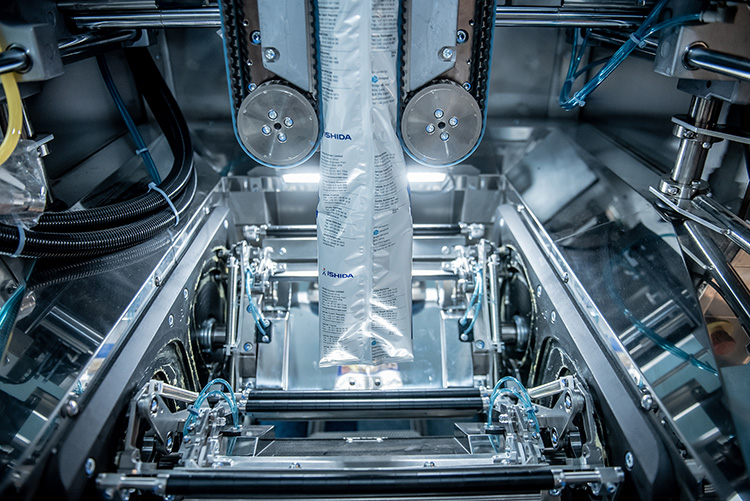

High End Vertical Packing Machine

- Large Capacity Storage Tank

- Anti-jamming Function

- Servo Motor Drive

Vertical Packing Machine

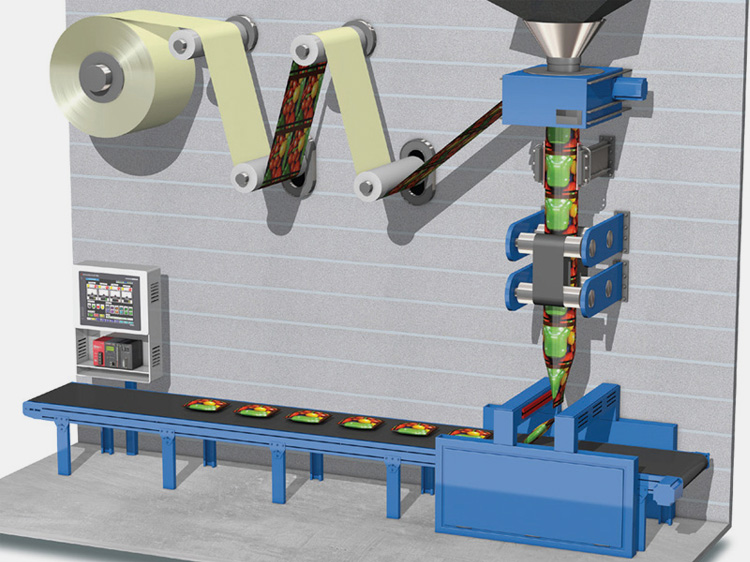

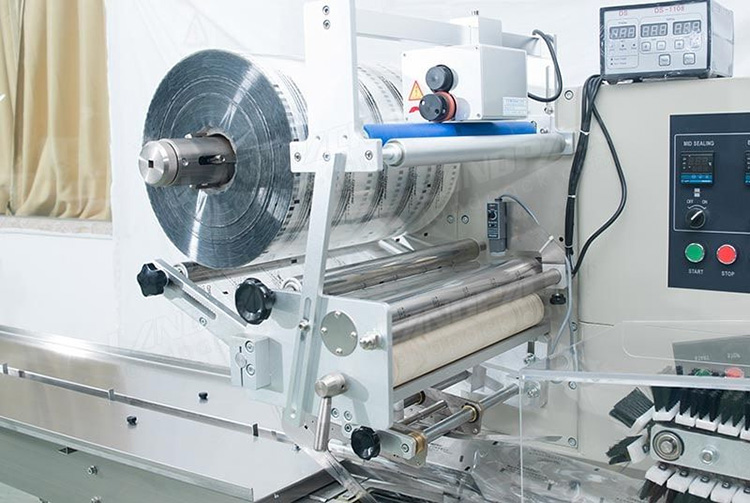

Allpack vertical packaging machine has a continuous sealing function, fast packaging speed, and various bag shapes and cutting methods. It is equipped with 14 or 16-head combination scales. The vertical packing machine can independently complete bag making, filling (inflating or degassing), sealing, cutting, coding, bag counting, etc., and is suitable for packaging of sheets or irregular shape materials.

This unit is composed of a weighing machine, a vertical filling and packaging machine, a platform, and a Z-type elevator. The vertical packing machine integrates the functions of feeding, metering, bag making, packaging, sealing, printing, punching, and counting. Allpack vertical packaging machine is widely used in food, beverage, pharmaceutical, chemical,electronic, agriculture industries,etc.

Vertical Packing Machine

SN-11 Tea Coffee Herbs Bag Vertical Packing Machine

SN-11 tea bag vertical packing machines are widely used for the automatic packaging of tea, tea powder, coffee, traditional Chinese medicine, and other filter items. It uses bubble tea bags as packaging material. The main components of tea bag vertical packing machine are filtered tissue paper, cotton, etc. The feature of this tea bag packaging machine is that it can automatically complete the steps of bag making, measuring, filling, sealing, cutting, and counting. And it can complete automatic labeling. This vertical packing machine uses a volumetric method to weigh and pack materials.

Automatic Labeling

Tea Powder Packaging

Volumetric Quantitative Method

SN-169 Tea Bag Coffee Herbs Vertical Packing Machine

SN-169 tea bag vertical packing machines are suitable for packaging disposable inner and outer bags for tea, herbal tea, health tea, small particles, and other materials. The outer seal of the packaging bag adopts stepper motor control, which makes the positioning accurate and the packaging stable. The heat sealing part adopts a PID temperature controller, which can accurately control the packaging temperature. The tea bag vertical packing machine adopts PLC control, and a man-machine interface display, easy to operate.

PLC Control

SUS304 Stainless Steel

Stepper Motor Control

SN-60CJ Liquid Paste Pouch Vertical Packing Machine

SN-60CJ liquid paste pouch vertical packing machine is widely used in the paste and liquid packaging in food, medicine, chemical, and other industries. It can provide you with four-sided sealed packaging. This liquid paste vertical packing machine can automatically complete bag making, measuring, unloading, sealing, cutting, and counting. At the same time, the function of printing batch numbers can be configured according to your requirements. It adopts an advanced PLC microcomputer controller and stepping motor control, which makes the machine performance stable, easy to adjust, and accurate to detect.

PID Adjustment

Four-side Sealing

Intelligent Temperature Controller

SN-60AK Particle Granule Spices Pouch Vertical Packing Machine

SN-60AK particle granule spices pouch vertical packaging machine is widely used in the automatic packaging of granules. These include the packaging of granular items such as satires, puffed food, shrimp, peanuts, and seasonings. This vertical packing machine can provide you with three-sided sealing. This machine can automatically complete bag making, measuring, unloading, sealing, cutting, and counting. At the same time, the batch number printing function can be configured according to your requirements.

Three-side Sealing

Batch Number Printing

Intelligent Temperature Controller

The Buyer's Guide

Vertical Packaging Machine: The Complete Buying Guide In 2024

The market has moved away from traditional trading techniques to modern techniques. Now it is the time for, the first impression! And i.e., perfect packaging. Packaging not only plays a vital role in attracting customers but also increases the production growth of your product. Whether you’re in contact with large or small-scale products, the right packaging is the key to customer satisfaction. For perfect packaging, of your product whether that is food or nonfood, a vertical packaging machine is a good choice.

If you are a buyer and want to buy a perfect vertical packaging machine! Then you are in the right place.

Here in this blog, you will find a complete buying guide for a new vertical packaging machine.

So, Let’s have a look!

1. What Is A Vertical Packaging Machine?

The vertical packaging machine is the latest type of packaging equipment that has numerous applications in different industries such as in medicines, beverages, food, and others. It has an advanced microcomputer system which increases its accuracy and speed.

Vertical packaging machine mainly comprises liquid, granules, and powder vertical packaging machines which depend on the products that use during packaging. It has a control system that controls all the functions of the machine and the cutter system automatically cuts the edge of the packed materials.

2. How Many Types Of Vertical Packaging Machines?

Types of vertical packaging machines

Vertical packaging machines can be divided into two categories

- According to automation

- According to the mechanism

- According to packaging style

In this category, vertical packaging machine has the following types

Manual vertical packaging machine

This type of machine is ideal for small-scale businesses where production can be dependent on manual work. This machine is made of durable materials like aluminum and metal. One of its attractive features is that it does not require a lot of energy to operate. Thus it saves a lot on energy bills, generating more profits. Since it can work pretty much on its own, it does not require a lot of manual labor for its operation, cutting down on labor costs.

The manual vertical packaging machine is available in various colors, designs, shapes and sizes. Thus it can be used to package a variety of bags according to the industry’s needs.

Semi-automatic vertical packaging machine

Semi-automatic machine is an innovative, versatile and an easy to operate machine. It is different from a manual packing machine in the way it operates. Semi-automatic machine works on its own completely and doesn’t require manual feeding, filling and discharging of the product as opposed to the manual one. It is made of stainless steel and can be used in various industries like pharmaceutical, nutraceutical, food and beverage industries to package bags of different shapes and sizes.

This machine doesn’t take up a lot of space, thus it can be installed easily anywhere in the production line.

Automatic vertical packaging machine

Automatic vertical packaging machine is an automated, intelligent, high speed and extremely efficient machine. This type of machine is perfect for anyone who is looking to package any kind of bag as quickly as possible. It can be used in small-scale industries, large-scale industries, or even in warehouses.

One of the best features of this type is that since it is automated, it can package virtually any kind of bag or packet by simply adding instructions to the computerized control system and the machine will operate accordingly. The whole process works automatically, giving quick results in a hygienic way since there is no human interference.

Vertical machines can also be categorized based on their mechanism

Intermittent vertical packaging machine

In this machine, the process can be terminated during film feeding pitch and the top and bottom parts are sealed with the help of an end seal unit which is fixed at its position. Due to this, only small products are suitable for this type of machine since the dropping of the product will damage large or fragile products.

Continuous vertical packaging machine

In a continuous vertical packaging machine, the process does not terminate during the film feeding pitch, unlike the intermittent machine. Instead, it relies on the upward and downward movement of the end seal unit by following the film feeding pitch. As a result, the products would not get damaged. Due to this, this type of machine is ideal for packing large products with high speed and efficiency.

This category has several different packaging styles. Some of them are

Pillow packing

This type of packing is conventional and ideal for the pharmaceutical industry where the products are filled in bags in the form of pillows or in the form of pouches.

Quad seal packing

This bag seals from four sides and has a huge capacity which allows large quantities of the product to be filled.

Stick packing

This type of packing is one of the most affordable and convenient types of packing. It can be used in various industries like pharmaceutical, beverage, and cosmetic industries.

Zipper bags

This type of bag features a zip to close or open the pack or pouch. It is also one of the most convenient type of packaging since it is easy to carry it anywhere or can be used to close or reopen anytime

Vertical packaging machine has different types, and each has similar parts with different feeding system. However, all types of vertical packaging machines have dissimilar applications. The kinds of vertical packaging machines include:

Liquid Vertical Packaging Machine: It can be used to pack liquid materials and can pack five to thirty bags within a minute and can pack bags of around 540 kg.

Granule Vertical Packaging Machine: The granule types of materials seal by the granule packaging machine. This machine can be packed materials from four sides can pack 30-70 bags within a minute and can carry a weight of 250 kg respectively.

Paste Vertical Packaging Machine: The sample in the paste form is packed by using a paste vertical packaging machine. It has a speed of packaging from 5 to 60 bags in a minute and can pack materials of 100 to 250 bags in width.

