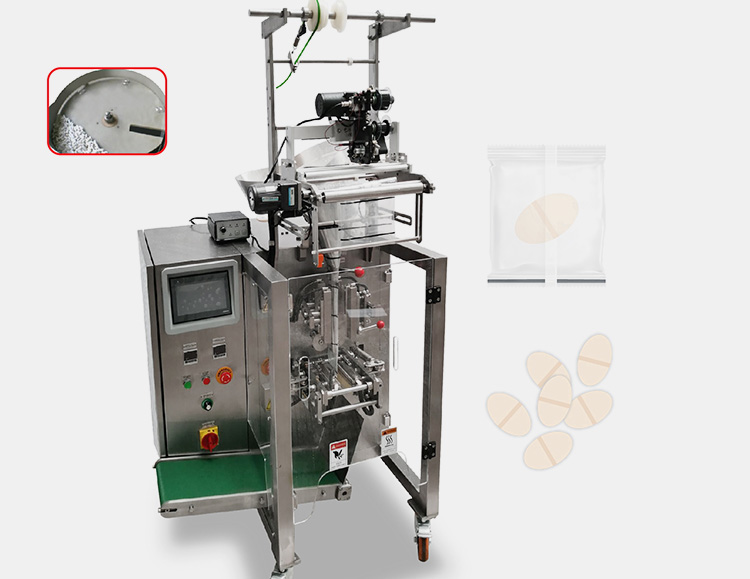

High Efficiency Tablet Packing Machine

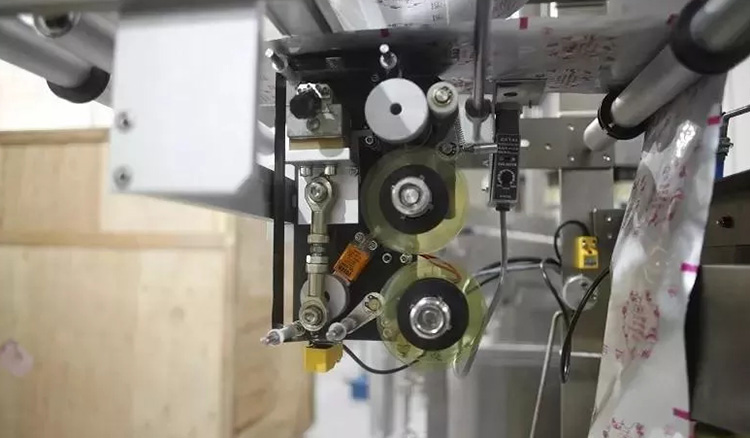

- Intelligent Eye-mark Sensor

- PLC Control, Operation On HMI Panel

- Servo Motor Driven Pouch Length Adjustable

Tablet Packing Machine

Allpack Tablet packing machine applies to medicine packaging, such as variety specification of sugar coated tablet,tablets,capsule,soft capsule and so on. It’s also suitable for packing small hardware, electronical element, medical devices and foods which the shape is similar with above pharmaceuticals. The machine is equipped with one set of vertical sealing roller, one set of horizontal sealing roller and one set of sealing roller for strengthen. The vertical sealing roller is completed, continuous grain vein with leak-resistant line. This machine is also suitable for the quantitative packing of materials such as screw, hardware, medicinal materials, tea, dry goods, machine parts, fruits, seeds, small tubes, etc. Tablet packing machine is specially applied for filling and sealing the tablets and pills in of food, medicine, chemical and agriculture.

Tablet Packing Machine

DXDP-150II Tablet Packing Machine

Allpack DXDP-1501I tablet packing machine combines forming -vertical sealing--filling -horizontal sealing -horizontal strengthen sealing--notching-cutting together.The feeding device of this tablet packing machine depends the physical state of packing product, which includes magnetic pump device M for liquid feeling; Hibar pump device H and Rotary pump device R for homogeneous viscosity, Piston pump P for viscosity with granule.

Stable performance

Convenient debugging

Accurate testing

DXDP-20II Tablet Packing Machine

Allpack DXDP-20II tablet packing machine can automatically complete the products of fasteners conveying, measuring, filling, bag making, date printing, heat sealing and cutting etc.To ensure the same length of each bag, high sensitive electro-optical sensor system is provide to the realize automatic alignment on the packing film.The electroic and pneumatic components of the machine are all supplied by reliable supplier cooperating with us for several years, which can ensure the quality of machine and save the cost of purchase meantime.

High precision&high efficiency

Low noise &saving energy

Adopt high precision servo film transport system

DXDP-40II Tablet Packing Machine

Allpack DXDP-40II tablet packing machine can be used to pack foods,electic parts and small hardware,such as:candy,pills,small bicuits,capsules,tablets,screws,nails,bolts,nuts,and small hard wares etc.This tablet packing machine is a self-developed high-intelligent product. It adopts intelligent microcomputer control and high-precision sensors. It has the characteristics of fast assembly speed, easy operation and compact structure. This machine is also suitable for the quantitative packing of materials such as screw, hardware, medicinal materials, tea, dry goods, machine parts, fruits, seeds, small tubes, etc.

Automatic packaging& quantitative accuracy

Simple operation&good quality

Suitable for a variety of materials

DXDP-5001I Tablet Packing Machine

Allpack DXDP-5001I tablet packing machine can carry out three or four sides sealing pouch. Equipped with different feeding device, it can pack liquid, viscosity product. If the machine has two feeding devices working at the same time, it can achieve twin pouch packing; three feeding devices for triple pouch packing. The machine is equipped with one set of vertical sealing roller, one set of horizontal sealing roller and one set of sealing roller for strengthen. The vertical sealing roller is completed, continuous grain vein with leak-resistant line.

PLC control, operation on HMI panel

Servo motor driven pouch length adjustable

Intelligent eye-mark sensor

Tablet Packing Machine Videos

The Buyer's Guide

Tablet Packing Machine: The Complete Buying Guide in 2025

In order to protect the stability, quality and circulation of the tablets, the tablets need to be packaged in the most suitable way according to the quality and weight. Therefore, the tablet packing machine is a good choice. This guide can offer you the complete information about the tablet packing machine. Let’s start now!

1.What Is Tablet Packing Machine?

Tablet packing machine is specially applied for filling and sealing the tablets and pills in of food, medicine, chemical and agriculture. Tablet packing machine adopts the automatic filling and sealing with the compound materials such as paper, aluminum foil, nylon, etc.

2.What Are the Applications of Tablet Packing Machine?

From the application industry, the tablet packing machines can be applied packaging the following pills and tablets:

Food Tablets and Pills

Tablet packing machines can be applied for packaging different food tablets and pills like candies, chocolate balls, sugar, salts, coffee, seasonings, peppers, beans, etc.

Medicine Tablets and Pills

Tablet packing machines can be applied for packaging different medicine tablets and pills such as capsules, regular tablets, oral tablets, chewable tablets, coated tablets, dispersible tablets, etc.

Chemical Tablets and Pills

Tablet packing machines can be applied for packaging different chemical tablets and pills such as naphthalene ball, mothballs, preservatives, chemical fertilizers, etc.

Agriculture Tablets and Pills

Tablet packing machines can be applied for packaging different agriculture tablets and pills such as phosphorous fertilizer, insect repellent, herbicide, etc.

There are more than these applications, you can pack any tablet or tablet-like balls with this tablet packing machine.

3.What Are the Features of Tablet Packing Machine?

The features of tablet packing machines are similar with the granules packing machines in the following ways:

Automatic Packing Process

Tablet packing machine can automatically complete the whole process of tablet materials feeding, counting, weighing, filling, heat sealing, cutting, etc., and all steps and details can be adjusted freely.

Sensor Tracking

Tablet packing machine adopts the sensor setting to locate the packaging target and the packaging positioning through photoelectric tracking. This whole process does not require manual adjustments.

Sensor Counting

Tablet packing machine adopts light sensor counting method. This method has high precision and small error, and is very suitable for the packaging of high-precision sachet tablet materials.

Intelligent Control System

Tablet packing machine adopts intelligent control system. You can intelligently set the Chinese and English systems. Before operation, you only need to set and adjust relevant parameters, and the whole packaging process will run intelligently.

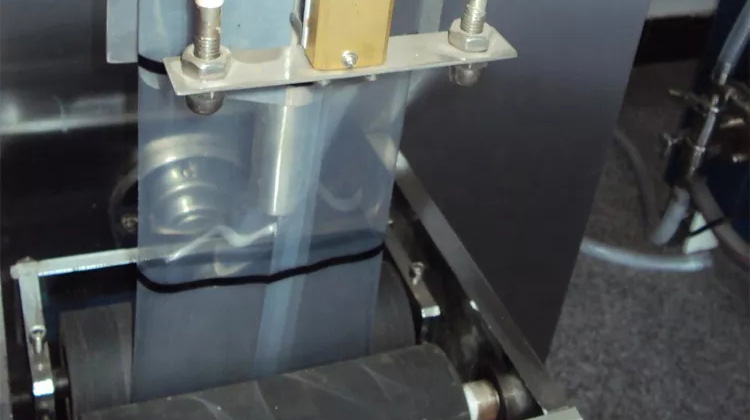

Heat Sealing Adjustable

Tablet packing machine adopts heat sealing system, so that the packaging bag will be heated evenly, and when heating, the heating position of the packaging bag can be adjusted up and down.

Clear and Nice Printing

It is simple and easy for you to operate this machine, and the bags will be sealed firmly and nicely. Tablet packing machines are equipped with the wheel type coding device which can print the clear information in the bag.

Various Cutting Types

There are various types of cutting for you to choose such as letter-shaped, pattern-shaped cutting, single-line cutting, etc.

Optional Device

There are various optional devices for your choices including ribbon printer, exhaust, horizontal sealing and punching device, batch Pneumatic Cutter, rotary cutter, etc.

Empty Alarm System

The tablet packing machine adopts the hopper empty material alarm setting, which is convenient for the staff to operate safely.

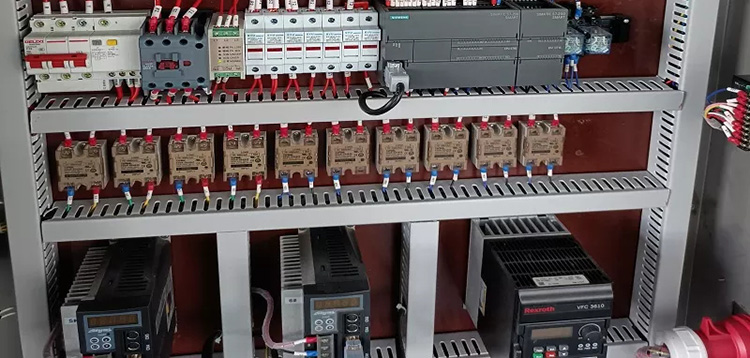

Brand Electrical Components

Tablet packing machine all use brand electrical components. The quality of these electrical components is stable and reliable, which can prolong the service life of the machine.

With all those features of the tablet packing machine, you can simple and safely perform the machine without any worries.

4.What Will You Benefit From the Tablet Packing Machine?

Tablet packing machines are widely applied by the food industry, chemical industry, pharmaceutical industry and agriculture industry, etc. The application prospect of Tablet packing machines is very broad.

Wide Application

Tablet packing machines can be applied in plenty of industries such as food industry, chemical industry, pharmaceutical industry and agriculture industry with all the tablet or tablet-like products.

Precise Filling and Packaging

The most important function of the tablet packing machine is accurate filling and packaging, which can make the finished product beautiful and beautiful. Tablet packing machine can help you achieve this very well. Tablet packing machine has advanced filling system and cutting, sealing system. This ensures that your finished product is beautiful and well-made.

Packaging Efficiency

Tablet packing machine is fully automatic design, without too much human participation.

During the packaging process, the machine can automatically complete the feeding, unloading, filling, heat sealing, thread cutting, batch number printing, punching, counting and other processes according to the parameters set in advance. Greatly reduce labor costs and improve packaging efficiency.

5.What Are the Main Components of Tablet Packing Machine?

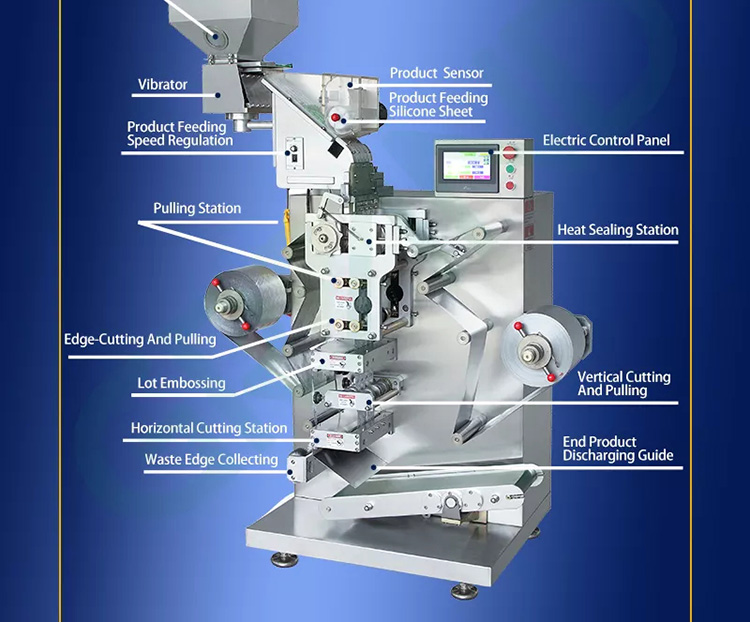

Structure of Tablet Packing Machine

There are more components of tablet packing machine than packaging machines, because it have the counting and weighing functions than other packaging machines.

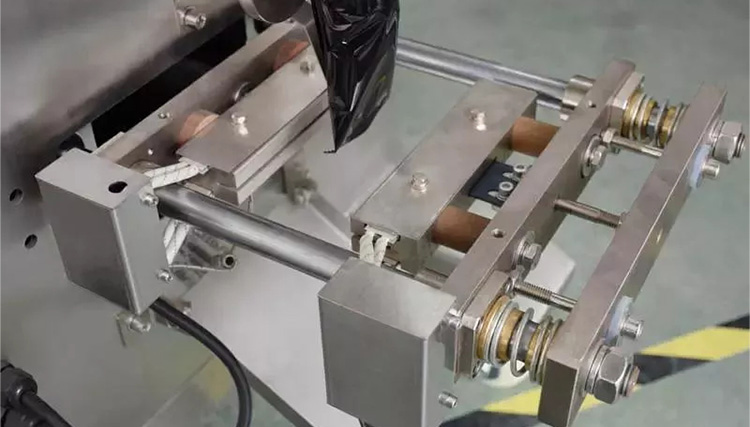

Cutting Device

This cutting device can complete the nice and clean cutting with high speed and high efficiency. It can meet your various sealing and cutting needs such as back sealing, three-side sealing, four-side sealing, etc.

Bag Forming Device

Bag forming device of the tablet packing machine can make firm and well-sealed bags with all film and paper materials. This device can provide all sizes for your choices and mostly are three-side seal or four-side seal, but also can provide customized bag sizes.

Coding Device

The coding device can complete 2 lines coding with 12 characters, or 4 lines with 16 characters. This coding system can provide color printing with safe, harmless, long-lasting effect.

Fragment Stop

The fragment stop system can improve your raw material utilization and reduce material waste with automatic alarm function.

Electric Box

With the high quality electric box, it can provide the tablet packing machine with high lasting and max power.

Measuring System

The measuring system can complete the weighing and counting of the tablets and pills which are easy for the filling.

PLD Temperature Control

The PLD temperature control is installed in the machine independently, it can provide the neat sealing and sharp knife block.

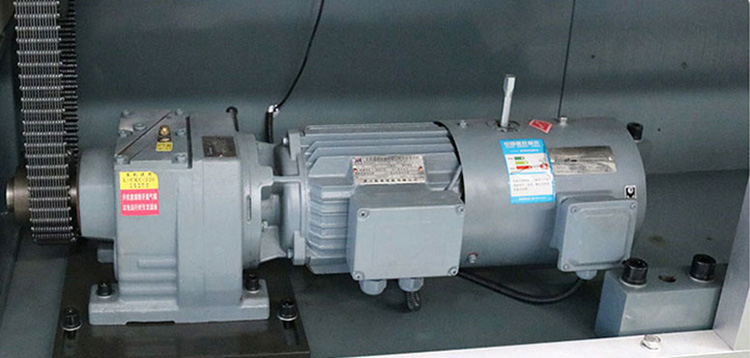

Gear Motor

The gear motor of tablet packing machine adopts the coaxial helical gear motor structure which are small in size with strong overload capacity. This gear motor can guarantee your long-stand and continuous packaging time.

Vibrating Plate

The vibrating plate, also called as feeding device, can assist tablet packing machine feeding. Vibrating plate uses frequency converter and motor to realize automatic material conveying. There is a pulse electromagnet under the vibrating plate hopper, which can make the hopper vibrate vertically.

6.What Are the Types of Tablet Packing Machine?

From the machine design views, there are three types including vertical tablet packing machine, horizontal tablet packing machine, and desktop tablet packing machine.

Vertical Tablet Packing Machine

Vertical tablet packing machine can package round and ball materials, such as candies, snacks, sugar coated tablets and capsules, chocolate beans, etc. This design can facilitate the operator to monitor the operating status of the machine in real time and make adjustments to the operation of the machine at any time.

Working Principles

Tablet packing machine can automatically complete the whole process of tablet materials feeding, counting, weighing, filling, heat sealing, cutting, etc., and all steps and details can be adjusted freely.

Horizontal Tablet Packing Machine

Horizontal tablet packing machines are applying clear or printed film for packaging the tablets and capsules, etc. It can pack materials by tight-fitting flexible packaging with horizontal back sealing and end sealing. This type machine is suitable for individually packaging needs.

Working Principles

With double transducer control, it can control the cutting easily and swiftly. The sealing and cutting can be more accurate with the high sensor and photoelectric color mark tracking system. Various tablets can be packed with the independent PID temperature control.

Desktop Tablet Packing Machine

Desktop tablet packing machines are mainly applied in pills packaging and sealing for sachet or pouch sizes. There are three packaging materials including glassie paper, pet films, and clear cellophane for your choice.

Working Principles of Desktop Tablet Packing Machine

Firstly, you need put the medicines in the slots, then you should set the relevant size and quantity parameters of the packaging bag. Switch the machine on, and the packaging will be started, then the product will be finished.

From the packaging forms, there are sachet tablet packing machine, tablet strip packing machine.

Tablet Sachet Packing Machine

Tablet sachet packing machines are mostly applied in filling, bag making, sealing, printing, output for pills, capsules, candies, chocolate chips, plastic bullets, pills, etc with sachets or pouches.

Working Principles

The tablet sachet packing machines are equipped with PLC color touch screen display. With the PLC color touch screen display, you can set the measurement range from 1-500 pieces.

Tablet Strip Packing Machine

Tablet strip packing machines, also called as plastic blister packing machines, are mostly applied for packaging various solid balls or tablets in the strip. This machine applies aluminum foil heat-sealing and packaging. The mould cooling system applies tap water and circulation water.

Working Principles

From the packing material views, there are effervescent tablet packing machine, soft tablet packing machine.

Effervescent Tablets Packing Machine

Effervescent tablet packing machines are mostly applied for packaging effervescent tablets such as vitamin effervescent tablets, antibacterial drug effervescent tablets, antipyretic drug effervescent tablets, etc. , and especially for bottling pills and capsules filling and capping.

Working Principles

Effervescent tablet packing machines adopt rubbing sheets and tracks。Effervescent tablets can be filled with the material gravity. Effervescent tablet packing machines are equipped with counter, and it is the ideal machine for tablet counting, filling and capping.

Soft Tablet Packing Machine

Soft tablet packing machines are mostly applied for packing tablets and capsules in soft group cell laminated paper or aluminum foil. This type machine is specially used for packaging tablets and capsules that need to be protected from light.

Working Principles

Soft tablet packing machines are specially equipped with a vibration feeding device. The entire packaging process for Soft tablet packing machines includes vibratory feeding, chip removal, weighing and metering, vertical and horizontal cutting, batch number coding. These processes are all fully automatic. This machine is ideal equipment for the pharmaceutical industry.

With all these types of tablet packing machines, you can choose the best one to suit your packaging needs according their different working principles and feature.

7.What Are the Working Principles of Tablet Packing Machine?

The working principles of table packing machine are:

Working Principles of Tablet Packing Machine

- Tablet materials will be feeded into the hopper automatically, and the vibrating device will sieve the materials will sieve and eliminate defective products.

- The volume cup will weighing and counting the tablet materials and filling them in the premade

- The filled bags will be sealed by the heat sealing device.

- After being coded with the batch number and production information, the bags will be cutting and vertical and horizontal perforation.

- During this process, defective products will be sorted out and the waste will be collected. The finished product will be output on the conveyor.

8.What Are the Packing Materials For the Tablet Packing Machine?

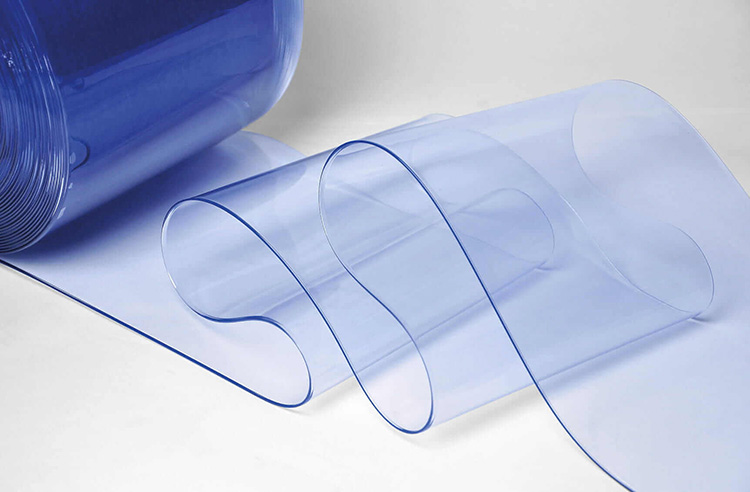

There are various packing materials for the tablet packing machine including aluminum foil films, PVC, PVDC, PET and PP.

Aluminum Foil Film

Aluminum foil is an extremely thin sheet formed by high-purity aluminum after multiple calendering. It is an excellent heat conductor and light-shielding body. It is an excellent packaging material for medicines like tablets, capsules, or food like candies and gums, or toys, etc.

PVC

PVC also called as polyvinyl chloride. PVC are widely used in building materials, industrial products, daily necessities, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, fibers, etc.

PVDC

PVDC also called as polyvinylidene chloride, has the characteristics of flame resistance, corrosion resistance and good air tightness. PVDC can be made into sheets, pipes, moldings, films and fibers, and is often regarded as an excellent type of packaging material.

PET

PET also called as polyethylene terephthalate, creep resistance, fatigue resistance, friction resistance, good dimensional stability. This material is very suitable for use as packaging material.

PP

PP also called as polypropylene, is a polymer made of propylene through addition polymerization. PP has excellent heat resistance, high-strength mechanical properties and good high wear-resistant processing properties, etc., and is an excellent packaging material.

9.What Are the Differences Between Tablet Packing Machine and Blister Packaging Machine?

The differences between tablet packing machine and blister packaging machine are mainly lie in the aspects of main functions, working principles, main components, main features and main appliance.

Main Functions

Main Functions of Tablet Packing Machine

Tablet packing machine mainly packs round flake and round granular items in medicine, chemical industry and industrial products. Such as: sugar-coated tablets, plain tablets, steel balls, capsules and other materials packaging.

It can continuously and automatically complete the whole packaging process of bag making, measuring, filling, sealing, cutting, counting, etc., and is equipped with a photoelectric trademark positioning device, and can also add functions such as typing and cutting.

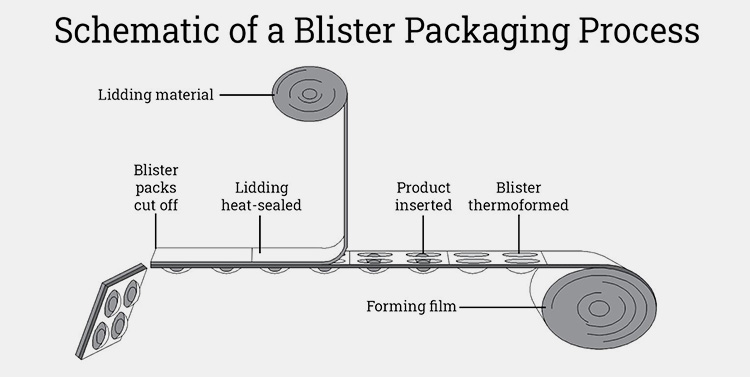

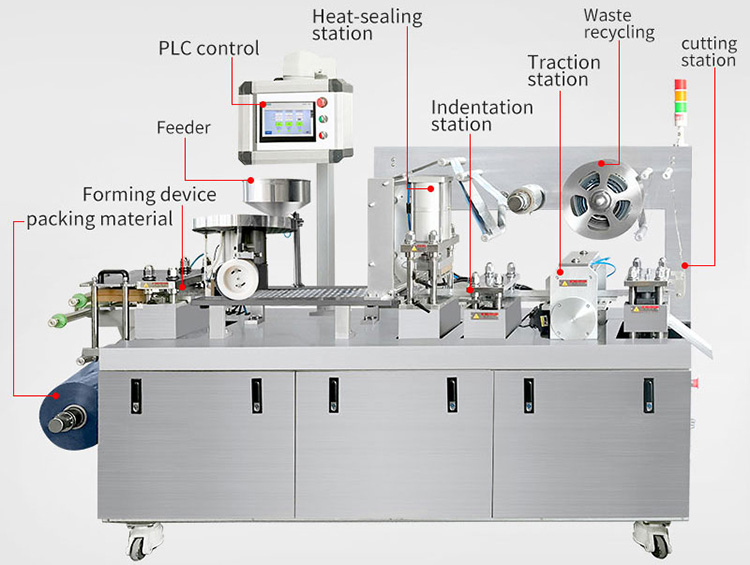

Main Functions of Blister Packaging Machine

Working Process of Blister Packaging Machine

The blister packaging machine is a machine that forms a blister with a transparent plastic film or sheet, and seals the product between the blister and the bottom plate by heat sealing, bonding, etc. The blister packaging machines are mostly applied in packaging the various tablets and capsules.

Working Principles

Working Principles of Tablet Packing Machine

Tablet materials will be feeded into the hopper automatically, and the vibrating device will sieve the materials will sieve and eliminate defective products. The volume cup will weighing and counting the tablet materials and filling them in the premade bag.

The filled bags will be sealed by the heat sealing device. After being coded with the batch number and production information, the bags will be cutting and vertical and horizontal perforation. During this process, defective products will be sorted out and the waste will be collected. The finished product will be output on the conveyor.

Working Principles of Blister Packaging Machine

First, the flat heating device heats and softens the forming film, and then the softened film is blown into a blister in the flat forming device. Tablets and capsules are automatically filled into the blister, and the filled blister will be sealed by the cover film through the sealing heating device.

The final finished product will be printed with batch number and breaking line by printer. Finally, the punching device will punch the finished product into the set size.

Main Components

Main Components of Tablet Packing Machine

The main components of tablet packing machine include vibrator, product sensor, product feeding silicone sheet, electric control panel, heating sealing station, edge-cutting and pulling device, vertical cutting and pulling device, horizontal cutting and pulling device, waste edge collecting, end product discharging guide, etc.

Main Components of Blister Packaging Machine

The main components of blister packaging machine include material feeder, PLC control system, vibrating device, blister card forming device, packing material, heat-sealing station, indentation station, traction station, waste recycling device, cutting station, etc.

Main Features

Main Features of Tablet Packing Machine

Tablet packing machine can automatically complete the whole process of tablet materials feeding, counting, weighing, filling, heat sealing, cutting, etc., and all steps and details can be adjusted freely.

Tablet packing machine is controlled by PLC and touch screen. Through this device, you can set the relevant parameters of the entire tablet materials packaging process by yourself.

Tablet packing machine adopts light sensor counting method. This method has high precision and small error, and is very suitable for the packaging of high-precision sachet tablet materials.

The tablet packing machine adopts the hopper empty material alarm setting, which is convenient for the staff to operate safely.

Tablet packing machine all use brand electrical components. The quality of these electrical components is stable and reliable, which can prolong the service life of the machine.

Main Features of Blister Packaging Machine

The Blister packaging machine adopts the method of heating aluminum and plastic inside the gallbladder, and adopts the method of coating the surface of the heating roller with fluorine, so that the PVC material can be heated evenly.

All parts of the Blister packaging machine are designed with gear transmission. This not only facilitates the maintenance of the staff, but also reduces the noise during the operation of the machine.

Blister packaging machine is suitable for material packaging in different shapes.

During the sealing process of the Blister packaging machine, a uniform heating device is used, so that the sealing method is firm, crisp and beautiful.

Blister packaging machine adopts cylinder heat sealing, this packaging method will not burn and damage blister card.

Main Appliance

Main Appliance of Tablet Packing Machine

Tablet packing machines are mainly applied in packaging tablets and capsules, pills, candies, chocolate balls, sugar, salts, coffee, seasonings, peppers, beans, naphthalene ball, mothballs, preservatives, chemical fertilizers, fertilizer, insect repellent, herbicide, etc.

Main Appliance of Blister Packaging Machine

Blister packaging machines are mainly applied in packaging tablets and capsules. But, blister packaging machines can also be applied in packaging candies, toys, tooth brushes, electronic products, tablewares, kitchenwares, etc.

Conclusion

In the past 10 years, the frequency of use of tablet packing machines by various industries has increased by 80%. Tablet packing machines are widely put into large-scale tablet materials packaging production now. Therefore, it is very important to choose the most suitable tablet materials packaging. Regarding this point, Allpack can give you the best suggestion and choice, welcome your consultation.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours