Your Best Granulator Machine Manufacturer

- High-speed Rotating Shear

- Horizontal Barrel(cone) Structure

- Consistent Programmed Technology

Granulator Machine

Allpack granulators are widely applied in trades such as the pharmaceutical trade, chemical trade as well as food trade, etc, more precise description: Mixing of powder and powder, Granulation of powder and bond. This machine has passed the appraisal of province-level new products and the certification of CE. All the granulation machine in Allpack has passed the appraisal of province-level New products and the certification of CE. It can mix uniformly even when the gravity difference between the main material and excipient is very big, without the phenomenon of delamination. It's widely used in food, beverages, fine chemicals, pigments, biopharmaceuticals, and other industries. The granulator consists of a high-speed rotor turning that is within a stationary stator. The granulator can also mix the powders and make then into granulation in them one procedure.

Granulator Machine

FL Series Fluidized High Shear Mixer Granulator

Allpack FL series high shear mixer granulator is suitable for mixing, dispersing, shearing, and homogenizing all kinds of viscous liquid and pastes. Batch Mixer could be applied in Food, Beverage, Chemical, Pharmaceutical, Paint& ink industries, etc. The mixer consists of a centrally located shaft, connected to a flanged type motor mounted on a steel housing. We can customize different types of batch mixer stators to suit different working conditions.

Overload protection, simple maintenance

Free of oil lubrication and leakage

Reliable operation

GHL Series High Speed Mixer/Granulator

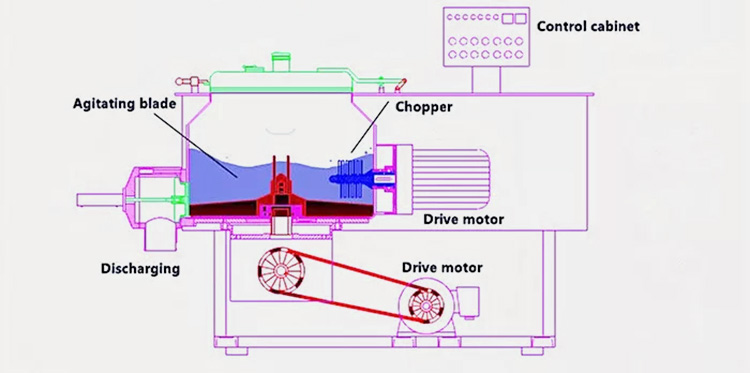

Allpack GHL series high shear mixer granulator is applied in trades such as pharmaceutical trade, chemical trade as well as food trade, etc, more precise description: Mixing of powder and powder, Granulation of powder and bond. This machine has passed the appraisal of province-level New products and the certification of CE. With consistent programmed technology ( man-machine interface if option selected ) , the machine can get assured of stability in quality, as well as easy manual operation for the convenience of technological parameters and flow progress.

Adopt frequency speed adjustment

Easy to operate

Automatic lifting of the pan cover

GK Series Dry Granulator/High Shear Mixer Granulator

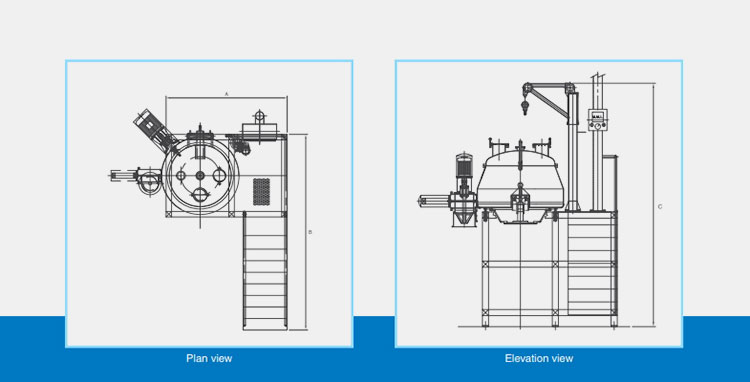

Allpack GHL series high-shear mixer granulator adopts a horizontal Barrel(cone) structure. The inner surface has no dead corners, it works in at sealed state and conforms to the requirement of short granulating time, high efficiency, and energy saving. The final granule is uniform and the fluidization is very good. It provided ideal granule material for the tablet pressing procedure. Compared with traditional processes, it can reduce 25% of binder and shorten drying time too. It can mix uniformly even when the gravity difference between the main material and the excipient is very big, without the phenomenon of delamination.

Adapts a practical horizontal cylinder structure

PLC Controls

Variable speed drive for main impeller & chopper

HLSG Series High Speed Wet Mixing Granulator

Allpack HLSG high shear mixer granulator is suitable for efficient and uniform mixing of solid-liquid, solid-powder, powder-powder, and powder-liquid. Products are widely used in fine chemicals, feed, electronics, food, hard materials, ceramic materials, biology, medicine, non-metallic mining, building materials, coatings, dyes, fertilizers, and metal powders for better mixing. Shear sensitive crystalline powder, batch product mixing, mixing liquid into solid.

Mix evenly&Strong blending ability

Advanced design, reasonable layout

Reliable seal, convenient operation

KZL Series High Speed Granulator

Allpack KZL series high shear mixer granulator is a highly efficient equipment for mixing liquid and solid powder with different viscosity at low speed, dispersing, dissolving, and mixing at high speed. It is pneumatic lifting, easy to operate, flexible to move, low noise, and stable operation. The machine uses high-speed rotating shear wheels and static shear wheels to fully and quickly emulsify, homogenize and disperse the mixture in the tank. It's widely used in food, beverages, biopharmaceuticals, fine chemicals, pigments, and other industries.

Compact&small in size

Light in weight, easy to operate

Low in noise and stable in operation

Model YK-160 Swing High Shear Mixer Granulator

Allpack YK-160 high-shear mixer granulator makes use of the rolling motion of a rotating barrel and granulates the wet powder materials into granules by sieve, it also can be directly used to crush the agglomerate material into small granules. In the chemical medicine field, it can be used to granulate the mixed powder into granules, and compressed granules into tablets after being dried. It also can be used to granulate the coagulated material that was formed during storage or during chemical processing.

Modular & Efficient Design

Fully Automatic Operation through Programmable

Uniform granules, higher output

Model ZL rotating High Shear Mixer Granulator

Allpack ZL high shear mixer granulator is applied in the industry of pharmaceutical, chemical, and foodstuff. It grinds wet powder into granules and crushes powder blocks to grind. When the pressure knife rotates, the powder material is pressurized and sent to the granulation knife. When the granulation knife rotates, the material is extruded out of the mesh by centrifugal force and curve thrust force to complete the granulation task. The output of 300-a two-sided discharging machine is 4 times higher than that of the swing granulator.

Stable operation, low noise

Safety and reliability

Easy operation, convenient maintenance

The Buyer's Guide

High Shear Mixer Granulator: The Complete Buying Guide In 2024

The high shear mixer granulator can also be called high shear mixers, which is a kind of machine can be used for mixing and granulating different powders and granules. The industrial demand of this machine is rapidly increasing due to its amazing features. This article will guide you all the complete knowledge when you are choosing one. Let us learn about this machine together!

1.What Is A High Shear Mixer Granulator?

High Shear Mixer Granulator

High Shear Mixer Granulator

The high shear mixer granulator can also be called high shear mixers, which is a kind of machine can be used for mixing and granulating different powders and granules.

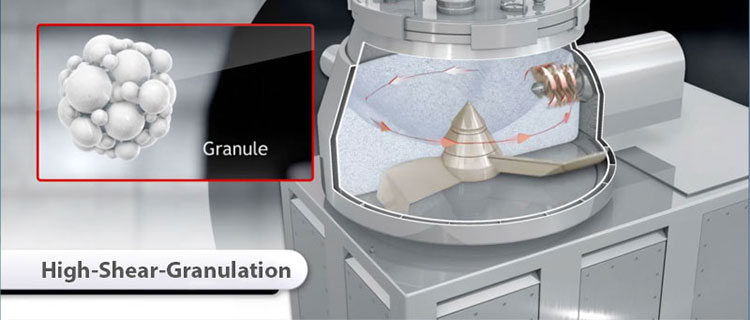

The high shear mixer granulator consists of a high speed rotor turning that is within a stationary stator. The high shear mixer granulator can also mixing the powders and made then into granulation at one procedure.

Powder

Powder and Granular

Powder is a fine element formed by the breakdown of solid substances. It is mixed with the help of binders and is converted into granules of desirable size and shape.

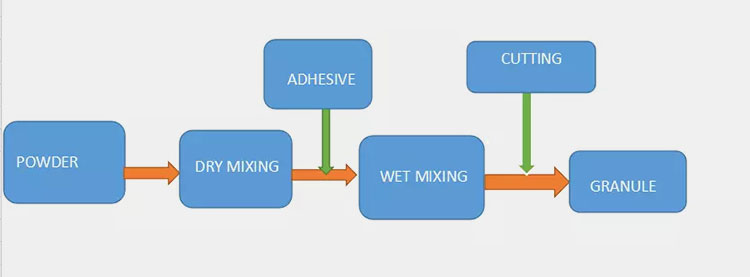

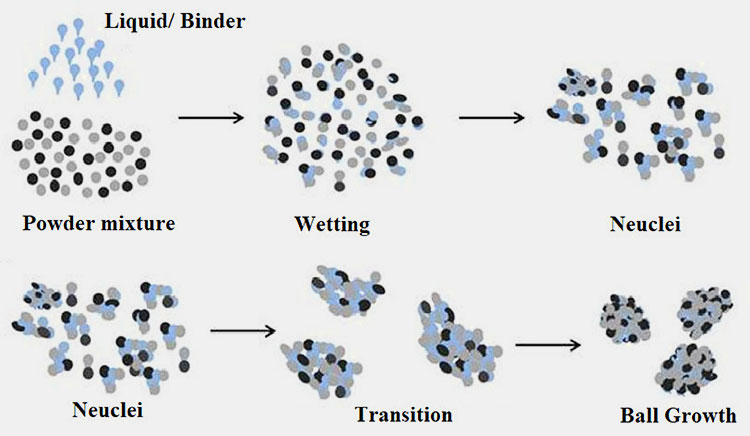

High Shear Mixer Granulator Working Process

The process need spontaneous spinning in such a way the powder is completely mixed. The cutters are then used to cut them into desirable shapes. It can also mix more than two forms of dry powder and is mainly used for pharmaceutical purposes. It is used in making capsules, chocolates, candies, milk powders, coffee powders and other useful items.

2.What Are The Advantages Of High Shear Mixer Granulators?

High shear mixer granulators are important for food, chemical and especially pharmaceutical industries. The application frequency and technology of High shear mixer granulators are also very mature.

Most world-renowned pharmaceutical and packaging companies have invested a lot of cost in the development of high shear mixer granulators such as gea, and syntegon. Because high shear mixer granulator can bring you a lot of convenience and benefits.

Gea Granulation Solutions

Time and Energy Saving

During the process of mixing materials and granulating, you need to add a small amount of binder solution to the high shear mixer granulator. This is more convenient for the speed and efficiency of granulation.

Dust Removal

Granulation Line

The end of the High shear mixer granulator is equipped with dust removal equipment, which can avoid any dust generation, and also avoid the possibility of the staff inhaling the dust.

Complete Granules

High shear mixer granulator can uniformly mix materials and auxiliary materials at high speed, so that the materials can be granulated with uniform size. The particles produced by this equipment have uniform size, higher density and are not fragile, which is very practical.

If you considering to purchase high shear mixer granulators to help your business or big your company, then you can totally know how to choose one after learning all the advantages of the high shear mixer granulators. If there are more types of high shear mixer granulators you want know or other devices to accompany the high shear mixer granulators, you can consult us anytime.

3.What Are The Applications Of High Shear Mixer Granulators?

High shear mixer granulators are widely used in the industry. Probably most of your exposure is in the pharmaceutical industry. However, high shear mixer granulators are also widely used in food industry, agriculture industry and chemical industry.

High shear mixer granulator has various applications in following industries:

- Pharmaceutical industry

- Food industry

- Agricultural industry

- Chemical industry

Pharmaceutical Industry

Pharmaceutical Industry

High shear mixer granulator are can be applied for mixing the drug powders and made into tablets and capsules. This results in good homogenization, bioavailabity, compressibility, and stability of products.

Food Industry

High shear mixer granulator can be applied for manufacturing a variety of products like chocolates, candies, jams, and others needs wet granulation for making. High shear mixer granulator has great importance in making processed foods like milk powders, chocolates, food tablets and capsules, etc.

Agricultural Industry

High shear mixer granulators can be applied for the agricultural industry for mixing the agricultural fertilizers like organic fertilizers, mineral fertilizers, etc. Granules are formed in a variety of shapes and sizes.

Chemical Industry

High shear mixer granulators can also be applied for chemical industry for mixing the mineral powder, water treatment, titanium dioxide, silica sand, etc.

In addition to these industries, there are other industries that are also using such machines. Including but not limited to tobacco processing industry, petrochemical industry, electronics manufacturing industry, etc.

4.How Many Types Of High Shear Mixer Granulator Are Availble In The Market?

Appearance Design

There are two types of high shear mixer granulator including horizontal type high shear mixer granulator and vertical type high shear mixer granulator and can be either continuously operated or batch operated.

Horizontal High Shear Mixer Granulator

The horizontal design can ensure that workers can monitor the production process of materials in real time. Horizontal high shear mixer granulators are suitable for small factories or small units of production.

Vertical High Shear Mixer Granulator

The vertical design can ensure that the machine can process a large amount of materials at one time. Vertical high shear mixer granulator is suitable for fully automatic machine operation and large-scale material handling in large factories.

Working Way

From the aspects of machine working way, there are two types of high shear mixer granulator including batch high shear mixer granulator, and lab high shear mixer granulator.

Batch High Shear Mixer Granulator

Batch high shear mixer granulator can mix different powders, liquids and granules in the high efficiency. Batch high shear mixer granulators are widely used for pharmaceutical industry, food industry and chemical industry, etc.

Batch high shear mixer granulators are is also widely used for mixing and producing wet granulation. By adding fine powder mixture to the binder step by step, that you can get uniform granules in a short time.

Lab High Shear Mixer Granulator

Lab high shear mixer granulator is an important process equipment for production of solid preparation in pharmaceutical industry, mix the raw materials, or the production of soft material.

Powder Materials

There are two types of high shear mixer granulator including food high shear mixer granulator, pharmaceutical high shear mixer granulator and chemical high shear mixer granulator.

Food High Shear Mixer Granulator

Food high shear mixer granulator is a special equipment for wet mixing and granulation of powder, starch, and adhesive in the production in food industry. It is also suitable for mixing powders and granules in chemical industries.

Pharmaceutical High Shear Mixer Granulator

Pharmaceutical high shear mixer granulator is widely used in such industries as drug, food, dairy products, chemical industry, etc. It is a process machine widely applied during production, for example, the production of tablets, capsules, granules, and other wet granules. It has many functions such as mixing, granulating, etc.

Pharmaceutical Powder and Granules

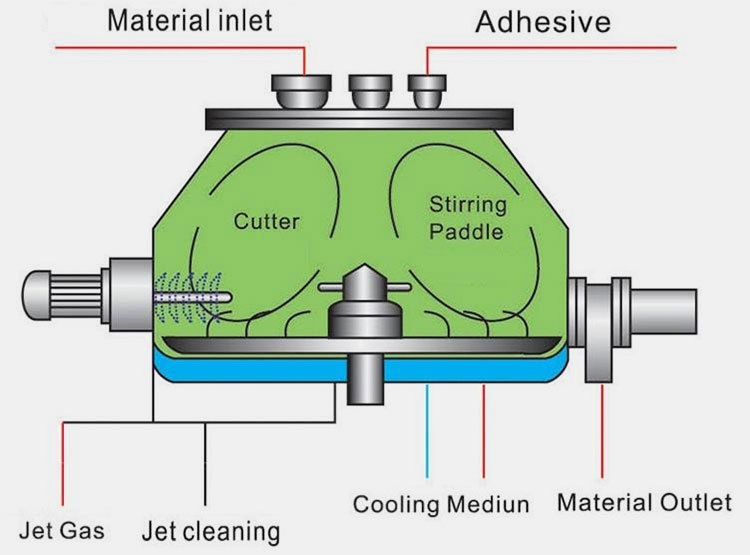

The materials are fed into the granulating pot through the vacuum feeder or lifting feeder. After the action of centrifugal force of mixing paddle, the pressure liquid supply system injects the adhesive through the spray gun. Meanwhile, the cutter rotates at a high speed. The materials are bonded into hollow granules in the pot and discharged to the next procedure (granule sizing or drying) after the granulating is finished.

Chemical High Shear Mixer Granulator

Chemical high shear mixer granulator is mainly applied for chemical industrial mixing chemical powders with liquid spray, powder with granule etc.

There are many types of High shear mixer granulators. Depending on the accessories used, high shear mixer granulators can also be classified into other types. If you are interested, you can search online or browse our website. We will serve you wholeheartedly.

After learning all these types of high shear mixer granulators, which type of high shear mixer granulator you think is the most suitable for you?

5.What Are The Key Features Of High Shear Mixer Granulators?

High shear mixer granulator is a complicated machine with multi-functions. There are various key features of the high shear mixer granulators. And you will learn the key features of the high shear mixer granulator from two aspects of horizontal shear mixer granulators and vertical shear mixer granulators. And they are all about machine design, machine work, and machine operation.

Features of Horizontal High Shear Mixer Granulator

Machine Design

This type applies horizontal structure that is easy for you to operate. All internal and external surfaces are made of stainless steel, which is very easy to clean and maintain. There is no dead angle of the inner surface, which is very convenient for the machine to work in a sealed state.

Machine Work

Horizontal high shear mixer granulator can evenly provide mixing for particles, and has strong fluidity and high mixing efficiency. It can efficiently mix different auxiliary materials without delamination between auxiliary materials. The speed of granulation is fast, which is about 5 times that of ordinary traditional machines.

Machine Operation

Horizontal high shear mixer granulator is user-friendly and easy to operate. And the manufacturer provides corresponding strict operation guidelines, which can solve your operation problems to the greatest extent.

Features of Vertical High Shear Mixer Granulator

Machine Design

Vertical high shear mixer granulator is modular design, different working parts are divided into different modules. This sub-module mode can best meet your process and production conditions.

The entire equipment of the vertical high shear mixer granulator adopts an airtight composite structure, which can avoid any material leakage and cross-infection. And it can meet your requirements for working in a fully enclosed and clean environment.

Machine Work

Vertical high shear mixer granulator adopts circular cone material mixing container structure and Z-shaped impeller, which can mix and granulate to the greatest extent.

Vertical high shear mixer granulator adopts vacuum feeding design to avoid dust and cross-contamination caused by manpower. This can meet your clean production requirements.

Machine Operation

The Vertical high shear mixer granulator is set up with a pressure spray that will give you the perfect wet granules.

Vertical high shear mixer granulator is equipped with granulation endpoint detection function, which can automatically detect your granulation quality and granulation quantity.

All theses key features will help you how to operate the high shear mixer granulators after when you are using them. And there may be some special types of high shear mixer granulators that we may not mention in this article, but we are please that if you come to us.

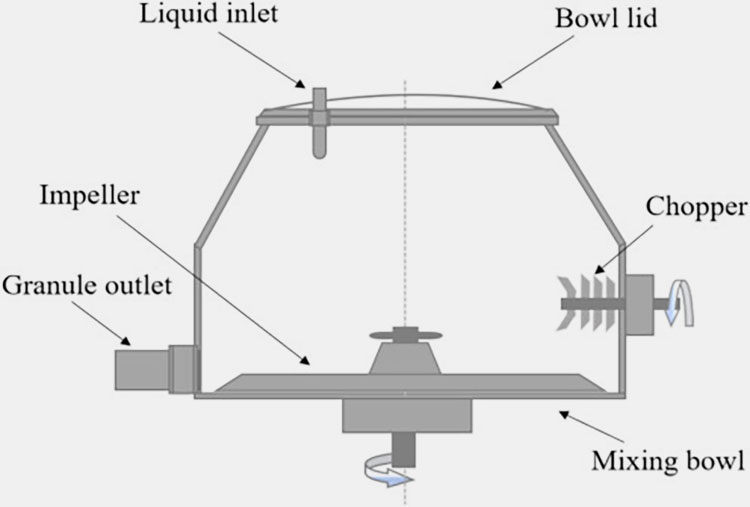

6.What Are The Main Parts Of High Shear Mixer Granulators?

Different types of high shear mixer granulators have different key parts. So here we will introduce the common main parts of every high shear mixer granulators and the optional main parts for some special types of high shear mixer granulators

Main Parts Of the High Shear Mixer Granulator

There are 7 main parts of the high shear mixer granulator including inlet, mixing impeller, cylindrical mixing bowl, discharge port, spray nozzle and vacuum pump, and control system.

Inlet

Inlet is applied for feeding the powder materials.

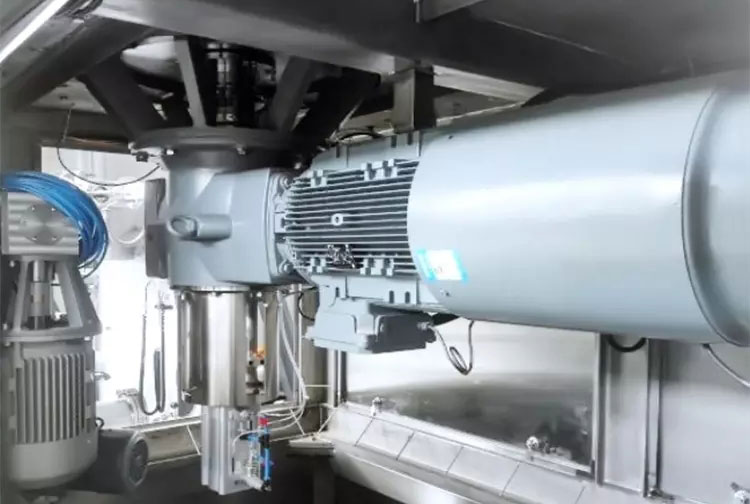

Mixing Impeller

The mixer impeller is the main part for mixing the material powders and granules. The mixer impeller are the key part of the high shear mixer granulators that consumes the main power.

- There are two types of mixing impeller including:

- Axial Flow: Responsible for up and down flow

- Radial Flow: Responsible for side by side flow.

Cylindrical Mixing Bowl

Cylindrical mixing bowl consists of a container that is in cylindrical shape. Cylindrical mixing bowl is the main part for every high shear mixer granulators to mix the powder materials.

Discharge Port

Discharge port is responsible for the work after the mixing. The product is then transferred into the discharge port that is present at the lower side of a dome.

Spray Nozzle

Spray nozzle helps to spray liquids which act as binders for the binding of powders after the mixing is done, binders need to be added.

Vacuum Pump

Vacuum pump is responsible for operating the entire machine

Control System

Control system actually monitors all the process, contains a control panel with a display and touch screen.

These are all the main parts for all types of the high shear mixer granulator, and all these parts are made from stainless which are not easy to break.

7.What Are The Working Principles Of High Shear Mixer Granulators?

There are 6 steps of the high shear mixer granulators working including granules mixing, shear granulation, granules stirring, crystallization, granules unloading, wet granules step by step.

Each of these steps will be accurately controlled by the high shear mixer granulators. The entire production process does not even require human manipulation.

Powder Processing

Granules Mixing

Granules Mixing

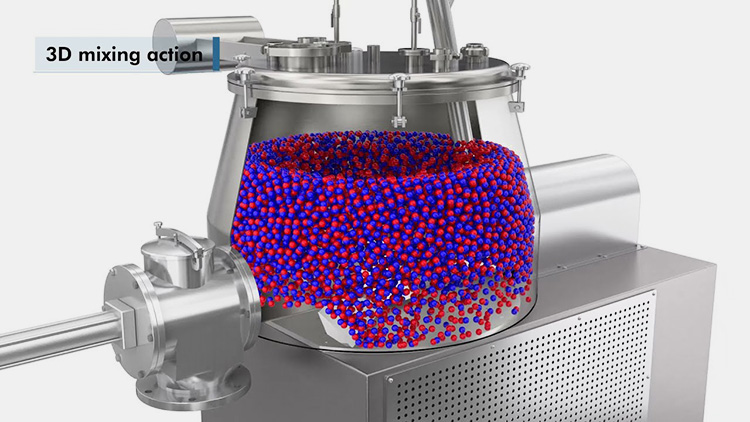

The mixing granulator also has good adaptability to the mixing of coarse materials, fine materials and ultrafine particles, and the disparity between materials will not cause stratification.

Shear Granulation

The high-speed granulation tool and fixed scraper of the mixing granulator perform a series of impact shearing, convection, stirring, mixing, and granulation on the material to realize mechanized adjustment and speed change, and the particle size can be adjusted.

Granules Stirring

The three-dimensional movement effect of the mixer granulator makes the materials continuously shear obliquely and radially, and the shearing surface is constantly moved during work, so that all materials can be stirred efficiently.

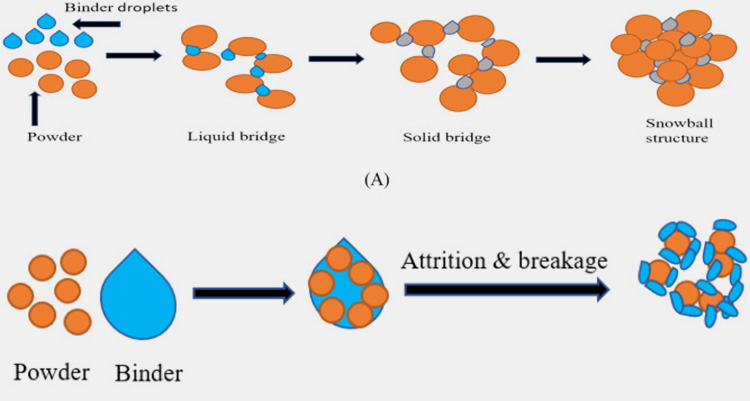

Crystallization

After the powder is added, it is equally mixed. Binders are then sprayed, they basically binds the powder particles together so that the granulation can take place. Powder become wet and crystallization start begin. It is then densified and attrition and breakage of granules occurs.

Granules Unloading

Mixing and granulating machine The tilting mixing and granulating machine meets the quality requirements of various materials, and the quality of the produced fine particles is complete, and the unloading speed of the materials is accelerated after mixing and granulating.

Wet Granules

Since the material through a vacuum (such as the choice of the feeding mode), or other ways to feed into the bin, in the impeller under the action of mechanical force flow, forming trajectory, are mixed evenly in a silo, injecting adhesive, pelletizing knife open.

Material formed by adhesive bonding bridge formation in masterbatch, mechanical energy conversion function, gradually grew up to meet the requirements of the wet particle.

The mixing and granulation of the powder is done so smoothly by using this machine. emulsification, homogenization, dispersion, and disintegration can also be performed by this device.

8.What Are The Differences Between High Shear Mixer Granulators And Low Shear Mixer Granulators?

High shear mixer granulators and low shear mixer granulators are the same type of machine but use different ways of shearing the material. The difference in this method is mainly reflected in three aspects: mixer impellers, powder materials, and power supply.

Mixer Impellers

High shear mixer granulators use high-strength mixing high-speed impellers, which can efficiently and quickly mix various materials.

Low shear mixer granulators use low-strength mixing low-speed impellers, which use flow and low rotational force to mix materials that are easier to mix. Low shear mixer granulators are more suitable for materials that can quickly dissolve each other.

Powder Materials

High shear mixer granulators are able to mix different materials containing liquid and solid components by using high shear mixing technology. High shear mixer granulators are equipped with mixing blades and impellers so that liquid and suspended particles can be mixed evenly. And the speed of mixing blade and impeller can be adjusted.

Low shear mixer granulators can mix mutually soluble materials by using low shear mixing devices. Low shear mixer granulators are equipped with hydrofoil impellers, axial flow turbines and radial flow turbines to mix easily fused materials.

Power Supply

High shear mixer granulators use a dispersed form to shear materials at high speed. The material becomes fluid in the process of being continuously sheared, broken and dissolved by high-speed dispersion. These fluids will be continuously circulated in the horizontal layer of the melting vessel. So this process requires more power and horsepower.

Low shear mixer granulators employ low speed drives, marine propellers and axial turbine impellers to shear, break and dissolve low density, more soluble and sticky materials. This process of shearing and processing materials is kept at a low speed, so the power and horsepower required for this process is lower than that of high shear mixer granulators.

All in all, the high shear mixer granulators are suitable for big business and large chain work and the low shear mixer granulators are suitable for you own use or small business.

Conclusions

High shear mixer granulator has amazing feature and it is a must have equipment in industrial sectors. It has been widely used by pharmaceutical industry in making capsules and tablets. If you are looking for a high quality high shear mixer granulator, ALLPACK is providing advanced machinery. If you have any inquiries contact us anytime.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours