Top Tray Vacuum Gas Flushing Packaging Machine

- Fault Real Time Prompting Function

- Programmable Control System

- Photoelectric Tracking System

Tray Vacuum Gas Flushing Packaging Machine

Allpack vacuum tray gas flushing packaging machine is made of stainless steel. It is controlled by electricity, gas, and machine, and the programmable logic controller (PLC) cooperates with the touch screen to realize the man-machine interface dialogue. The client can change gases ratio on the touch screen as needed, each part of the action and control parameters can be set and modified by the PLC. Equipped with a photoelectric tracking system, perfectly combine the plastic box and the color film. The packaging process is automatically completed after the packing box filled with items is put into the lower mold cavity: vacuuming, inflating – hot-pressing sealing – slitting – discharging of the packaged product, saving time and labor.It can be widely used in cold meat, cooked meat products, poultry, fish, sauce and brine, as well as fruits and vegetables and other supermarket food.

Tray Vacuum Gas Flushing Packaging Machine

HVT-450A Continuous Tray Vacuum Gas Flushing Packaging Machine

Allpack HVT-450A continuous tray vacuum gas flushing packaging machine is used to pack all kinds of PP or PE trays by replace air with protective mixture gas, for the purpose to avoid food spoilage. This tray vacuum gas flushing packaging machine can complete vacuuming, gas flushing, sealing and cutting operations automatically and continuously, therefore, it has high production speed, can increase efficiency for industries, it is commonly used in food industry.

Customizable&Removable Molds

Continuous Packaging Operation

Extend Storage Time

HVT-450M Continuous Tray Vacuum Gas Flushing Packaging Machine

The HVT-450M continuous tray vacuum gas flushing packaging machine of Allpack is used for vacuuming, gas flushing, sealing and cutting trays which are made of PEF or PP. This tray vacuum gas flushing packaging machine is widely applied in food, beverage, medical, chemical industries, etc, it is fast and accurate, can pack trays in a pretty high speed and with low errors. The shape and size of the mold can be customized to adapt to various types of products, which is very convenient for industries.

High Gas Replacement Rate

High Level Temperature Controller

Emergency Stop Function

The Buyer's Guide

Gas Flushing Machine: The Complete Buying Guide In 2025

Are you looking for a gas flushing machine? Or are you constantly searching for its working, functions, requirements and features that fulfill your manufacturing needs.

Don’t fret! We are here to assist you in providing every possible information related to a gas flushing machine. It does not only suck oxygen from packages but also insert particular gases so the shelf life of your products can be prolonged with appealing look. Stay hooked to know more about it.

1.What Is A Gas Flushing Machine?

A gas flushing machine is the most common type of modified atmosphere packaging (MAP), where particular gases are repetitively infused and sucked out from bags so the oxygen present inside can be completely eliminated.

By using nitrogen, carbon dioxide and other exotic gases it increases the lifespan of food without any type of quality degradation. It also leaves the packages puffed up so the fragile products remain safe in their original form during transit.

2.What Benefits You Can Get By Using A Gas Flushing Machine?

No doubt! The reason for popularity of a gas flushing machine is its substantial benefits in the packaging industry. But how these benefits assist you is what we have explained below:

Increase Shelf Life

A gas flushing machine can better enhance the shelf life of food and allow more time for it to pass through the distribution chain. Packed food with protective gases also helps in increasing the product range in markets.

Fast Processing

With high degree automation this machine works effectively and process huge number of products in an hour which ultimately increase your production rate and packaging efficiency.

Hygienic

The gases used by a gas flushing machine act as a buffer for your products. In addition, it provides protective layers of film over packed food so their susceptibility could be well maintained.

Versatile

A gas flushing machine is highly versatile in a way that it can be applied to different types of pouch, containers and bags. It uses various gases for numerous products which indicate its flexibility.

Reduce Wastage

It also reduces the wastage of food through infiltrating various gases and avoids any type of food wastage.

Prevent Food Breakdown

Gases released by a gas flushing machine helps in the prevention of molecular breakdown of food. It maintains the integrity and conformity of food and gives them a chance to stay fresh and avoid crumbling.

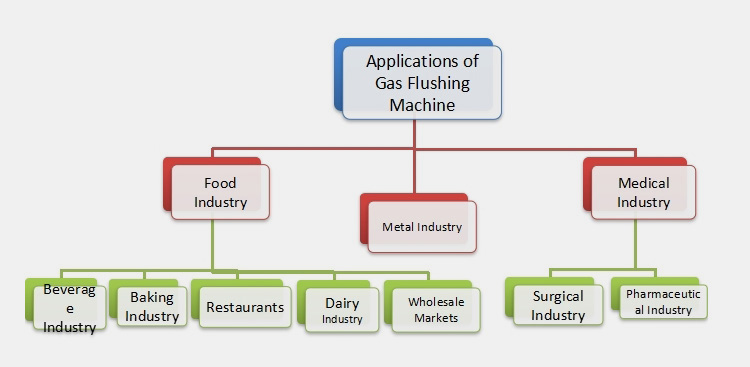

3.In Which Areas A Gas Flushing Machine Is Popularly Used?

To grasp the attention of consumers, large food industries are taking the services of a gas flushing machine and beautifully pack their products via this machine. These industries include:

Food Industries

Beverage Industry

Most of the beverage industries are utilizing gas flushing machine to preserve the quality of juices, cold drinks, wine and bottled water for long time.

Baking Industry

This machine is highly reliable for products with soft nature like those of baked breads, cakes, pastries etc. This is the answer why every baking owner is keen to incorporate this technology into their business sphere.

Confectionary Industry

Confectionary products like sweets, candies and chocolates are sticky and soft. Thus, their packaging is a challenging task. To prevent them from damage packets are first flushed properly by gas after which they are packed. This is done by a gas flushing machine.

Dairy Industry

To protect the natural taste and affect of milk, cheese and butter nitrogen gas by a gas flushing machine is used in dairy industries.

Restaurants

Another place which is definitely using this modified gas flushing equipment is restaurants. To store large amount of raw food and ready meals this machine is required.

Wholesale Markets

This machine enables the companies to expand their reach. It also play crucial role in stabilizing the position of famous industrial owners, that’s why wholesale markets use this machine for fast execution.

Medical Industry

Surgical Industry

Various surgical instruments including scissors, blades, test kits and sterile medical devices are packed in gas flushed vacuum bag to prevent them from rust and corrosion.

Nutraceutical Industry

Any material that is derived from food sources in order to cure any disease or to take as a supplement can be called nutraceuticals. They are present in form of capsules, tablets, protein powders or vitamins etc. These all substances need proper packaging for the preservation of their quality. Here a gas flushing machine with best packaging equipment is the best solution.

Pharmaceutical Industry

Gas flushing is used on major level for blister packaging and pharmaceutical water like purified water of injection.

Metal Industry

The absence of oxygen also helps in reducing the risk of rust on metal tools and gadgets which resultantly indicates its essence in metal Industry.

4.What Type Of Food Can Be Processed By A Gas Flushing Machine?

A gas flushing machine is capable of processing large number of foods with both sensitive and sturdy nature. Few of them are highlighted below:

Snack Foods

Any type of ready to eat meal such as potato chips, popcorn, cookies, pretzels etc are known as snacks and are often taken as a light meal due to its quality of being prepared. A gas flushing machine can better preserve its original taste, crisp and prevent them from stale.

Sea Food

Finding sea food is not an easy job and storing it is another difficult task to perform. Due to high sensitive nature, enzymes present in fish can cause bad smell and taste. In this way, a gas flushing machine is perfectly preserving shelf life of raw fishes and various other sea foods by releasing nitrogen gas.

Meat

Meat is susceptible product and bacterial growth is more likely to affect its nutrient rich and moisturized content. To keep it safe, contamination free and retain its freshness this machine is perfectly suitable with generating carbon monoxide gas.

Dry Fruits

Dry fruits are beneficial for good health due to containing good amount of fibre. They are consumed whole year without waiting for any particular season thus requiring proper packaging with firm sealing to avoid external moisture. Due to this reason, almonds, peanuts, cashews, dates and many other items are packed in gas flushed pouches.

Cereals and Beans

This machine is very crucial for protecting different type of cereals, pulses and beans such as coffee beans, oats, lentils etc.

Liquids

A gas flushing machine does not only process hard or dry eatables but also huge number of liquids including sauces, drinks, milk, ketchup etc.

Vegetables

Fresh cut vegetables require nitrogen gas for packaging that is effectively done by a gas flusher.

Fruits

Fresh fruits quickly get spoil if not consumed in few days. To store them for a longer time they need gas flushing machine so all oxygen inside pack can be exclude and their lifespan can be increased.

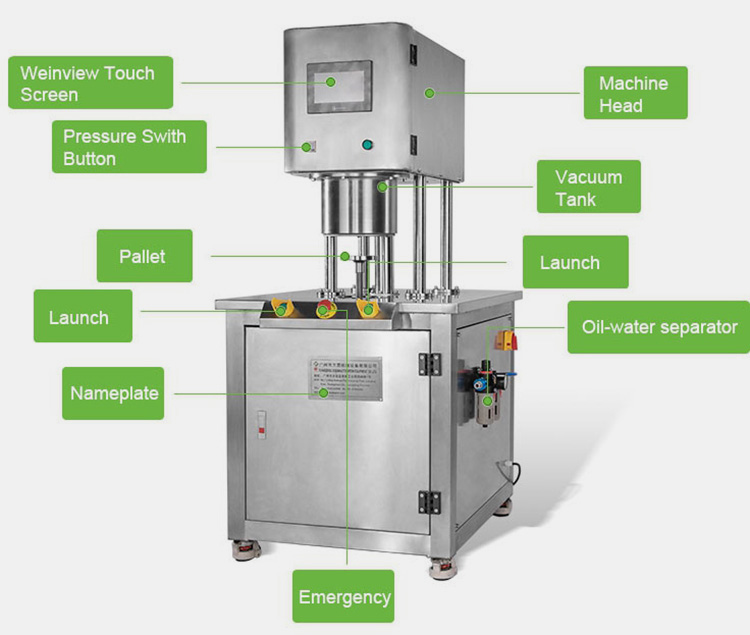

5.Describe The Major Parts Of A Gas Flushing Machine?

A gas flushing machine is the compound of various parts which consist of:

Control Panel

This part of machine is actually touch screen display through which configurations and dimensions of a gas flusher are fixed. It is usually located on the top front of machine.

Emergency Button

Emergency button keeps the processing safe and allow quick break of whole mechanism if any sort of sudden emergency or mishap occurs.

Table

Almost every gas flushing machine has straight, flat table on which the task of packaging is accomplished. One by one bags are kept on it, gas flushed and sealed sequentially.

Film Roller

Another component of a gas flushing machine is the film roller, fixed in specific direction to the goods so the film can be applied in perfect way without leaving any food uncovered.

Sealer

Sealer is located on the upper front of machine. It consists of sealing frame and is required to seal the loaded bags with thick layer.

Gas Pump

The most significant part of a gas flusher is obviously a gas pump comprised of inert gases. It supplies the machine with sufficient amount of gas to complete its modified air packaging. It constantly fills the pouches with gas and extract accordingly.

6.How Does A Gas Flushing Machine Can Be Operated?

The operating procedure of a gas flushing machine is quite easy. The only thing you need to understand is to maintain the level of gases and make sure that sealing is firm. Further process can be analysed by following steps:

Barrier bag is essential for protecting food and especially when using a gas flushing machine. In this way, a loaded vacuum container is placed in a gas flushing machine, where it injects gas into bag and displaces the oxygen inside it.

The infused gas act as a buffer against bacteria and the repeated flushing of gas completely remove oxygen from package. Consequently, a tight thick layer of sealing is applied.

For fragile products which are likely to crush and damage, some amount of gas is leaved in bag. Once the sealing is completed, package is fully enclosed and ready for shipping to stores.

7.What Are The Types Of A Gas Flushing Machine?

There are six types of a gas flushing machine available in market which is described below:

Vertical Flow-Pack

In vertical flow pack machine film is drawn down and single layer of film is applied over the product. After the continuous gas flushing the film is sealed under the center of package. This machine is mostly used for bulk products and diced-food stuff.

Working Principles

In vertical flow pack machine film accurately weighed and drawn down from film roller. A vertical pouch is then formed after single layer of film is dispensed. At this stage products are released from hopper and the continuous gas flushing is going on after which sealing is achieved under the center of package.

Components

This machine is comprised of touch screen control panel, film holder, film collar, ribbon printer, bag former, gas filling device, weighing device, sensor, hopper, vertical sealing, horizontal sealing, film cutter and bag discharger.

Application

This machine is mostly used for bulk products, powders and diced-food stuff like coffee powder, peanuts, sweets, medicines etc. That’s why this machine has been utilized in most of the Industries including bakeries, pharmaceutical industry, fertilizers, pet food, dry fruits and cereals processing industries.

Horizontal Flow-Pack

This type of machine is suitable for processing bakery food, pizza and sausages etc. Products are placed on horizontal flowing tube which forms the wrapping over food. The rolling belts push it forward and during that time flushing gas purge the air and seal bag accurately.

Working Principles

Products are placed on horizontal flowing tube which forms the wrapping over food. The rolling belts push it forward and during that time flushing gas purge the air inside bag after which it is accurately sealed.

Components

This gas flushing equipment is comprised of film reel, film former, film folding, gas flusher, optical sensor, 4th seal, vertical sealing jaws, conveyor belt, scissors, pulling fingers, opener and discharge funnel.

Application

This type of machine is suitable for processing all types of liquid and solid material like baked food, snacks, cheese, sausages etc. Thus it is used in cosmetic, pharmaceutical, agricultural and food processing industries.

Tray Sealer Machine

Tray sealing machine can be operated as fully automatic, semi automatic or manually. It can pack the readymade trays along with flushing gas. It is widely used for prepared meal, salads and sea food etc.

Working Principles

Tray sealing machine can be operated as fully automatic,semi automatic or manually. The process starts with date printing of film which passed under the printing device. Loaded trays are then placed in machine. After detecting the presence of trays machine start gas flushing, apply film over trays, seals them through temperature and cut the film. The product is finally discharged.

Components

The main parts of machine includes film feeding, pneumatic system, gas pump, servo system, film pulling motor, sensor, temperature controller, conveyor control, tray feeding, emergency stop, aluminum holder, control panel, heating plate and cutting blade.

Application

It is widely used for prepared meal, salads and sea food etc to preserve their taste, color and appearance. Due to these factors the tray sealer machine is used in various areas associated with production of fresh meat, herbs, powders, spices, agricultural products, vegetables and fruits etc.

Deep-Drawing Machine

This machine is capable of producing trays during process. It loads the material in trays after forming, extract the air and inject gas consequently, seal the trays by welding. This is perfect for readymade food, fish and meat.

Working Principles

Such type of machine consists of top and bottom film. The layer of film is initially applied inside the tray, heated by machine and turned to desired shape or size. Once the bottom film is formed the material is loaded in trays, air is extracted and gas is ejected. After that, layer or film is dispensed on the upper side of tray and is welded by machine. The trays are ready for discharge.

Components

The major components of machine are PLC control system, sealing system, film reel, top and bottom film applying device, driving motor, gas station, tray holders and film cutters.

Application

Restaurants, food Industries and large markets taking the services of this machine for packaging of fresh vegetables, fruits, ready to eat meals, sea food and meat fast food etc.

Vacuum Chamber Machine

Chamber machine completes the entire processing of bags inside the chamber. When loaded package is placed in it, the machine sucks air and infuses flushing gas repeatedly, after which bag is sealed with using welding. It is best for liquids and is mostly used in small scale industries due to low cost and good performance.

Working Principles

The plastic bags or tray are filled with materials placed inside the machine. Air is then sucked out and gas is infused repeatedly. After this step, machine seals the bag through temperature by sealing strips.

Components

The structure of vacuum chamber is made up of control panel, air suction device, swing arm, main frame, transparent window, gas pump, sealing strips, cellular type radiator, movable wheels and vacuum cover.

Application

It is best for liquids and is mostly used in small scale industries due to low cost and good performance. Restaurants, food industries and dairy industries are employing this machine on greater extent.

Bag in Box Sealing Machine

This machine seals the prefabricated loaded boxes. By using snorkel it eliminates the air from box and fed the box with flushing gas. Its applicability is more in poultry and meat firms.

Working Principles

This machine at a time perform dual tasks. The first one is to process the plastic bag that is place inside the carton. It uses snorkel for eliminates the air from box and feed the box with flushing gas. The bag is then sealed through heat. After the completion of this task machine closes the carton and seal it by applying tape.

Components

This machine has been structured with quality stainless steel. Main parts includes gas pump, control system, sealing device, conveyor belt, sealing tape, snorkel and tape cutter.

Application

Its applicability is more in industries where large packages of meat, poultry or fish is used for example. It can be also used in medical industries, food Industries and cosmetic industries as well so as to preserve their quality by providing safe and hygienic environment.

8.Explain The Common Gases Used By A Gas Flushing Machine?

A gas flushing machine commonly uses nitrogen and other exotic gases for flushing vacuum containers. These gases varies in their nature and functions such as:

Nitrogen

Nitrogen is an inert non reactive gas which is mostly used by a gas flushing machine particularly for eliminating oxygen present inside the vacuum containers. It is best for snack foods and fat containing food as it prevent them from oxidative deterioration.

Carbon Dioxide

Carbon dioxide is an anti microbial agent which restrains aerobic bacteria and molds from growing. The higher level of carbon dioxide can further extend the shelf life of products. Meanwhile, balance should be kept for level of carbon dioxide because its extreme degree can lead to the flavor tainting and drip loss.

Argon

Similar to Nitrogen, argon is also an inert gas. Having been a tasteless and odorless gas, argon is heavier than nitrogen and inhibits the microbial buildup, degrative chemical reactions and enzymic activities.

Carbon Monoxide

Carbon monoxide is a toxic gas which is formed by the incomplete combustion of feul. It is best for maintaining the bloom red color of meat along with retaining its actual tenderness and juiciness. It may be hazardous for inhaling but is safe for packaging purpose thus it keeps the pathogenic bacteria far away from meat and allow it to stay longer.

9.What Factors Are Necessary To Determine The Required Gas Flushing For Foodstuff?

The amount of gases necessary for storing your food is not always be the same. You have to consider some factors for knowing the required amount. For this we have pinned three most important points:

Type of Food

Food that gets spoiled quickly will definitely require more time and amount of gas flushing than that of food with stable shelf life. For instance, vegetables are more likely to influence by the surrounding atmosphere compare to dry cereals.

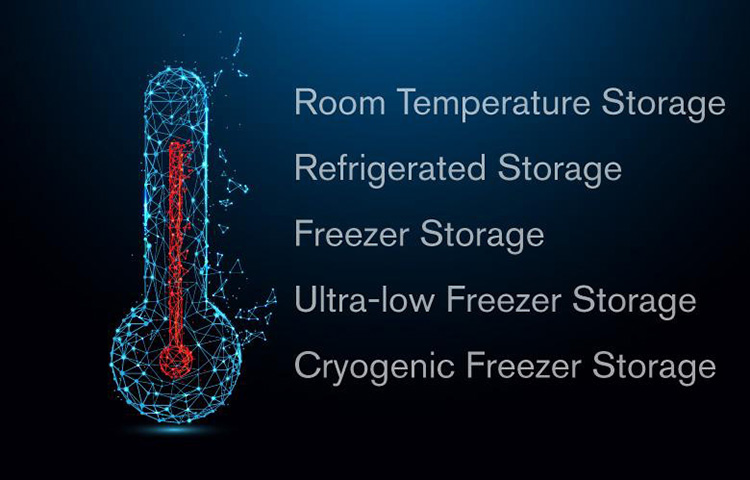

Type of Packaging

Check whether your packaging containers are sturdy or porous. If they are solid and dense few blows of gas flushing are good. While as, weak containers have tendency of gas escaping.

Type of Storage

We are familiar with the fact that packed food can be stored either in refrigerator, freezer or in open shelves. Here it is important to note that a product which is supposed to be stored in room temperature would need more amount of gas for its preservation.

10.Which Is More Suitable Between Gas Flushing And Vacuum Extraction?

| No | Factors | Vacuum Extraction | Gas Flushing |

| 1 | Definition | Vacuum extraction only relies on air removal and suck out the air from container but a small amount of oxygen is still present inside which can grow microbe. | Gas flushing not only excludes the air out but also infiltrates the gases continuously to ensure zero percent of oxygen presence. |

| 2 | Size | Vacuum packaging machine is based on “one size fits all” method. | Gas flushing machine is not confined to any particular size rather it is more versatile |

| 3 | Material | Vacuum packaging is suitable for meat, hard cheese, dry food etc. | Gas flushing is best for processing sensitive to sturdy products like soft cheese, bakery products etc. |

| 4 | Application | Vacuum packaging is better for small scale industries and is inexpensive. | Gas flushing machine is bulky with expensive price although it is best for large scale industries. |

| 5 | Presence of gas | As it extracts the air out from bag, material may collapse or released from bag due to spoilage. | Since, it replaces oxygen with other gases so the beautiful shape of products can be maintained which also prevent food damage. |

| 6 | Example |  |

|

11.How Long Will A Gas Flushing Machine Extend The Shelf Life Of Your Food?

A gas flushing machine can help you in extending the shelf life of your food. It is shown in table below:

| Product | Air Shelf Life | Gas Flushed |

| Meat | Raw: 4-7 days

Cooked: 2-4 days |

Raw: 16-21 days

Cooked: 2-5 weeks |

| Fish | Raw: 3-5 days

Cooked: 7 days |

Raw: 5-14 days

Cooked: 30 days |

| Pizza | 1 week | 3 weeks |

| Ready Meals | 4 days | 21 days |

| Mix Salad | 2-5 days | 6-11 days |

| Bread | 5 days | 20 days |

| Peanuts | 12 weeks | 52 weeks |

| Cheese | Soft: 4-14 days

Hard: 2-3 weeks |

Soft: 1-3 weeks

Hard: 4-10 weeks |

| Pasta | 1 week | 3 weeks |

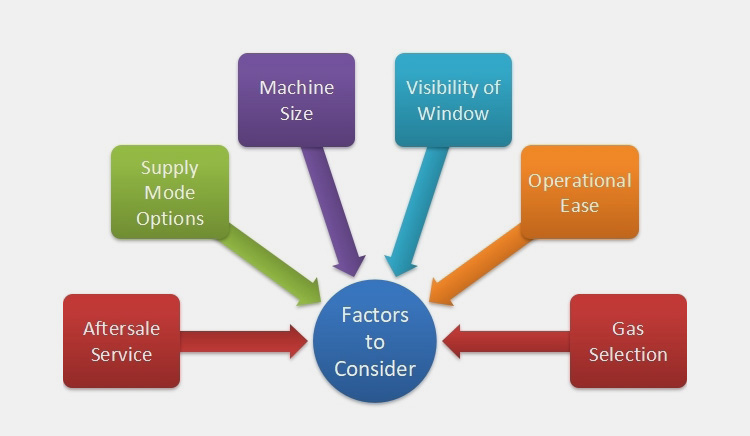

12.What Should Be Considered Before Purchasing A Best Gas Flushing Machine?

Choosing right machinery for your business is somehow challenging task. You have to consider the every possible factor that may affect your production. In this way following points are highlighted for your assistance:

Machine Size

Have you considered the size and volume of machine? This is important to think about because a compact, precise and durable equipment is easy to mobilize also it would occupy less space to adjust.

Visibility of Window

Check for the transparency of window, because a crystal clear window can help you to monitor the whole process. For this a chamber vacuum gas flushing machine is best suitable.

Operational Ease

Never forget to ask about the operation of machine because a machine with complex processing methods can lead you towards further intricacies. You will need the help of any specialized engineer for running machine which would ultimately burden you economically.

Pouch Type

Consult any packaging expert to advise you for accurate pouches that can compliment the size, weight and volume of your items.

Supply Mode Options

Another important factor you need to look for is the gas supply mode options. Check whether it can be customized to the manufacturer’s needs. The option of microbulk, cylinders and tube trailers helps in fast delivery of gas and ensures future growth accomodation.

After Sale Service

Always go for a manufacturer who assures you the quality of machine with full guarantee and after sale service like free training, installation and customer support.

Gas Selection

Lastly, you have to be careful in selecting the type of gas for your products. It will solely depend upon the nature of your goods. An experienced supplier can better assist you in choosing a right blend of gas.

Conclusion

To sum up, the rapid increase of production in almost every manufacturing firm has rise the demand for a gas flushing machine. Allpack is thus supplying most economical, fast and effective gas flushing machines which are lucrative for your business. If you want to learn more please Contact Us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586