High Level Automatic Vacuum Packaging Machine

- High-speed Accurate Rotation Locator

- Adjustable Inclined Working Table

- Shockproof Vacuum Gauge

Automatic Vacuum Packaging Machine

Allpack automatic vacuum packaging machine is made of 304 stainless steel, it meets the requirements of food hygiene, can prevent oxidation, corrosion, mildew, moth-eaten and moisture, prolong the storage period of food and keep it fresh. This machine uses the motor to drive the belt so that it can achieve continuous operation. For the purpose to increase production efficiency, the angle of its working table can be adjusted according to different packaging requirements.The automatic vacuum packaging machine is widely used in large-sclae production, it is suitable for packing all kinds of products, such as fried food (fried fries etc.), aquatic products, native prducts, various drugs medicines, chemical material, etc. All kinds of plastic bags and aluminum foil bags are applicable for our automatic vacuum packing machine.

Automatic Vacuum Packaging Machine

HVB-1020F Continuous Belt Type Automatic Vacuum Packaging Machine

Allpack HVB-1020F continuous belt type automatic vacuum packaging machine is always used to pack fruit, vegetable, meat, corn, beans, pickles, cheese, herb, chemicals, grains and so on. This vacuum packaging machine is made of 304 stainless steel ,which provides its with the ability of corrosion resistant, it is driven by chain so that it can realize continuous sealing operation. The machine can vacuum and seal products instantly, and it has long sealing length so that it can pack all kinds of products.

Anti-Pinch Device

Multi-Angle Titling

Water Circulation System

HVB-1020F/2 Continuous Rolling Vacuum Automatic Packaging Machine

Allpack HVB-1020F/2 continuous rolling automatic vacuum packaging machine has long heat strip, so it has long sealing length, and the angle of the working platform is adjustable, therefore, it can seal a wide range of products. The machine is equipped with advanced control panel, thus it is easy and convenient to operate. In addition, this vacuum packaging machine is made of food grade stainless steel, it is durable and hygiene, and it has long service life. It is suitable for all kinds of food products, beverages, chemicals, etc.

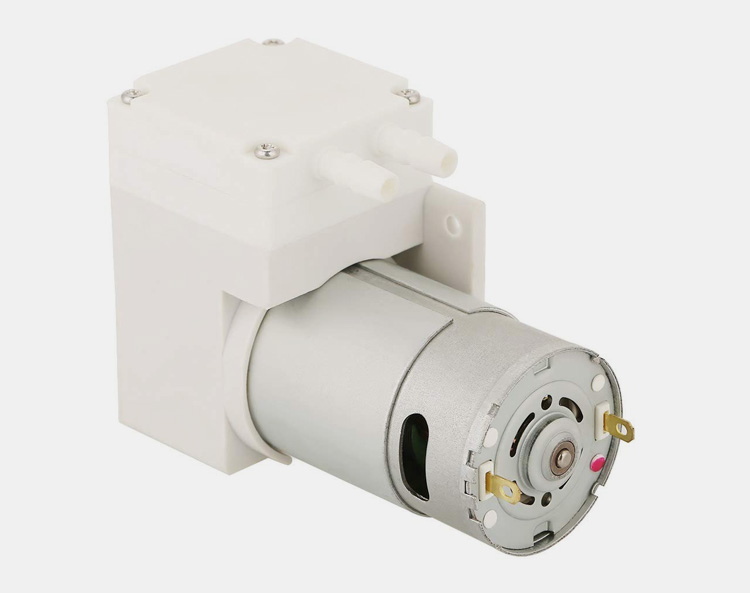

Cooling Water Pump

Excellent Quality Components

Run Location System

The Buyer's Guide

Automatic Vacuum Packaging Machine: The Complete Buying Guide In 2025

When you are looking to expand the life cycle and safety of your packaging item then most probably you go for vacuum packaging.

Automatic Vacuum packaging machine is a uniquely designed equipment that you can use for vacuum packaging of multiple food products and many more grocery items etc.

You may be wondering how & which way this Automatic Vacuum packaging machine can perform such kind of work well, this guide will answer to your all questions just keep connected with us.

1.What is Automatic Vacuum packaging machine?

An automatic vacuum packaging machine is a device that can be used to pack different food products using the vacuum packing method. This machine is usually used in commercial kitchens and restaurants.

It is mainly a process used to seal products through a vacuum chamber. Before sealing the products, this automatic vacuum packaging machine removes the air. This makes the products fresh for a more extended period of time.

By this vacuum machine, you can also prevent the product from entering any compound material in the can. This prevents the food from spoilage.

Tired of dealing with the hassle of packing your food items individually? Well, say goodbye to those days as automatic vacuum packaging machines are here to make your life much easier! Simply place your food items in the designated space and let the machine do its job.

2.How an Automatic Vacuum packaging machine works?

Automatic vacuum packaging machines work by first sealing the open end of the bag. The bag is then placed on a platform inside the machine. A piston or pump is used to remove the air from the bag. Once the air has been removed, the machine seals the other end of the bag.

Most automatic vacuum packaging machines can seal bags that are up to 12 inches wide. Some machines can seal bags that are up to 18 inches wide.

The size of the machine will determine how many bags can be sealed at one time. Smaller machines can usually seal one or two bags at a time, while larger machines can seal four or more bags at a time.

3.What are the types of Automatic Vacuum Packaging Machine?

Automatic Vacuum Packaging Machine is used to pack the products in a safe and clean manner. There are different types of Automatic Vacuum Packaging Machine available in the market. Some of the popular types of Automatic Vacuum Packaging Machine are as follows:

Tabletop Automatic Vacuum Packaging Machine

Tabletop automatic vacuum packaging machine is one of the most popular types of automatic vacuum packaging machine. It is widely used in commercial and industrial applications.

This type of machine is compact in size and easy to operate. It can be used to pack various products such as food, drugs, cosmetics, etc.

Working

The working principle of a tabletop automatic vacuum packaging machine is actually quite simple. when the lid is closed, a powerful vacuum pump sucks all the air out of the chamber, creating a partial vacuum.

This in turn causes the atmospheric pressure to force the product down onto the sealing tray where it is then sealed inside a bag or pouch.

Advantages

- The advantage of using this type of machine is that it can package a wide variety of products, from delicate items like fruits and vegetables to tougher items like meats and cheeses.

- Plus, the bags or pouches can be made from a variety of materials, including biodegradable options.

- The machine is very efficient and fast in working

Disadvantages

- First, these machines are not as durable as their floor-standing counterparts

- Second, tabletop vacuum packaging machines take up more counter space than manual vacuums or even some floor-standing models.

- Finally, tabletop automatic vacuum packaging machines are generally more expensive than other types of vacuum packing machines.

Parts

Vacuum Sealer

This is the main component of the machine and is responsible for removing all the air from the bag.

Packaging Tray

This is where the food item will be placed before being sealed.

Machine Base

This is what the machine sits on and helps to keep it stable during operation.

Control Panel

This is where all the settings and controls are located, allowing you to customize the sealing process to your specific needs.

Floor Standing Automatic Vacuum Packaging Machine

Floor standing automatic vacuum packaging machine is another popular type of automatic vacuum packaging machine. It is widely used in industrial applications.

This type of machine is bigger in size as compared to tabletop vacuum packaging machine. It can be used to pack various products such as food, drugs, cosmetics, etc.

Working

This machine is designed to work with both vacuum bags and sealable pouches, making it a great choice for businesses that need to package products of all shapes and sizes. The machine operates by first sealing the bag or pouch shut, then drawing out the air to create a vacuum.

This process locks in freshness and prevents spoilage, making it ideal for food packaging applications.

Advantages

- The machine is very easy to use

- It is considered the most versatile machine than other types of automatic vacuum packaging machine

- During packaging this type of machine also prevents spoilage

Disadvantages

- These machines can be quite noisy and can vibrate the floor

- Additionally, this type of machine requires a power outlet and can be quite expensive

- The automatic feature of these machines can actually be more of a hindrance than a help

Parts

Sealing Bar

Sealing bar is the first part of this type of automatic vacuum packaging machine which helps to create an airtight seal around the product.

Vacuum Pump

Vacuum pump helps the machine to draws the air out of the packaging material and creates a vacuum seal.

The Cover Plate

The cover plate sits on top of the product and helps to keep it in place during the packaging process.

Portable Automatic Vacuum Packaging Machine

Portable automatic vacuum packaging machine is another popular type of automatic vacuum packaging machine. It is compact in size and easy to carry from one place to another.

This type of machine can be used to pack various products such as food, drugs, cosmetics, etc.

Working

A Portable Automatic Vacuum Packaging Machine is a device that can be used to seal food in a plastic bag. It works by using a vacuum pump to remove the air from the bag, which creates a vacuum seal. This seal prevents the food from spoiling and keeps it fresh for a longer period of time. The machine can also be used to seal other items such as clothing or bedding.

Advantages

- The portable automatic vacuum packaging machine is lightweight

- It is also portable

- It is affordable as not more expensive than other types

Disadvantages

- The machine creates a lot of noise while working on it

- And it may not work as well on thicker fabrics

Parts

Power Cord

The power cord is the most important part of this type of automatic vacuum packaging machine. This part mainly provides the power to the equipment.

Pressure Gauge

The pressure gauge is there that helps in measuring the pressure that is below then atmospheric pressure.

Heating Element

Heating element is another part of this type of machine. The function of this part to give heat to the product.

4.What are the benefits of using Automatic Vacuum packaging machine?

An automatic vacuum packaging machine is a device that is very profitable for all industries. It is very easily packaged all the products.

There are many benefits of using an automatic vacuum packaging machine. These advantages are as follows:

Preserve the Food for a Longer Period of Time

Food Preservation

First, this process can help to preserve the freshness of food. Vacuum-packed foods will last longer than those that are not packed in this way.

This is because the lack of air prevents bacteria from growing and spoiling the food.

Prevent the Food from Any Damage

Food preservation

Second, vacuum-packing can help to prevent damage to products during transport. When products are packed in a vacuum, they are less likely to be damaged by bumps or vibrations.

This is because there is no air inside the container to absorb the impact of these things.

Takes Less Space

Third, vacuum-packed products take up less space than those that are not packed in this way. This is because the absence of air means that the container takes up less room.

This can be helpful for businesses that need to save space, such as when shipping products or storing them in a warehouse.

Increases the Production

Production Increasing

The fourth advantage of automatic vacuum packaging machine is that it increases the production of industry. You can easily seal more products than manual or other types of vacuum packaging machines.

Fast to Use

The next and most important advantage of an automatic vacuum packaging machine is that it is very fast to use. It rapidly seals the product very easily.

Easy to Use

The sixth advantage of an automatic vacuum packaging machine is that it is very easy to use. You do not need any rocket science to work. Simply oy can start work by switching on the button of the machine.

Reduce the Labor

Another best advantage of an automatic vacuum packaging machine is that it reduces labor costs. As this machine is fully automatic so there is no need for any extra labor to handle this machine.

Multiple Packaging Options

With an automatic vacuum packaging machine, you can get multiple packaging options. This advantage makes this machine superior to others.

The things you can pack by this machine are bags, foils films medicines, and more. You can get a superior seal for every material you are using for packaging.

Saves Money

Automatic vacuum packaging is also very advantageous as it saves money. Because this machine reduces the spoilage of food.

Sealed the Liquid Easily

The next advantage of the automatic vacuum packaging machine is that it seals the liquid product easily. You just have to place the liquid in the freezer before sealing. When it gets hard then you can place the liquid that is frozen in a sealing bag.

From this machine, you can also seal the liquid inside the jar.

Overall, there are many benefits of using an automatic vacuum packaging machine.

5.Can you seal cooked food with Automatic Vacuum packaging machine?

Vacuum Sealed Bags

Automatic Vacuum packaging machines are not just for sealing raw foods. They can be used to seal cooked foods as well.

Cooked foods can be sealed in an automatic vacuum packaging machine just like raw foods. However, there are a few things to keep in mind when sealing cooked foods.

Completely Cooled the Food before Sealing

First, it is important to make sure that the food is completely cooled before sealing it. If the food is still hot, it could cause the machine to overheat and potentially damage the food.

Seal the Food in an Airtight Container

Second, it is important to seal the food in an airtight container before sealing it with the machine. This will help to ensure that the food stays fresh and does not spoil.

Overall, automatic vacuum packaging machines can be used to seal both raw and cooked foods. Just be sure to keep these tips in mind when sealing cooked foods.

6.What kinds of products you can vacuum pack using an Automatic Vacuum packaging machine?

You can use an automatic vacuum packaging machine to vacuum pack a variety of products. Some of the most common items that are vacuum-packed include food, medicine, and electronics.

These products include:

Cereals

The automatic vacuum packaging vacuum packed the cereals. This can be packed easily and simply.

Cheese

Cheese is another product that is needed to be vacuum packed by the automatic vacuum packaging machine.

Cured Meat

The next product that is vacuum packed by an automatic vacuum packaging machine is cured meat. This product also has low oxygen permeability which is why it is vacuum packed.

Fatty Fish

Vacuum Packed Fatty Fish

Fatty fish is another important product these days. An automatic vacuum packaging machine is used to seal this product. This also has less oxygen permeability which is why it is best to seal vacuum packed.

Moreover, vacuum packing food helps to keep it fresh for longer. It also protects food from freezer burn and extends its shelf life. Vacuum packing medicine helps to keep it potent and free from contaminants. Vacuum packing electronics help to protect them from moisture and other environmental factors.

Overall, an automatic vacuum packaging machine is a versatile tool that can be used to vacuum pack a variety of products.

7.Types of plastics used in Vacuum packaging?

When it comes to food packaging, there are many different types of plastics that can be used. But not all plastics are created equal. Some types of plastics are better suited for vacuum packaging than others.

Polyethylene (PET)

The most common type of plastic used in vacuum packaging is Polyethylene Terephthalate (PET). PET is a strong, lightweight plastic that is shatter-resistant and doesn’t absorb flavors or odors. It’s also FDA-approved for food contact.

Low-Density Polyethylene (LDPE)

Low density Polyethylene

Low-Density polyethylene (LDPE) is a soft, flexible plastic that is often used for bags and wrappers. This can also be used in vacuum packaging.

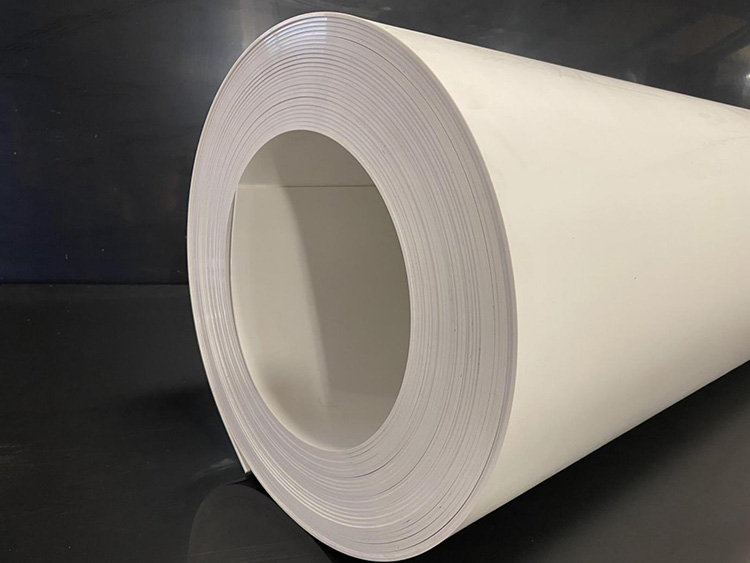

High-Density Polyethylene (HDPE)

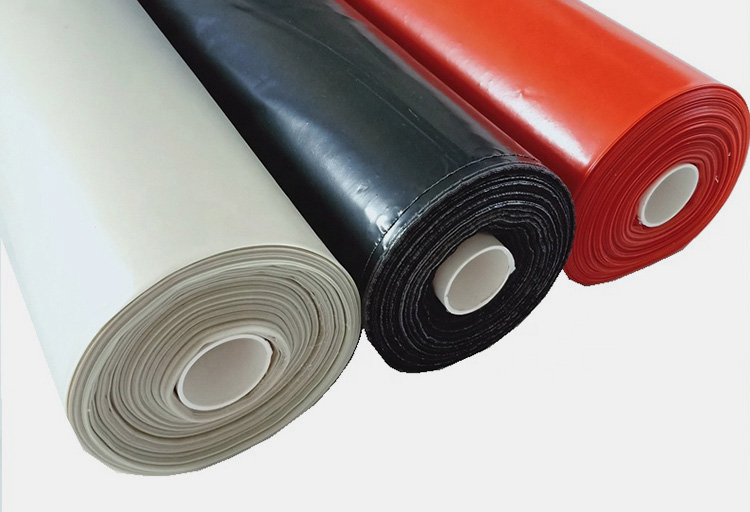

HDPE Roll

High-Density polyethylene (HDPE) is a strong, rigid plastic that is resistant to chemicals and temperatures. This plastic is good for sealing products.

