Your Premier Doypack Filling&Capping Machine Supplier

- Precise Quantitative Filling

- High reliablity&Convenient Operation

- Automatic Capping&Precise Capping&Solid Capping

Allpack Automatic Doypack Filling &Screw Capping Machine

Allpack Automatic doypack filling&screw capping machine is suitable for cold chain of yoghurt, soybean milk, soymilk yoghurt, fruit juice, etc. food in doypack pouch filling and capping. The automatic doypack filling&screw capping machine could have accurate product quantification, clean cleaning, tight capping, and reliable quality.It adopts an electromagnetic rotating cover (servo click rotating cover can be selected), with no bag or filling,no cap, no screw cap. With waterproof design of boom electrical cabinet, 10 inch true color super large screen, circular shape.The sealed bucket can be used for CIP cleaning. The rack comes standard with a clean hood and can be optionally equipped with a laminar flow hood. The electrical components of this automatic doypack filling&screw capping machine also adopts brands such as Siemens from Germany and Schneider from France,the pneumatic components adopts brands from German Festo and Japanese SMC.

Automatic Doypack Filling &Screw Capping Machine

APK-230 Automatic Doypack Filling&Capping Machine Rotary Premade Stand Up Spout Pouch Laundry Doypack Detergent Lotion Filling Capping And Sealing Machine

Allpack APK-230 automatic doypack filling&capping machine is mainly used for filling and sealing of stand-up pouches with spout. Can be filled with viscous or non-viscous liquids such as milk, jelly, ketchup, hand sanitizer, laundry detergent, liquid soap, etc. First it will load the pouches automatically, then the machine will automatically finish all the process of filling, pouch opening cleaning, cap neatening, capping and finished product outputting etc. The machine adopts a combination of pneumatic mechanical transmission and electric control.

High Speed Filling

Driven by servo motor,easy to adjust

No pouch or pouch open error, no fill, no seal

The Buyer's Guide

Doypack Filling & Screw Capping Machine: The Complete Buying Guide In 2025

Doypack is the most favored type of flexible packaging when it comes to packing large volume of liquids such a as ketchup, mayonnaise, and honey etc. However, its filling and capping are considered the most challenging tasks. To tackle this issue, Doypack Filling & Screw Capping Machine has been created.

This machine has an advanced technology which fully support automatic filling and screw capping of doypacks. You can upgrade the quality and essence of the machine and extend its working life by adopting simple steps such as daily cleaning, routine maintenance, and right adjustment of the machine. Moreover, you can get the desired machine based upon your needs. So, be ready to discover these all one by one!

1.What Is Doypack Filling & Screw Capping Machine?

Allpack- APK-230 Automatic doypack filling & capping machine

Doypack is a form of flexible packaging which is often termed as standup pouch due to its body that stand upright as a result of gusset inclusion in its bottom. When used for liquids, doypacks are often made with spouts for convenient handling. Therefore, to pack such these pouches with liquids a specific machine is introduced into the packaging world which is known as doypack filling & screw capping machine.

It is an automatic machine used to fill accurate amount of liquid into doypacks with great precision. Along with that, it carries out the function of capping these doypacks through screwing. Hence, its use brings into your production line the efficiency, consistency as well as packaging accuracy which are all prerequisites for professional packaging.

2.Explain The Features Of A Doypack Filling & Screw Capping Machine?

Doypack filling & screw capping machine is created with advanced features which are described below:

Robust Construction

Compact body of doypack filling & screw capping machine- Picture Courtesy: tenco.it

The machine features 304 stainless steel main frame or support structure with all components in direct contact with material made up of 316 stainless steel. It has a transparent protected window installed on all sides surrounding the working area. Moreover, the height of machine is adjustable, and it can be easily mobilized from one place to another.

High Automation

Automatic processing of doypacks- Picture Courtesy: tenco.it

Doypack filling & screw capping machine has high automation in terms of doypack filling and capping as well as taking action independently in case of malfunction. For instance, the electric photocell stop the working if caps are not provided and the same device reparts machine when it is fed with caps.

Ultimate Precision

Precisely filled & capped ketchup doypack

Well, precision is what every manufacturer and consumer look for. This is the reason why a doypack filling & screw capping machine come up with dosing valve support system which eliminate overfilling, that bother manufacturer due to material waste, and under-filling, which annoy consumers.

Wide Application

Allpack- Various types of liquid filled doypacks

Doypack filling & screw capping machine is widely applicable to liquids with different properties such as free-flowing liquids, viscous liquids, and liquids with particulates. Along with that, you can process doypacks with spouts on side corner, in middle, and with irregular shape doypacks. Thus, the machine can be employed in range of industries.

Simple Operation

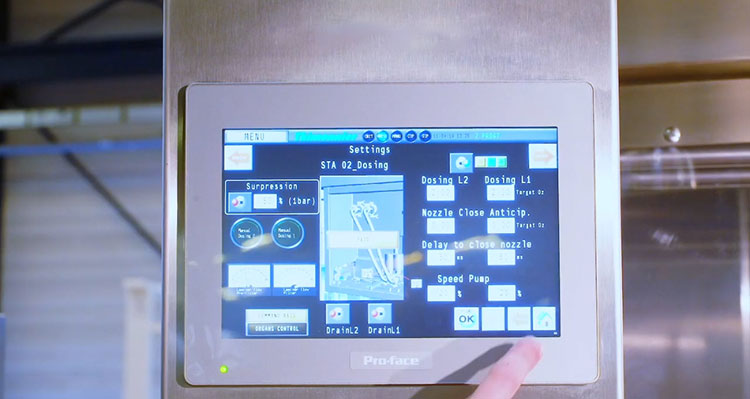

Simple operating control panel of doypack filling & screw capping machine- Picture Courtesy: Thimonnier.com

Another attribute of the machine is that it is extremely user-friendly with electronic control panel which is solely responsible for operating machine. Moreover, it requires little maintenance due to enclosed design that restrict the way for machine contamination.

3.What Products Are Filled By Doypack Filling & Screw Capping Machine?

Doypack filling & screw capping machine has gained proficiency in processing different types of materials which are enumerated below:

Sauces

Ketchup sauces doypack- Picture Courtesy: Behance

Sauces are thick liquid composition made from the combination and processing of various vegetables, condiments, and other stuff. They are used to add flavor into food and served as dressings. The common sauces and seasoning processed by this machine include ketchup, mayonnaise, chicken spread, soy sauce, and chilli sauce etc.

Drinks

Various cocktail doypacks- Picture Courtesy: worldofzing.com

Drinks are now also delivered in flexible packaging such as doypacks and sachets etc. That's why, doypack filling & screw capping machine is designed to pack all kinds of soft drinks, juices, and spirits along with milk shakes in doypacks.

Creams

Beauty cream- Picture Courtesy: sephora.com

Beauty creams, shampoo, hair conditioner, and lotion etc., are the other liquids which can be easily packed by using a doypack filling & screw capping machine.

Cleaning Agents

Dishwashing liquid doypack- Picture Courtesy: soap.com.ua

Hand washing gel, dish washing liquid, and detergent liquids are commonly used cleaning agents on daily basis. Therefore, manufacturers tend to ease their customers as well as reduce their packaging costs. So, doypack filling & screw capping machine is what they consider the suitable machine which helps them in meeting the goal of employing doypacks for packaging.

Edible Oil

Roasted garlic oil- Picture Courtesy: howsweetseats.com

Edible oil is free-flowing and require extra care in handling especially during packaging. However, this machine has enclosed structure and accurate weighing and filling mechanism which makes it perfect to process edible oils including olive oil, coconut oil, canola oil, sunflower oil, and and other vegetable oils.

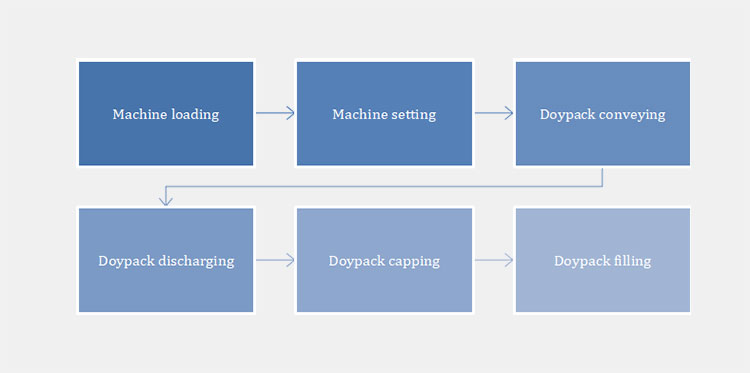

4.How To Operate A Doypack Filling & Screw Capping Machine?

A doypack filling & screw capping machine can be operated by following few easy steps which are enlisted below:

Machine Loading

Doypack loading into machine- Picture Courtesy: thimonnier.com

The very first step required for operating the machine is loading it with material. In case of doypack filling & screw capping machine, it must be fed with premade empty doypacks, sufficient volume of liquid to be filled in pouches, and stock of caps to be placed over filled doypacks. Now, it is significant to know that each mentioned material has its fixed place in the machine, and you need to load these objects in relevant components.

Machine Setting

Machine setting- Picture Courtesy: tenco.it

Once the loading phase gets done, the setting of machine will be carried out in next step. Here, the operator will adjust basic parameters of the machine including the volume of liquid for each doypack, speed of filling, temperature of material hopper, and the pressure of torque for cap screwing etc.

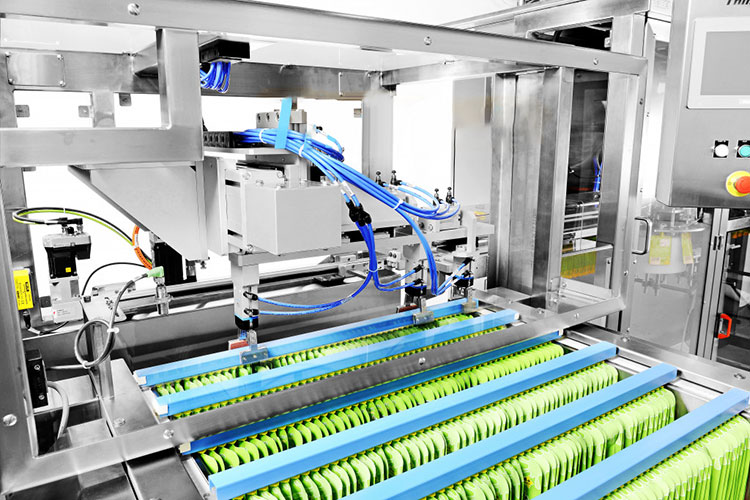

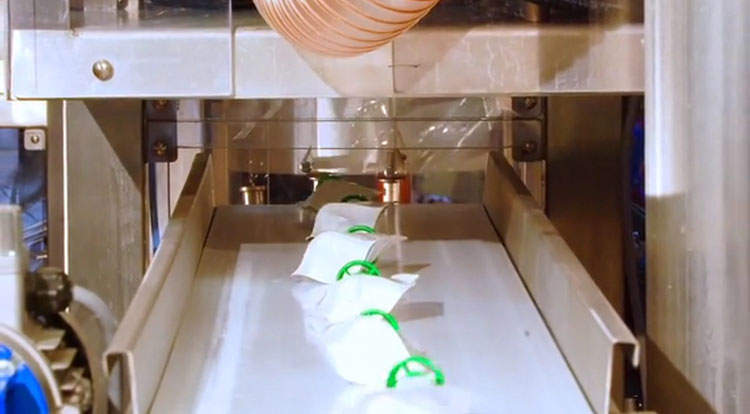

Doypack Conveying

Doypack conveying- Picture Courtesy: thimonnier.com

During this phase, the machine will be turned on by operator after which it will begin functioning. As the machine is powered on, it will start conveying empty doypacks from rack towards main machine. This is carried out when the spouts of pouches are gripped in the collar of gripping unit and doypacks are mobilized forward.

Doypack Filling

Doypack filling- Picture Courtesy: thimonnier.com

Once doypacks reach to the filling station, the diving nozzles sit on the spout to ensure enclosed filling for proper pouch expansion. Similarly, the material coming from hopper through the weighing system is gently dispensed into doypacks. During this time, the machine control system makes sure to maintain precise filling while reducing waste and fill level inconsistencies.

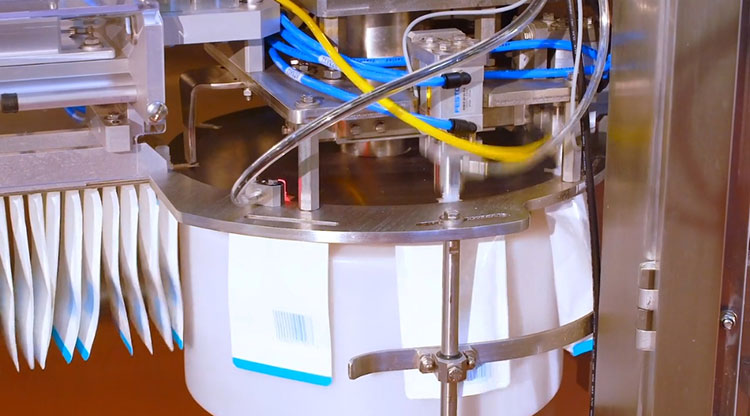

Doypack Capping

Doypack capping- Picture Courtesy: thimonnier.com

Proceeding further, the filled doypacks are moved ahead for capping where a vibratory or rotary sorter convey the caps to chute. This chute, when contacting the passing filled doypacks, keep releasing the caps over doypacks. In this way, caps are placed over pouches and then by using a rotating capping head, caps are tightly screwed.

Doypack Discharging

Finished doypacks discharging- Picture Courtesy: thimonnier.com

Once the doypacks are capped, they are discharged from machine through a chute and transported through a conveyor for further packaging or collection into a container. At this point, the defective doypacks are rejected from the properly packed ones to reduce production line stoppage.

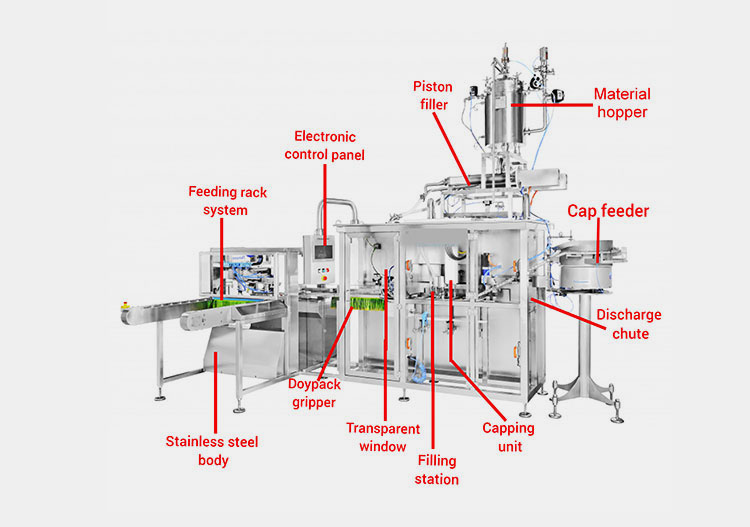

5.Describe The Components Of A Doypack Filling & Screw Capping Machine?

Doypack filling & screw capping machine is composed of several parts each performing its own task. However, these components may vary from one type of machine to another with more or less having same functions. In this question, you will know about the various parts of a fully automatic doypack filling & screw capping machine:

Components of SF RANGE FOOD- SPOUT FILLING/CAPPING MACHINE- Picture Courtesy: thimonnier.com

Material Hopper

Material hopper is one of the essential components of a doypack filling & screw capping machine which comes in large size to hold large volume of liquids for processing. Inside hopper is the fitted system of heat which keeps the material at suitable temperature level to avoid jamming.

Piston Filler

Piston filler is another core part of the machine that is attached to the hopper of machine. It is a weighing device that measure the exact volume of liquid by using piston. Therefore, the material is first transfered from hopper into piston filler and then transported from here for filling into doypack through nozzles.

Cap Feeder

The machine has another feeding unit which is known as cap feeder. Here, bulk of caps are loaded before initiating the process and caps are supplied to machine through this unit.

Electronic Control Panel

This tool is considered the brain of the machine as it is the sole part through which machine can be regulated and its functioning can be controlled. It mainly consists of a PLC touch screen which display over it multiple information regarding machine like filling volume, sealing temperature, and torque pressure for capping. Along with that, this part has certain knobs like emergency stop, power switch and indicators etc.

Feeding Rack System

Feeding rack system is a tool attached to the main machine. Its function is to supply the machine with prearranged empty doypacks.

Stainless Steel Body

The body of machine is made up of GMP'S regulated stainless steel with all parts contacting material are fully corrosion resistant and antibacterial. The overall structure of machine is highly stable with several feet which enable machine to stand stable on surface.

Doypack Gripper

As the name demonstrate, doypack gripper is a device which takes the doypack from feeder towards filling station by perfectly gripping their spouts in its clamps. Therefore, it removes the fear of doypacks getting deviated from path.

Transparent Window

The machine has a transparent protected window which enables you to observe the operation while as protecting the inside operation from external environment that may pollute it.

Filling Station

It refers to the station where doypacks are filled with liquids. This filling station has multiple filling nozzles through which liquid is dispensed into doypacks.

Capping Unit

Capping unit is located right after the filling station. It includes the cap placing device, screw device, and a torque. It basically carries out the function of placing caps over doypacks and screwing them tightly.

Discharge Chute

Discharge chute is the last section of machine through which finished doypacks are ejected out of machine for further packaging.

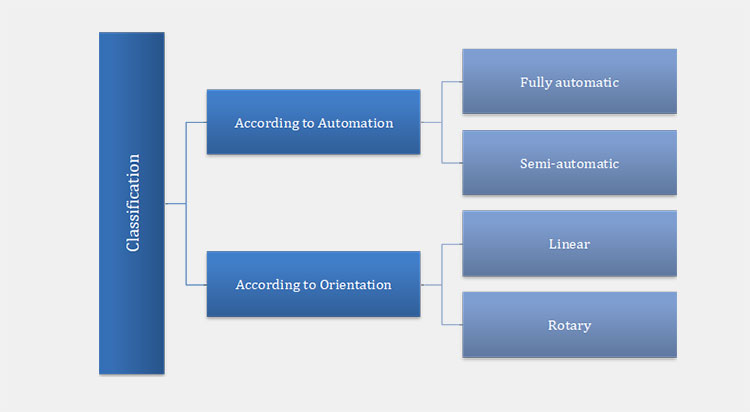

6.What Is The Classification Of A Doypack Filling & Screw Capping Machine?

Keeping in view the diverse needs on part of liquid manufacturers, the packaging machine producers have created multiple types of doypack filling & screw capping machine. So, these machines will help you achieve your daily tasks. A detailed description of these types is given below:

According to Automation

Fully Automatic Doypack Filling & Screw Capping Machine

SF RANGE FOOD- SPOUT FILLING/CAPPING MACHINE- Picture Courtesy: thimonnier.com

Fully automatic doypack filling & screw capping machine is a top-notch machine that comes in high automation thereby performing all the tasks automatically in one run. The machine fully supports integration of other machines for enhancing productivity.

Structure

The structure of machine is complex with many components including cap feeder, material hopper, doypacks feeding rack, control system, main frame, control cabinet, filling station, capping station, and ejection chute.

Working Principles

It works automatically where the machine is initially fed with desired liquid material, empty doypacks, and caps. Then, machine is powered on after setting gets completed. Once started, the machine automatically finish material weighing, doypacks filling, capping, and discharging.

Semi-Automatic Doypack Filling & Screw Capping Machine

Filling-capping machine for spouted pouches- Picture Courtesy: tenco.it

Semi-automatic doypack filling & screw capping machine is an ideal equipment that come in semi-automatic technology. It can be equipped with any kind of capping machine for capping different style caps over doypac. Its production output stands optimal at 500 doypacks per hour.

Structure

The structure of machine highly resembles a trolley with wheels which makes it quite easy to move. The overall body is composed of quality stainless steel, a product hopper, filling nozzle, screw capping device, a handle, and weighing system etc.

Working Process

The working process of the machine is easy but dependent upon user. Therefore, user manually fed the machine with doypacks. Afterwards, material is weighed by machine and filled into doypacks. For capping, operator place the caps over doypacks and the machine then tight it through screwing.

According to Orientation

Linear Doypack Filling & Screw Capping Machine

SERIE SF Filling/ Capping Machine for Doypacks with Spouts- Picture Courtesy: thimonnier.com

Linear doypack filling and screw capping machine is another type of machine which undergo doypacks in a straight linear position through different stages.

Structure

This machine has comparatively small vertical structure which is easy to mobilize. Apart from this, the machine includes all general components of a standard doypack filling & screw capping machine with essential system which distinguishes it from the rotary machine is its linear mechanism for doypack filling and capping.

Working Principles

It functions by taking empty doypacks from magazine and passing it through filling stage. After filling, the filled doypacks are moved ahead in a straight way without changing their direction and then capped by first placing caps over them and then tightening these caps through screwing.

Rotary Doypack Filling & Screw Capping Machine

Allpack- APK-230 Automatic doypack filling & capping machine

Rotary doypack filling & screw capping machine is ultrafast machine with unique design rotary table that assist in efficient finishing of doypack.

Structure

The structure of machine is characterized by its rotary disc which play pivotal role in quick processing of doypacks. Other components include hopper, vibratory cap feeder, control system, filling, and capping mechanism.

Working Principles

It processes doypacks by gripping spouts in the collar of rotary disc which then passes these doypacks through filling, capping, and ultimately discharging phase.

7.Differentiate Between Doypack Filling & Screw Capping Machine And Doypack Filling & Sealing Machine?

Doypack filling & screw capping machine and doypack filling & sealing machine are two different equipment utilized for doypack packaging, however, they are often misunderstood. To clear these misconceptions, we have highlighted the differences which prevail between both. So, consider the table below:

| No | Aspects | Doypack Filling & Screw Capping Machine | Doypack Filling & Sealing Machine |

| 1 | Definition | It is a machine employed to fill material into spouted doypacks through filling nozzles and closing these spouts by screwing caps over them. | It is an equipment designed to fill substances into broadly opened doypacks and closing the opening of doypacks through heat sealing. |

| 2 | Process | It functions by first grabbing the pre-made doypacks, weighing the material and then dispensing it into doypacks. After filling, it caps the doypacks and tightly screw caps over them. | While as, doypack filling and sealing machine works by gripping readymade doypacks, loading the measured volume of material into doypacks and then undergoing doypacks through heat sealing step for stringent sealing. |

| 3 | Structure | It has a vertical structure with small footprint, therefore, offer convenience in handling and mobilization. | In contrast, this matches it has a horizontal body while covering large space. |

| 4 | Material Processed | The machine can process only liquid substances such as sauces, oil, drinks, and creams etc. | On the other hand, doypack filling & sealing machine can deal with both liquid as well as solid products such as beverages, powders, and granules etc. |

| 5 | Type of doypack | It is only applicable to spouted doypacks. | Contrary to doypack filling & screw capping machine, this equipment is capable of processing both spouted and unspouted doypacks and can add spouts to filled doypacks during sealing. |

| 6 | Picture |

Filler/Capper monoblock for spouted doypack- Picture Courtesy: tenco.it |

Allpack- APK-200 Automatic Horizontal Liquid Premade Pouch Filling Machine |

8.Highlight The Applications Of A Doypack Filling & Screw Capping Machine?

Industries which are associated with any kind of liquid processing especially in food sector, are always in need of a doypack filling & screw capping machine. Some of these applications are highlighted below:

Seasoning & Dressings Industry

Sauces doypacks presentation idea- Picture Courtesy: Behance

Seasoning industry is an area that constantly deal with manufacturing and packaging of various condiments. They are often delivered in liquid form such as chilli sauce, ketchup, sauces, soups, and dressings etc. Therefore, to pack these seasonings in doypacks, a doypack filling & screw capping machine is used.

Edible Oil Industry

Edible oil rigid & flexible packaging- Picture Courtesy: packagingoftheworld.com

To aid consumers in handling edible oil for daily use in kitchen, while as, minimizing their packaging costs, edible oil producers has now opted for flexible packaging options such as pillow pouches and doypacks etc. Hence, the use of a doypack filling & screw capping machine become inevitable in this way.

Beverage Industry

Multiple doypacks of various juices- Picture Courtesy: packagingoftheworld.com

As people like to take their favorite spirits, milk shakes, and other drinks along with them on outing, they prefer to use more handy and reusable packaging options on which spouted doypacks always stand tall. So, this machine is popularly utilized in beverage sector.

Pharmaceutical Industry

Various pharmaceutical drugs & bandages- Picture Courtesy: packaging-warehouse.com

When other fields are in race for winning consumers' trust how pharmaceutical industry can be left behind! That's why now you will find certain kinds of syrups and other liquids such as protein drinks, liquid supplements, and herbal pastes etc.

Pet Food Industry

Pet food flexible packaging- Picture Courtesy: petfoodprocessing.net

Doypack filling & screw capping machine is also applicable to pet food industry where multiple pet food in form of liquid is packed in doypacks. These include broth, cooked meat curry, milk, and creamy food.

Cosmetic Industry

Shampoo doypack- Picture Courtesy: midetergente.cl

Another notable application of the machine is cosmetic industry where materials like hand washing gel, lotion, dyes, shampoo, conditioner, and liquid body wash etc., are packed in spouted doypacks.

9.What Quality Standards Should A Doypack Filling & Screw Capping Machine Meet With?

A doypack filling & screw capping machine should meet with specific but essential quality standards in order to be termed as a quality machine. Therefore, to help manufacturers and entrepreneurs who are new in packaging world, international society has established few prominent standards whose compliance will guarantee the safety of machine. These are mentioned below:

FDA quality standard- Picture Courtesy: kffhealthnews.org

ISO:International Organization for Standardization is a must have certifications for all types of doypack filling & screw capping machine to ensure their safety and quality.

GMP:Good Manufacturing Practices is another organization established to maintain strict principles regarding the use of construction material for machines.

FDA:Similarly, Food and Drug Administration is USA based agency created to ensure that machine adhering to its rules is fully safe for processing food related products.

CE:CE is abbreviated for European Conformity which means that a doypack filling & screw capping machine which is meant to be used in European Union countries must comply its principles and gain the certification of CE.

10.How To Maintain A Doypack Filling & Screw Capping Machine?

Regular maintenance is very important for keeping your doypack filling & screw capping machine on right track. It can extend the lifespan of your machine along with its efficiency level and reducing potential downtime. In contrast, neglecting it will be detrimental for your in every aspect. So, make sure to perform daily preventive maintenance for your machine:

Maintenance icon- Picture Courtesy: vecteezy.com

Cleaning:Cleaning is inevitable for carrying out safe and hygienic processing. Therefore, make sure to clean your machine on daily basis and remove out all the dirt, dust, and residues accumulated or left behind in machine.

Lubrication:Lack of lubrication can cause parts friction and wear and tear. It can be simply ended by adding recommended oil to necessary parts such as rotary disc, conveyor belt, and rollers etc.

Parts Replacement:Over time, certain components of machine may get damaged or out of order. Ignoring such parts may affect the machine performance and will lead to interruptions. Therefore, it is crucial to replace these parts with new ones.

Software Updates:If your doypack filling & screw capping machine is equipped with software, then you need to keep upgrading it with latest updates. It will fix bugs and programming errors.

Inspection:Regular inspection should be conducted for parts functioning and noise coming from machine. It will help keep you alert of the inconsistencies, so, that you will be able to take steps accordingly.

11.Diagnose The Common Pitfalls Of A Doypack Filling & Screw Capping Machine?

While operation a doypack filling & screw capping machine you may encounter sudden issues with it. Therefore, we have provided some practical solutions to the common errors caused by this machine. Consider these in explanation below:

Filing inaccuracies

Encircled filling nozzle into doypack spout- Picture Courtesy: tenco.it

Cause

Either the filling system is not properly calibrated, or it is not fulfilling the specific needs of material.

There is issue in material supply which is causing filling inaccuracy.

Inappropriate filling speed and cycle time for material filling.

Solution

Make sure to calibrate the filling system accurately and use the type of filling system in accordance with material specifications.

Ensure the consistent supply of material to filling nozzles by removing possible accumulation of material in nozzles.

Modify the filling speed and cycle time for smooth functioning.

Cap is missing on spout

Displaying doypack spout without cap- Picture Courtesy: tenco.it

Cause

The cap supply stock is running out.

Incompatibility in the speed of passing doypacks and that of caps supply.

Blockage of cap conveying path.

Solution

Restock the cap feeder to continue capping process.

Adjust the speed of doypack conveying to that of cap supplying.

Examine and take relevant measure for correcting cap placing chute.

Cap get cracked or defected

Indicating capping error- Picture Courtesy: thimonnier.com

Cause

Too much pressure application.

Unsuitable cap size.

Solution

Reduce the torque pressure during screwing.

Use caps in accordance with the size of spouts.

12.Factors To Look For Choosing The Best Doypack Filling & Screw Capping Machine?

Who wish to buy a machine that has no credibility and essential features? Of course no one! Instead, every manufacturer has a dream to purchase an equipment which is best suitable to cater their needs. However, it requires proper considerations which will ultimately lead you to make a sound purchase. Similar is the case with a doypack filling & screw capping machine. So, let's begin discovering these factors!

Filling Material

Free-flowing & thick liquids in doypacks

The material you process can be of various nature such as free-flowing edible oil or viscous honey and mayonnaise. Therefore, it is obligatory to determine the nature of material you want to process. It will help you opt for the right doypack filling & screw capping machine in terms of filling system that may be piston filling, gravity filling, or net weigh filling.

Production Capacity

Various beverage doypacks- Picture Courtesy: vogue.co.jp

It is a matter of fact, that production capacity of manufacturing firms vary from one industry to another. So, you need to check your production growth and fix an output target that you want to expect from your doypack filling & screw capping machine. For instance, there is a semi-automatic machine which is desirable for low to medium size production facilities, in contrast, fully automatic machine is ideal for large and extra large industries.

Cost

Calculating cost- Picture: mrpeasy.com

Another important factor is to calculate all the expenses which are directly or indirectly related to the purchase of a doypack filling & screw capping machine. It will include its original price, the cost of installation, maintenance, and parts changeover etc. In case you find no solution suitable or is expensive, then buying a secondhand machine from reputable supplier is a wise decision.

Conclusion

Let's sum up this comprehensive buying guide about a Doypack Filling & Screw Capping Machine with a positive note that choosing the right machine can play an instrumental role in your business success. Similarly, if you are processing flexible packaging like doypacks, then right machine is the dire need for you. So, if you want to get the best, efficient, and quality doypack filling & screw capping machine machine with one year of warranty then contact Allpack who has over 11 years of experience in the field. Stay in contact with us for further information and drop your queries if any!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586