High End Semi-automatic Strapping Machine

- Integrated Circuit Board

- Heavy-duty Casters

- Energy Saving

Semi Automatic Strapping Machine

Allpack semi automatic strapping machine is capable of allotting, tightening and fastening polypropylene straps around the packages, automatically.The function is to make the plastic strapping tape can be tied close to the surface of the package, ensure that packages in transport, storage is not due to binding is not strong and scattered, while also bundling tidy.Its heater assists in applying pressure on the strap and connects the ends with heat welds. Semi automatic strapping machine power switch have inbuilt sensors that makes the motor to switch off while not working and again restarts automatically with the insertion of strap. It is widely used in food, beverage, pharmaceutical, construction, wooden industries, etc.The machine can automatically conduct strap collecting, thermal sealing, cutting and with full automatic stopping operation.

Semi Automatic Strapping Machine

KZB-I Table Type Semi Automatic Strapping Machine

The KZB-I table type semi automatic strapping machine is used to tighten and fasten straps on cartons, boxes, books, woods, construction materials, etc. The machine can fasten the and cut off straps automatically but it need a operator to place products and put straps on them. This semi automatic strapping machine is equipped with easy-to-operate control panel which can turn on&off the machine and set up temperature and other parameters, it has high strapping speed and adjustable strapping force, which make it user friendly.

Temperature Adjustment

Stable&Durable

Small Volume To Save Space

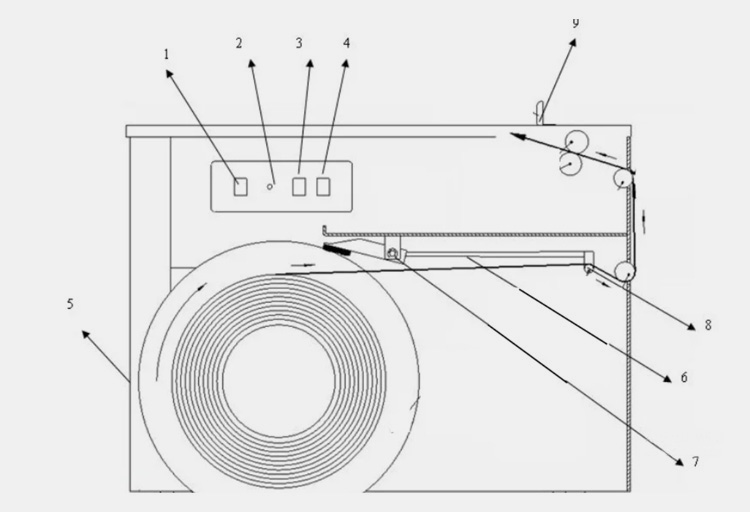

KZB-Il Versatile Semi Automatic Strapping Machine

Allpack KZB-Il versatile semi automatic strapping machine is widely used in food&beverage industries, pharmaceutical industry, chemical industry, construction industry, ceramic industry, etc. It can strap products quickly and accurately, it is user friendly and cost saving, it is ideal for strapping large and heavy products. The semi automatic strapping machine can dispatch, tighten and cut the straps automatically ,which largely increase production speed.

Dual Motor Operation

High Quality Clutch

Controlled Heating&Cooling Time

KZB-T Table Type Semi Automatic Strapping Machine

Allpack KZB-T table type semi automatic strapping machine is designed compact, it can be used in small workshop, it is suitable for strapping small products such as money, books, gifts, office supplies, etc. This semi automatic strapping machine can heat instantly and strap precisely, it is easy to operate and it has stable performance, even though this machine is driven by a single motor, its speed is fast, it can improve the production efficiency for industries.

Power Saving Function

Broad Scope Of Application

Simple&Neat Appearance

SK-1 Energy Saving Semi Automatic Strapping Machine

The SK-1 energy saving semi automatic strapping machine of Allpack is versatile, it has a wide range of application such as food, medical, beverage, chemical, stationery, apparel, textile, printing industries. It is suitable for strapping cartons, calcium-plastic cases, books, soft and hard packages, etc, it can also strap irregular shaped products. The semi automatic strapping machine can dispatch, tighten and cut straps automatically, which largely save time for industrial production.

Integrated Circuit Board Control System

Precise Bonding & High Availability

Auto Motor Shut Off Function

SK-2 Energy Saving Semi Automatic Strapping Machine

Allpack SK-2 energy saving semi automatic strapping machine is suitable for heavy and duty products, it is equipped with simple control panel which makes it easy to use. This machine has low power consumption, and it has a unique function that it can auto shut off the working process at once when the machine is paused , thus it is energy saving. This semi automatic strapping machine is an ideal equipment for food&beverage industries, commodity industry, chemical industry, pharmaceutical industry and so on.

Temperature Adjustment

Wide Application

Stable &Durable

The Buyer's Guide

Semi-Automatic Strapping Machine: The Complete Buying Guide In 2025

Strapping machines are used to strap products which provides them protection and security. Manufacturers and industries are now focused in buying these strapping machines to provide security to products while travelling globally.

Like other strapping machines, semi-automatic strapping machine is highly recommended by manufacturers for medium and large volume packaging setups. This buying guide will assist you regarding the features, applications and advantages of semi-automatic strapping machine.

Take most if it!!

1.What Is A Semi-Automatic Strapping Machine?

Semi-automatic strapping machines are used for wrapping of materials or pallets in plastic film. It prevents the product from being damaged during any transportation. The product is packed in such high tensile material that it remains secured even if it falls or observes any collision.

A semi-automatic strapping machine uses both manual and automatic operations. An operator inserts the product into the machine and initiates the process. The operator is also involved in wrapping the free end of strap onto the product. Afterwards, the machine automatically tightens the straps according to the given conditions. These are usually preferred in industries where the desired output rate lies between 1 to 3 straps / second.

2.In Which Industries Semi-Automatic Strapping Machines Are Widely Used?

Some of the industries which uses semi-automatic strapping machines are

Paper Industry

Newspaper, printed pages, packaging, merchandiser and papers are strapped in small or medium scale industries. This industry uses semi-automatic strapping machine to tightly pack these packages to ensure safe travelling.

Food Industry

Food products are strapped using a semi-automatic strapping machine. This tightly bounds them and cannot be easily separated. Food products are then placed in cartons and boxes and occupy less space when packed by a semi-automatic strapping machine. This type of strapping also keeps them safe from environmental influences.

Metal Industry

Somehow metal industry also uses semi-automatic strapping machine to packed steel and metal products. Closely packed strapping allows safe travelling of metal products globally.

Lumber Industry

Likewise paper industries, wood industry are also the biggest consumer of semi-automatic strapping machine. Wood products are often strapped by manual or semi-automatic strapping machines which provide strong bonding to them.

3.What Are The Working Principle Of Semi-Automatic Strapping Machine?

The working principle of a semi-automatic strapping machine is not much complex to understand. It follows following steps.

- All the strapping parameters are closely monitored initially before performing the operation.

- Secondly, the operator manually feeds the product into the strapping machine.

- Sensors present on the machines table detect the presence of product. If the product identification is successfully completed, the guide feeds the strapping material by a pulley system and the arms rotate straps around the product.

- The rotation can be done both manually and automatically and allows the operator to stop the system where required.

- The strapping is properly done on the product and then it is carried out from the system.

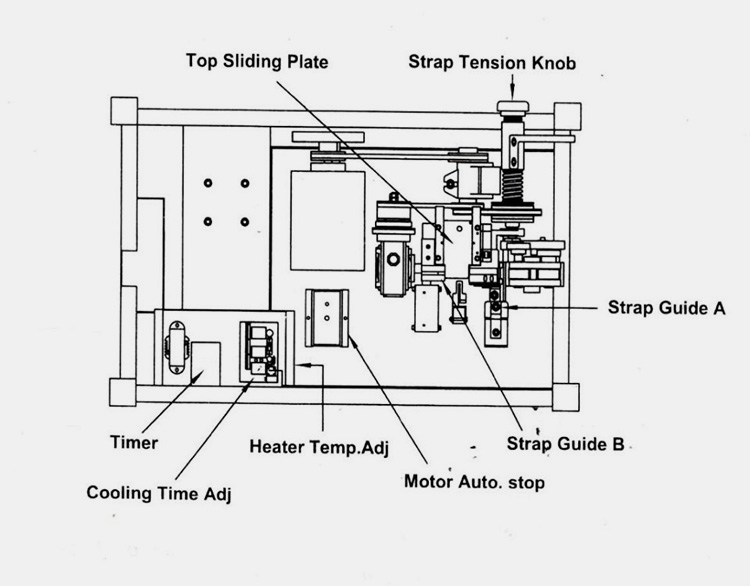

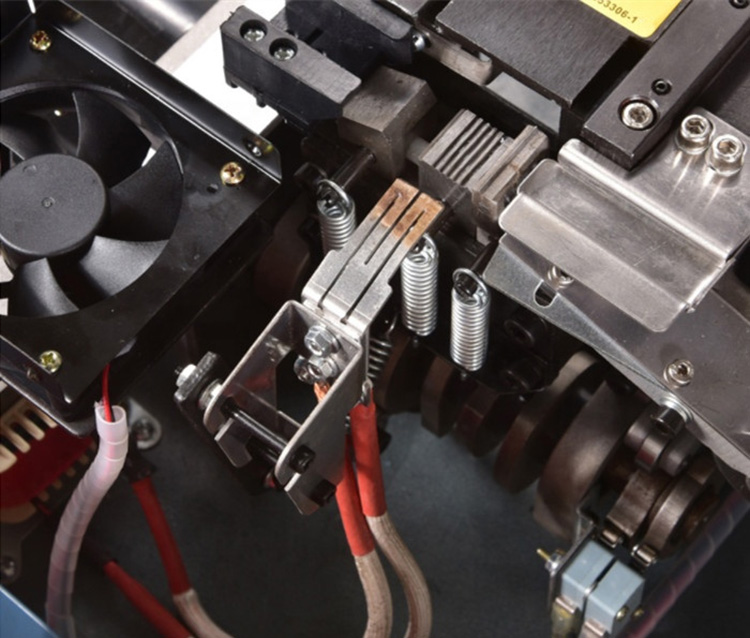

4.What Are The Components Of A Semi-Automatic Strapping Machine?

The main components of a semi-automatic strapping machines are

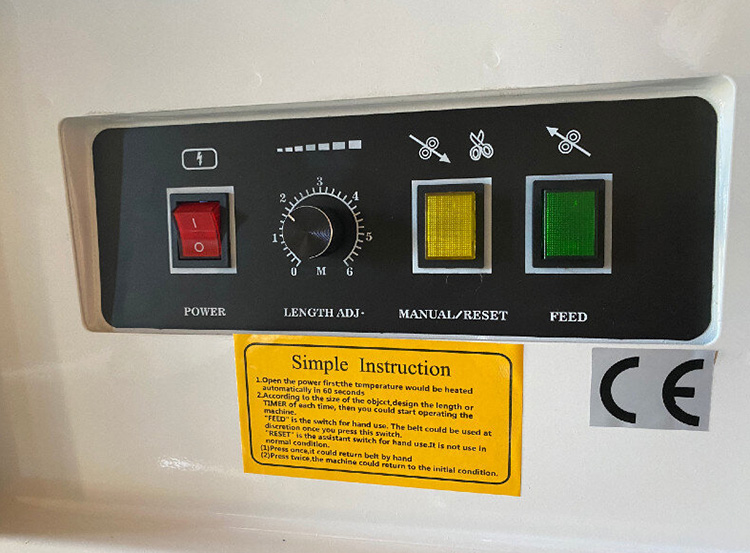

Power Switch

The power switch is used to turn on a semi-automatic strapping machine. As the machine gets powered on the motors start rotating and also the strapping feed moves.

Feeding Length Knob

The feeding knob is used to control the feeding of strap automatically during operation. The amount of strap that is to be applied on particular product is also controlled from this length knob.

Reset Switch

Reset switch is used when any mishap on getting the strap back to its position occurs. The system is then reset to its original position so that proper strapping process may be carried out.

Strap Feed Switch

Strap feed switch is responsible to get the strap out of machine freely whenever the product enters the system.

Power Plug

Power plugs are connected to provide required supply to the semi-automatic strapping machine. This mainly operates on a voltage range of 110-220V

Brake

Brakes are applied for stopping the rotation of motors. These brakes are there in a semi-automatic strapping machine which works opposite to the strap feeding unit. As the desired strap is applied on the product, these brakes get operational and stop extra feeding of strap material. .

Strap guide for brake

Threading of strap in a semi-automatic strapping machine is done through these guides. A strap guide helps proper sized strap implementation on product and breaks it when completed.

Strap bypass guide

The strap passes through this guide when it is applied on the product. After the strapping is done, this bypass system helps the product to move to the next stage or removed from the platform

Packaging Stopper

Packaging stopper is used to stop or hold the product on the table. The alignment of these components is always important as the product direction is defined by packaging stopper. If the product is not properly aligned, it can cause poor strapping.

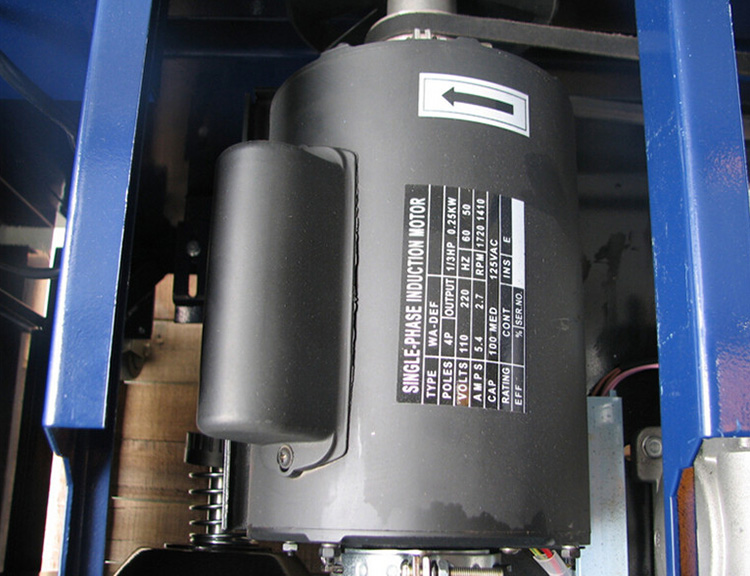

Motors

All the inlet of strap material from strap guide is the responsibility of motors. Motors also set the direction of feeding units. To enhance the production capacity and efficiency.

Sensors

When the product enters the system, it is detected through these sensors. Once the sensors get activated the strap is applied on all sides of it.

5.What Type Of Strapping Tape Should You Use In A Semi-Automatic Strapping Machine?

Semi-automatic strapping material purely depends on material strength and quality. Quality remains an important factor. The material should be strong, stretchable and durable that the product may keep away from any damages. Some of the materials that are commonly used in semi-automatic strapping

Steel

Steel is the most ancient and best material used for strapping of products. It is highly suitable because of its strength and wide ranges of grades available. It gives minimum stretching range but high strength to keep the product safe. It remains effected with weather change and adopts the atmosphere accordingly. Also, steel is an UV resistant material.

Polyester

Polyester is widely used in semi-automatic strapping machines more than steel and polypropylene nowadays. High tensile strength, durability and ability to stretch its properties make it very popular among many groups. It can easily bear heavy duty and medium loads.

Polypropylene

After steel propylene is commonly used material in strapping machine. Due to its availability is various width sizes and tensile strength, industries are using this material for packaging of material. It can be used in both automatic and manual machine that also makes it very durable.

6.How Will You Benefit From A Semi-Automatic Strapping Machine?

Some of the advantages of a semi-automatic strapping machine are

Product Security

Semi-automatic strapping machine provides high level security to the products as it tightly wraps it and don’t allows it scatter easily. If the right property is selected according to the product then one has to be rest assured that the product will reach its destination safely.

Easy Handling

The machines are very easy to handle and no such expertise are required for controlling the operation of it. The operational manuals and guidelines equally participate in easy handling of machine.

Economical

Semi-automatic strapping machines are very economical as only one-time investment is to be done and it lasts for a longer period. It also reduces human effort and helps the operator to uses its energy on other things.

Time Saving

Large area of time is saved using these machines. The product gets strapped in no time. The amount of product that gets strapped as compare to manually operated machines is also very high.

Business Growth

Semi-automatic strapping machines help the manufacturer to expand its business to a large level and produce as much products as it can. It makes the industries much profitable.

7.What Is An Automatic Strapping Machine?

Industries that have mass production and are of large volume use fully automatic strapping machines. A fully automatic strapping machine is not different then a semi-automatic strapping machine in construction but the only difference is that no manual influence in strapping process is there in an automatic strapping machine.

The product is installed in the machine and the further processes are carried out by the machine itself. Machines are much easy to handle and give fast strapping rate. Even the last cutting of strap is also done by the machine. A strapping rate of more than 2 to 5 straps/ second can be achieved using an automatic strapping machine

8.What Are The Differences Between Semi-Automatic Strapping Machine And Automatic Strapping Machine?

Both semi-automatic and automatic strapping machines are differentiated on the basis of

Feeding Method

In an automatic strapping machine the product is just placed on the machines table and when the operator presses the push button, automatically strapping process is carried out.

For a semi-automatic strapping machine the strap is manually feeded by the operator on both sides of the product. The strap is fed back to the other side of the machine

Production Capacity

Semi-automatic strapping machines gives an output rate of 1 – 3 straps / seconds and are favorable for low or medium scale production setups.

Whereas the number increase to 2 – 5 straps / seconds in an automatic strapping machine and can be used in large scale industries due to their greater productivity.

Efficiency

Semi-automatic strapping machines are highly efficient as they apply clean and efficient strapping on products in no time. The human influence can sometimes cause trouble but experienced and trained operator can work in an effective way.

On the other hand, automatic strapping machines are more efficient and precise then semi-automatic strapping machines due to their less rely on human efficiency. All the straps applied on products are identical and have no dissimilarity.

Both the machines tends to perform standardized strap packaging to minimize human error.

Product Security

Products are highly secured while using either of the strapping machines. The strength of strapping remains same in both. Some quality influence can occur in a semi-automatic strapping machine due to human involvement in the process.

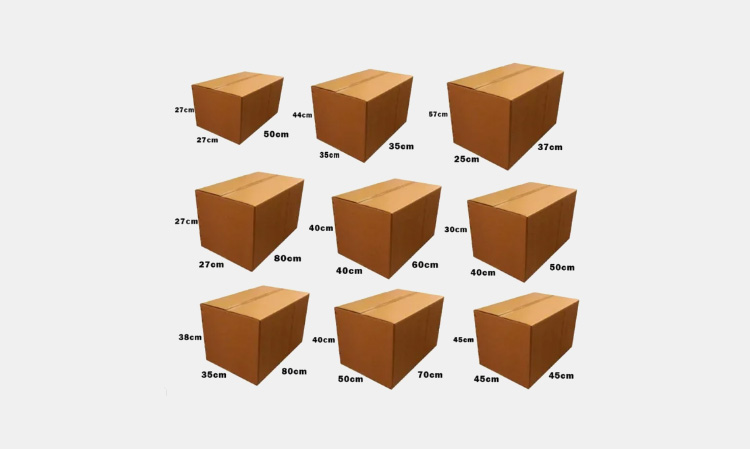

Packaging Size

Semi-automatic strapping machines are highly durable and its alignment can be done manually according to the size of product. Semi-automatic strapping machines are ideal for production setups where different size of packaging is carried out. The machine can also be moved from one place to another.

In an automatic strapping machine, the product is automatically selected by sensors according to size and width and then the table is adjusted accordingly. They are preferred for large production setups but of similar sizes.

Production Setup

Low and medium scale industries use semi-automatic strapping machine to fulfill their production demand. These machines are used as an individual stand and cannot be merged to production setups. An operator inputs the packaging material himself on the strapping bed.

Industries with mass production or high scale manufacturing recommend usage of automatic strapping machines. Fully automatic strapping machines can be used as an individual machine or can easily accompany in a production setup.

9.What Other Equipment Are Used To Accompany With A Semi-Automatic Strapping Machine?

Semi-automatic strapping machines are sometimes associated with other secondary parts. These are not actually its parts but accompanied with it to enhance product quality, safety and appearance. Some of the equipment used along with semi-automatic strapping machine are

Rollers

In some semi-automatic strapping machines, rollers are present at the beginning for entrance of product. Automatic conveyor or rollers are mostly present in a fully automatic strapping machine but some manufacturers use it here to ease human operation.

Carton Sealer

Before the carton or box is strapped, it is passed through a carton sealer where all the edges of it are properly sealed.

Laser Ink-jet

Some straps contain graphics, bar codes and QR codes. This presentable stuff is applied on them using laser ink-jets that catch the eyes to customer.

Strap Checking Sensors

Few semi-automatic strapping machines have these checking sensors at the end of process to have a quality check. It indicates whether the strap has been cleanly applied or not on the product.

Pallet Stand

A pallet stand is also there at the ending section of a semi-automatic strapping machine in which the finished product is kept and maintained for further packaging.

10.How Is A Semi-Automatic Strapping Machine Maintained?

The methods to maintain a semi-automatic strapping machine are

Trained Operator

The most important thing to have is a trained operator. Semi-automatic strapping machines might have a complex procedure of working but proper training can make the operator expert in its operation. It is always recommended to designate an experience individual which can fully maintain the machine and avoid any accident to occur.

Cleaning Of Semi-Automatic Strapping Machine

Cleaning of semi-automatic strapping machines should be scheduled at the end of every production process as there might be some unused strap in the system. Try to remove those straps or reenter those into the feeding reel. Leftovers can cause dispensing problems in future.

Dust present on the machine and its hidden parts should be cleaned so that the machine should perform its operation with maximum efficiency and avoid any jam.

Lubrication Of Machine

A semi-automatic strapping machines has different mechanical parts like gear box, motor, rolling parts that require proper lubrication with the passage of time. It is recommended to check the lubrication every month and do if required

Vacuuming

Vacuuming of interior is also recommended by many manufacturers after a certain number of straps applied. Mostly manufacturers assist to vacuum the interior after 10 to 15 thousand straps but it solely depends on the machines specification and its quality

Preparing Machine Checklist

In the end proper maintenance check sheets should be maintained and reviewed as per the schedule. All important parts of a semi-automatic strapping machine should be covered in those check sheets and the operator is to be advised to act accordingly. This will ensure the checking of each part and replacement of those if required. Maintaining machines checklist will also minimize machine and man accidents to a distinct level

11.Top 5 Best Manufacturers Of Semi-Automatic Strapping Machine

For better assistance in selecting a semi-automatic strapping machine, here is the list of top 5 best manufacturers of semi-automatic strapping machine

StraPack

Headquarters: JAPAN

StraPack has been producing packaging machines for the last 50 years and are much professional in manufacturing semi-automatic strapping machine. They guarantee machines quality and distribute in every part of world.

Quality Strapping

Headquarters: United States of America

Quality Strapping was established in 1995 and since then they have been the most popular ones in manufacturing strapping machines. Their machines provide complete ease to the operator and are much easy to use. They are renowned for less and competitive pricing of strapping machines and provide high speed delivery worldwide.

Allpack

Headquarters: CHINA

Allpack has an 11 versatile years of experience in manufacturing automated and efficient food, pharmaceutical and cosmetics machines. Allpack is now getting worldwide famous for their 24/7 assistance and providing infrastructural facility to their customers. Variety of machines are making them a global competitive in the field of packaging industry.

MOSCA

Headquarters: GERMANY

MOSCA is a German based innovative technology manufacturer that has an experience of more than 55 years. They are producing variety of semi-automatic strapping machines with advanced components and technology. Their highly qualified and experience staff are manufacturing best quality products that are worth it.

Crawford Packaging

Headquarters: United Kingdom

With 50 years of vast experience, Crawford packaging are busy in manufacturing efficient, durable, easily handled and convenient semi-automatic strapping machines. They started their business from United Kingdom and are now present in almost 25 countries worldwide providing best customer services. The unique advantage in opting Crawford packaging is that they have their own logistics and distribution setup which directly reduces the cost of machine.

12.How To Choose A Semi-Automatic Strapping Machine?

Before deciding the purchase of a semi-automatic strapping machine, there are few important features that should be considered on priority. Those important features are

Annual Production

Before choosing a semi-automatic strapping machine, it is important for the buyer to have a complete overview of its production setup. Either the setup lies in low, medium or large scale industries; the machine should be considered or according to it.

This decision can cost a lot of time and money waste if not taken wisely. Proper forecasting of industry is also requires to choose a right type of semi-automatic strapping machine.

Buying Cost

Semi-automatic strapping machine which lies in the allocated budget or gives the best return on investment (ROI) should be consider. By having proper research the industry can get profit in quick time with greater returns.

Authentication of Manufacturer

With the excessive demand in semi-automatic strapping machine, numbers of local and international manufacturers are busy in producing these machines. It is always important to search for a manufacturer that produces high quality semi-automatic strapping machine and also gives machines guarantee for a longer period.

Ease of Operation

Machines that have simple operational procedures are always the best one to choose. It makes an operator expert in less time and ensures easy handling too.

Local Assistance by the Manufacturer

Manufacturer that provides local assistance and guidance are always the best ones to choose. This helps the buyer to get proper assistance whenever required and also ensures availability of machines spares.

Structural Material

A semi-automatic strapping machine made up to tin, MS or other less quality material can always be a threat to the industry. It is always recommended to buy machines made up of stainless steel as it resists the humid conditions and increase the life of machine.

CONCLUSION

Product security and material handling has been one of the major concerns of global world. Manufacturers and suppliers both are focused for proper product travelling and getting satisfactory remarks from the consumer. We offer you highly flexible semi-automatic strapping machine with better outputs. For further details, we are always here for your assistance. Feel free to ask anything 24/7 from our customer support or visit our website http://www.allpackchina.com/ .

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586