Polypropylene

Polypropylene (PP) is a lightweight, shatter-resistant plastic that can withstand high temperatures. It is also the common thermoplastic used in the world nowadays.

When choosing plastic for vacuum packaging, it’s important to consider the type of food you’ll be packing. Some foods are more acidic than others, which can cause some plastics to break down over time. Other foods may be greasy or oily, which can cause problems with sealing.

8.What is the average life rate of a Vacuum sealed item?

Different items have different life rate according to their type. These products are as follows:

Meat Products

The products like meat used to be cooked for some days before it gets started to spoil. But if you packed the meat with an automatic vacuum packaging machine then you can preserve it for a longer period of time.

The normal lifespan of these types of products is almost 6 months when frozen. And when they are vacuum sealed then they can preserve for almost 2 to 3 years. These products also remain fresh during this lifespan.

Fruits

Vacuum packed fruits

Fruits are other products that needed to be packed by an automatic vacuum packaging machine. The average lifespan of fruits is 3 to 6 days. But you can preserve them for a longer period by vacuum packaging. They can last up to weeks.

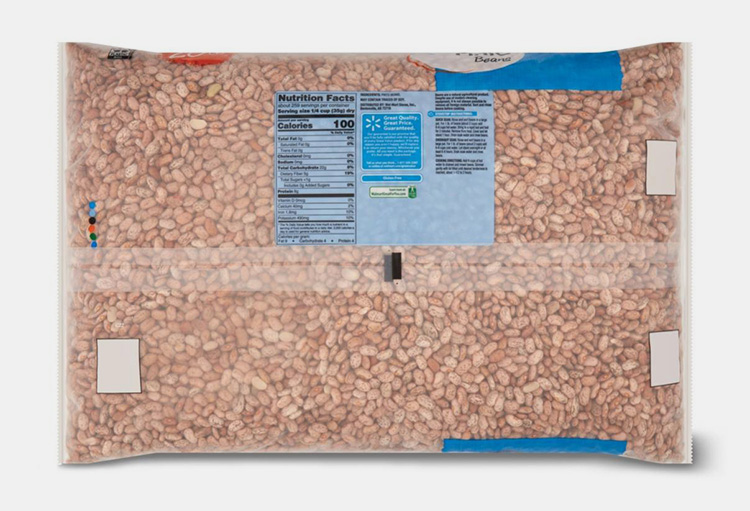

Beans

The beans are the type of product that can be preserved for almost 3 to 4 weeks without using vacuum packaging. And if you packed the product with an automatic vacuum packaging machine then you can preserve them for almost 2 to 3 years.

Oil Products

Oil products can also be stored for a longer period of time than other products by using an vacuum packaging. You can store them for a maximum of 12 to 20 months. But without using vacuum packaging it can be preserved for only 5 to 7 months.

Baking Products

Baking products can be preserved for almost 2 or 2.5 years if you kept the at room temperature by using automatic vacuum packaging machine for sealing the product. On the other hand, its normal lifespan is almost nearly six months which is very less compared to the vacuum-packed product.

9.What is the difference between an automatic vacuum packaging machine and a vacuum sealing machine?

Vacuum sealing machines and automatic vacuum packaging machines are both used to remove air from a package in order to extend its shelf life. However, there are some key differences between the two types of machines.

Automatic vacuum packaging machines are typically larger and more expensive than vacuum sealing machines. They also have more features and can be used for a wider range of applications.

For example, some automatic vacuum packaging machines have the ability to seal multiple packages at once, while others have built-in scales that weigh the contents of each package before sealing it.

Vacuum sealing machines are smaller and less expensive than automatic vacuum packaging machines. They typically only have one or two features, such as the ability to seal multiple packages at once or an adjustable seal time.

Conclusion

The automatic vacuum packaging machine is a widely used product in different industries. It is very beneficial for you to enhance your business. ALLPACK’s automatic vacuum packaging machine is one of the best machines for your industry. You can start your business with ALLPACK’s automatic vacuum packaging machine. If you have any questions regarding this machine, you can contact us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours