Your Best Bleach Filling Machine Manufacturer

Allpack Bleach Filling Machine

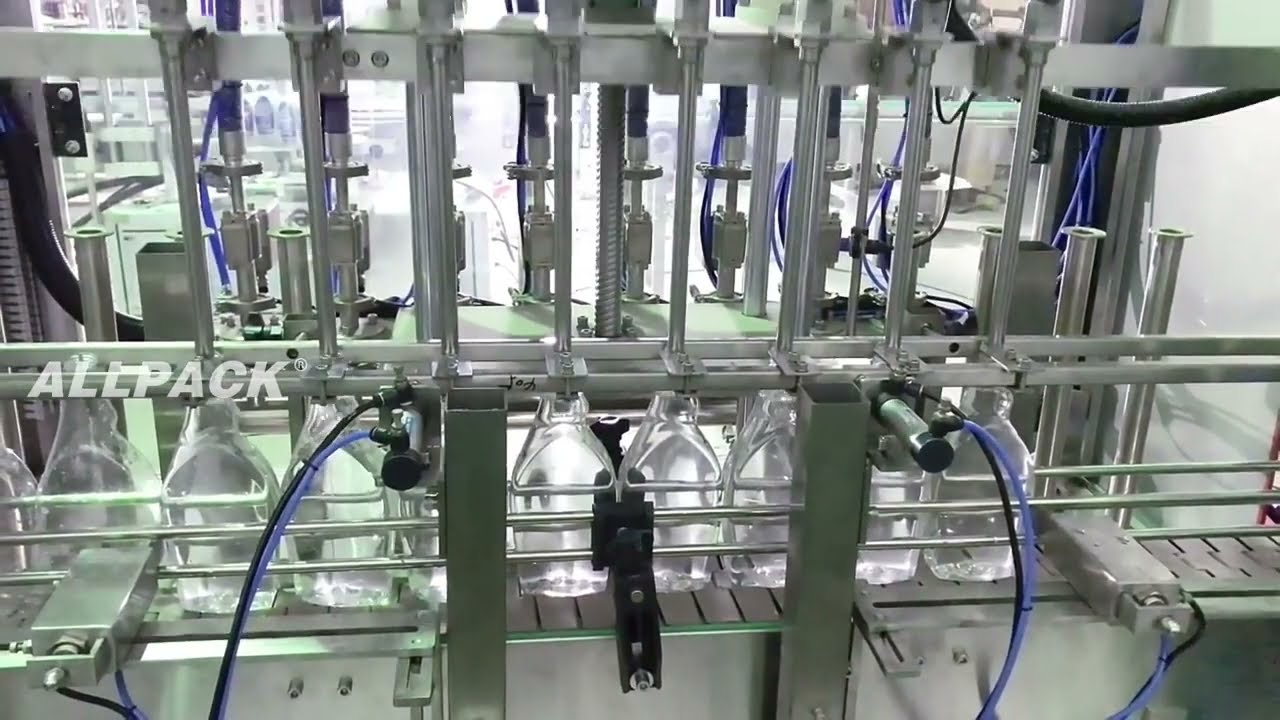

Allpack bleach filling machine is the perfect solution for handling liquid filling challenges such as strong acids and bases, bleach, Clorox, corrosive liquid, alkali materials, highly corrosive pesticides, disinfectants, toilet cleaner, iodine, and other low viscous and corrosive liquids with fast and efficient bottle filling and packaging processes. This bleach filling machine can offer you the best quality bleach filling line for bleach filling, sealing, capping, labeling, and so on to help ensure your bleach bottles will be filled efficiently and safely. All the surfaces of the bleach filling machine are stainless steel, making your machines corrosion-resistant, and easy to sanitize. There is everything you need for a bleach bottle packaging line here. With stable performance and easy parameter setting, this bleach filling machine and bleach filling line is easy to operate and control.

Allpack Bleach Filling Machine Video

Bleach Filling Machines

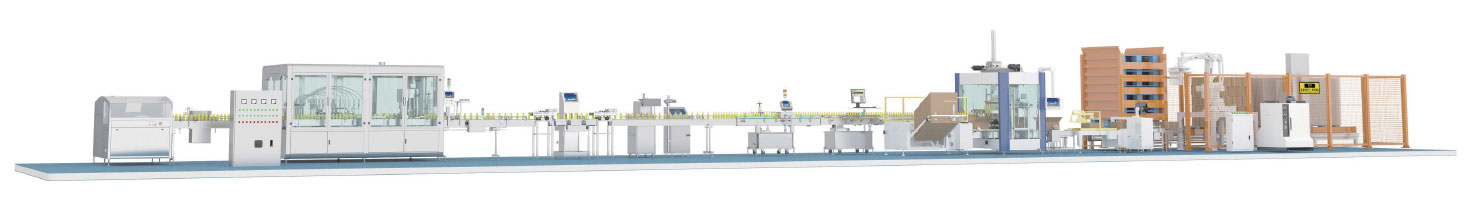

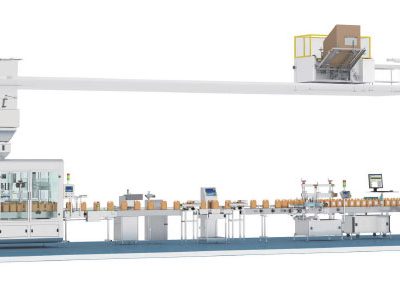

Allpack 10-100ml High-Speed Bleach Filling Machine Acid Alkali Corrosive Liquid Disinfectant Toilet Cleaner Iodine Bleach Filling Line

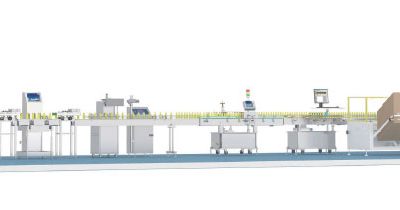

Allpack 10-100ml bleach filling machine is used for different liquid products such as bleach, strong acids & bases, corrosive liquid, alkali materials, highly corrosive pesticides, disinfectants, toilet cleaners, iodine, and other low viscous and corrosive liquids. Consisting of an automatic rotary plate bottle unscrambler, integrated filling & capping machine, weight checking machine, induction sealing machine, inkjet printer, self-adhesive labeling machine, QR Code collection system, auto carton erector, carton packing machine, carton sealing & strapping, and palletizing machine, this bleach filling line can offer you best bleach filling effects without labor work.

Photo-electric Sensing

Intelligent PLC Control

Close Positioning Design

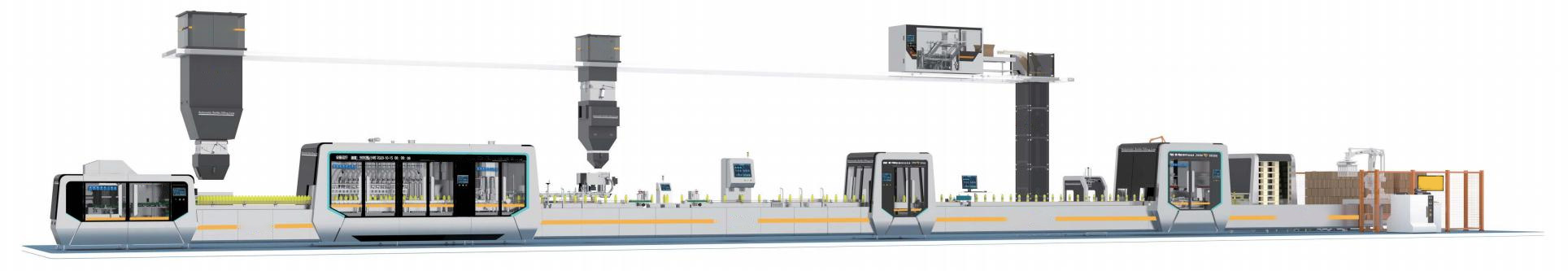

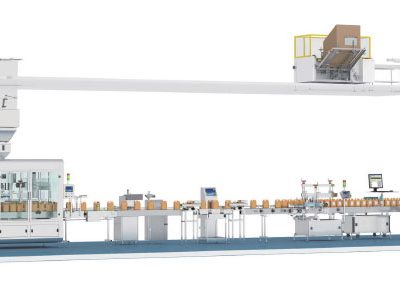

Allpack 50-1000ml High-Speed Railway Bleach Filling Machine Acid Alkali Corrosive Liquid Bleach Filling Line

Allpack 50-1000ml high-speed railway bleach filling machine is specially designed for large-capacity bleach filling and packaging. This automatic bleach filling line can offer you bleach bottle unscrambling, liquid filling, bottle capping, weight checking, induction sealing, inkjet printing, buffering, bottle labeling, carton erecting, carton packing, carton sealing and strapping, and robot palletizing. With this bleaching filling line, you can get the intellectual and high-speed bleach bottle filling with high efficiency and high capacity.

Electric-proof & Dust-proof

High Strength and Corrosion Resistance

Independent Anti-corrosion Electrical Control

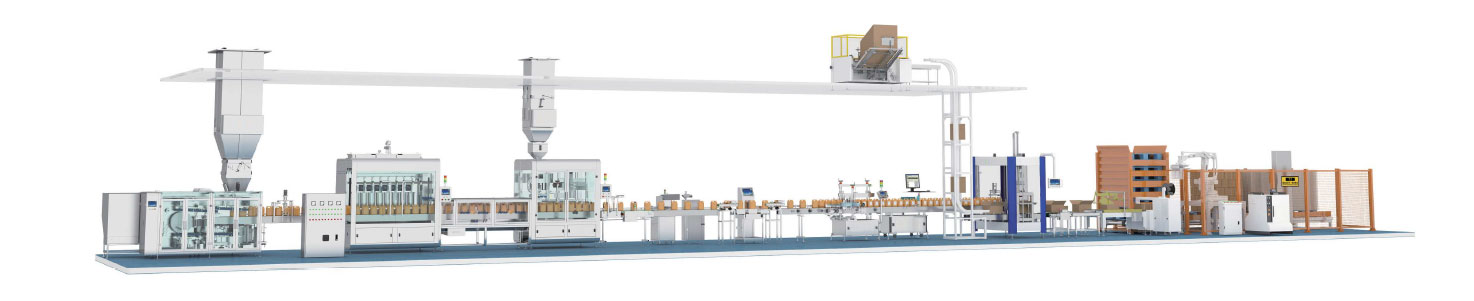

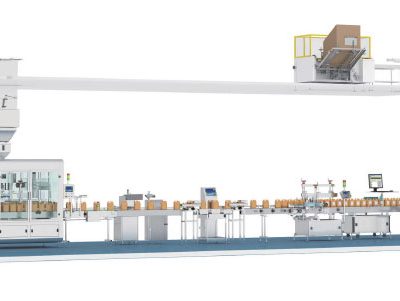

Allpack 1-5L Bullet Train Bleach Filling Machine Intellectual Packaging Bleach Liquid Filling Line

Allpack 1-5L bullet train bleach filling machine is specially developed for low viscosity but corrosive liquid filling with large capacity. This machine is widely applied for filling acid, alkali materials, highly corrosive pesticides, 84 disinfectants, toilet cleaners, iodine, etc. Controlled by intelligent PLC, this bleach filling machine can realize precise filling, stable performance, and easy parameter setting. Equipped with a piston filling machine, it can ensure long-term stable operation. The machinery is easy to operate and has the ability to quickly and accurately fill bleach containers and seal them in one pass.

PLC Control System

Long-term Stable Operation

Precise Filling & Stable Performance

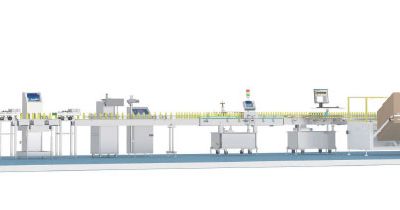

Allpack 5-30L Bleach Filling Machine Bleach Bottles Drum Filling Line for High Volume and High Capacity

Allpack 5-30L bleach filling machine is applicable to bleach bottles drum filling and packaging for high volume and high capacity. This bleach drum filling line consists of the automatic weight filling machine, auto cap elevator, follow type capping machine, induction sealing machine, inkjet printer, drum two sides self-adhesive labeling machine, and the vacuum pneumatic lifting machine for your high volume production with high efficiency. This bleach filling machine can help you with corrosive products that are dangerous to personnel and accelerate the depreciation of capital equipment.

No Bottle No Filling

Automatic Bottle Sensing System

Automatic Filling With Diving System

Allpack Bleach Filling Machine Process Flow & Duration Estimation

Allpack has been a professional manufacturer of filling lines for over 10 years, customized filling lines for different industries like food, beverage, cosmetic, medical industry, chemical industry, and so on. The full automatic liquid filling machine is designed to save time on adjusting and testing machines, and it can fill a liquid or paste accurately by entering a certain filling volume. Check below the Allpack bleach filling machine manufacturing process.

Step 1: Plate Cutting (5-7 days)

The initial step is the plate cutting, which takes 5-7 days to complete the process, with which various thicknesses with accepted dimensional accuracy can be achieved. It is done either by a mechanical or thermal process. It is done either by a mechanical or thermal process. With this process, your machine surface finish will be improved and the machine surface will be protected from corrosion.

Step 2: Welding (5-7 days)

The 2nd step is welding, which takes about 5-7 days, it is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. During this welding process, you will get strong or permanent joints for your machine structure. It is such a crucial process as it is the backbone of the machine.

Step 3: CNC Process (14-18 days)

The 3rd step is the CNC process, which takes about 14-18 days to complete. It is a manufacturing process in which pre-programmed computer software dictates the movements of the machine. In CNC manufacturing, machines are operated via numerical control, the language in the CNC process will control the various behaviors of the machine, such as the speed, feeding rate, and coordination.

Step 4: Polishing (3-5 days)

The 4th step is polishing, which takes about 1-3 days. It actually includes two stages. Firstly, remove the clear coat scratches, and the second stage is polishing the refined finish. After this polishing process, the machine surface will look smoother on an even more microscopic level. It will also reduce the amount of surface and sub-surface damage and provide better uniformity of surfaces requiring epitaxial processes or deposited materials.

Step 5: Inspection (1-3 days)

The 5th step is inspection, and it is the most important process during the whole machine manufacturing process often overlooked. Allpack bleach filling machine inspection process not only includes an overall visual inspection of machine functionality and components but also includes scheduled, purposeful, proactive equipment checks that are carefully designed to identify possible issues and forecast necessary maintenance needs. Through careful inspection, documentation, inspection summary, and report will be generated.

Step 6: Assembly (5-7 days)

The 6th step is the assembly, which is the most important process of the machine’s mass production, here several parts or materials of the machine are added in sequence by various workers. This process will also utilize different types of hardware to assemble the parts together, like nuts, bolts, screws, and similar materials.

Step 7: Debugging (5-7 days)

The 7th step is debugging, which is also the most important process of the bleach filling machine manufacturing process. Allpack engineers will debug the machine from several aspects to detect any errors or bugs at the early stage. If any parts of the machine do not work as expected, they will study and solve the errors or bugs before getting to the next to guarantee the best factory quality.

Step 8: Packaging (1-3 days)

The 8th step is the packaging, which is to enclose and protect the machine by encasing it in a container for sale, distribution, shipping, storage, and usage, or efficiently and quickly placing the machine in a protective container or wrapping. It completes a process that is an essential part of marketing and presents the proper image and design of a machine.

Step 9: Loading (1 days)

The last step is loading. The finished bleach filling machine will be loaded onto the track for further shipment using the lift truck.

Why Choose Us

Allpack offer a variety of bleach filling machine and solutions for different applications, including viscous liquids, aggressive liquids, acid liquids, etc.

Each bleach filling machine and solution has undergone rigorous trials with original products or placebos at our lab to ensure full functionality.

We can offer you the most versatile and efficient solution for filling bleach and other liquid disinfectants into various containers with high efficiency.

Allpack bleach filing machines are widely applied in chemicals, cosmetics, pharmaceuticals, lubricants, grease, and other products around the world.

The Buyer's Guide

Bleach Filling Machine: The Complete Buying Guide in 2025

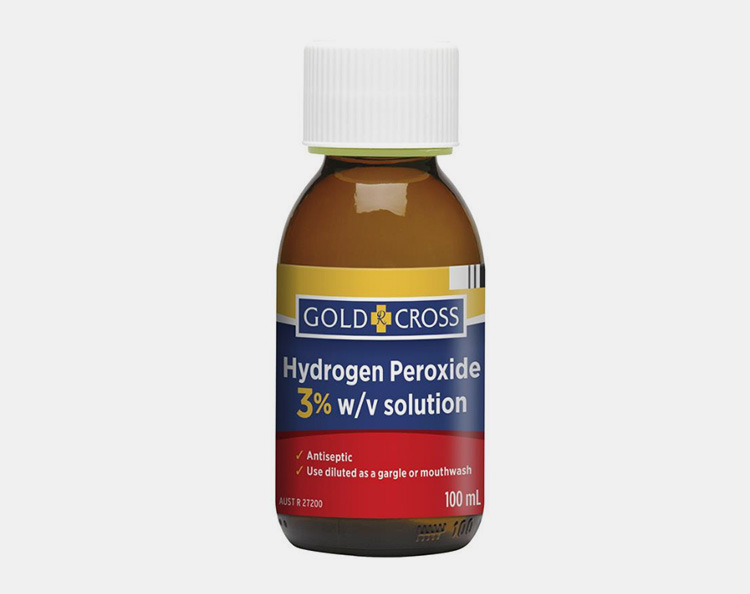

Have you ever wondered about filling machines that dispense an aggressive bleach solution? Bleach is a reactive compound that is used for sterilization, cleaning stains, hair dyes, and other important tasks. They are presented in various packaging forms. The bleach-filling machine is an ideal solution that does this job efficiently.

If you’re interested in purchasing a bleach filling machine; we would suggest reading this blog to explore the basics about the machine to get the right one for your production line.

1.What Is A Bleach Filling Machine?

Bleach Filling Machine

A bleach filling machine which is also known as a bleach filler, is a robust and reliable addition into the world of production and packaging fields. This machine is used to fill the packaging containers with formulated bleach efficiently.

The machine is sleek and compact in structure which is able to work with light, mild as well as harsh chemicals without any worry for harming you and your mother environment.

This is due to its innovative construction and design that is made up to keeping customer requirements in minds. The machine is designed to offer low to large volume of filling accurately and under a controlled manner.

2.What Are Industrial Applications Of Bleach Filling Machine?

Bleach filling machine is used in several different industries. These range from large scale to small scale ones. Let us discuss each of these industries below.

Pharmaceutical Industry

The use of bleach filling machine in pharma

In pharmaceutical industry, it can be used to fill products such as aerosols, sprays, oral solutions, suspensions and sterile solutions. By using bleach filling machine in your factory, you can maintain the potency and efficacy of these volatile solutions till they can be used when needed.

Chemical Industry

The use of Bleach Filling Machine- Picture Courtesy: Clean Plus Chemical

The bleach filling machine is an integral component of dealing general applications of chemical manufacturing and packaging. The chemical industry deals with products such as benzene, bleach, isopropanol, paints, inks and much more. Thus, the machine is a safest solution relevant to it.

Agriculture Industry

The use of Bleach Filling Machine

Many agro based products such as liquid fertilizers, pesticides and molasses based liquid supplements for animals require an accurate and cost effective machine to fill them in cans and bottles. Bleach filling machine has relevant filling nozzles which can pour these products concisely into containers so that they can be packaged and shipped for delivery.

Petroleum Industry

Application of Bleach filling Machine in Petroleum Industry- Picture Courtesy:

Petroleum industry is one of the most crucial industries for growth of the world since its products are responsible for running the economy. These products are diesel, petrol, jet fuel and crude oil. These products viscosities range from low to high.

Food Industry

The Use of Bleach Filling Machine in Food Industry- Picture Courtesy: Solvey

Even though, this industry deals with food items, bleach filling machine can still be used here since it serves the same purpose of filling liquid-based products into their desired packaging.

Products such as ketchup, hot sauce, mustard sauce, honey, syrups, soda drinks and water can be packaged by this machine, thus ensuring their freshness and taste.

Cosmetic Industry

The Use of Bleach Filling Machine in Cosmetic Industry- Picture Courtesy: The Active Oxygen

This multi-billion dollar industry is growing exponentially over the past few years. Its products such as serums, lotions, shampoos, conditioners, toners and soaps are used globally with their demand continuously increasingly.

By using bleach filling machine in this industry, these beauty products can be packaged into various bottles and jars, providing a colorful and aesthetically pleasing products to the consumer.

Textile Industry

The Use of Bleach Filling Machine in Textile Industry- Picture Courtesy: Spure

Textile industry which is responsible for manufacturing clothes, towels, bags, carpets and rugs require dyes and chemicals to color them and enhance their beauty. These colors can be packaged with the help of bleach filling machine which will protect them from disintegration.

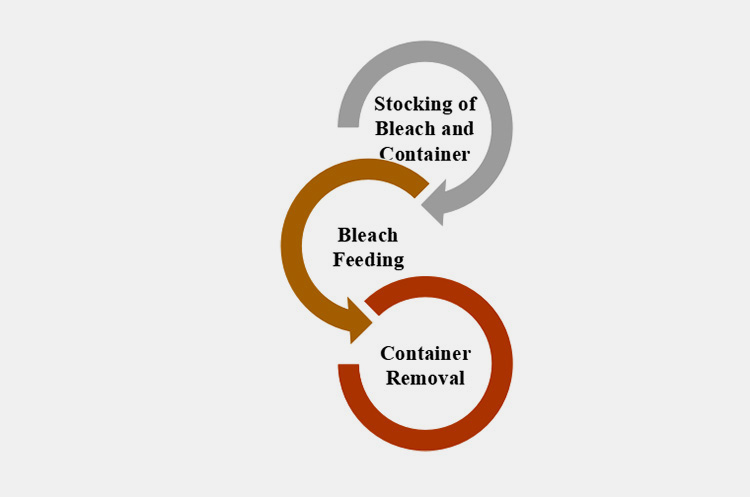

3.What Is Working Principle Of Bleach Filling Machine?

The working of the bleach filling machine is identical to any other kind of liquid filling machine. This machine is offered with highly accurate sensors that provide accuracy in bulk volume filling. Some basic working steps of bleach filling machine are:

Stocking of Bleach and Containers

Stocking of Bleach and Container- Picture Courtesy: White Steel Gmbh

First infeed tanks are used for loading bulk volume of bleach inside the machine hopper. Secondly, containers are placed on the conveyors at repeated intervals, either manually or by the container unscrambling machine for bleach filling.

Bleach Feeding

Bleach Container Filling- Picture Courtesy: Valley Chemical Solution

For bleach loading in large-sized containers, when the container is sensed under the filling nozzle, the sensors signal the PLC unit, which commands the opening of valves in the filling systems. This leads to a gradual flow of bleach from the hopper to filling pistons and pumps. From filling devices, the bleach trickles down to the filling nozzle. These nozzles extend to the centre or bottom of the container.

At first, bleach is filled at maximum speed and when preprogrammed volume or weight is reached, the filling slows down to acquire accuracy in fill.

Container Removal

Bleach Container Removal- Picture Courtesy: strpackerfiller.com

When the container is filled to the required threshold, the PLC unit signals for the closing of the fill valve and the filling process is stopped. Then container is transported to another machine down the line for further packaging.

4.What Are Benefits Of Bleach Filling Machine?

The benefits of bleach filling machine are mentioned below:

Safe, Consistent and Uniform Filling

Bleach filling machine offer high consistency- Picture Courtesy: Colorox

Certain products such as bleach, chemicals, petro-chemicals, and other are extremely vulnerable to external harmful factors like moisture, sunlight and air pollutants.

Thus, they need an effective machine which would be able to package them in their appropriate containers. Bleach filling machine would be the best choice for this purpose and fill a number of liquid chemical products with uniformity and efficiency.

Suitable for Products with Various Viscosities

Bleach Filling is idea to dispense various viscosities liquids- Picture Courtesy: Anton Paar

Bleach filling machine can package these different viscosity products easily into containers and bottles, protecting them for contamination and in some cases, evaporation.

Offering Various Automation

The bleach filling machine is displayed with various features and automation that let you to select up to your requirement, budget, and production capacity.

Flexible Integration with Other Units

Traditionally, the filling process was tiresome, but today’s bleach filling machine user’s friendly options allows you to connect the machine with other working units in no time and you can enjoy perfect production output.

Capable of Handling Various Volumes

Bleach Filling Machine is Ideal for Small, Moderate and Large volume Dispensing Picture Courtesy: Syntegon

The bleach filling machine is excellent machine that deals with small to large volume bleach filling very well. The well-engineered machine offering precise and accurate measurement that is required to get actual demand.

Promising Production Capacity

High Adaptability of Bleach Filling Machine- Picture Courtesy: neostar

If you’re handling with large production facility where day and night production procedures are carried out; the bleach filling machine is a promising equipment to bring your dream come true via demonstrating true results in a shorter time.

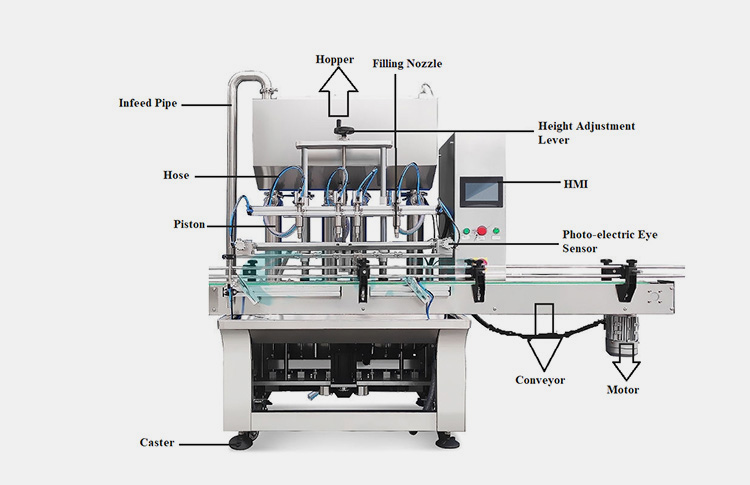

5.What Are Basic Parts of Bleach Filling Machine?

The bleach filling machine is comprised of different technological and electric parts that provide efficiency in the bleach fill. These parts and their functions are listed below:

Parts of Bleach Filling Machine

| Infeed Pipe | These pipes connect the hopper to infeed tanks and are employed for supplying hopper with the bleach. These pipes are part of a bleach filling machine in the large production plant. |

| Hose | These are the part of the filling station in the bleach filling machine. It is produced using resistant stainless steel that protects against harsh bleach. The hose regulates the flow of bleach product from the hopper to the filling nozzle. |

| Piston | It is a cylindrical device that moves forth and backward to exert pressure on the bleach and this force draws the bleach to filling nozzles. |

| Caster | The caster is a part of the bleach filling machine that aids in the portability of the machine. The wheels of the machine rotate by displacement of the caster. |

| Hopper | It is a rectangular-shaped component, typically found at the upper part of the machine. Bleaches are loaded in the hopper before initiation of filling for an uninterpreted flow of bleach. |

| Filling Nozzle | These are tubular devices that dispense bleach inside bulk-capacity containers. The filling capacity is dependent upon the number of filling nozzles present in the machine. |

| Height Adjustment Lever | It is a wheel-like part that is rotated to adjust the height of the filling nozzle according to the height of the container. It is present in the bleach filling machine to avoid bleach spills during dispensing. |

| HMI | It is an intelligent control system that is employed for adjusting filling parameters in automatic and semi-automatic bleach filling machines. Quick format change is accomplished by pre-saving data recipes in HMI. |

| Photo-electric Eye Sensor | This is used for detecting the number of containers under the fill nozzle. It is equipped with camera-vision systems that identify containers moving on conveyors. This part is essential in acquiring precision in bleach fill. |

| Conveyor | The conveyors are like a railway and are employed for the transport of containers between different stations in the bleach filling machine. |

| Motor | This part transforms electric supply into mechanical energy to move different mechanical parts like filling systems, conveyors, etc. |

6.What Are Available Types Of Bleach Filling Machine?

The Bleach Filling Machine

Bleach filling machine is a multi-purpose, versatile equipment which is available in many different forms. Each of this type has its own unique features which makes it suitable for several industries. By looking at the different types, you can easily decide which one is the most suitable one for your company by taking a look at its features. Let’s take a look at them.

Bleach filling machine is divided into the following types.

Types Of Bleach Filling Machine- Based on Automation

Bleach filling machine is based on three types of automation.

| Manual Bleach Filling Machine

|

This manually operated equipment is the cheapest option available in the market and is ideal for small businesses and companies with limited financial budget. Although it requires a worker to carry out its process.

The worker first places the empty bottles or containers near the filling nozzles. After this, he uses the handle so that the machine fills the empty bottle with the liquid. The filled bottles are capped and discharged for final shipping. |

| Semi-Automatic Bleach Filling Machine

|

This semi-automatic equipment is suitable for medium sized factories which require a machine which has high production capacity but is still within the financial budget.

The worker places the empty bottles inside the conveyor belt. The machine then begins the process of filling the bottles with the help of nozzles. After the filling, the bottles are manually carried by the worker to the next unit. The machine is then introduced to the next batch of bottles. |

| Automatic Bleach Filling Machine

|

Automatic bleach filling machine is the most advanced type available which carries out the whole process on its own, without the human intervention. It is capable of filling thousands of bottles in a day, making it ideal for large scale industries.

The machine orients the empty bottles in a specific direction. The oriented bottles move through the conveyor belt and enter the filling section. The sensors detect this and fills them with high precision. After the filling, the bottles are capped and discharged automatically to the next section of the production line. The worker only has to monitor the whole process by using the touch screen. |

Types Of Bleach Filling Machine- Based on Filling Heads

Bleach filling machine is based on three filling heads.

| Single Head Bleach Filling Machine

|

This type of machine is best suited for thick foamy liquid and is appropriate for small factories and companies.

As the name implies, this single head machine consists of a single piston which is responsible for pumping the desired liquid from the tank into the nozzles which then pours the liquid inside the bottle. The filled bottles are moved to the packaging unit for the final step. |

| Double Head Bleach Filling Machine

|

As the name implies, this equipment comes with two pistons to carry out the filling process. It has mid-level capacity and fills few bottles per minute. Thus, making it ideal for medium ranged businesses. It is great for filling milk, soda drinks and oil.

The bottles are first introduced to the coveyor belt which then transports them to the tank. The tank then pours the liquid into the filling nozzles after which the twin piston discharges the liquid into the containers. The infeed and outfeed of the machine is controlled by the sensors. |

| Multi-Head Bleach Filling Machine

|

Multi-head bleach filling machine can contain multiple filling nozzles ranging from 3 to 8. This increased number of nozzles enables the machine to fill hundreds of bottles per minute, making it ideal for large scale industries.

The machine carries out the process automatically. Right from transporting the empty bottles, filling and packaging them, it is controlled by highly sophisticated software system. It is ideal for filling thick, viscous liquid. |

Types Of Bleach Filling Machine- Based on Filling Orientation

| Gravity Bleach Filling Machine

Picture Courtesy: Profruite Machinery |

This simple machine is great for filling thin watery liquids like water, solvents, bleach, alcohol, soda drinks.

The machine is equipped with pneumatic valves which control the amount of liquid which will flow from the tank. Thus the bottles are fed with liquid by gravity so that each container is filled with the same amount of liquid every time. |

| Pump Bleach Filling Machine

|

This machine has several types of pumps like rotor, gear, cavity and lobe pumps which can fill low to high viscous liquids into the containers.

These pumps which are controlled by the valves fill the bottles accurately which are then packaged. The use of this machine would be beneficial for pharmaceutical and petroleum industry. |

| Molten Bleach Filling Machine

Picture Courtesy: Filmatic |

Molten bleach filling machines are used for products which are melted at high temperatures and cooled down in the container. Thus they are great for cosmetic industries which deal with products like petroleum jelly, scented candles and lip balm.

The desired liquid is first heated as high as 200 Fahrenheit. The molted liquid is poured into the container which then cools down and is packaged. The temperature is controlled strictly by the sensors which can be adjusted using PLC control. |

| Pressure Bleach Filling Machine

|

This machine works almost exactly like gravity bleach filling machine except that it uses high pressure during the filling process. It is capable of filling every kind of liquid, from aqueous solutions to thick viscous liquid.

Working at the pressure of 0.4 to 0.6 MPa, the pressurized liquid easily flows into the bottles which are capped and packaged, ready to be shipped to their final destination. |

| Net weigh bleach filling machine

|

Net weigh bleach filling machine are ideal for products which need to be filled in bulk quantities.

The machine fills the containers at an already pre-set value. The liquid pumps into the container by gravity and the amount is controlled by a set of pneumatic valves. It is good for filling products like alcohol, bleach, solvents etc. |

Types Of Bleach Filling Machine- Based on Machine Size

| Small bleach filling machine

|

If you have a home business or a very small workshop, then this type is the one for you. Its size is of a desktop and can be put anywhere. Its cheap price makes it more accessible for those who are starting a business.

It can be used to fill fruit juice, soda drinks, alcohol, solvents etc. |

| Large bleach filling machine

Picture Courtesy: Diverseco |

This complex, advanced type is equipped with multiple filling nozzles and automated process which have high production capacity. Thus it is best for large scale factories and companies.

The whole process is automated and is done in a matter of a few minutes, yielding quick results. |

7.How Bleach Filling Machine Is An Anti-Corrosive In Nature?

Bleach Filling

Bleach is an oxidizing agent that can degrade the metallic construction and other components of the machine. Therefore, bleach filling machine is made with corrosion-resistant materials such as stainless steel.

This material is an alloy of iron and chromium with a low percentage of carbon. This combination is essential in providing resistance against rusting and corrosion.

Moreover, filling pistons, pumps, hoses, and filling nozzles are usually made with Teflon, Perfluoroalkoxy alkane (PFA), and fluorinated ethylene propylene (FEP). These are the anti-corrosive materials that have a long life. Also, the hose and nozzles of the machine are constructed using PP and PVDF that can resistant oxidizing environments.

Sometimes, these filling units are coated with epoxy resins and paint to offer the highest chance of resistance against disintegration.

8.What Is Production Line Of Bleach Filling Machine?

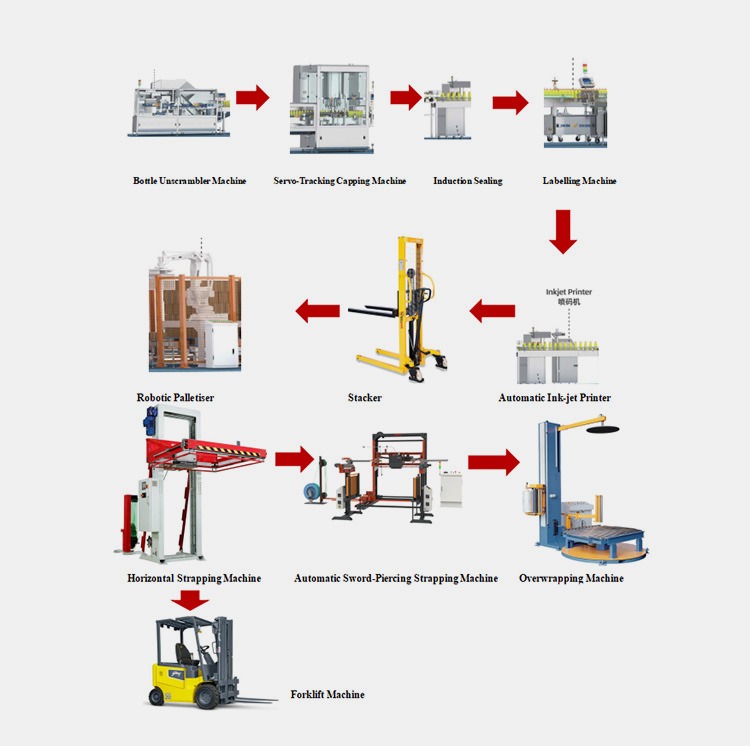

A bleach filling machine is the part of production lines where different feeding and packaging equipment are present together as one unit to compactly package bleach containers for transportation. Complete order of these machines is detailed below:

| Bottle Unscrambler | It is the machine that is employed first in the bleach filling line to orient the bottles in an upright position for uniform supply of empty bottles toward filling station. |

| Servo-Tracking Capping Machine | It is equipment that has servo controls and capping systems for lidding and capping large-capacity bleach containers. The servo motor regulates the rotation of the capping and lidding parts. |

| Induction Sealing Machine | This machine utilizes electromagnetic radiation field to induce the melting of inner lining of the cap which forms a firm and strong bond once it is cool down to create a tamper evident sealing around the bottle neck. |

| Automatic Labeling Machine | This machine sticks or glues different kinds of add-on stickers and labels to identify the inner content of the bleach containers. It also prints and labels containers with shipping instructions, batch numbers and expiry dates. |

| Stacker | A stacker is an electric or hydraulic lifting machine that elevates and stacks heavy-duty bleach containers. It places containers over others for shipment and storage. |

| Robotic Palletiser | It is an essential part of the bleach filling line and consists of heavy-lifting robotic arms that easily pick up large stacks of bleach containers and place them on wooden pallets for transportation. This aids in securing and fortifying containers during delivery and cargo. |

| Horizontal Strapping Machine | Large stacks of containers are compacted by the horizontal strapping machine. Then, these compressed stacks are bundled using sturdy and heavyweight tapes or cables. This machine straps the stacks at the sides. |

| Automatic Sword-Piercing Machine | This machine is comprised of a sword-like part that fastens and bundles the wooden pallets vertically. This sword pierces the bottom of the pallet and ties it in an upward direction. This prevents the smattering of bleach container stacks. |

| Automatic Overwrapping Machine | To prevent dust debris or any other foreign object from getting into the bundled pallet, these are completely wrapped with tough plastic film by the overwrapping machine. This also averts the counterfeiting of bleach containers. |

| Fork Lifter Machine | For hauling up the wrapped tied wooden pallets, a heavy-duty fork lifter machine is employed. This machine carries the pallets to the storage area. In this area, these pallets are kept while awaiting final shipment. |

9.What Are The Filling Materials And Volume Of Bleach Filling Machine?

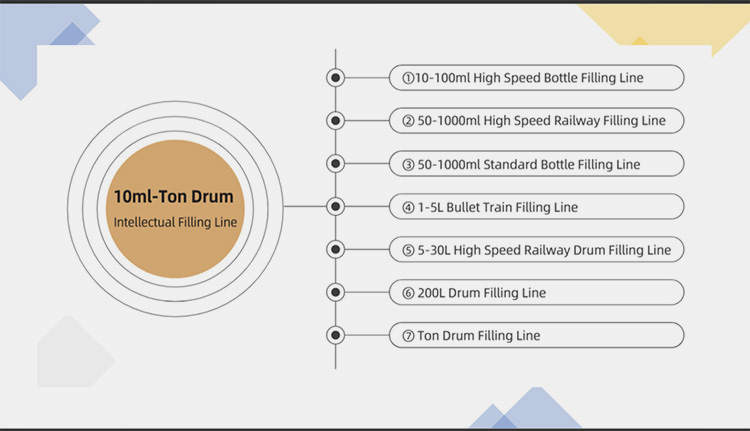

A bleach filling machine can dispense bleaches for both household and industrial use so, the filling volume varies with the size of the filling container.

For household use and retailing, it can dispense to about

- 10-100ml High Speed Bottle Filling Line

- 50-1000ml High Speed Railway Filling Line

- 50- 1000ml Standard Bottle Filling Line

- 1-5L Buttlet Train Filling Line

- 5- 30 L High Speed Railway Drum Filling Line

- 200 L Drum Filling Line

- Ton Drum Filling Line

Since the bleach filling machine can handle both small and large-sized containers, there are diverse kinds of filling materials processed by the bleach filling machine in the market.

These filling materials are penned below:

IBCs

Bleach IBCs- Picture Courtesy: Safety Store

It is an industrial equipment that comes in cubic shape. It has an integrated wooden base that is easily lifted by the forklifter. It is composed of metals, plastics and sometimes both of these materials. It is also known as a tote or IBC tank. Their holding size is in between the drum and transportation tank hence, it is termed an intermediate bulk container (IBC).

Drums

Bleach Drum

It is a cylindrical device that has two openings. It is manufactured using steel, metals and, plastics. It sometimes comes with lids that have flanges for bleach filling. It is stackable and is often used in bleach supply chains.

Jerrycans

Bleach Jerrycans

The bleach filling machine also dispenses a bulk volume of bleach in the jerrycans. It is a rectangular or cylindrical container with a flat base. It is typically made with plastic and metals. It has handles that provide support for carrying this container.

Buckets

Bleach Buckets

Bleach comes in industrial buckets. These are cylindrical or round containers with a flat bottom. Buckets have re-closable lids for resealing containers after use. Moreover, they also have a handle that is gripped for lifting and carrying buckets.

Bottles

Bleach Bottles

Bleach bottles are available in a diverse range of styles. These are cylindrical, rectangular, square, and round. Bottles are made using metals, glass, and plastics. They are used for packing both household and industrial bleach.

10.What Are the Problems and Troubleshooting Of Bleach Filling Machine?

The bleach filling machine like every machine may confronts with some wear and tear as well as some technical problems. These issues can affect the filling consistency of the bleach solution during process. Though, not every cause but we have discussed some of the major problems here to avoid common problems.

Bleach Filling Machine with Inconsistent Filling

Bleach Filling Machine- Picture Courtesy: Colorox

This is common problem regardless of the working principle, this could be due to installing machine with uneven flooring and problems with its casters. To solve this issue, we would recommend to add leveling legs just behind the machine and observe the proper adjustments. Relocate the machine toward smooth flooring section.

An Air Bubble in the Connections

Air bubble formation in the machine- Picture Courtesy: Syntegon

Some users overlook the loose connections of the pipes present in the bleach filling machine which results in entrapping of the air into the lines which results in variation of filling volume.

This is deem recommended to monitor the connections, their integrity and run rigours flow of solvent to assess if connections are working smoothly. Make ensure that no air is remain left inside the pipes to avoid inconsistencies.

Over Filling of the Bleach Filling Machine

Over Filling Problem- Picture Courtesy: Advance Dynamic

This condition can be occurred due to wear of either nozzle seal, or spring which ultimately can cause over flow of bleach solution during filling process. It is recommended to check and replace nozzle seals, spacers, and spring in case of wear and tear.

Secondly a back pressure is another important reason behind the overflow of solvents which reverse the flow from the tank and overflow the bottles. For that it is recommended to assess the filling tube and clear to avoid re-circulation of solvents.

11.What Is the Future of Bleach Filling Machine?

Future Innovation in Bleach Filling Machine- Picture Courtesy: Beverage Industry

The future prospect of bleach filling machine is quite skyrocketing as manufacturing companies and research brings amazing additions in its technology. Thanks to innovation that is implemented into bleach filling machine which would be able to make the unit to withstand against occurrence of problems and improving throughput with lesser downtime.

Plus, the emergence of major tends such as single, bi, as well as multi-functional filling head has shorten the time of filling for larger capacities batches. That’s why it is expected that the market value of bleach filling machine will be valued as CAGR 5.6% between 2023 to 2033 means around 6.9 billion USD. Moreover, the major demand for bleach filling machine is estimated in pharmaceutical, chemicals, cosmetic, and beverages.

Conclusion

Bleach filling machine has consistency and high speed. These two features help prove the worth of this machine in the production lines and also generate handy income for the manufacturers. It is a turnkey solution that automates the bleach filling and is equipped with different filling controls that can process both small and large-sized bleach packaging. Want to upgrade your existing bleach filling machine then browse our main Allpack for the best offers.

Allpack Bleach Filling Machine Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586