Powder Vertical Packaging Machines: The materials in powder form are sealed by the powder vertical packaging machine. They can also pack the backside, along with three and four sides of the packaging materials in the same way as the granule vertical packaging machine perform. It has a speed of packaging from 20 to 80 bags in a minute and can be seal bag of 250 kg.

3. What Are The Components Of A Vertical Packaging Machine?

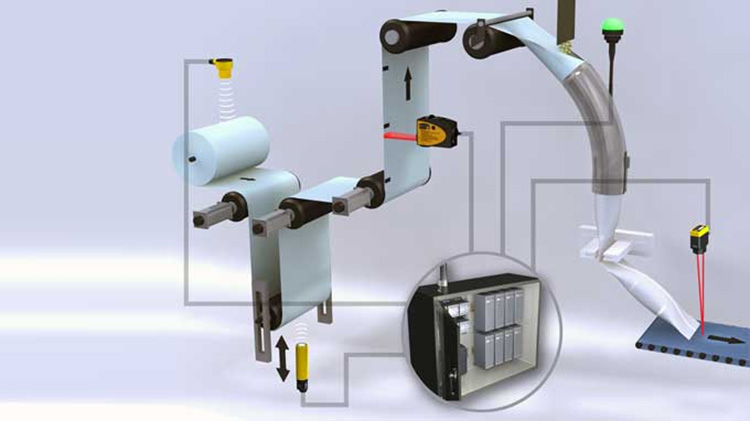

Vertical packaging machine uses to pack a variety of materials such as to used to seal food, bread, popcorn, candy, coffee, etc. This machine can be used to save money and time, it has six main parts for proper functioning, which comprise of;

- The blanking part

- The film released part

- The packaging part

- Printer

- Cutter

- Control cabinet

The blanking part consists of screw weighting, a rotating measuring cup, a combined weight, and the liquid pump, respectively. Whereas the film release part comprises tensioners and unwinding rolls. There is also a film roll which is a roll of film and it is driven by a motor to provide smoothness and pulling motion. The printer uses to print the label of date, and other information too. After packaging materials, the cutter that is inside the sealing machine cuts the edge of the pack.

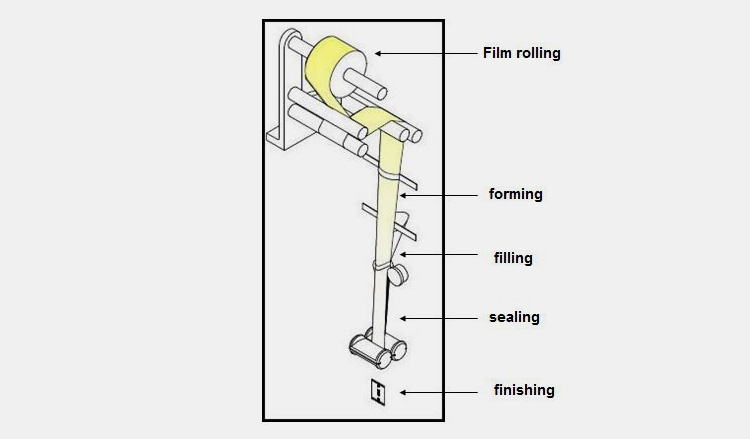

4. What Is The Working Principle Of Vertical Packaging Machines?

Vertical packaging machines such as snack packing machines, rice packing machines, and biscuit packing machines are used to seal products in a good manner. During its working, the film container is positioned on the supporting maneuver that is mixing around the rod. Initially, the longitudinal heat sealing instrument is used to fix the film, after that the tube-shaped film moves from the longitudinal heat device to the transverse heat sealing instrument which forms a packaging bag. The weight item in the sealing bag then fills with the weighing device through the filling pipe. Finally, the heated packaging device is transferred to the transverse heat sealer which is cut off to make a sealed unit.

5. What Are The Features Of Vertical Packaging Machines?

The vertical packaging machine has a wide variety of applications in numerous aspects, these include:

The vertical packaging machine uses a variety of materials to pack, these include such as nuts, seeds, popcorn, other particles, liquid including water, paste, chili oil, beverages, and powders.

Since the manual packaging machine can take more time and labor to complete the task, the automatic vertical packaging machine can save money and also reduces the power of pressure and less labor required to operate it.

The vertical packaging machine is relatively small in size which is convenient. Since vertical packaging materials have a control system which makes them more attractive because their maintenance is easy and it can control the function of the machine.

The vertical packaging machine uses to pack materials composed of polyethylene, polypropylene, and others.

The vertical packaging machine can be used to seal low-weight to high-weight packaging products.

It has a cutter inside it, which automatically cut the edge of the packed materials.

6. What Are The Industrial Applications Of Vertical Packaging Machines?

Vertical packaging machines can be used in various industries such as pharmaceutical, nutraceutical, food, fertilizer, and chemical industries. Let us discuss each of the industries below.

Pharmaceutical industry

Pharmaceutical are large-scale industries where thousands of medicines and drugs are manufactured every day. These medicines need to be packed in the best way possible to maintain the potency of the drug and prevent it from any contamination. The use of vertical packaging machine would be an ideal way to pack these medicines in a quick, clean and an efficient way.

Nutraceutical industry

This industry deals with the manufacture of vitamins and food supplement to improve one’s lifestyle. Vertical packaging machine can easily package these supplements in a safe and secure way.

Food industry

Food industry produces a number of products such as sugar, powdered spices, granulated coffee, soda drinks, juices, etc. Vertical packaging machine can package these products since it is ideal for products in powdered, granulated or liquid form.

Fertilizer industry

This industry deals with the manufacture of chemical fertilizers that help to enhance the productiveness of soil. These fertilizers need to be packed safely in a clean environment to maintain their potency and effectiveness. Vertical packaging machines can cater to all these requirements easily.

Chemical industry

Chemical industry produces a number of chemicals that are then used in other industries to male the final product. These chemicals need to be filled in bags or pouches and sealed as efficiently as possible since they are highly vulnerable to the external environment and may change their chemical composition. Vertical packaging machines can seal these chemicals in bags without any hindrance.

Cosmetic industry

This industry is involved in the manufacture of facial creams, moisturizers, serums, facial masks and shampoos. These products are either packed in bags or pouches. Their production has been increasingly growing over the past few years due to their high demand. Thus they need to be packaged as quickly as possible. This machine can easily package them in high speed.

7. What Is The Purpose Of A Vertical Packaging Machine?

Large-scale industries such as pharmaceutical, chemical, food and agriculture industries have the job to package thousands of products in a sustainable and cost-effective way in a short period of time. Vertical packaging machine due to its versatility and high speed mechanism is the perfect choice to package these industry's products.

8. How Does Cost Effects The Types Of Vertical Packaging Machines?

The vertical packaging machine has a variety of shapes, styles, and prices. So, it has a different price based on some aspects of parameters and models. The price mainly depends on the internal structure of the vertical packaging machine such as cutter, former, barrel, and stainless steel, and also mainly on the size of the cutter and former. Before buying a vertical packaging machine, one must look at the quality of the product packaging which depends on the materials used to make a vertical packaging machine, these effects the quality and quantity of the packaging.

9. What Are The Advantages Of Vertical Packaging Machines?

Vertical packaging machine is one of the best machines out there to package your products in the most sustainable and effective way. Due to a number of favorable aspects this machine offers, it is a manufacturer’s number one choice to install it in his production line. Let us discuss some of its advantages below.

High speed

Vertical packaging machine has the ability to package thousands of products in a single day. This not only increases the productivity but will also generate more profits.

Cost effective

This machine is very cost-effective. Thus the buyer does not have to worry about investing a lot of money to buy this machine.

Multi-purpose

This machine is quite unique since it has the ability to weigh, fill, seal, package and cut at the same time. Thus making it a multi-purpose machine.

Increased shelf life

Vertical packaging machine packages products in the best way possible. This prevents the product from any contamination, increasing the shelf life.

Computerized system

The whole process of this machine is under the control of a computerized system that operates it, ruling out the possibility of any human error.

Ability to package various types of products

Different types of products such as nylon, aluminum, PE, and other products from various industries can be packaged with the help of vertical packaging machines.

10. Problems And Solutions Of Vertical Packaging Machines

| Problems | Solutions |

| A component or a part of the machine has broken down. | Replace that component with a new one. |

| The fuse has burnt. | Change the fuse with a new one. |

| There is high pressure buildup on seals. | Reduce the pressure to an appropriate level. |

| The guide slot has been misaligned. | Adjust the alignment of it. |

| The heating wire has burnt. | Replace the wire with a new one. |

| Improper functioning of electric connections. | Check to see where the problem lies and adjust the electrical connections. |

| The knife blades have been damaged. | Buy new knife blades and replace the old one with it. |

11. What Type Of Product A Vertical Packaging Machine Can Pack?

Vertical packaging machines can be used to fill products in powdered form, granular form or in liquid form. Some of the products which the vertical packaging machine can package are

- Spices

- Powdered coffee

- Sugar

- Rice

- Cocoa powder

- Therapeutic powdered sachet

- Vitamins

- Fertilizers

12. What Are The Differences Between Vertical And Horizontal Packaging Machines?

Although there are lots of similarities between horizontal and vertical packaging machines, they have a few differences as well. These differences are

Different Working Principles

Horizontal and vertical packaging machines have different working principles. A horizontal machine uses a film roll to run it over a plow. This allows the film to be pulled through the machine with much less force. Whereas the vertical packaging machine uses way more force than the horizontal one.

Different Process

The horizontal machine has a film that is folded in two dimensions. As a result, the process can be preheated, heated and cooled at different intervals. On the other hand, in a vertical packaging machine, the sealing process and packaging process occur simultaneously. Furthermore, the process of preheating, heating, and cooling occurs in a single cycle, unlike the horizontal machine.

Filling Of Product

In a horizontal machine, the product is filled while the bag is open. Due to its full bottom gusset, it has the capability of filling to a 100% capacity. While in a vertical machine, the product is filled when two sides of the bag are opened. Moreover, the gussets are not opened completely. As a result, it does not have a 100% capacity like the horizontal machine.

13. How To Maintain A Vertical Packaging Machine ?

Just like every other machine, vertical packaging machine also needs constant maintenance to work as efficiently as possible. Below are some of the points which can be read in order to maintain this machine properly.

- Lubricate the machine to prevent any friction.

- Check if each and every component is working properly.

- Look for any loose wire connection.

- Adjust the belt alignment.

- Clean the machine to prevent it from any dust contamination.

- Oil levels should be maintained at an appropriate level.

- Copper brushes should be used to clean rollers and knives.

- Pay close attention to the way the machine is operating and check if it is making any abnormal sounds.

14. What Points Should Be Considered Before Buying Vertical Packaging Machines?

Vertical packaging machine has numerous application in different areas, so before buying one must consider some points. These include,

The first point should depend on the stable quality of the product packaging which should be high-cost performance. If the materials used for making packaging machine is high-quality packaging should be stable and faster. The other important point should depend on the packaging materials that you are going to pack.

The main points considered before buying a vertical packaging machine is depending on the types of products related to the type of machine, for instance, the liquid materials can be packed by a liquid vertical packaging machine, and so on.

Conclusion

In the year 2023, the vertical packaging machine is considered the newest kind of sealing equipment because it has numerous applications in different industries such as medicine, beverage, food, popcorn, coffee, nuts, and others. It is a less expensive and faster machine that is used to seal a variety of items in a short time. Are You Interested In Procurement?“Allpack” is the best company that provides the most economical and One Stop Solution to your needs. Contact Us Now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours