Your Best Powder Filling Machine Manufacturer

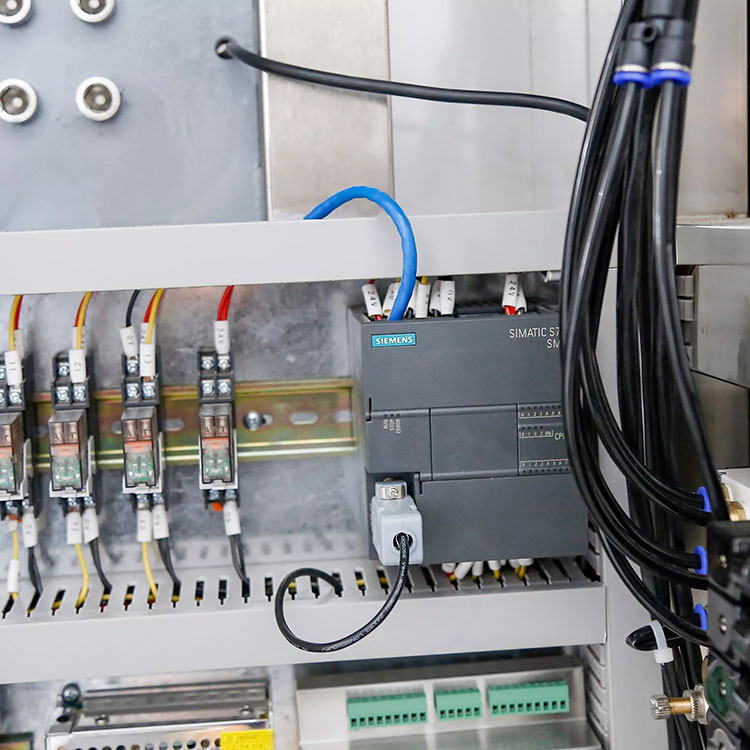

- Signal Transmission and Stability

- High Precision Weighing Sensor

- Micro-computer Control Technology

Powder Filling Machine

Allpack powder filling machine can be also called an auger filling machine, auger fille is designed for different kinds dry powder filling into bottles, like protein powder, pepper powder, other backing powder, coffee powder organic powder, etc. It is also suited for packing powder and small granular materials, such as veterinary medicine, granular additive, white granulated sugar, cotton, sugar, glucose, solid beverage, pharmaceutical solids, carbon powder, talcum powder, pesticides, dyes, flavors, and fragrances. The hopper of the powder filling machine is made of high-quality stainless steel, which is corrosion resistant, easy to operate, and intuitive; filling with a stepper motor drive, the use of a Taiwan maintenance-free motor. All Allpack powder filling machines have stable performance and high packaging accuracy.

Powder Filling Machine

1-10kg Semi Automatic High Accuracy Auger Filler Machine/Net Weight Protein Spice Nutrition Powder Filling Packing Machine

Allpack semi automatic powder filling machine is suitable for filling powder item like bread flour,cake flour, milk powder, dry spice powder etc. Usually it is filling capacity 100g - 5000g.The semi automatic auger filling machine adopts stainless steel design(contact part 304SS which is food grade), meet the health-class standards, mainly for pesticides, veterinary drugs, etc.It has been widely used as packaging machine of pesticides, veterinary drugs, premixes, additives, milk powder, starch, seasonings, enzyme preparations, fodder and other powder-like quantitative packing.

Cost-effective machine

High precision&high speed

PLC control and touch screen display

KFG-1000 Granule Filling Machine

Allpack KFG-1000 granule filling machine adopts micro-computer control technology, high precision weighing sensor, optimal alternating vibrated materials transforming mode and simple operating mode, to solve the old problems of complicated procedures,low speed, imprecise weighing.With the advantages of humanized design, small shape, simple operation mode, high effeciency and energy-saving.This auger filler machine is suitable for the quantitative filling of granular and powders such as grains, beans, coffee, seeds, nuts, dog food, seeds, salt, fertilizer, hardware, etc.

Suitable for a variety of material

Simple operation

One machine multi-purpose

KFG-2000 Granule Filling Machine

Allpack KFG-2000 granule filling machine has been excellent engineers carefully study design, the use of microcomputer control of optical technology, high accuracy, fast, good quality, solve the traditional tea packaging tedious process. An automatic dosers several labor equivalent amount of tea production and tea shop is a good helper.Suitable for tea, food, food, seeds, fruit, grain shape chemicals and pharmaceuticals, micro and small components such as general non-sticky solid materials.

Simple operation&installation

PLC control technology

signal transmission and stability

KFG-250 Granule Filling Machine

Allpack KFG-250 granule filling machine adopts all-stainless steel body, which is truly multi-purpose. Highly intelligent sub-assembly design, more efficient. This machine adheres to international standards and challenges strict inspection. Low energy consumption and environmental protection. The machine adopts interchangeable outlet design, equipped with original large discharge port, medium discharge port and small discharge port. Three different size outlets, easy to replace, the button can be opened, suitable for a variety of bag materials, making your receiving more convenient.

High precision, without prejudice broken material

Running smoothly&low noise

Simple operation&automatic weighing

KFG-3000 Granule Filling Machine

Allpack KFG-3000 granule filling machine is suitable for the granular materials, irregular materials.It adopts pneumatic gate feed or belt feeding and with the advanced non - pole frequency conversion technology.This auger/powder filling machine contains the automatic weighing and packing machine, conveying device, sewing machine, feeding machine. Witha reasonable structure, beautiful appearance, convenient operation, weighing accurate characteristics.

Full stainless steel production technology

Signal transmission and stability

PLC controlling system

KFG-500 Granule Filling Machine

Allpack KFG-500 granule filling machine is mainly suitable for quantitative packaging of granular, granular powder,strip, block, tobacco and other materials. Such as: fertilizer, feed, Chinese medicine decoction pieces, Chinese medicine granules, premix, washing powder, snack food, candy, melon seeds, peanuts, dried fruit, roasted seeds and nuts, salt, monosodium glutamate, chicken essence, seeds, grain, hardware and other granular materials quantitative filling packaging.

High efficiency

Made of stainless steel

Convenient&durbale

High-Precision Double-Head Automatic Screw Feeding Powder Filling Machine

Allpack double-head automatic powder filling machine can do dosing and filling work. Due to the special professional design, so it is suitable to the fluidic or low-fluidity materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agriculture pesticide, dyestuff, and so on. With stainless steel structure; Quick disconnecting or split hopper could be washed easily without tools. Servo motor drive screw.

Suitable for bag or bottle or container

Stable &convenient operation

High weighing precision

Screw Blanking Powder Filling Machine / FLG-1000A

Allpack double side corner automatic labeling machine is able to label the single angle or diagonal position of different size flat carton and square carton (to be connected with cartoning machine)feeding steady and leaving enough space for buffering.The synchronous chain proofreading mechanism of this automatic labeling machine ensures stable and precise proofreading.With screw type adjustment mechanism,the labeling of this automatic labeling machine is precise,the adjustment range is wide.

PLC control system

Easy to operation

Multiple functions

FLG-20A Screw Blanking Powder Filling Machine

Allpack FLG-20A powder filling machine adopts PLC and auger filling mechanism.It is applied to fill powdered materials in the fields of food, daily chemical and medicine etc.The machine adopts high precision servo film transport system, PLC program control, developed touchable human-machine interface of advanced automatic positioning, photoelectric tracking, digital temperature control,etc.It s operation is simple and it is the first choice of food packaging industry to Improve the production efficiency,reduce Labor Intensity, improve the grade of packaging equipment.

High precision&high efficiency

Low noise&saving energy

304 Stainless steel

FLG-5000A Screw Blanking Powder Filling Machine

Allpack FLG-5000A powder filling machine all stainless steel material,with feeding machine can realize automatic level control,it is suitable for all kinds of powders to granules.Adopting with touch screen ,the auger filler machine will be easy for you to set the parameter,and easy operate the machine.The machine can also work long hours with low failure rate,long-last-ingand durable.It can fill the materials like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals,powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.

PLC control and touch screen display

Servo motor drive

Quick disconnecting hopper

FLG-500A Screw Blanking Powder Filling Machine

Allpack FLG-500A powder filling machine adopts speed two speed spiral feeding, pneumatic clamps the hand automatic bag clamping, electronic weighing filling,cCan realize the automatic filling and automatic quantitative and high precision filling. Applicable to all kinds of powder, powder mixed powder material weighing and filling, such as: fertilizer, additives, flour, milk powder, washing powder, solid drink, sugar, monosodium glutamate, compound seasoning , natural seasoning, enzyme preparation, feed and other powder (powder, superfine powder), quantitative filling powder mixed.

Machine material is stainless steel

PLC touch screen interface

PLC works stably &anti-interference

Semi Automatic Auger /Powder Filling Machine With Weighing

Allpack semi automatic powder filling machine is specially and professionally designed to do dosing and filling work,it has mixing and filling function,It is suitable to fill the powders into bottles,cans,and bags. The filling mouth is adjustable according to different containers.It can fill the materials like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals,powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.It is high precision, error≤±1%, with high speed.With digital tube display, the powder filler machine is simple and convenient to operate.

Good for bottle bag filling for powder granule

Easy to operate and save labor

PLC screen control

Single Head Automatic Powder Filling Machine

Allpack single head automatic powder filling machine is is an automatic filling machine for powder and small particles, which can complete the automatic positioning, filling and measuring of bottles. It consists of a filling head, a chain conveyor belt and a positioning device. It adopts servo motor, PLC and Touch screen control, easy operation and high stability. It can be combined with bottle unscrambler, capping machine, labeling machine, etc. to form a complete filling line. It is suitable for packaging powder and small granular materials, such as powder, small granule drugs, veterinary drugs, glucose, condiments, solid beverages, carbon powder, talcum powder, pesticides, etc.

Suitable for all kinds of bottles, cans, bags of quantitative filling packaging container

The filling motor speed can be adjustable

All stainless steel

The Buyer's Guide

Powder Filling Machine: The Complete Buying Guide In 2024

Are you a manufacturer who doesn’t even use a powder filling machine? You need to buy this machine right now. In this blog, you will get to know detailed information about this magical device. Continue reading this article to learn more about what a powder filling machine is, how it operates, what it can be used for, its advantages, and much more.

1.What Is A Powder Filling Machine?

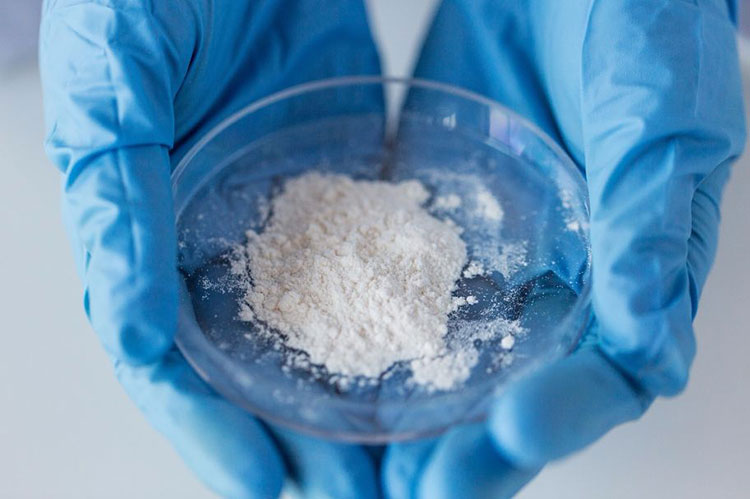

Screw Blanking Powder Filling Machine

The powder filling machine is a device which is used in the filling of products that are in the form of powder such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, condiments, enzyme preparations, feed and other powdery and granular materials.

The powder is a fine component made through the grinding of solid substances. The powder filling machine has a wide range of application for powdered items are made by different industries like in pharmaceutical industries, food industries, chemical industries, and in making cosmetics.

There are various types and different application of powder filling machine. Let’s learn the various types of powder filling machine together!

2.How Many Types Of Powder Filling Machines Are There?

There are many types of powder filling machines. According to different application materials and different filling methods, powder filling machines have different application types

From the perspective of filling process, there are two main types of powder filling machines. Mainly including semi-automatic powder filling machine, fully automatic powder filling machine.

Semi-automatic Powder Filling Machine

Semi-automatic powder filling machine also called as semi-automatic auger filler is a small-scale economical semi-automatic filling machine suitable for dry powder and tiny particles.

Semi-automatic powder filling machine uses electronic weighing and measuring methods, combined with a single-chip microcomputer for powder filling. It is capable of automatic quantification, automatic filling, automatic error correction and material cleaning, etc.

The semi-automatic powder filling machine can fill food additives, condiments, flour, milk powder, protein powder, solid beverages, detergents, enzyme preparations, feed additives, etc.

Fully Automatic Powder Filling Machine

Fully automatic powder filling machine is a highly automated machine that can meet the needs of mass production and production lines.

Fully automatic powder filling machine is an automatic machine that can independently complete the processes of feeding, weighing, measuring, filling, capping, etc., and the entire process can be done without manual participation. It can greatly improve the work efficiency of the production line and is favored by most factories.

Milk Powders

Fully automatic powder filling machine adopts mechanical conveying of materials, normal pressure for filling, measuring cup for quantification, and finally filling valve for filling and capping.

The whole process adopts a fully closed and fully automatic form, which can ensure a sterile environment during the material filling process. Such machines have adjustable filling speeds.

From the perspective of filling materials, there are mainly 3 types of powder filling machines. It mainly includes bulk powder filling machine, capsule powder filling machine, granule filling machine.

Bulk Powder Filling Machine

Bulk powder filling machine also called as bulk powder filler, capable of filling various powders into flexible bulk containers such as bulk bags, bulk big bags, bulk jumbo bags and super sacks, etc.

Bulk powder filling machine also includes semi-automatic and fully automatic models. While the powder is in the filling process, moderate manual handling is required.

Bulk Bags

The feature of the bulk powder filling machine is that it can maximize the volume of the bag to fill the powder material. During the filling process, this machine first fills the bag with gas and expands the bag to the maximum extent, and then fills the material.

During the filling process, the bulk powder filling machine will compact the bag for filling.

Capsule Powder Filling Machine

Capsule powder filling machine also called as capsule powder filler is a kind of equipment used to fill empty capsules with pharmaceutical ingredients powders. Capsule filling machines are applied in large-scale and efficient pharmaceutical production.

Powders and Capsules

Capsule powder filling machine integrates electricity and gas, and can automatically complete operations such as positioning, separation, filling, locking, and counting. Capsule powder filling machine can greatly reduce the manual labor intensity.

Compared with manual operation, the capsule powder filling machine is highly intelligent, and the production efficiency is significantly improved. The device meets all pharmaceutical hygiene requirements and is widely used in many pharmaceutical companies.

Granule Filling Machine

Granule filling machines are usually applied for filling granules and powders like rice, tea, cereals, medical herbs, dry goods, condiments, powders, chemicals, hardware and so on.

Granule filling machines are consist of parts including inlet, cover lock, power supply, control panel, infrared sensor, outlet, and see-through observable panel.

Granules

Granule filling machines are full of intelligent design with simple operation. Automatic micro-computer control system, granule powder filling machine can be operated with scientific weighing and filling process.

From the perspective of filling methods, there are three main types of powder filling machines. Mainly including vacuum powder filling machine, screw powder filling machine, net weight powder filling machine.

Vacuum Powder Filling Machine

Vacuum powder filling machine can minimize product failure and ensure the integrity of the product during the powder filling process. Vacuum powder filling machine can fill powders into cans, glass and plastic containers of any shape or size by vacuum filling powders.

Vacuum Powder Filling

The benefits of vacuum powder filling machines are easy to clean. Machines can be changed over quickly, reducing machine maintenance costs. This machine is equipped with a belt drive system. The machine is designed with a single head for maximum weight control. Vacuum powder filling machines are oil-free designed to use minimal lubricant.

Vacuum powder filling machines also include semi-automatic type and fully automatic type. Head design includes single head, double head, triple head. The machine head also includes extremely high rotational speeds for maximum utilization.

Screw Powder Filling Machine

Screw powder filling machines are the ideal machine for filling powders in the fields of food, daily chemical, medicine, etc. Screw powder filling machines are designed with a PLC-controlled auger filing system. Custom specifications are available to meet specific requirements.

Net Weight Powder Filling Machine

Net weight powder filling machines are mainly applied for filling powders like condiment, cosmetic, coffee powder, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agriculture pesticide, dyestuff, and so on with the operation of dosing and filling.

With all these types of powder filling machines, you may have a lot choice and you can choose the most suitable type for yourself.

3.What Powder Materials Can Be Filled With Powder Filling Machines?

There are a wide range of powders can be filled with powder filling machines. The different powders can be applied with different types of powder filling machines. Here are the details below.

From the perspective of powder volume, there are 3 main types of powder materials that can be filled by the powder filling machines which are particles, fine powders and granules.

Particles

Powder filling machine can be applied for filling particles in a wide range. The powder quality of particles is finer than that of fine powders. Particles are often used for cosmetic purposes.

Because people always ask for a more delicate powder in the process of makeup. In this way, these particles can be used on the face to achieve the thinnest and most delicate effect.

Fine Powders

Powder filling machine can be applied for filling fine powders in a wide range. Fine powders are coarser than particles.

If fine powders are mixed together for a long time, they may agglomerate. Fine powders are more widely used than particles. There are medical uses, industrial uses, chemical uses and even food uses.

Granules

Powder filling machine can be applied for filling granules in a wide range. The powder quality of granules are the largest among particles and fine powders. This material is often made into tablets by a tablet pressing machine for patients to take.

From the perspective of application, there are 3 main types of powder materials that can be filled by the powder filling machines which are food powders, chemical powders, pharmaceutical powders.

Food Powders

Common food powders include milk powder, tea powder, cocoa powder, coffee powder, soybean flour, wheat flour, and chili powder. Powders are particulate discrete solid particles of size ranging from nanometres to millimetres that generally flow freely when shaken or tilted.

Chemical Powders

There are a wide range of chemical powders including titanium dioxide powder, potassium titanate powder, sodium alginate powder, cellulose powder, barium carbonate, potassium cryolite powder, sodium cryolite powder, graphite powder and so on.

Pharmaceutical Powders

A pharmaceutical powder is defined as a dry, solid substance, composed of finely divided drugs with or without excipients and intended for internal or external use. It is a solid substance in finely divided state typically obtained by crushing, grinding.

Those powders are including all the types that can be filled with the powder filling machine.

4.What Are Basic Components And Optional Components For A Powder Filling Machine?

Powder filling machine is a very precise equipment and consists of many parts. Some parts may not be very common in your fill, and some parts you may not need. So let us learn about the basic components and the optional parts.

There are 6 basic components both for the semi-automatic powder filling machine and the fully automatic powder filling machine which are hopper, filling heads, mechanical drive system, sensors, PLC control system, measuring cup, servo motor.

Hopper

The hopper holds bulk quantities of your powder product before they are dispensed into the containers.

Filling Heads

They are applied to fill the bottles.

Mechanical Drive System

They are mainly responsible for the movement of its components. Gear, conveyor, and mechanical motors are included in this system.

Sensors

Sensor monitors how accurately the product is packed. If any mistake occurs, it gives signal to the machine to stop working.

PLC Control System

These control systems are used to configure the settings.

Measuring Cup or Weigher

Few of the filling machines have measuring cups to weigh the product for more accuracy.

Servo Motor

This is the key component for powder filling machine which can drive the auger and can change for different pack weight.

There are 3 optional components for the semi-automatic powder filling machine and the fully automatic powder filling machine which are dust remove device, position belt, capping head,

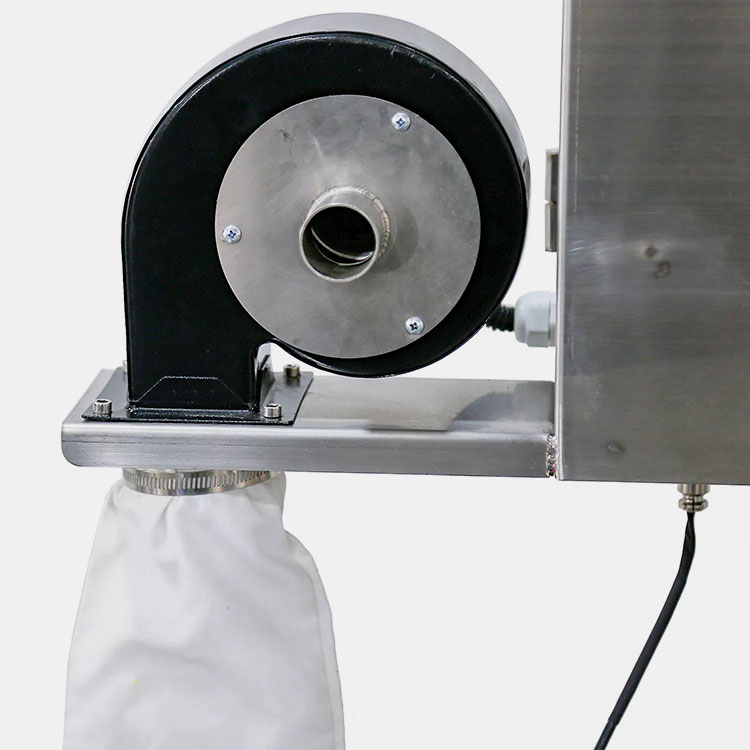

Dust Remove Device

This is specially designed anti-leakage device ensures a cleaner and more hygienic environment.

Position Belt

It can connect with filling machine, make it automatic and faster.

Capping Head

The diameter of capping head is usually in the range of 20-50mm, and this is part can be customized by your needs.

It is obvious that the fully automatic powder filling machines require more parts and need the components maintenance more.

5.What Are The Working Principles Of The Powder Filling Machine?

There are two types of powder filling machine from the working way including the semi-automatic one and the fully automatic one. And the working principles of these two types are different in some ways.

Machine Working Process

Working Principles Of Semi-automatic Powder Filling Machine

Weighing Process

The semi-automatic powder filling machine adopts servo motors for powder, food and non-food products, which can quickly and accurately weigh powder according to your usage in advance. And this machine can adjust the product weight according to the number of turns of the filling screw.

Filling Process

The Semi-automatic powder filling machine uses a mixer system, which can be filled according to the target powder filling volume and powder type classification. This can effectively prevent the powder from being able to completely enter the package without remaining in the hopper.

By placing the filled container and bag under the funnel, the semi-automatic powder filling machine can directly fill the powder into the container through the bellows of the funnel.

Machine Working Process

Semi-automatic powder filling machine adopts spiral heating device, and adopts combined assembly and split structure, which makes the structure of the machine simple and convenient for later cleaning and maintenance of the machine.

The semi-automatic powder filling machine adopts the screw volumetric principle and uses a precisely designed auger to replace the funnel. This machine is equipped with a digital timer to control the required quantity and filling volume of the unit filling.

Working Principles Of Fully Automatic Powder Filling Machine

Powder Processing

The filling process of powder in the fully automatic powder filling machine mainly includes sorting packaging containers, powder ingredients, powder mixing, powder filling, nitrogen filling of packaging containers, sealing or capping, quality inspection and outsourcing.

Weighing Process

The filling metering device adopts screw quantitative, accurate metering, fast filling speed and high efficiency, and different specifications of metering screws can be replaced according to the filling volume.

Filling Process

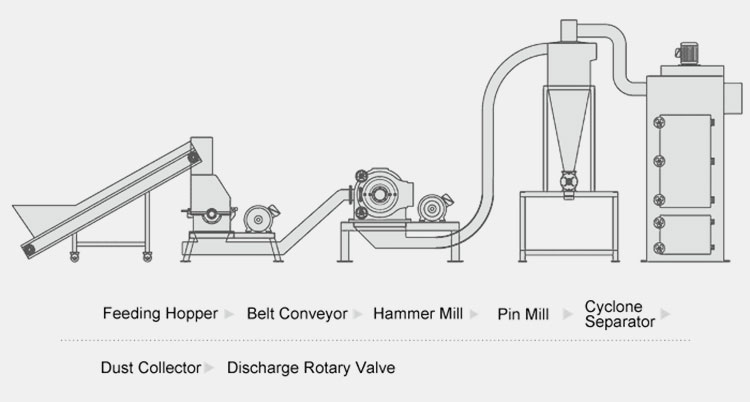

Fully automatic powder filling machine whole working process including machine, electricity, light and instrument in one. This machine can automatically arrange packaging containers, powder conveying, powder filling, powder metering, powder positioning, powder filling, container capping, container screw capping, container labeling, container coding, etc.

Machine Working Process

The working powder filling process of fully automatic powder filling machine includes automatic powder positioning, powder filling, material metering, packaging bag labeling, packaging bag coding.

Machine Weighing and Working Units

Machine Working Units

Fully automatic powder filling machine Other equipment in the complete powder filling line includes feeding machines, weighing machines, conveyors, pneumatic positioning devices, etc.

Optional Accessories

According to the characteristics of the material, a dust removal device can be installed, and a specially designed anti-leakage device ensures a cleaner and more hygienic environment.

After learning the different working principles that you can know that the efficiency of the fully automatic type of powder filling machine is more high, and it need less labor work. If you wanna to apply the powder filling machine in your chain business then the fully automatic types are highly recommended.

6.What Are The Differences From Powder Filling Machine And The Liquid Filling Machine?

The powder filling machines are more ways different from the liquid filling machines. They are main vary from 3 aspects which are the components, filling materials, quantitative methods, and filling ways.

Filling Materials

Powders

The powder filling machine is a machine specially used for filling powders. The powders that can be filled mainly include various food powders such as milk powder, protein powder, seasoning, additive powder, coarse grain powder, flour, etc. Chemical powders, including insecticides, herbicides, etc. Industrial powders such as paint powder, lime powder, cement, talcum powder, etc.

Liquids

The liquid filling machine is a machine specially used for filling liquids. The liquids that can be filled mainly include edible liquids, such as fruit juice, wine, beverage, purified water, nutrition, etc. Medicinal liquids include prescription drugs, chemical liquids, and many other products. Chemical liquids such as inorganic chemical products, organic chemical products, biochemical products and fine chemical products, etc.

Machine Components

Structures of Powder Filling Machines

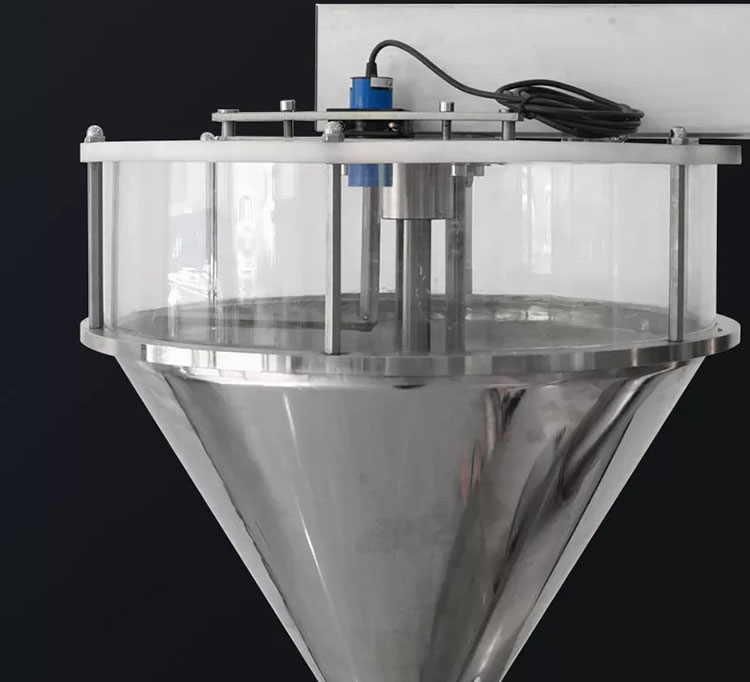

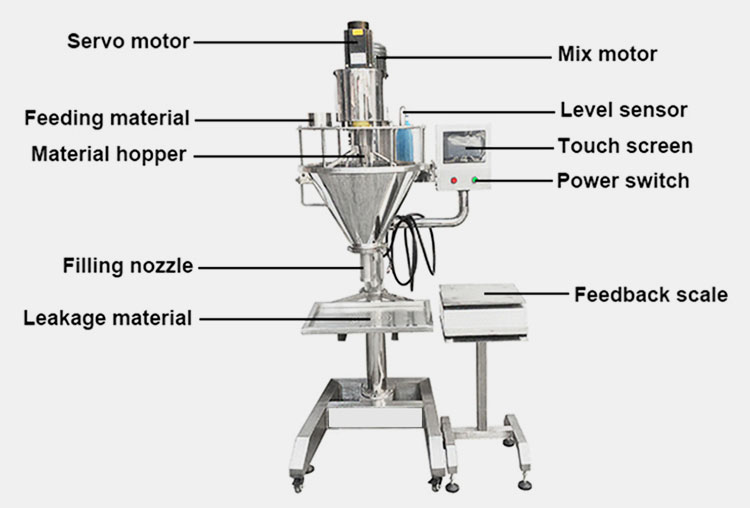

For the semi-automatic type, there are 10 main parts of the powder filling machine including servo motor, feeding material, material hopper, filling nozzle, leakage material, feedback scale, power switch, touch screen, level sensor, mix motor.

Structures of Liquid Filling Machines

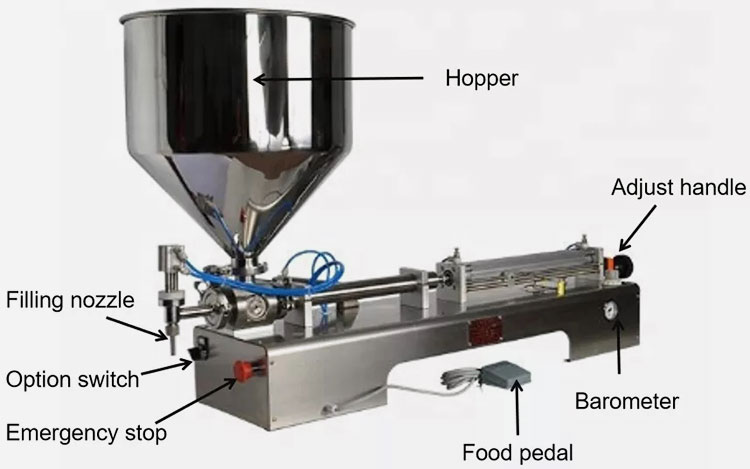

For the semi-automatic type liquid filling machine, there are 7 main parts including hopper, filling nozzle, option switch, emergency stop, food petal, barometer, adjust handle.

There are 2 same parts for each machine which are hopper and nozzle, and the rest are different parts for the powder filling machine and the liquid filling machine.

Quantitative Methods

Quantitative Methods of Powder Filling Machine

The powder filling machine generally adopts the quantitative method of screw and combination scale.

Quantitative Methods of Liquid Filling Machine

Liquid filling machines generally use quantitative methods such as piston, negative pressure, and direct current.

Filling Way

Filling Way of Powder Filling Machine

From the perspective of powder filling structure, powder filling machines generally use screw filling and measuring cup filling; from the perspective of powder filling methods, powder filling machines generally use servo filling, weighing filling, and measuring cup filling Wait.

Filling Way of Liquid Filling Machine

From the perspective of the principle of liquid filling, liquid filling machines can be divided into normal pressure filling, pressure filling, and vacuum filling; from the perspective of liquid filling operation methods, liquid filling machines can be divided into semi-automatic and Fully automatic liquid filling;

After knowing all the details about the powder filling machines, you may understand this machine well now and you can choose the right powder filling machine for yourself.

Conclusions

Powder filling machine is a great invention indeed. It has tremendous uses in different type of industries like food industry, chemical industry, cosmetic industry, agricultural industry and pharmaceutical industry. It has made powder filling so easy, you can fill up any kind of powder product in a very less time with high accuracy. If you are looking for a high quality powder filling machine, ALLPACK is providing the most reliable products in the market. In case of any enquiry you can ask us anytime.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours