Top Double Chamber Vacuum Packaging Machine

- Balanced Tension Spring Structure

- Flat Vacuum Chamber Design

- Water Proof Electric Box

Double Chamber Vacuum Packaging Machine

Allpack double chamber vacuum packaging machine can finish the whole program of vacuum extraction, gas flushing (optional), sealing, cooling, and exhausting automatically. It is reliable and durable, and can offer high flexibility in production. Allpack double chamber vacuum packaging machines can be equipped with semi-automatic or automatic cover movement for even more efficient production. The double chambers of the machine can be equipped with an external pump. This machine is characterized by safe operation, energy saving and short vacuum seal time. It can prevent the products from oxidization, mildew, and moisture. Also, the machine can keep the quality and freshness of packaged products and prolong their storage time of them. It is widely used in food, hardware, pharmaceuticals, chemicals, aquatic products, and electronic components industries, etc.

Double Chamber Vacuum Packaging Machine

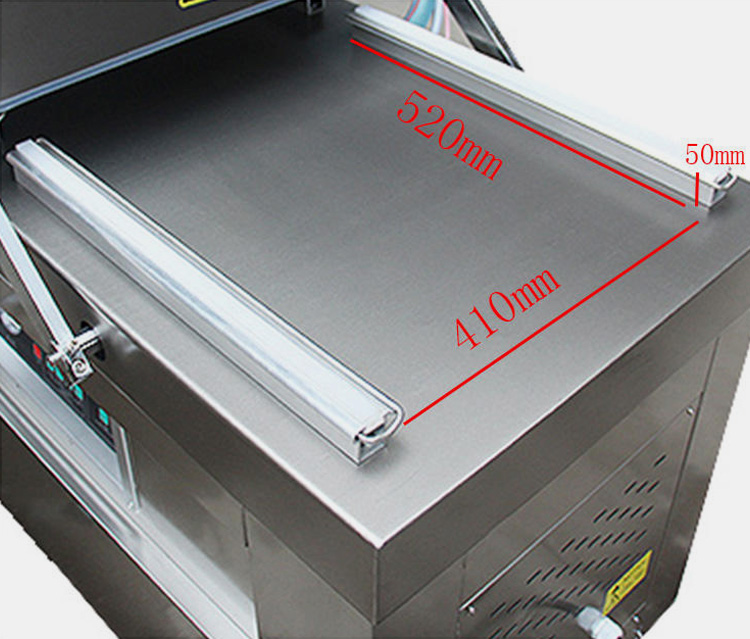

DZK-500/S High Efficient Double Chamber Vacuum Packaging Machine

Allpack DZK-500/S high efficient double chamber vacuum packaging machine has a simple structure, its vacuum chambers are designed inclined so the machine has the ability to pack those products which are easy to pour. This double chamber vacuum packaging machine is equipped with a support board whose height is adjustable. This double chamber vacuum packaging machine is generally used to pack products that require vertical or square packagingdouble-chamber.

Digital Control System

Adjustable Height

Movable Wheels

HVC-410S/2A Large Capacity Double Chamber Vacuum Packaging Machine

Allpack HVC-410S/2A double chamber vacuum packaging machine has two chambers so that it has higher production capacity than single chamber vacuum packaging machine, also, it has higher production efficiency. This double chamber vacuum packaging machine is made of high quality stainless steel, it is equipped with advanced control panel, which let it convenient to operate. It is widely used to pack snacks, fruit, powder, paste, medicines, chemicals, electronic components, metals, etc.

Digital Display Time Relay

Aluminum Heating Plate

Ultimate Vacuum

HVC-410S/2B Large Capacity Double Chamber Vacuum Packaging Machine

Allpack HVC-410S/2B large capacity double chamber vacuum packaging machine is to help people keep their food products fresh, it extracts air inside pouches and then seal them, this is , vacuum packaging. The double chamber vacuum packaging machine is suitable for industrial and commercial applications, it has high volume, high efficiency and high suction, it is an ideal equipment for industries. It can be used to pack various food products such as snacks, meat, fried food, soups, sauces, spices, seafood, dry foo, etc.

Powerful Pumping Ability

High Quality Heating Rod Subassembly

Full Stainless Steel Construction

HVC-510/2SA Strong Power Double Chamber Vacuum Packaging Machine

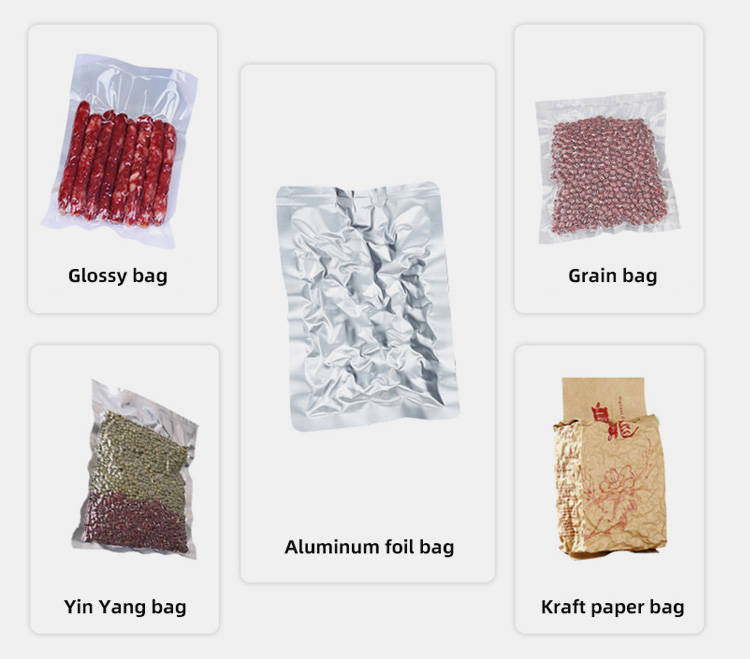

The HVC-510/2SA strong power double chamber vacuum packaging machine of Allpack is widely used in apparel, food, beverage, chemical, hardware, pharmaceutical industries, etc, it is compatible with all kinds of plastic and plastic-aluminum vacuum sealer bags. It is high efficient, durable and reliable, it can work continuously without downtime, this double chamber vacuum packaging machine conforms to the ISO9001 certification, it is very high quality and is popular in industries.

ISO9001 Certification

Four-In-One Vacuum Preservation

Circulating Cooling Holes

HVC-510S/2B High Speed Double Chamber Vacuum Packaging Machine

Allpack HVC-510S/2B high speed double chamber vacuum packaging machine is suitable for many food products such as fruit, meat, vegetables, etc, and it is also suitable for granular medicines, electric components, hardware and so on. The double chamber vacuum packaging machine has long service life and high efficiency, it can help with small scale continuous vacuu packaging operation. It is easy to operate, it has a clear control panel which is easy to understand, the operating process will be smooth and simple.

Moveable Pressure Bar

Mobile Universal Wheel

High Sealing Strength

HVC-610/2SA Efficient Double Chamber Vacuum Packaging Machine

Allpack HVC-610/2SA efficient double chamber vacuum packaging machine is suitable for packing a variety of products such as sauce products, aluminum foil shrinkage packed products, fresh products, rice brick products, oily products, etc. This machine is suitable for industrial and commercial use, it can keep products fresh in the largest degree. The double-chamber vacuum packaging machine is made of 304 stainless steel, it is hard and durable.

Power Pumping Ability

Oil Gas Separation Device

Large Capacity Vacuum Chamber

HVC-610/2SB Large Capacity Double Chamber Vacuum Packaging Machine

Allpack HVC-610/2SB large capacity double chamber vacuum packaging machine is to pack products to prevent them from being oxydic and moldy, it is suitable for different products and vacuum bags. It is easy to operate, when you set up all parameters and close the chamber lid, the machine will complete all the left operations such as air extracting and sealing, which is very convenient. The products which are packaged by this double chamber vacuum packaging machine have beautiful appearances.

Full Stainless Steel Body

Continuous Working

Durable&Strong Air Exhaust

HVC-610/4SC Double Chamber Vacuum Packaging Machine With Roller Wheels

The HVC-610/4SC double chamber vacuum packaging machine with roller wheels of Allpack has a modern and beautiful design, it is made of high grade stainless steel which makes it look high end. This double chamber vacuum packaging machine is widely used in food, beverage, pharmaceutical, chemical, apparel, textile, electronic, metal industries, etc. A feature of this machine is that the depth of its vacuum chambers and the vacuum pump are customizable.

Double-balanced Turnover Device

Relay Control & PCB Control Optional

Excellent Quality Electronic Components

HVC-720/2SA Industrial&Commercial Double Chamber Vacuum Packaging Machine

Allpack HVC-720/2SA industrial&commercial double chamber vacuum packaging machine can be widely used in food, pharmaceutical, chemical, agriculture, electronic, beverage industries, etc. It can automatically complete the working steps such as vacuuming, sealing, cooling and exhausting, it has high performance and high efficiency, can give products beautiful packages. This double chamber vacuum packaging machine is convenient to operate and maintain, is an ideal equipment in packaging industry.

On-screen Key Operation

Oil-water Separation Device

Imported Vacuum Pump

HVC-720/2SB Strong Power Double Chamber Vacuum Packaging Machine

Allpack HVC-720/2SB strong power double chamber vacuum packaging machine is suitable for small to middle scale production, it has high production capacity so that it can meet all kinds of vacuum packaging demands. It is equipped with advanced control panel, therefore, it is easy to operate. The two vacuum chambers of this machine can be used to pack products alternately so that the machine can realize continuous production, which largely increase the production efficiency, this is the reason why it is preferred by many so many industries.

High Quality Electromagnetic Valve

Support Customization

Integrated Forming Stretching Process

HVC-820/2SB Middle Sized Double Chamber Vacuum Packaging Machine

Allpack HVC-820/2SB middle sized double chamber vacuum packaging machine has a wide range of applications such as food, beverage, medical, hardware, electronic, chemical industries, etc. The whole frame of this machine is made of 304 stainless steel, it is hard, can resist attacks, which can enlarge middle-sizedits service life. It is equipped with easy-to-operate control board, circulation cooling holes, bakelite heat seal, which let it has a smooth and stable working process.

Independent Porous Heat Dissipation

Movable Universal Caster

Brushed Stainless Steel Body

The Buyer's Guide

Double Chamber Vacuum Packaging Machine: The Complete Buying Guide In 2025

It is hard sometimes to keep your eatable products fresh because you do not have a proper solution for this task.

Do not worry anymore, double chamber vacuum packaging machine is a strongly manufactured machine especially, designed for vacuum packaging purpose.

You will learn all and every kind of detail about the double chamber vacuum packaging machine in this article including the advantages of vacuum packaging and many more. So, keep reading and keep exploring.

1.What is double chamber vacuum packaging machine?

The double chamber vacuum packaging machine is an efficient chamber vacuum sealing machine that can be custom made according to your business size and production requirements. It can be used to seal a variety of powder, solid and liquid food and non-food products for their safety during the shelf life.

It is referred to as double chamber vacuum packaging machine because it has two chambers, while only one chamber cover can swing from one chamber to another.

2.How can you benefit from double chamber vacuum packaging machine?

A double chamber vacuum packaging machine can help your business in a variety of ways. Some of the benefits that you can get from a double chamber vacuum packaging machine are described below.

Fast Speed of Packaging

A double chamber vacuum packaging machine is a very fast machine when it comes to seal your products. The vacuum pump used in this type of vacuum packaging machine is so efficient that it can easily give you a sealing speed of up to 5 times per cycle. This increases the efficiency which leads to a greater productivity and ultimately a greater profit.

Ensures Quality of Packed Products

A double chamber vacuum packaging machine ensures that the quality of the product that you have packed remains the same throughout its shelf life. In this way, the double chamber vacuum packaging machine can save you from losses that might have occurred due to expiry of products.

Easy Installation

A double chamber vacuum packaging machine is very easy to install. You just need to have a proper space to place your machine. Just plug in your machine and you are good to go. So, you do not have to spend a heavy amount on its installation.

Saves the Space

A double chamber vacuum packaging machine does not require a lot of space to get installed. They are not very big in size and mostly that can fit in place of about one cubic meter.

Easy Maintenance

A double chamber vacuum packaging machine is very easy to maintain. You are just required to take care of the electronics and clean your machine regularly to ensure its smooth working. This saves you from a lot of inconvenience and also saves a lot of money that you would have to spend for maintenance.

Versatility

The double chamber vacuum packaging machine is a very versatile machine as it can be used for packaging different kinds of products in different sizes and shapes of packages. In this way it can help you by doing a lot of work on its own.

3.Applications of double chamber packaging machine?

The double chamber vacuum packaging machine has a wide range of applications in a variety of industries. Some of these applications are described below.

The Food Industry

The double chamber vacuum packaging machine is a very important asset in the food industry. It is used for packaging a variety of products such as fruits, vegetables, pulses, meats, fresh and ready to eat foods etc. Vacuum packaging of food products is very important as it saves the food from any contamination.

The reason behind this lies in the fact that the micro-organisms need oxygen for their growth and there is absolutely no presence of oxygen in the vacuum. So, no oxygen means no microbial growth and so no contamination.

The atmospheric moisture is another factor that causes the food to get soggy. The vacuum sealing is also a solution to this problem. The vacuum seal does not allow any moisture to pass through the seal and in this way, the food remains fresh and free of any contamination during its shelf life.

For these reasons, the double chamber vacuum packaging machine is widely used in the food industry and restaurants.

The Pharmaceutical Industry

The double chamber vacuum packaging machine is also very vastly used in the packaging of the pharmaceutical products that are prone to get damaged from contamination of microbes or the atmospheric moisture. This helps the pharmaceutical product to maintain its safety and efficacy during the intended shelf life.

The Hardware and Mechanical Industry

The double chamber vacuum packaging machine is used for packaging a wide variety of equipment, accessories, spare parts, surgical instruments, and machines etc. The vacuum seal does not allow any moisture into the package and thus saving your products from damage due to rust.

4.What is the difference between double chamber vacuum packaging machine & normal one?

As the name indicates, the main difference between double chamber vacuum packaging machine and normal or single chamber vacuum packaging machine is the number of chambers. The double chamber vacuum packaging machine has two vacuum chambers while single chamber vacuum packaging machine has only one vacuum chamber.

This basic difference in the structures of the two types of the chamber vacuum packaging machine leads to difference in their performance speed and efficiency. Due to presence of two vacuum chambers, the packaging speed of the double chamber vacuum packaging machine is twice the packaging speed of single chamber vacuum packaging machine.

5.What are the different types of double chamber vacuum packaging machine?

A double chamber vacuum packaging machine is a typically designed packaging machine used to seal plastic bags using vacuum and at is mostly used at industrial level coming in two main variants.

Semi-automatic double chamber vacuum packaging machine

A semi-automatic double chamber vacuum packaging machine is a different machine that comes with two packaging chamber and these chambers controlled manually.

Working

The working of semi-automatic double chamber packaging machine is almost same as compared to automatic double chamber packaging machine except at some points the semi-automatic double chamber machine needs some human effort.

For example, when the product enters into the vacuum chamber assembly it is covered with the plastic film after the vacuuming is done on the packet and then a person put the chamber on the product to make the sealing.

Advantages

- Less expensive & heavy-duty machine for industrial usage.

- Easy to operate and require less maintenance.

- You can install it by your own.

Disadvantages

- Not appropriate enough to handle large size business line.

Working Parts

Semi-automatic double chamber vacuum packaging machine consists on different working parts.

Swing Arm

Swingable arms on both sides of the chamber provide the flexibility to chamber lid you can simply move it forward and backward depending upon your machines model.

Handrail

It simply used to hold the chamber lid in order to perform the vacuum sealing on a package you need to move the chamber lid using handrail.

Vacuum Pump

This part is very common in other double chamber vacuum packaging machines as well because it is one of the basic part in your double chamber packaging machine.

Vacuum pump simply perform the vacuum process such as removing oxygen present inside the package and adding nitrogen in it.

Fully Automatic Double Chamber Vacuum packaging machine

A fully automatic double chamber vacuum packaging machine is a mysterious machine which works out of the box for you to pack multiple products in a single line with a complete automation process.

Working

The working of automatic double chamber vacuum packaging machine is simple yet complex the thing is you just set up the pre requisites like give the instructions using a screen that has a display.

When an items comes in for packaging a sensor system measures the size of it and pass it to film packaging chamber where the product get packed inside a plastic bag then a vacuum chamber performs the vacuum operation to remove any air from the bag.

Then, the chamber lid seal the packet as it comes into contact with the chamber machine.

Advantages

- High speed and cost efficient.

- Reliable for large size production unit.

- Fast and quick in terms of packing multiple items in a single cycle.

- Require very less human effort to perform vacuum packaging.

Disadvantages

- A bit expensive you will say and very complex to understand.

Working Parts

Here are fully automatic double chamber vacuum packaging machine parts.

Chamber Lid

You will probably see a top part of the double chamber vacuum packaging machine with some rods holding it called chamber lid.

Very important during packaging and works automatically in this machine.

Control Panel

It is like a display board and instruction input set where user can set its instructions and communicate with the machine by using some buttons or other actions present on control panel.

Silicon Bars

These silicon bars helps your product to stay in the machine and make sure your product do not get in touch with any kind of outer particle that can damage its ingredient quality.

6.What are the main working parts of the double chamber packaging machine?

A double chamber vacuum packaging machine has many different parts that work in perfect coordination to make sure the smooth conduction of sealing operation. Some of the important parts of double chamber vacuum packaging machine are described below.

The Chamber Lid

IT is the lid or covering of the vacuum chamber of the double chamber vacuum packaging machine.

The Handles

The handles are used to hold and move the chamber lid of the double chamber vacuum packaging machine.

The Silicon Strips

The silicon strips of the double chamber vacuum packaging machine are placed on the stainless steel body.

The Connecting Rods

The connecting rods of the double chamber vacuum packaging machine are used for connecting the chamber lid to the body.

The Frame

The frame of the double chamber vacuum packaging machine is entirely made up of stainless steel to avoid rusting and corrosion. This helps to increase the life of your double chamber vacuum packaging machine.

The Emergency Stop Button

The emergency stop button of the double chamber vacuum packaging machine is used for stopping the machine in emergency situation. You can stop the machine immediately at any instant by pressing this button.

The Control Panel

The control panel of the double chamber vacuum packaging machine is the most important part as it is used to control the functioning of the whole machine. The operator can change the settings such as speed of sealing process easily from the control panel.

The Wheels

The wheels are present at the bottom of the double chamber vacuum packaging machine. These are helpful in moving the machine from one place to another. When the machine placed at the right place, the wheels can be locked so that the machine does not move freely.

7.How double chamber vacuum packaging machine works?

First of all, you have to make sure the availability of the plastic bags in which you want to pack your products. The operator is required to manually put your products into the plastic bags in which they are supposed to be packed.

After the plastic bags have been filled by the products, these bags are placed in to the vacuum chamber. The opening sides of the plastic bags are then placed one by one in to the sealing bar. For the purpose of sorting the openings of plastic bags, the metal press bar is flipped.

The vacuum chamber lid is then pressed to start the process of vacuum sealing. The vacuum is then started and the process of sealing takes place according to the standards set by the operator on the control panel. The plastic bags are then placed to another chamber to go through another cycle.

The process of vacuum sealing is completed by this step. The vacuum lid of the double chamber vacuum packaging machine then moves to the other sides’ chamber. After the completion of this step, you can take out the vacuum sealed packs.

In this way, the double chamber vacuum packaging machine vacuum seals your products for prolonged preservation of quality during the shelf life.

8.What type of products you can pack using double chamber vacuum packaging machine?

The double chamber vacuum packaging machine is a very widely used machine for the packaging of many different products. Some of these products are listed below.

The Food Products

The double chamber vacuum packaging machine is used to pack a variety of food products. Foods such as fruits, vegetables, sea food, meat, dairy products, pulses, and spices etc are packed using the double chamber vacuum packaging machine.

A variety of cooked and uncooked foods can be vacuum packed using the double chamber vacuum packaging machine.

The main reason behind the vast usage of double chamber vacuum packaging machine for food packaging is that it does not allow moisture or microbial contamination.

The Pharmaceutical Products

The pharmaceutical products require great care from the atmospheric moisture, microbial growth and contamination to ensure the maintenance of its safety and efficacy during the intended shelf life.

The Laboratory Equipment

The double chamber vacuum packaging machine is used to seal a variety of laboratory equipment to save them from rusting and corrosion due to atmospheric moisture.

The Auto Mobile Parts

The auto mobile parts are also packed by the double chamber vacuum packaging machine so that they stay in a rust resistant environment.

The Surgical Instruments

The surgical and dental instruments are vacuum sealed by the double chamber vacuum packaging machine to keep them safe from any contamination. In this way, the surgical products remain safe for the surgical process.

9.How to choose the right kind of double chamber vacuum packaging machine?

Choosing the right double chamber vacuum packaging machine is very important for benefitting your business in the right way. Following are the few important factors that you must consider while buying the double chamber vacuum packaging machine.

Compatibility

When buying a double chamber vacuum packaging machine, make sure that it is compatible with your business. Always check the details about size, weight, packaging speed etc of different variants of the double chamber vacuum packaging machine and then carefully choose the one that best suits your business requirements.

The Best Quality

Quality should always be the top priority while buying a double chamber vacuum packaging machine. You should go for the best possible quality because if you compromise on quality, the machine may not give you the desired results, leading to financial loss.

Cost Effective

The double chamber vacuum packaging machine you are going to buy must be cost effective. This means that you should try to get maximum features in a reasonable price. Always explore for the best price. In this way, you can save money.

Trusted Seller

Finding a trusted seller is the most important step while buying a double chamber vacuum packaging machine. If you do notb make sure that your seller is trust worthy, you may end up getting scammed.

Easily Repairable

Before buying a double chamber vacuum packaging machine, make sure that the machine you are buying can be repaired easily and the professional technician can be easily found to fix it when required.

10How to troubleshoot double chamber vacuum packaging machine problems?

Double chamber vacuum packaging machine might look simple to you but it is not a simple one when you have to cope with errors and working problems.

No vacuum but the pump is running

This commonly known as vacuum problem happen because of some reasons that are like the chamber lid of the machine is not tighten correctly or the motor working in reverse.

Try to solve these small problems to overcome vacuum problem.

Air not deflating

Sometimes machine did not deflating the air from the packet so the vacuum free packaging will not be done.

This mainly happen because of these two reasons broken air circuit or damaged deflation valve.

Simply try to replace these two parts in order to fix this issue.

No Heating inside

There are multiple things that can cause this kind of problem when there is no heat you will not be able to seal the package.

Most appropriately, this happens when a heater relay is not working appropriately or your heater transformer is broken or clattered with outer particle.

Look forward to fix them to get solution to this specific problem.

11.Is it possible to print date on packages using double chamber packaging machine?

Yes, there is a small unit called batch which is installed in the double chamber vacuum packaging machine that specifically used to put numeric values on packets.

You can simply need to set the combination of different keys in order to set the batch date and other information which is a good practice to tell your customers for how much time period you can store or use this product.

Conclusion

The double chamber vacuum packaging machine is very important for the industries that make products which require safety from atmospheric moisture, contamination and microbial attacks.It helps maintain the freshness and quality of your products during the shelf life. A right double chamber vacuum packaging machine can revolutionize your business so you should consider buying it ALLPACK. Do not hesitate to contact us at any time we are available 24/7.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours