezer.

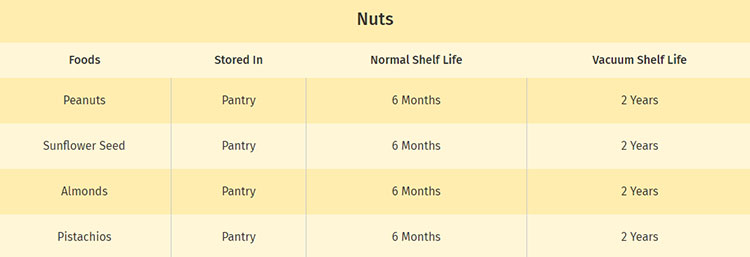

Vacuum Sealed Food Shelf-Life Chart of Nuts

Vacuum Sealed Nuts

Including nuts in daily routine adds omega-3 fatty acids and antioxidants to the diet. People preserved nuts by pickling them in the old days.

Here is a comparative chart of the normal and vacuum shelf life of nuts.

| Nuts | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Peanuts | Pantry | 6 Months | 2 Years |

| Sunflower Seed | Pantry | 6 Months | 2 Years |

| Almonds | Pantry | 6 Months | 2 Years |

| Pistachios | Pantry | 6 Months | 2 Years |

The state-of-the-art vacuum sealing is a reliable method of maintaining the shelf life of nuts without any hustle. Yes, you can keep your vacuum sealed nuts and seeds like peanuts, sunflowers, etc. up to 2 years in the pantry as opposed to 6 months in normal packaging.

Vacuum Sealed Food Shelf-Life Chart of Coffee and Tea

Vacuum Sealed Coffee

Coffee and tea are the most consumable beverages in the world. Thus, manufacturers employ vacuum sealing to boost the longevity of their coffee and tea products.

| Coffee and Tea | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Coffee Beans | Pantry / Freezer | 1-3 Months / 6-8 Months | 1 Year / 2-3 Years |

| Ground Coffee | Pantry / Freezer | 1-2 Months / 4-6 Months | 5-6 Months / 2 Years |

| Tea (loose or in bags) | Pantry / Freezer | 8-12 Months | 1-2 Years |

A worth-mentioning effect of vacuum sealing for about 1-3 years is seen in the shelf life of coffee and tea. For example, vacuum sealed coffee beans have a serviceable life of 1 year in the pantry as compared to the normal shelf life of 1-3 months.

Similarly, loose tea or tea bags last around 1-2 years in the pantry as opposed to their normal shelf life of 8-12 months.

Vacuum Sealed Food Shelf-Life Chart of Powdery Foods

Vacuum Sealed Powdery Food- Picture Courtesy: Design Rush

Powdery foods are a staple source of nutrition for many people around the world. Therefore, it is important to increase their expiration period with vacuum sealing. On average, it is estimated that the shelf life of powdery food is increased up to 1-2 with vacuum sealing.

| Powdery Foods | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Flour | Pantry | 5-6 Months | 1-2 Years |

| Flour (whole or wheat) | Pantry | 5-6 Months | 1-2 Years |

| Dry Milk | Pantry | 5-6 Months | 1-2 Years |

| Baking Powder | Pantry | 18 Months | 2 Years |

| Baking Soda | Pantry | 2 Years | 2-3 Years |

| Dried Coconut | Pantry | 5-6 Months | 1-2 Years |

| Gelatin | Pantry | 18 Months | 2 Years |

| Sugar and Brown Sugar | Pantry | 5-6 Months | 1-2 Years |

Flours have a normal shelf life of 5-6 months and in contrast, their vacuum shelf life is 1-2 years. Likewise, the typical serviceable life of Gelatin and sugar is 18 months and 5-6 months, respectively. The shelf life of these products is significantly increased with vacuum sealing with a upsurge of 1-2 years of Gelatin and sugars.

Vacuum Sealed Food Shelf-Life Chart of Prepared Liquids

Vacuum Sealed Prepared Liquids- Picture Courtesy: Dieline

Soups and stews are best for combating cold winters. As compared to the old way of storing prepared liquid products in a freezer, the vacuum sealed packaging stretches out the shelf-life of soups, sauces, stews and oils to 1-2 years. Their normal shelf life is 3-6 months when kept in freezer.

| Prepared Liquids | |||

| Foods | Stored In | Normal Shelf Life | Vacuum Shelf Life |

| Soups | Freezer | 3-6 Months | 1-2 Years |

| Sauces | Freezer | 3-6 Months | 1-2 Years |

| Stews | Freezer | 3-6 Months | 1-2 Years |

| Oil (no preservatives) | Freezer | 3-6 Months | 1-2 Years |

Conclusion

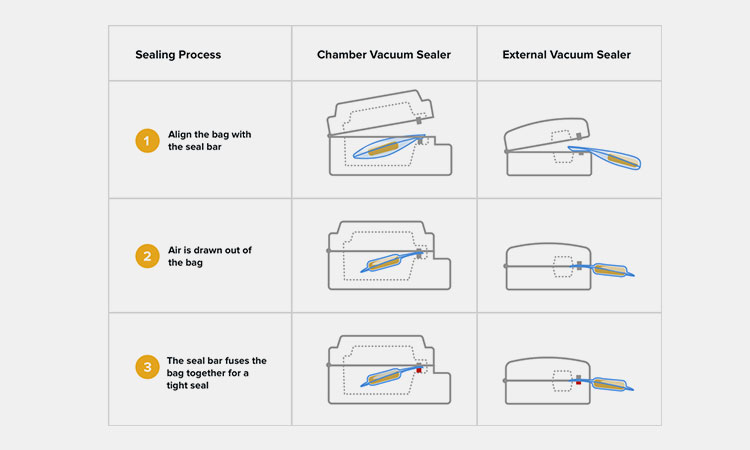

The technology of extending shelf life and maintaining the quality of food products has come a long way with vacuum seal packaging. Vacuum sealed food shelf life is notably higher about 2-3 times than food enclosed in normal packaging. These food products last up to years and taste good without spoiling in contrast to normal food packaging. Vacuum sealed food is packed in the absence of oxygen which is the main agent, spoiling food by oxidation and providing a growing environment for microbes. Vacuum sealed food shelf life is extended with the use of special machines called vacuum sealers. Keen on trying vacuum sealing for your food product, then visit our Allpack for the best deals and discounts.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Vacuum Sealed Food Shelf Life Chart Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours