Your Premier Premade Pouch Filling Machine

- Servo Motor Filler

- Independent Digital Temperature Controller

- Advanced Photoelectric Sensor Tracking System

Allpack Premade Pouch Filling Machine

Allpack premade pouch filling machines are specially designed to fill and seal premade pouches with different materials. There are two main types of premade pouch filling machines including the horizontal type and the vertical rotary type. All those premade pouch filling machines are fully automatical controlled and operated. They are widely applied in food, beverage, cosmetics, chemicals, and pharmaceutical industries, and offer you various bag styles including stand-up pouches, zipper pouches, spout pouches, quad pouches with zippers, etc. All types of liquids, pastes, solid materials, and products can be filled and sealed with the premade pouch filling machine, and the packaging material can be regular laminated film such as PE/NY/AL/ PET/CPP. Premade pouch filling machines can offer great profit to both small- and large-scale organizations. It is an effective alternative solution to manual packaging, providing fully automatic operation.

Premade Pouch Filling Machine Videos

The Buyer's Guide

Premade Pouch Filling Machine: The Complete Buying Guide 2025

Manufacturers might enjoy purchasing directly available premade pouches for filling and packaging of various materials. Whether wholesalers or retailers, they take benefits from purchasing a premade pouch filling machine which is efficient to make stand-up pouches, zipper bags, pillow pouches, gusseted bags , doypacks and any customized form of pouches for your requirement.

We have outlined a comprehensive and reliable blog that will serve to help you with your queries before you think of buying a premade pouch filling machine for your industry.

1.What Is a Premade Pouch Filling Machine?

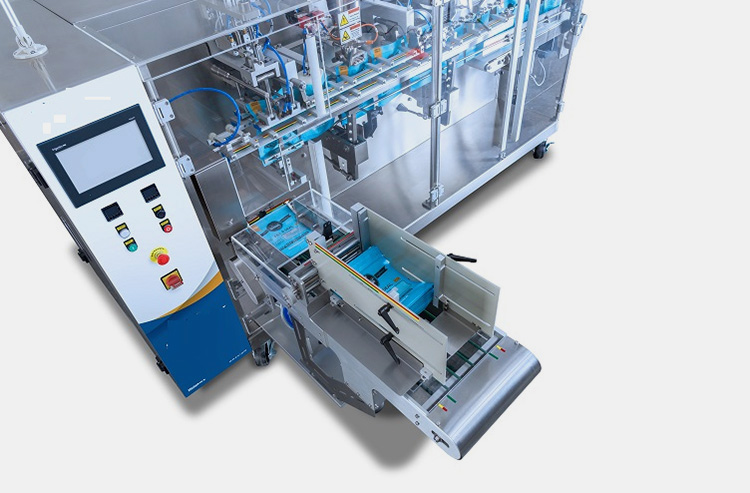

Premade Pouch Filling Machine – Picture courtesy: Paxiom.com

Either you want to invigorate and enhance your existing production line or launch an innovative product , utilizing a premade pouch filling machine will be like streamlining your manufacturing processes .

A Premade Pouch Filling Machine is an equipment that is used for automatic filling, sealing, coding and packaging variety of products that belong to food and confectionery industry, medical industry, cosmetics industry, veterinary industry, agricultural industry and in many different applications. This machine brings a systematic production output , which is helpful to pack various styles and sizes of premade pouches with captivating aesthetics.

A premade pouch filling machine can handle filling many types of materials that range from solid, powderous, granular to liquid form.

2.What Are the Industrial Applications Of A Premade Pouch Filling Machine?

As you read about what is a premade pouch filling machine now you’ll understand and be able to correlate it’s uses according to different industrial applications.

Food and Confectionery Industry

Premade food pouches- Picture courtesy: WowBrow

This machine has transformed the food industry’s manufacturing process to be sustainable and preservative in providing their products to their consumers in terms of safekeeping its freshness and delivering appealing packaging. Food items such as solid, granular or paste like products ranging from packaging of snacks like chips, nuts, frozen food like vegetables and fruits , powders like spices , sugar and salt , milk powder etc. can be packaged in a way that is safeguarded by enhancing shelf life, liquids like sauces and ready to drink beverages can be enclosed in a spouted pouch, perishable items and even ready to eat meals can be securely sealed involving the premade pouch filling machine.

Pharmaceutical Industry

Pharmaceutical pouch packaging – Picture courtesy: Logos Pack

In accordance with maintaining quality assurance and the medicine’s efficacy, pharmaceutical industry finds this premade pouch filling machine appropriately suitable. Pharmaceutical manufacturers package and seals their products like liquid syrups and suspensions, powders and pills, medical devices or products using this machine which offers protective sealing integrity and keeps the content safe against contamination. They also need to ensure that the product filled is not underdose or overdose packaged.

Veterinary Industry

Pet food in Premade Pouch – Picture courtesy: Layfield Group

Small and bulk quantities of pet food like dry kibble, treats, wet food are packaged in premade pouches such as zipper closure bags or spout pouches. These packaging types carried by the premade pouch filling machine enables freshness and allows resealable closing option for next use.

Agricultural Industry

Fertilizer pouch packaging

Advancement of technologies have collaborated with agricultural industry finding it’s major use in premade pouch filling machine. This machine is used to fill and pack seeds, fertilizers, and other agricultural products in premade pouches. It can handle effectively heavy bags for bulk filling too. For e.g.: packaging of loose tea leaves or coffee beans.

Cosmetics Industry

Cosmetic product pouch packaging – Picture courtesy: BAO Skincare

Cosmetics industry uses premade pouch filling machines for packaging of their different products such as lotions, creams, powders, wax beans etc. They need to be filled with precision and care in order to ensure that the product delivered to the consumer is free from contaminants and maintains its quality standard.

Chemical Industry

Chemical industry pouch designs- Picture courtesy: WOO Packing

Chemical manufacturers need extreme precautionary measures to package their products for preventing any disaster and delivering it effectively. They utilize this machinery for filling of granular, solid or liquid type chemicals with high accuracy and also following strict cleanliness measures to maintain product’s vitality.

3.What Are the Benefits Of Using A Premade Pouch Filling Machine?

Reading the above heading related to the machine’s industrial applications, you might have noticed how beneficial it is for various sectors of industries. The benefits are not only limited to certain applications, it’s versatile uses are taken advantage of by many manufacturers.

Versatility In Types

Different Types Of Premade Pouches- Picture courtesy: Spackmachine

A Premade Pouch Filling Machine is able to fill and seal many types of pouches such as stand-up pouch, gusseted bags, doypacks, quad seal, fin seal pouches, spout pouches, zipper bags, flat pouches etc. The machine can do this without you having to modify or replace it’s parts.

Options In Sizes

Different Sizes Of Premade Pouches- Picture courtesy: Paxiom

It is efficiently able to handle many sizes of pouches and bags for bulk or small quantity of filling, without the need for changing machine’s parts.

Efficiency

High efficiency premade pouch filling- Picture courtesy: Honorpack

The automated process of filling and sealing cuts down the labor cost and enhances efficiency in working process as no tedious task is required for filling accurate amount of products into the pouches as it is done by the machine itself.

Reduction In Wastage, Deduction in Packaging cost

Controlled Quantity Filling In Premade Pouch – Picture courtesy: Sirane Group

Using a premade pouch filling machine ensures there is no wastage of product as it controls the exact quantity of filling, along with causing deduction in packaging costs.

High Productivity

High Productivity Working Of Premade Pouch Filling Machine – Picture courtesy: Pouch Packaging

This machine does not require forming bags to fill any product , which means it can handle filling of more products at a quicker pace within a minute.

Flexibility

Flexibility In Packaging Line- Picture courtesy: Dairy Foods Magazine

It can be flexibly integrated with any infeed or outfeed conveyor machines and any type of fillers.

Long time Service

Long time service of machinery- Picture courtesy: Lenis

Using excellent quality components of this machine would manage to run the equipment flawlessly for a longer time period.

4.Explain The Working Procedure of A Premade Pouch Filling Machine?

In order to understand the working procedure of a premade pouch filling machine, we have designed the flow chart and explained it for you.

Bag Loading

Bag loading – Picture courtesy: Viking Masek

Bags or pouches are supplied and transferred from the bag stacker or bag magazine area with the help of a pneumatic clamp and moved to the clamping device on rotary table. An operator ensures that bags are fed into bag feeding roller to be conveyed to the machine.

Bag Gripping

Bag Gripping – Picture courtesy: Viking Masek

When the vacuum bag loader picks up this bag upon detection by proximity sensor, bag grippers holds the bag to be transported around the rotary stations. These grippers can hold weights upto 10 kg.

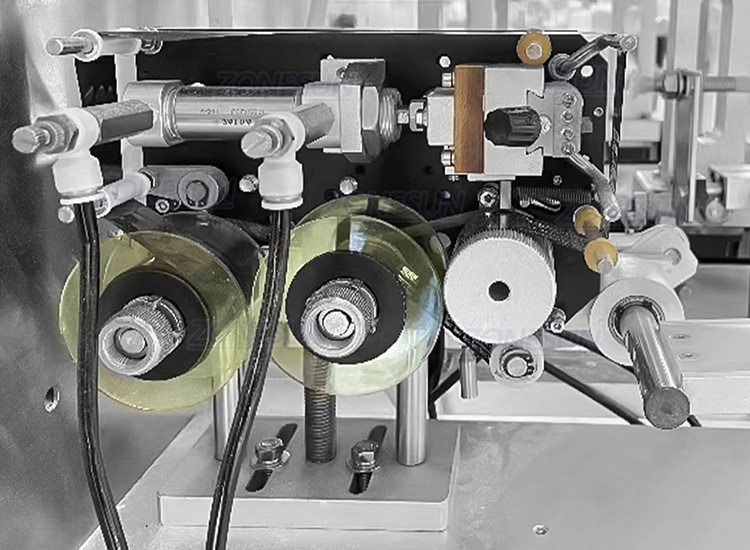

Date Coding

Printing/ Date embossing

The suction cup picks up the bag from rotary table when it falls down and the production date, expiration date, batch number and any other details that needs to be printed is coded on the bag . Either ink jet coder or thermal transfer coder are used as printer options.

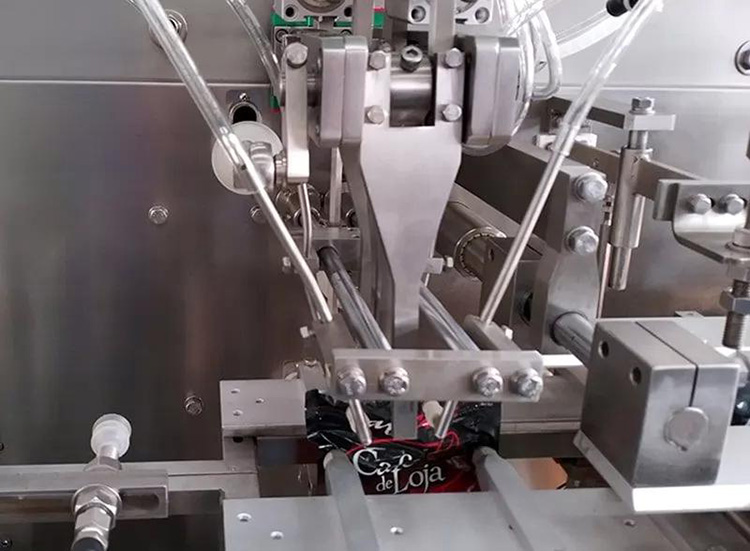

Bag Opening

Bag Opening – Picture courtesy: Makwell

With the use of suction cup (that are present on top and bottom of the bag), the bags are opened. A sensor detects whether the pouch is properly opened or not and if it is incorrectly opened, it won’t be transferred further for filling.

Gas Flushing

Nitrogen Gas flushing

This step is an optional one which some manufacturers might choose as per the requirement of their product. Gas flushing is also known as Modified Atmosphere Packaging or MAP. If the product needs to be shelf life stable, gas like nitrogen is flushed into the bag which displaces oxygen and serves to preserve the product’s quality and freshness (such as food items).

Weighing and Filling

Weighing and filling – Picture courtesy: Landpack Packing Machine

Those products that needs to be filled with precision in weight and quantity are measured by using a multi-head combined weigher. The turntable rotators will move and transfer these bags directly to feeding station below the feeding hopper where the valve will be opened and product will descend down straight into the bag. Type of filler chosen depends upon the type of product. If it is powder, auger filler is used. Liquid products are pumped into the pouches with help of liquid piston filling nozzle. Granules can be filled using multi-head scales or linear scales. Sometimes the pouch is also moved to a secondary spare station for second time filling if required to do so.

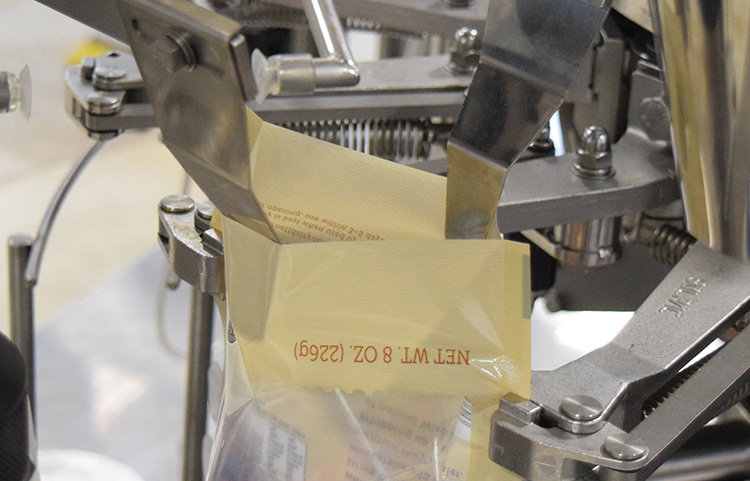

Heat sealing

Sealing Of Premade Pouch – Picture courtesy: Rotarypack

The bags are moved to the sealing station where it will be sealed at a constant high temperature twice, as a preheat sealing step the pouch mouth will be sealed and if no pouch is detected no sealing will be performed.

Forming and discharge:

Forming and discharge - Picture courtesy: Echo Machinery

The pouch can now be shaped or punched, and the gripper will release it to the conveying device.

5.What Are the Different Types Of Pouches That Are Made Using Premade Pouch Filling Machine?

Premade Pouch Filling Machine

Premade Pouch Filling Machine can make such sealable bags which are preformed and just ready to be filled and further packaged.

| Types Of Pouches | Description |

| Stand Up Pouches

Stand-up Pouch design |

One of the most popular forms of premade bags is the stand-up pouch which grabs consumers attention due to it’s unparalleled shelf display along with providing safety to the product that is filled inside. Stand-up pouches have zipper closure, spouted closure or window feature which allows easy usability option. It is bottom gusseted which can stand up on its own and hence its name. Applications that find uses of this pouch are confectionery and food products, dry fruits, pet food, cosmetics, chemical products and some condiments too. |

| Flat Pouches

Flat Pouches design – Picture courtesy: VistaPrint |

Economically they are ideal and efficient as these flat pouches can be sealed without gussets and thus save time and cost. Flat pouches as the name indicates are more pronounced as pillow pouches and are available in different sizes and shapes. They can be used to fill wide variety of products including food and non-food items. |

| Gusseted Bags

Gusseted pouch design |

Gusseted bags are premade pouches that have two side seals ,flat bottom and a centrally running back seal. This allows the bag to be more spacious and stand on the shelf for consumer display. They provide excellent sealing strength and keep the product safe. These pouches are available in many dimensions and can be fit for filling of food products, chemicals, agricultural products etc. |

| Quad seal pouches

The Bag Broker Uk Quad Seal Pouches |

Similar to gusseted bags in shape and structure, quad seal pouches are sealed from four sides by each corner of the pouch. It enables good shelf display allowing heavier products packaging and can support various sizes. They are available as premade pouches which can be used for many applications.

|

4 Side Sealed Pouches

4 side seal pouch - Picture courtesy: Guiacalles.com |

Four side sealed pouches are sealed from three sides first and when the product is filled and ready for packaging it is sealed from top as well , closing it securely. Available as premade pouch, it serves purposes of light weight products filling usually in food industry and cosmetics industry. |

Zipper Pouches

Zipper Pouches design |

Pouches are premade with resealable zipper closure feature , either in stand-up bag design or gusseted bags design. They provide freshness to the product and preserve it against environmental conditions. It is mostly used by food industry.

|

6.What Are The Material Applications Of A Premade Pouch Filling Machine?

Premade Pouch Filling Machine- Picture Courtesy:weighpack

Materials that can be filled using a premade pouch filling machine are:

| Solid | Packaging and filling of products like candies, toffees, dry fruits like peanuts, pistachios, almonds, cashew nuts, and green beans, puffed foods. |  |

| Granules | Rice grains, granular medicines, condiments like whole spices chemical fertilizer, seeds, granulated sugar, feed. |  |

| Powders | Condiments like powderous form of spices, salt, sugar, milk powder, detergent powder, grain powder, corn powder, flour and many other powder forms of material. |  |

| Liquids | Filling and packaging of various sauces like soy sauce, rice vinegar, drinks and beverages, liquid detergents, chemicals. |  |

| Sauces | Thick paste forms of sauces like hot sauce, chili sauce, ketchup, mayonnaise, peanut butter, chocolate sauce, bean paste. |  |

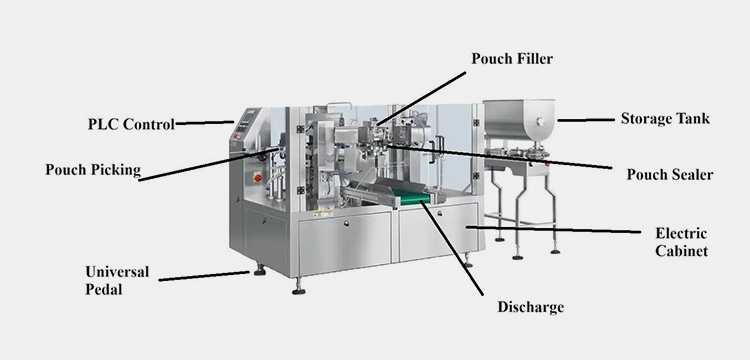

7.Describe The Structure of A Premade Pouch Filling Machine?

PLC Control: A touchscreen programmable control machine that can set parameters of functioning and control the working process of whole machinery.

Pouch Picking: This is the first step in the premade pouch filling process which is conducted by pouch grippers that is driven by a servo motor. These grippers holds the top of the pouch and deliver it to the pouch opening suction cups which opens up the pouch for further filling.

Pouch Filler: Here, the type of filler you have selected for your particular product would fill the required product after accurate weighing into the pouch and transfer it further to sealing station.

Pouch Sealer: Ultrasonic heat or heat seal methods will be applied using this pouch sealer which will seal shut the pouch opening. Additionally, if you require dates or codes to be embossed are applied after sealing on the sealed area.

Storage Tank: This holds the supplies of filling material that will be filled into the pouches.

Electric Cabinet: All the electrical wires, circuits and devices are located here safely inside this cabinet.

Universal Pedal: It protects the machine from getting any high voltage current as it has rubber insulated bottom support as a regulating component.

Discharge: This is the discharge station, where all the premade pouches that have been filled and packaged are delivered for dispensing or output.

8.What Are The Different Types Of A Premade Pouch Filling Machine?

There are two types of premade pouch filling machine which can be modified according to different types of fillers and used as per the requirement of your product. You will see them below.

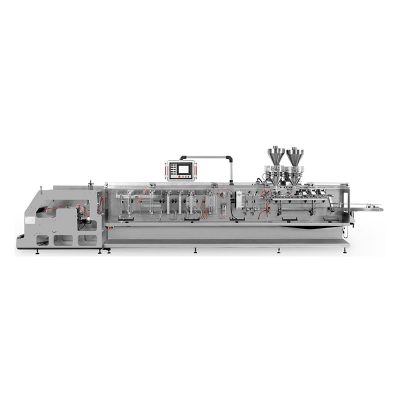

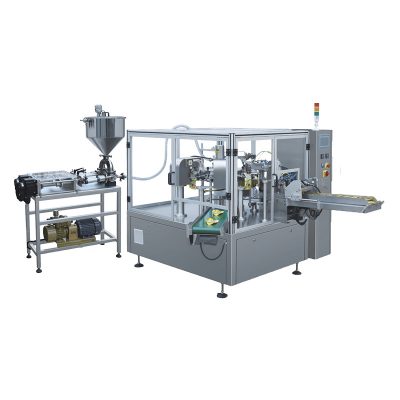

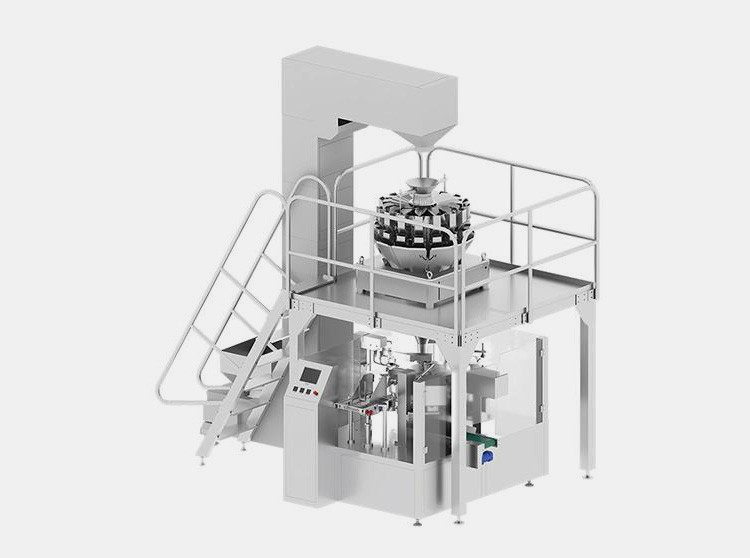

Rotary Premade Pouch Filling Machine

Rotary Premade Pouch Filling Machine – Picture courtesy: Xhteapack

A rotary Premade Pouch Filling Machine offers high efficiency and great speed filling and sealing of multiple pouches via a rotation turret . It offers to be an ideal equipment for those industries requiring high output production.

This machine has another variant model called as vacuum rotary premade pouch filling machine. It has an additional step of vacuum sealing and the remaining working and structure of the machine remains same. It find it’s suitable applications in packaging of powders, cereal, coffee beans, tea leavesand other liquid products. It is very competent and can handle filling of various styles of pouches such a as doypacks, flat pouches, zipper bags, gusseted bags, and quad seal pouches.

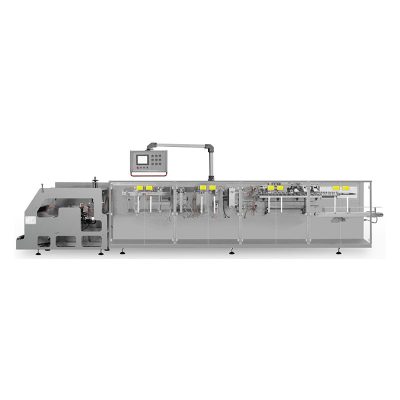

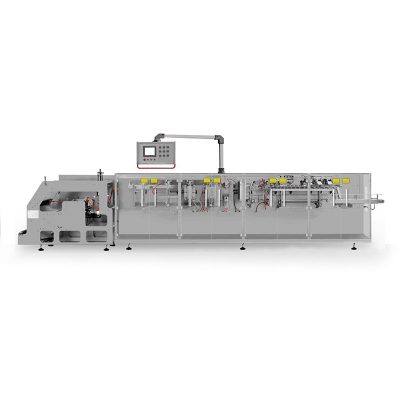

Linear/ Horizontal Premade Pouch Filling Machine

Horizontal Premade Pouch Filling Machine – Picture courtesy: Xhteapack

Linear Premade Pouch Filling Machine or also known as Horizontal Premade Pouch Filling Machine has a linear working structure, with a straight conveyor where the pouches move along for the process of filling and sealing, one at a time. This makes it more compact and suitable for small production setups.

A horizontal Premade Pouch Filling Machine can fill up to 30-50 bags per minute depending upon your product type and it’s weight. The products can be filled using any type of filler such as volumetric filler, multi-head filler or auger filler. It can handle multiple pouches at a time of various styles whether it is stand-up pouch, gusseted pouch, flat pouch or quad seal pouch . Usually food and agricultural industry finds it’s application in using it.

9.What Are the Problems Faced By A Premade Pouch Filling Machine and how is it troubleshoot?

| Problems | Causes | Troubleshooting |

| Pouches not being loaded properly

Pouches not loading-Picture courtesy: Viking Masek |

Pouches were not fed into the bag magazine properly due to: Blockage by any foreign body in the hose. Trouble in air valve. Vacuum generator problem or vacuum pad breakdown. Sensors have dirt on it. |

Ensure that there is adequate supply of pouches in the bag magazine and that they are being properly fed whether it is manually or via a robotic arm. Clean and maintain the hose and sensors and replace the vacuum part if it’s damaged. |

| Pouches are not opening after loading

Pouches not opening – Picture courtesy: Viking Masek |

The pouches loaded might be sagging or not gripped properly. Trouble in air valve. Filter causing error. Vacuum pad breakdown |

Timings set through the PLC might be incorrect. If the filter is causing error it needs to be changed. Air valve must be cleaned and maintained. Vacuum pad must be replaced or changed. |

| Defects in sealing

Pouch sealing defect- Picture courtesy: K-Flex Packaging System |

Packaging might result in defected weak or wrinkled sealing possibly if: Sealing bar temperature is too high. Sealing bar pressure is not accurate. Surface of sealing bar is unclean or has dirt on it. Pouches are not gripped properly. |

Check whether the heater temperature is set in the specified range or not and also check it’s pressure. Proper cleaning must be done of working parts of the machine so that dirt doesn’t hinder in the process. |

10.What Factors Should Be Considered While Buying A Premade Pouch Filling Machine?

Premade Pouch Filling Machine

Before purchasing a premade pouch filling machine, there are many things which you must take note of and consider those factors if you want to avoid the hassle or confusion. What shall be those factors which you must know? Read below to get insights!

11.How fast does the machine produce bags per minute?

Fast production of pouches

Deciding at what speed your machine will be producing bags per minute will also decide how productive your working process would be and how quick you want to get the output of filled and packaged goods! There are machines that can pack 20 bags per minute and then there are machines that can even pack 200 bags per minute! Moreover, this can also be customized if you want a speedier response.

12.How can this machine be integrated with my existing equipment?

Machine integration -Picture courtAAesy: Viking Masek

You might have read above what different equipment’s can be incorporated with a premade pouch filling machine. A good and beneficial packaging line can be constructed including this machine if you contact a best professional equipment provider that would surely design as per your needs.

13.What will be the cost of the machine and How will it give good returns on investment?

A premade pouch filling machine with a good revenue

Considering buying cost is important too, so that you will have an idea to open a large scale or small scale setup based on the selection of type of premade pouch filling machine you are going to choose for your industry. Selecting an integrated packaging line with fulfilling all of your manufacturing requirements will cut down on your extra costs and also improve efficiency.

Conclusion

A premade pouch filling machine serves to have productive and efficient working output as it saves time and cost rather than requiring making pouch packaging out of a roll film. It has three types of machine models which have different specifications and can suit according to your different needs. Whether you have a small scale setup or a large manufacturing company you can find the right choice for your industry by going through our buying guide that our experts have carefully designed for you. Allpack manufacturers have experience of several years in providing industrial equipment’s, just per your needs! You can feel unhesitant to contact our team, to give you an expert advice and we promise you won’t regret because of our helpful and friendly staff.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586