Top Quality Triangle Bag Packing Machine

- Servo Motor Film Pulling

- Intelligent Temperature Control

- High-sensitivity Photoelectric Color Tracing

Triangle Bag Packing Machine

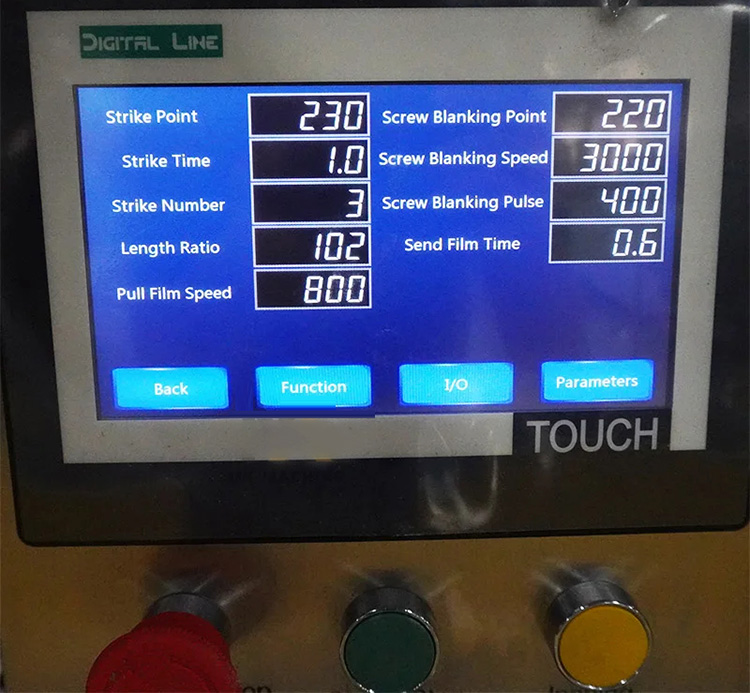

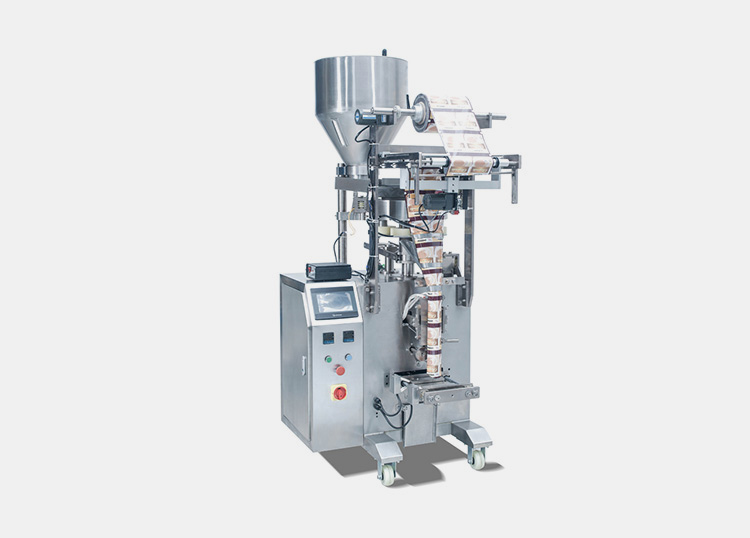

Allpack Triangle Bag Packing Machine can pack triangle/pyramid tea bag, also can adjust to sqaure tea bags, 1 hour can pack 2000-4500bags, tea bags can be covered with plastic bags.This machine can packing nylon tea bags, corn fiber bag, using ultrasonic sealing, the bag will not be damaged and no harmful substances will be produced. The triangle packing machine is easy to operate,instructions and working conditions are clearly shown on touch screen. This machine can be equipped with automatic coding production date, inflation, pressure, bag, cut, seal and complete the package. The film pulling device is controlled by a servo motor, ensuring accurate bag length positioning. The triangle packing machine can make a pillow -shape bags according to customers' requirements.This machine is suitable for food, beverage, tea, retail industries, etc.

Triangle Bag Packing Machine

DXDF-100ZAX Triangle Bag Packing Machine

Allpack DXDF-100ZAX triangle bag packing machine is suitable for the packaging of various large-capacity light foam materials for food, chemical, seasoning, medicine, powder, and granules (such as puffed food, dried tablets, Chinese herbal medicines, melon seeds, nuts, small Packaging of biscuits, chips, washing powder, oatmeal, milk powder, sugar, coffee, tea, toys, etc.). The machine can be equipped with automatic coding production date, inflation, pressure, bag, cut, seal and complete the package. Intelligent PLC control system, stable operation of the machine, convenient and fast operation. Automatically this packing machine can complete all tasks such as measurement, bag making, filling, sealing, batch number printing, cutting, and counting.

High accurate & automatic

High-sensitivity photoelectric color tracing

The material contact is stainless steel

DXDG-100ZII Triangle Bag Packing Machine

Allpack DXDG-100ZII triangle bag packing machine can be equipped with different weight and filling systems for various granules, and packaging such as peanuts, candies, cookies, potato chips, snacks, candy, pistachio, rice, sugar, beans, lentil, dried fruit, pet food, small hardware, etc. The triangle packing machine is easy to operate, and instructions and working conditions are clearly shown on the touch screen. With the PLC control system, the machine has a constable working program and can preset 10 formulas, easier to change product packaging. A variety of automatic alarm protection functions can effectively reduce the loss of materials and ensure work safety.

Intelligent temperature control

Servo motor film pulling

Pneumatic sealing device

DXDK-100ZI Triangle Bag Packing Machine

Allpack DXDK-100ZI triangle bag packing machine adopts an advanced PLC system, it can automatically accomplish measuring, filling, counting, and printing codes. The bags made by this machine are triangle style, which is very novel and unique. It can be used to pack puffed foods, peanuts, melon seeds, tea, sugar, creamer, coffee, etc., and also pack liquid products, such as sour, juice, jelly, cream, etc. The process of bag making measuring, filling, sealing, cutting, logo positioning, and counting can be finished automatically. The film-pulling popcorning device is controlled by a servo motor, ensuring accurate bag length positioning.

Adopts fully automatic computer control

The machine is easy to operate

PLC and HMI controller

DXDY-100ZII Triangle Bag Packing Machine

Allpack DXDY-100ZIII triangle bag packing machine can automatically complete such functions as bag-making, filling, measuring, sealing, Thread feeding, labeling, cutting, counting, etc, thus reducing labor expenses and improving production efficiency. Adopts intelligent temperature and temperature control is highly accurate. Ensure that the sealing is beautiful and smooth. The triangle packing machine can make a pillow -shape bags according to customers’ requirements. Equipped with rolled cup device enables volume of packing changing anytime, loss reducing and improving productivity. Set the machine parameters through the touch screen, the operation is simple and convenient, and it supports multiple languages.

Fast and stable

PLC control system

Safety protection

The Buyer's Guide

Triangle Bag Packing Machine:The Complete FAQ Guide in 2025

The Triangle Bag Packing Machine has been the go-to solution for high-volume industry packaging since its introduction. It’s an essential tool that helps businesses speed up their operations, increase productivity and improve product safety. But for all its benefits, the triangle bag packing machine can be a mystery to many small business owners.

What does it do exactly? How difficult is it to use? Is there anything special you should be aware of before investing in one? These are just some of the questions we attempt to answer in this comprehensive guide. We will also explain why investing in these powerful machines can be a great choice for your business in 2025. From technical specifications to the types of bags that can be effectively used, this guide has covered everything so you can make sure your business is one step ahead!

1.What Is A Triangle Bag Packing Machine?

A triangle bag packing machine is a highly automated device used by producers to quickly and efficiently fill pre-made bags with the product. It is designed for use in an industrial environment but can also be found in smaller operations. The machine takes advantage of the triangular shape of most pre-made bags to ensure that the product is evenly distributed and efficiently filled.

Additionally, the triangle bag packing machine has several features to streamline the process, including automated bag loading, product volume measurements, heat sealing, and more. This machine can be used for a range of products, including powdered mixes, liquids, and granular materials. It can also handle different size bags, allowing for maximum flexibility in production.

In short, with their versatile design and easy operation, triangle bag packing machines are an ideal choice for many industrial applications.

2.What Are The Components Of A Triangle Bag Packing Machine?

Triangle bag packing machines have several components that efficiently package products such as snack foods, coffee grounds, grains, and other bulk items. The components of these machines include:

Frame

The frame of a triangle bag packing machine is responsible for holding all the other components together and providing structural support. It is usually made of steel or aluminum and may have additional braces or supports for increased stability.

Hopper

The hopper is where the product or material that needs to be packaged is placed. It is usually a funnel-shaped device that feeds the material into the other components of the machine.

Weigher

This component measures and records the weight of the product or material as it is fed into the bag-packing machine, ensuring proper packaging and portioning.

Vacuum Pump

This component creates a vacuum seal around the product or material as it is placed into the bag. This helps protect the item from outside contamination and ensures that its integrity is maintained.

Sealing Rollers

These rollers are responsible for creating a secure seal on the bag, locking in any gasses or liquids inside. The spacing of these rollers can be adjusted depending on the product or material being packaged.

Control Panel

The control panel is responsible for managing all of the components within the machine, ensuring that everything runs and functions properly. It also allows for adjustments to be made on different settings, such as speed and bag size.

3.What Are The Applications Of A Triangle Bag Packing Machine?

Businesses are increasingly using triangle bag packing machines for a wide range of applications. These machines are very versatile and can be used to package various products quickly and efficiently. Some of the most common applications include:

Food Packaging

A triangle bag packing machine is commonly used for packaging food products such as chips, popcorn, tea leaves, and nuts. The triangle-shaped bags provide superior protection to the product due to their shape, which ensures that the contents are adequately secured and remain fresh.

Pharmaceuticals

Triangle bag packing machines can also be used for packing pharmaceuticals such as tablets and capsules. The triangular shape ensures that the contents are securely contained and remain uncontaminated.

Industrial Products

A triangle bag packing machine is also suitable for packaging industrial goods like nuts, bolts, screws, nails, and other small mechanical components. This type of machine is ideal for packing these items since it can ensure that the contents are well-organized and compacted. They also help protect the product from moisture and other contaminants during shipping and storage.

Personal Care Products

Triangle bag packing machines can also be used for packaging various personal care products such as soaps, shampoos, conditioners, lotions, and creams. The bags’ triangular shape helps keep these items neatly organized and tightly sealed, which helps preserve the product’s shelf life.

4.What Are The Advantages Of A Triangle Bag Packing Machine?

As a large-scale manufacturer, a triangle bag packing machine can offer many advantages regarding packaging needs.

Increased Efficiency

A triangle bag packing machine increases production efficiency by allowing for faster and more accurate packaging, thanks to its automated design. Packaging speed is increased by up to 200%, drastically decreasing the time spent on manual packing operations.

Cost Savings

Using a triangle bag packing machine eliminates labor costs associated with manual packing operations, thus resulting in considerable cost savings. Additionally, the machine’s automated design helps reduce wastage due to incorrect packaging or damaged goods.

Improved Accuracy

Due to its automated design, a triangle bag packing machine ensures more accurate and consistent packaging than manual labor allows. This reduces the odds of errors occurring, which in turn helps to ensure customer satisfaction.

Enhanced Productivity

The automated design of a triangle bag packing machine also leads to enhanced productivity on the production line. This is due to its ability to package more products faster, allowing for higher volume production runs.

Reduced Waste

The automated design of a triangle bag packing machine helps to reduce waste due to incorrect packaging or damaged goods. As the machine can package more products at a faster rate, there is less chance of errors occurring and thus less wastage.

Enhanced Safety

A triangle bag packing machine eliminates manual labor associated with packaging operations which greatly reduces the risk of employee injuries. Therefore, workers are better protected, and the risk of workplace accidents is significantly reduced.

Versatility

A triangle bag packing machine can be used to package a variety of products ranging from small items, such as cosmetic containers and health care products, to more oversized items, such as electronic components and kitchenware. Additionally, the machine has adjustable settings, which allow it to be used for different sizes and shapes of bags.

5.How Does A Triangle Bag Packing Machine Work?

A triangle bag packing machine is an automated system that quickly and efficiently fills bags with various products. The machine works by first gathering the ingredients for the bag. This could include food, candy, or other products. Once the ingredients have been collected, they are placed into a hopper which feeds them into the forming area of the machine.

The forming area consists of several rollers that shape the material into a triangular bag. Depending on the specific type of product being packed, the rollers can be adjusted to create different size bags or adjust heat settings to help seal them. The rolled material is then cut to precise measurements and fed through a sealing mechanism that creates an airtight seal.

The final step of the process is to fill the bag with the desired product. This can be done by either a mechanical or pneumatic dispenser device, which you can adjust for different product types and volumes. Once filled, the bag is passed through a system that transports them to their destination. The entire process is fast and efficient, making it an excellent option for those looking to package their products quickly.

6.What Are The Different Types Of Triangle Bag Packing Machines?

When it comes to packing products in triangle bags, there are several types of machines available to choose from. Here is a quick overview of the most common options:

Fully Automatic Triangle Bag Packing Machines

These machines typically include an automated filling system that can be customized for various product sizes and shapes. The process is relatively simple – the operator manually places the product into the bag and then presses a button to seal it. This machine is ideal for small- to large-sized businesses that need to package products quickly and efficiently.

Vacuum Forming Triangle Bag Packing Machines

These machines are ideal for packaging food products like chips and biscuits. The process involves single-sheet forming with vacuum suction over a heated mold to form the triangle bags. This is followed by feeding the product into the bag, sealing it through heating elements, and then cutting it open at the top.

Rotary Triangle Bag Packing Machines

This packing machine is typically used in more specialized jobs, such as filling snack bags or medical supplies. The rotary design allows for greater control over the product placement and packaging speed. The machine uses a rotating platform that continuously transports bags to be filled along its circumference and then automatically seals them when complete.

Multi-Head Triangle Bag Packing Machines

As the name suggests, these machines are equipped with multiple heads for increased packing efficiency. Multi-head triangle bag packing machines are designed to fill multiple triangle bags at once, which makes them well-suited for high-volume applications. They use an array of tubes and nozzles that dispense the product into each bag simultaneously.

7.What Types Of Products Can Be Sealed By A Triangle Bag Packing Machine?

Chips

Chips are a type of snack food made from fried potatoes or other vegetables. You can seal them in triangle bags using a triangle bag packing machine. This machine creates an airtight seal that prevents the chips from spoiling or exposure to moisture and other contaminants.

Biscuits

Biscuits can come in all shapes and sizes, but no matter what shape they take, a triangle bag packing machine can quickly seal them in an airtight package. It keeps biscuits fresh and protected from the elements while preventing them from becoming soggy or crumbling.

Spices

Spices such as pepper, cinnamon, and cumin are often used in small amounts, making it convenient to use a triangle bag packing machine to portion out the right amount into individual packages. It allows for easy portioning and storage while preventing spices from becoming stale or clumping together.

Milk

Milk is a valuable commodity that needs to be well-sealed to keep it safe and fresh. A triangle bag packing machine can provide an airtight seal for various milk products, such as flavored and almond milk. It ensures that the milk stays fresh and the vitamins remain intact.

Lotions

Lotions and creams are often sold in small containers to help consumers get the exact amount they need. A triangle bag packing machine can seal these containers in an airtight package that preserves the product’s freshness.

Shampoo

A shampoo is a liquid form of hair care, and the triangle bag packing machine is perfect for sealing it in a leak-proof package. This ensures that no shampoo will spill out, keeping both the product and surfaces clean.

Tablets

Tablets, such as pills and vitamins, can be packaged in a triangle bag packing machine for easy consumption. This makes taking the tablets easier and keeps them fresh and away from moisture.

Screws

Screws are small items that need to be kept organized and secure. A triangle bag packing machine can easily provide an efficient and airtight seal for screws, nuts, and bolts. This will help keep them organized and protected from dust and moisture.

8.What Are The Different Types Of Packaging Materials That Can Be Used With A Triangle Bag Packing Machine?

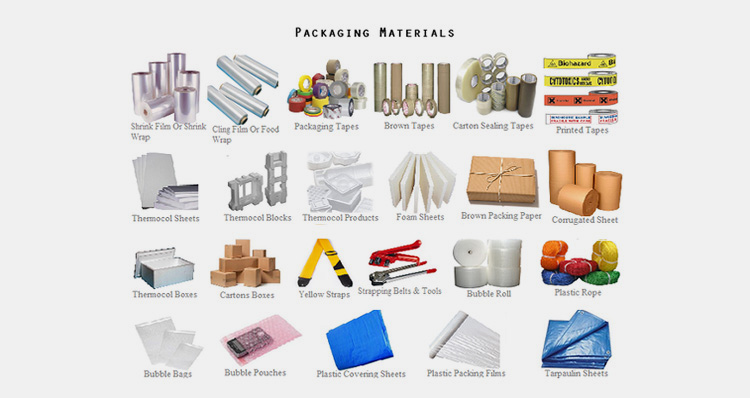

A triangle bag packing machine can be used to create a variety of packaging solutions, depending on the material and application. Here are the most common types of packaging materials that can be used with this versatile machine:

Polyethylene (PE)

The most commonly used material for triangle bag packing machines, PE is highly durable, flexible, and cost-effective. It is suitable for a wide range of applications, from food to pharmaceutical goods.

Polypropylene (PP)

A popular choice for vacuum packing, PP provides an airtight seal that protects contents from moisture and oxygen. It can be used for everything from dry goods to liquids or fragile items such as electronics.

Polyvinyl Chloride (PVC)

PVC is a popular choice for triangle bag packing machines due to its high strength and durability. It is often used for medical solutions, offering an effective barrier against bacteria and other contaminants.

Nylon

With its strong tear resistance, nylon is ideal for triangle bag packing machines. It is often used to package products that require extra protection, such as heavy-duty items or medical supplies.

9.How Do I Troubleshoot A Triangle Bag Packing Machine?

First, check the power supply and cables to ensure they are securely connected. Make sure that all moving parts are functioning correctly. Inspect any sensors or switches for damage or improper alignment.

Next, check the settings of the controls. Adjust if necessary according to the user manual specifications. A setting may have been inadvertently changed.

Also, test the output of the machine by running a test cycle. This will allow you to identify if there is an issue with the actual functioning of the machine. Check for any abnormal sounds or vibrations from the motor, and ensure that all parts move smoothly.

If needed, replace any faulty components or worn-out parts. Make sure to follow the manufacturer’s guidelines when replacing any parts.

Finally, clean and lubricate any moving parts on the machine. Ensure that all areas are appropriately lubricated to maintain the optimum functioning of the Triangle Bag Packing Machine.

10.What Are The Common Problems and Solutions Associated With Triangle Bag Packing Machines?

A triangle bag packing machine provides an efficient and cost-effective way to package products for sale. However, like any other piece of machinery, it is not immune to issues that can result in a loss of productivity or product quality. Here are some common problems found with triangle bag packing machines and solutions you can consider:

Bag Jam

Jamming can occur when the packing material is too thick or contains debris that gets stuck in the machine. It can also happen when the material needs to be cut to the correct size and shape beforehand.

Solution: Check the heat seal area, ensure all settings are correct and double-check bag positioning when loading. Also, carefully clear any jammed bags from the machine, ensuring no damage to any parts in the process.

Sealing Quality

Poor quality seals can lead to product spoilage and customer dissatisfaction. The main cause of this is usually improper temperature settings on the sealing mechanism.

Solution: it’s essential to ensure that temperatures are set correctly. Sealing pressures can also be adjusted to prevent leakage.

Product Separation

If products are not appropriately separated when loaded, they could get stuck in the machine and cause a jam.

Solution: Make sure you adjust the product separator to ensure products are correctly separated.

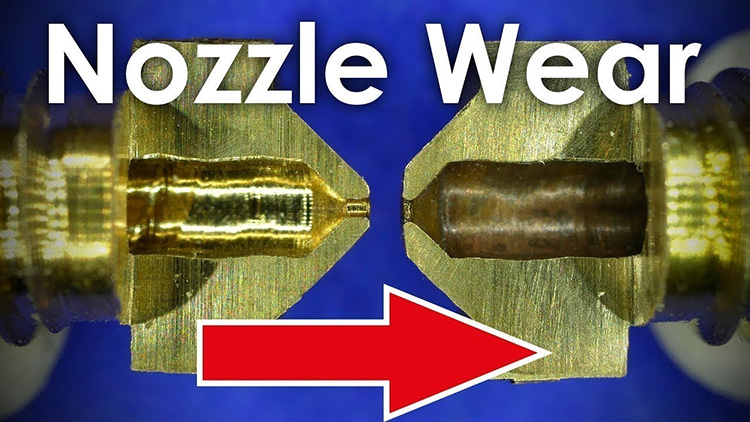

Excessive Nozzle Wear

The nozzles used for filling bags can become worn over time, resulting in an uneven product flow.

Solution: Inspect the nozzles regularly and replace them if worn, ensuring you select a nozzle compatible with your machine’s specifications.

Product Size

If a triangle bag packing machine needs to be set up for the correct product size, it can result in bags being filled too full or insufficient.

Solution: Make sure the machine is calibrated for the exact size of the product you are using and adjust as needed if there are changes in product size.

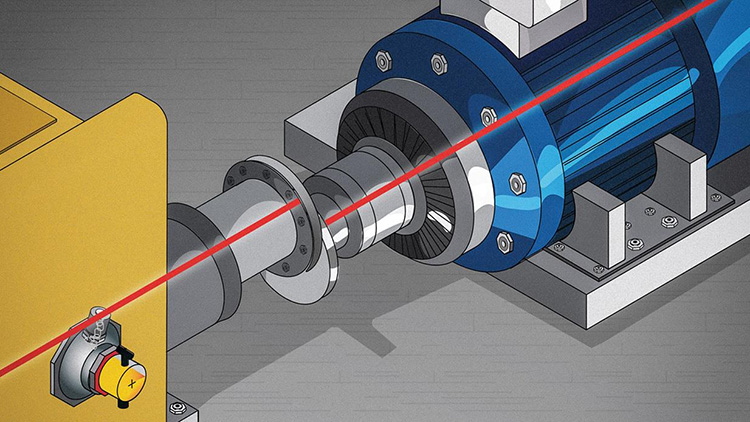

Misalignment

Misalignment can occur when the machine’s packing material isn’t aligned correctly. This can lead to inefficient packing and reduced productivity.

Solution: The best way to prevent misalignment is to regularly calibrate the machine and ensure that all components are correctly aligned. Additionally, it’s essential to ensure that the material being fed into the machine is cut to the correct size and shape beforehand.

11.How Often Does A Triangle Bag Packing Machine Need To Be Maintained?

Regular maintenance is essential to ensure the long-term effectiveness and safety of your triangle bag packing machine. To keep it running at peak performance, you should inspect and clean the machine on a regular basis. Depending on the size and complexity of your machine, you may need to have maintenance performed more often than others.

Typically, triangle bag packing machines should be inspected and cleaned at least once every three months. This will ensure that all the parts are working properly and in good condition, as well as reduce the risk of unexpected breakdowns and malfunctions.

Additionally, it is recommended to have an annual professional maintenance service performed by a qualified technician to check for any wear and tear or defects in the machine. It will help to identify any potential problem areas and allow you to address them before they become serious issues.

12.What Factors Should Be Considered Before Purchasing A Triangle Bag Packing Machine?

Packaging Material

The packaging material you plan to use in your triangle bag packing machine should be considered first and foremost. Different materials such as paper, plastic, aluminum foil, or even laminated films may require different machines for effective packaging. Consider the needs of your product and choose the most suitable machine for it.

Speed

Depending on the needs of your business, you may require different speeds from your machine. Some machines can pack at high speeds, while others offer slower rates. Consider the speed needed for efficient packaging and choose an appropriate machine.

Size

The size and capacity of a machine should be considered before making a purchase. Consider how many bags need to be packed at once and whether the machine can accommodate your needs.

Cost

The cost associated with purchasing and maintaining a triangle bag packing machine is a factor that must be taken into consideration. Compare the costs of different machines, including spare parts, to ensure you are getting the most value for your money.

Ease of Use

The ability to quickly and easily use a triangle bag packing machine is essential to ensure efficient packaging. Make sure you know how to operate the machine before purchasing it and that sufficient instructions are included for its operation should any problems arise.

Maintenance

It would be best to consider the ease of maintenance when choosing a triangle bag packing machine. Consider the frequency with which spare parts will need to be replaced, and whether these can easily be obtained from the manufacturer or other sources.

Quality

The quality of the machine itself is an essential factor to take into consideration before purchasing. Ensure that the machine is made of quality materials and has features such as adjustable settings to ensure your product is packaged effectively.

Conclusion

A triangle bag packing machine is a versatile and reliable packaging solution for small-scale and commercial businesses. With its ability to easily pack various products such as tea leaves, coffee beans, spices, cereal, and rice, among others, this machine saves on time and labor costs. So, for the best performance and efficiency in your packaging process, buy from reputable manufacturers like Allpack company. Their machines are of high-quality standards and designed to meet customer demands. So don’t hesitate to contact them today for all your packaging needs!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours