Your Best Tablet Press Machine Manufacturer

- Electronic Control System

- Twice Compression Forming

- Mechanical and Electrical Integration

Tablet Press Machine

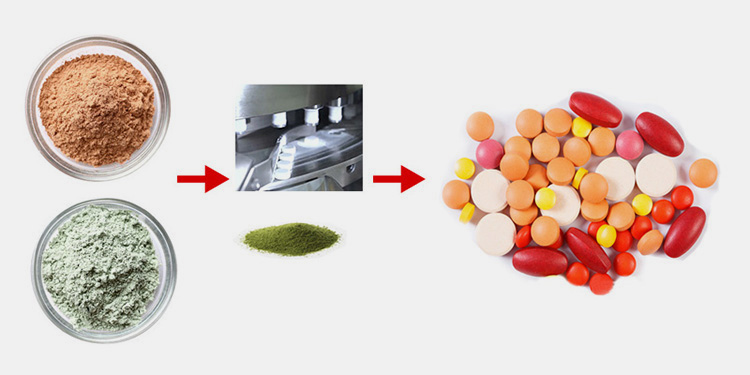

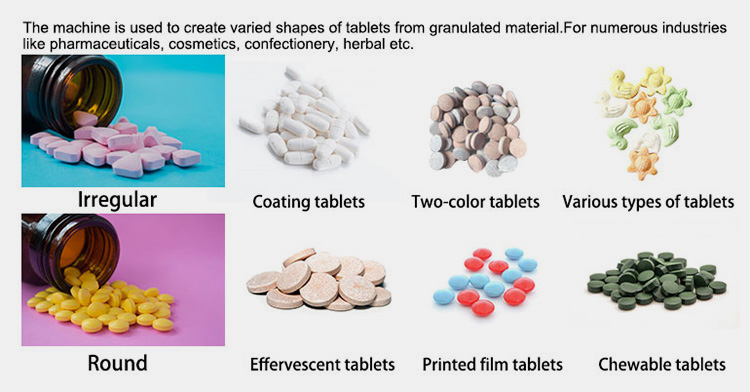

If you are looking for a machine to compress your powders or granules into uniform size and weight of tablets,a tablet press machine may very well suit your needs.A tablet press machine can be used to manufacture a wide variety of materials,including pharmaceuticals, nutraceuticals, cleaning products and cosmetics into tablets. To form a tablet, the granulated material must be metered into a cavity formed by two punches and a die, and then the punches must be pressed together with great force to fuse the material together.All tablet press machine has the same basic principe of compression.The most critical part of the tablet press machine is the tooling that consists of two punches and a die called a station.The upper and lower punches come together in the die that contains the tablet formulation.

Tablet Press Machine

China Unique Compressed Biscuit Making Equipment Zpw-4 Rotary Compressed Block Press Machine

Allpack ZPW-4 rotary compressed block press machine is dedicated for manufacturing civilian hard stacks. The manufacturing process for hard stack is subdivided into five sections, biscuit forming, flour applying, mixing, pressing and packing. In the manufacturing course, biscuit compressor is the key device for pressing.This rotary tablet press is a type of food machinery, which is used to produce compressed biscuits for military and civilian use. Compressed biscuit production involves five main processes, that is, biscuit baking, powderizing, mixing, compressing and packaging. The rotary tablet press plays an important role in making compressed biscuits.

Full automation

Military and civilian compressed cookie machine

Hard bread biscuit making machine

Gzps Series 660 Automatic High Capacity Press Machinery Intelligent Tablet Press Machine

Allpack GZPS series 660 tablet press machine is one kind of double side rotary tablet press machine, which can press granular materials into round shape tablet, irregular tablet or double-side engraved tablet. This machine is mainly used in pharmaceutical, chemistry, foodstuff, electronic industries.The machine adopts advanced operation system and tablet weight control system, adjust each operation parameter (main pressure, pre-pressure and filling depth) easily without handwheel. Effective detecting and adjusting for tablet hardness and weight is achieved.GZPS660 Model can record all the process parameters for each production batch, it is convenient for operator to control the machine.

High speed with large quantity punches

Perfect tableting system, twice compression forming

Reliable electronic control system

ZP25 effervescent rotary tablet press machine for Pharmacy

Allpack ZP25 effervescent rotary tablet press machine is a double-pressing automatically resolving piece-pressing machine which could make grain be pressed to be round piece, be carved characters, special shapes and double color piece prescription. It is mainly used in manufacturing piece prescription for pharmacrutical industry enterprises like chemical industry, food, eletronics.The cover of this tablet press machine is made of stainless steel with close type.The inner tablet surface is also made of stainless steel materials which could keep surface luster and prevent from cross pollution, meets GMP requirement. This rotary tablet press is primarily composed of mechanical structure, hydraulic system.

Adjustable pressure

Mechanical and electrical integration

Enclosed compression area

ZP5/7/9 High Speed Automatic Rotary Tablet Press Pill Presser Tablet Press Machine

Allpack ZP5/7/9 rotary tablet press machine is a single-press type tablet press machine. It can rotate automatically and press tablet continuously. It makes the granular materials into tablets. It is suitable for laboratory and produce that needs small production capacity.Equipped with plexi glass perspective window which could help to observe the status of pressing piece. Side blank could be fully opened, easy to clean and maintain. All monitors and operating components are in good order. Applying with frequency changing, speed regulating apparatus to do electricity regulation. The convenient operation and smooth revolving are safe and correct.

Reliable safety sealing system and dust-proof system

High visibility isolated door to prevent cross contamination

Easily remove parts for quick machine's maintenance

The Buyer's Guide

Tablet Press Machine: The Complete FAQ Guide In 2025

Are you tired of the manual process involved in creating tablets from raw ingredients? Do you wish to increase your production speed and capacity without sacrificing quality? Well, worry no more! The answer lies with a tablet press machine.

This revolutionary piece of equipment can drastically reduce manufacturing times and costs while ensuring that every single tablet produced is exactly the same as its predecessors. With so many innovative technological advances available on the market today, it can be difficult to determine which type of tablet press machine is right for your business needs.

In this blog post, we’ll provide an overview of tablet press machines, discuss their features and benefits, explore the different types of machinery available, and provide guidance on how to select a machine that is best suited for you. Through exploring all these aspects in detail we hope you can gain some clarity when making an investment in a new or used tablet press machine!

1.What Is A Tablet Press Machine?

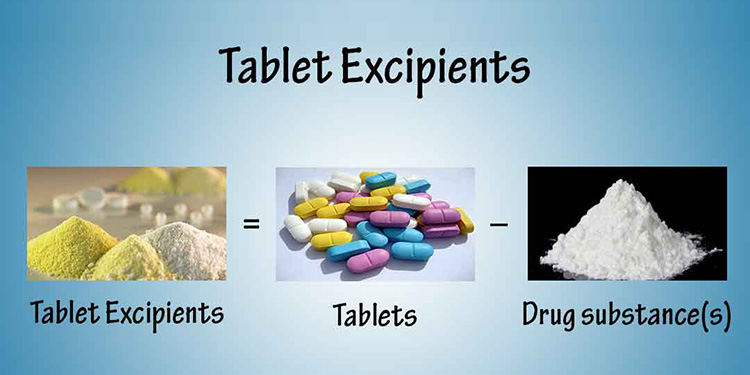

A tablet press machine is a specialized device that compresses fine powders into tablet form. The tablet press compresses the powder between two punches, which can be either smooth or grooved. Tablet presses are commonly used in pharmaceutical and food production to form various sizes of tablets.

Tablets are typically made from sugar, granules, fillers, and binders. Tablet presses are designed to provide consistent tablet size and shape with every tablet produced. The tablet press also provides adjustable tablet weight and varying tablet thickness that can be customized according to product requirements.

Furthermore, tablet presses offer features such as variable filling depth and pressure control which helps in controlling the tablet production process. Tablet presses are also used in chemicals, cosmetics, and nutraceuticals to produce tablets in various shapes, sizes, and weights.

2.What Are The Components Of A Tablet Press Machine?

Hopper

This is a component of the tablet press machine which holds the raw material that will be compressed into tablets. The hopper has an adjustable opening to allow the desired amount of powder to enter the tablet press tooling.

Auger Feeder

This component allows accurate and consistent material dosing into the tablet press tooling. It can feed powder at an adjustable rate controlled by a frequency drive to ensure that the desired powder enters the tablet press machine.

Compression Rollers

These components pressure the tableting die to compress the powder into tablets. The compression rollers are located at the top of the tablet press machine and can be adjusted to provide the desired tableting force.

Tableting Die

This component shapes the tablet into its desired shape and size. It consists of a die cavity filled with powder by an auger feeder and then compressed by compression rollers to form a tablet.

Turret

The turret is a component of the tablet press machine that holds the tableting dies. It rotates to move the tableting die from one station to another during operation, allowing for the efficient production of tablets.

Tablet Discharge Chute

The tablet discharge chute is responsible for transporting the tablets from the tablet press machine to a collection bin or tablet counter. It consists of a curved tube that directs the tablets downward into the desired location.

Tablet Counting System

This component counts and weighs tablets discharged from the tablet press machine. It can read the tablet weight and reject tablets that do not meet the desired tablet size and weight specifications.

Control Panel

The control panel controls all the tablet press machine’s functions and parameters. It allows you to adjust the settings on the tablet press machine to achieve optimal tableting performance.

Motors

The tablet press machine is powered by electric motors, which provide the necessary power for the tablet press to operate. The control panel controls these motors to adjust speed and force during tableting operations.

Tooling

This component consists of a tablet punch; tablet dies, tablet rollers, tablet blanking die, and tablet ejection system are all required for the tableting process. The tooling is responsible for forming the tablet from powder and then ejecting it from the tablet press machine.

3.What Are The Advantages Of A Tablet Press Machine?

A tablet press machine has a wide range of advantages. Here are some:

Increased Productivity

Tablet press machines are designed to handle high tablet production volumes quickly and accurately. This increases tablet output, increasing productivity, and better profitability for tablet manufacturers.

Reduced Labor Costs

Tablet press machines offer increased automation and reduce the number of workers needed to complete tablet production, leading to savings in labor costs.

Improved Efficiency

Automating tablet production with a tablet press machine can significantly improve efficiency compared to manual tablet production processes. This improved efficiency allows for faster and higher quality tablet production.

Increased Accuracy

Tablet press machines offer precise control over tablet size, shape, and weight, allowing tablet manufacturers to produce more consistent tablet products.

Cost Savings

Since tablet presses offer higher productivity, improved accuracy, and increased safety, tablet manufacturers can save money in the long term. Tablet presses are also fairly easy to set up and use, which can result in further cost savings.

4.What Are The Applications Of A Tablet Press Machine?

Pharmaceutical Industry

Tablet press machines are used to produce tablets for medicinal purposes, including vitamins, supplements and drugs. The machine can precisely control the tablet hardness, size and shape to ensure that it meets industry standards.

Cosmetic Industry

Tablet presses are also used in the production of cosmetic products such as creams, gels and powders. The tablet press can precisely control tablet size, hardness and shape to produce a consistent product.

Food Industry

Tablet press machines are also used in food manufacturing for producing candy, chocolate, gummy candy and other products. The tablet press can control the tablet’s size, shape and strength to ensure that it meets food safety standards.

Veterinary Industry

Tablet press machines are used to create tablets for veterinary applications. In this case, tablet production is often focused on tablet shapes and sizes that fit the anatomical structure or digestive system of animals. This allows for optimal absorption and efficacy of the tablet’s active ingredients.

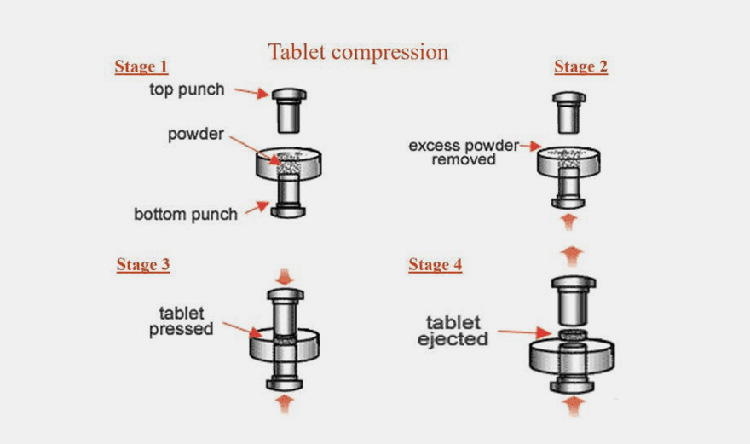

5.What Are The Working Principles Of A Tablet Press Machine?

The tablet-forming process involves several stages, each of which relies on the working principles of the tablet press machine.

First, all ingredients are weighed and loaded into the hopper, or feeder bin, at the top of the tablet press machine. This hopper is sealed, and a tablet dies inserted into the tablet press chamber.

Next, the tablet press lever is actuated to fill the tablet die with powder from the hopper. The amount of powder fed into each tablet die can be adjusted through settings on the tablet press control panel. Once filled, the tablet die is sealed, and the tablet compression force is applied to form tablets from the powder.

The tablet press applies pressure in two steps: pre-compression and main compression. During pre-compression, a relatively low compaction force is used to reduce the porosity of the tablet granules. This creates a more uniform tablet shape and tablet hardness. A higher compaction force is applied during the main compression to reduce tablet porosity further and form the desired tablet shape.

When the tablet press lever is released, the tablet die is unsealed, and tablets are ejected from the tablet die into a collection bin. The entire process is repeated for each tablet production batch until all ingredients are used.

6.Is There Any Customization For Tablet Press Machines?

Tablet press machines are highly customizable and can be tailored to meet the needs of tablet manufacturers. Tablet presses come with various features, such as interchangeable tooling systems, pre-programmed tablet shape and size settings, adjustable tablet hardness settings, automated batch tracking systems, high-speed tablet ejection systems, and more.

Some tablet presses even allow tablet weight and size accuracy to be adjusted. Tablet manufacturers can customize tablet press machines to produce tablets with specific shapes and sizes, as well as tablet hardness levels.

Additionally, tablet presses can produce tablet batches in various colors, flavors, and coatings. With this level of customization, tablet press machines are an ideal solution for tablet manufacturing needs.

7.What Are The Different Types Of Tablet Press Machines Available On The Market?

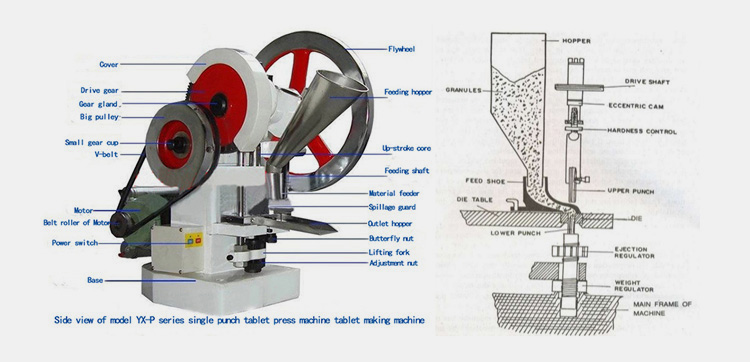

a) Single-Punch Tablet Press Machines

These tablet press machines are the most common type of tablet press machine available on the market and are used for pressing tablets from a single die cavity. They usually come with two or four tooling stations, offering a wide range of tablet sizes and shapes.

Components

Hopper

This unit holds the powder material and dispenses it into the die cavity.

Turret Disc

This is a rotating disc on which tooling dies are mounted. The single-punch tablet press machine turret typically has 12 or 16 stations with sizes ranging from 5/8″ to 2″ in diameter.

Single-Punch Tablet Press Machine Head

This unit houses the turret disc, tooling dies, and punches used to form a tablet from powder material by applying pressure.

Compression Rollers

These two or four rollers compress the granulated material in the die cavity from either side to form a tablet.

Ejection Mechanism

This is used for ejecting tablets from the single-punch tablet press machine and consists of an ejection system that can be either manually operated or have automatic ejection capabilities.

Tooling Dies and Punches

These are the components that form the tablet from powder. Single-punch tablet press machines typically use a round die and punch to form tablets. Other shapes can be formed with special tooling dies and punches.

Control Panel

This is used for controlling all single-punch tablet press machine parameters such as tablet size, thickness, weight, etc. It also includes safety features to ensure that the single-punch tablet press machine is operated safely and efficiently.

Lubrication System

This ensures that all single-punch tablet press machine moving parts, such as tooling dies, punches, and compression rollers, are adequately lubricated for the proper functioning of the single-punch tablet press machine.

Seals and Gaskets

These are used to ensure that all parts of the single-punch tablet press machine are airtight and contamination-free. They are also responsible for maintaining pressure inside the single-punch tablet press machine during operation.

Electric motor

This is used to power the single-punch tablet press machine and rotate the turret disc. The electric motor typically ranges from 0.5 to 5 hp depending on the single-punch tablet press machine size, capacity, and type of material being processed.

Working Principles

The process starts by filling the hopper with the desired powder feed material. The feed materials are then transferred to the die table. This is when the punch, connected to a drive mechanism, descends and compresses the material in the die table into a tablet of specific thickness and weight.

Finally, an ejector pushes the tablet out of the die table. The whole process can be monitored and adjusted by using the control panel on the single-punch tablet press machine. This allows for the precise control of each tablet produced.

Applications

Single-punch tablet press machines have become a popular choice for the pharmaceutical industry, where they are used to produce tablets for prescription and over-the-counter drugs.

Also, these machines are used in the nutraceutical industry, where they are used to produce tablets containing vitamins and other dietary supplements.

Moreover, single-punch tablet press machines are also used in the food industry, where they are used to create chocolates and candy tablets

b) Multi-Punch Tablet Press Machines

These tablet press machines are designed to press tablets from multiple die cavities and offer a higher tablet output than single-punch tablet presses. They usually come with four, six, or eight tooling stations, capable of making larger tablet sizes and shapes.

Components

Multi-punch tablet press machines contain a variety of components, including:

Punching Mechanism

This includes the die rollers, feeds and other mechanisms used to punch or form tablets from materials such as powders, pellets, or granules.

Feeder System

This consists of various feeders, such as hoppers and augers, which are used to insert raw materials into the multi-punch tablet press machine.

Unscrambler

This device helps align tablets before they reach the tablet press. It ensures the tablets are properly aligned to be accurately pressed into shape.

Tablet Counter

This device is used to count the number of tablets that have been pressed.

Safety System

Multi-punch tablet press machines have safety features such as emergency stops, guards, and alarms that help prevent the machine’s accidents or malfunctions.

Control panel

This component contains all the operating buttons, dials, and switches used to control the multi-punch tablet press machine.

Compression Rollers

This refers to the rollers that compress raw materials into the desired shape and size of the tablet before they are pressed.

Dust Extractor

Multi-punch tablet press machines come with dust extractors that suck up any dust or debris released during the tablet pressing process.

Tablet Ejection System

This system helps eject tablets from the multi-punch tablet press machine after they are pressed.

Lubrication System

Multi-punch tablet press machines also contain an automated lubrication system that ensures all parts run smoothly without wear and tear.

Working Principles

The multi-punch tablet press machine uses a combination of pressure and dies cavities to form the desired shape and size of the tablet. These machines have four main components: a feed frame, punch head, upper and lower punch set, and a die table.

The feed frame holds the desired powder, which is then fed into the punch head through an inlet port. Inside the punch head, a rotating arm rotates to move the upper and lower punches, which compress the powder together.

Once the correct pressure has been applied to the powder, it is moved to the die table. Here, the powder is pressed into a die cavity of the desired shape and size using specialized punches. The tablet is then ejected via an outlet port from the multi-punch tablet press machine.

Applications

Multi-punch tablet press machines are commonly used in the pharmaceutical industry to produce various medications and supplements. Also, multi-punch tablet press machines are used to create various products for the food, chemical, and cosmetic industries. Moreover, these machines can produce candy, cake decorations, other food items, shampoos, cosmetics, and cleaning products.

c)Rotary Tablet Press Machines

This type of tablet press machine is designed to produce high tablet output with minimal manual operation. It consists of multiple tooling stations arranged circularly and can press tablets from single and multi-die cavities.

Components

Rotary Tablet Dies

These are the shape-forming dies used for forming individual tablets. They come in different shapes and sizes, depending on the tablet’s manufacturing type.

Upper and Lower Punching Tool

This is a set of tools that punch into the rotary tablet dies to form a tablet. The upper and lower tools can be adjusted to shape the tablet according to specifications.

Rotary Table

This turntable holds the rotary tablet dies in place and rotates them as the upper and lower punching tools punch them.

Motor

This electric motor powers the rotary table, allowing it to rotate at the desired speed.

Feeder

This device feeds powders and other materials into the rotary tablet dies to form tablets.

Control Panel

This control panel enables the operator to control all aspects of the rotary tablet press machine, including the speed of the rotary table, the pressure of the upper and lower punching tools, and the amount of material to be fed by the feeder.

Safety Guards

These safety devices protect the operator from moving parts or debris generated by the operation of rotary tablet press machines.

Waste-Eject System

This system ejects any excess material or waste generated by the rotary tablet press machine, ensuring that no excessive powder buildup occurs in the rotary tablet dies.

Dust Collector

This device collects dust and other debris created during the operation of rotary tablet press machines, ensuring a clean and safe working environment.

Working Principles

A rotary tablet press machine consists of two main parts – the die table, where the tablet is formed, and the upper punch head, which applies pressure to form the tablet. The machine forces granules through a die hole in a rotating motion, producing a flat, round tablet. The granules are first blended with the desired additives and binders.

This mixture is then placed into the die table, which is compressed by the upper punch head to form the tablet. Once the desired tablet shape is obtained, the rotary tablet press machine continues to rotate at a set speed until all tablets have been compressed in the die table. This process is repeated until the desired number of tablets has been created.

Applications

Rotary tablet presses are commonly used in the pharmaceutical industry to create pill forms of medication and in the food and nutraceutical industries to produce supplements and other products.

d) Flower Basket Press Machines

Flower basket press machines are specialized machines used to produce flower baskets and other products made of pressed flowers. Flower basket presses help create intricate, sealed flower arrangements and other products, preserving the beauty of the blooms for years to come.

Components

Here are some of the components of a flower basket press machine.

Flower Basket

This is the main component of flower basket press machine, which is used to hold the flower baskets that are being pressed.

Flower Basket Press Plates

These are the metal plates that surround and fit into the flower baskets in order to compress them.

Flower Basket Press Hydraulic System

This is the hydraulic system which applies pressure to the flower baskets and helps keep the baskets in place during the pressing process.

Flower Basket Press Motor

This is the motor that powers the flower basket press machine and helps it function properly.

Flower Basket Press Control Panel

This is the control panel which allows the operator to set and monitor the Flower Basket Press Machine’s settings and parameters.

Flower Basket Press Safety Features

These are various safety features built into the Flower Basket Press Machine, such as emergency stop switches, safety guards and covers, which help ensure that the Flower Basket Press Machine is operated safely.

Working Principles

Flower basket press machines use a combination of heat, pressure, and a special press to form the petals and leaves into the desired shape. The flower basket press machine first begins by heating up the flower petals and leaves using a heated platen.

Once the petals are heated, they are then pressed between two plates of the flower basket press machine. The pressure of the flower basket press machine, which is usually adjustable, helps to form the petals and leaves into a uniform shape.

After the flower basket press machine has formed the petals and leaves into their desired shapes, they are then allowed to cool down before being removed.

Application

Flower basket press machines are commonly used in the flower industry to create beautiful and unique baskets. The machines can be used to press a variety of materials, such as paper, fabric, and plastic.

Flower baskets are often used in floral arrangements or to add decoration to a room. In addition, these machines are also used to create potpourri baskets, which can be a great gift for friends or family.

Flower basket press machines are easy to use and can be used to create unique gifts for any occasion. Flower basket press machines are also great for creating floral arrangements for special occasions, such as weddings or anniversaries.

e) Effervescent Tablet Press Machines

Effervescent tablet press machine is a type of machinery used for producing effervescent tablets. It is mainly used in the pharmaceutical industry to produce effervescent tablets, which are a type of drug that helps to treat various ailments. Effervescent tablets are made by mixing active ingredients with effervescent components such as sodium bicarbonate, citric acid and tartaric acid.

Components

Upper Punch Assembly

The upper punch assembly is the part of an effervescent tablet press machine that forms tablets by pressing powders through a die. It consists of an upper punch, lower punch and collar that are used to compress the powder into the tablet form.

Feeder Hopper

The feeder hopper is the area of the effervescent tablet press machine that contains raw material powder. The feeder hopper regulates the dosage of powder that is fed into the machine.

Tableting Chamber

The tableting chamber is the area of the effervescent tablet press machine where the powder is compressed into tablets. The tableting chamber contains a die and upper and lower punches.

Die

The die is the part of an effervescent tablet press machine that shapes and forms the tablets. It also determines the size and shape of the tablets.

Tablet Ejector

The tablet ejector is the part of an effervescent tablet press machine that ejects the tablets from the tableting chamber after they have been formed.

Discharge Chute

The discharge chute is the part of an effervescent tablet press machine where the formed tablets are transferred from the tableting chamber to a container.

Drive Mechanism

The drive mechanism is the part of an effervescent tablet press machine that provides power to the upper and lower punches. It consists of a motor, gearbox and other components.

Control Panel

The control panel is the part of an effervescent tablet press machine where the user can set parameters and monitor the machine’s performance. It consists of buttons, knobs and a digital display screen.

Working Principles

The effervescent tablet press machine uses pressure and temperature to compact the powder into tablet form. The process begins by adding the ingredients into a hopper. The powder is then fed into a die by an auger feeder, where it is compacted under pressure.

The pressure and temperature are adjusted based on the hardness of the tablet being produced. After the desired tablet size is achieved, they are then ejected from the die.

Applications

Effervescent tablet press machines are used in the pharmaceutical and food industries, primarily for the production of effervescent tablets. These machines are also used to produce sugar-coated tablets, chewable tablets, and other specialty tablets.

8.What Type Of Materials Can Be Used By A Tablet Press Machine?

A tablet press machine can be used with a variety of materials, including powders, granules, and pastes.

Powders

Small particles or crystals that have been ground into a fine dust are the most common type of powder used in tablet presses. This includes ingredients such as APIs, fillers, binders, and excipients.

Granules

These are a mix of various particles that range in size between 0.2mm to 4mm, which can be either spherical or irregularly shaped. This includes ingredients such as sugar, starch, salts, and tablet coating materials.

Pellets

Pellets are usually composed of a mixture of excipients, active ingredients and other materials that can be compressed into tablet form.

9.Which Type Of Products Can Be Produced Using A Tablet Press Machine?

A tablet press machine can be used to produce a variety of products, including:

Pharmaceutical Tablets

A tablet press machine is typically used in the pharmaceutical industry to form compressed tablets. This process is often referred to as tablet compaction.

Dietary supplements

Tablet presses are commonly utilized for producing dietary supplements and nutraceuticals.

Cosmetics

In the cosmetics industry, tablet presses are used to produce tablet forms of creams and lotions. Other cosmetic products can also be produced using tablet presses.

10.What Are The Safety Measures Taken When Using A Tablet Press Machine?

- Always wear safety glasses when working on tablet press machines: Safety glasses should be worn at all times to protect the eyes from dust particles or other flying debris that may occur during tablet pressing operations.

- Never operate a tablet press without proper training: All tablet press operators should have had prior instruction on how to safely use tablet presses before operating one. This includes being familiar with all safety procedures, as well as understanding the tablet press’s specific operational capabilities.

- Ensure that all safety guards and panels are in place: Before operating tablet presses, make sure to check that all moving parts are covered by safety guards and panels. This will help to prevent accidental contact with these areas while they are in operation.

- Check tablet press controls before use: Always be sure to check tablet press controls and settings prior to tablet pressing operations. This includes checking the tablet weight, tablet size, tablet speed, and other tablet settings.

- Use caution when clearing any jams or blockages: If a tablet jam or blockage is encountered while operating tablet presses, it should be cleared with caution. This can help to minimize the risk of injury or damage to tablet press components.

- Avoid operating tablet presses when under the influence of drugs or alcohol: Operating tablet presses while under the influence of drugs or alcohol may significantly increase the risk of injury, as well as impair judgement and concentration.

- stop tablet pressing operations if any unusual noise or vibration is heard: Unusual noises and vibrations can indicate a malfunctioning tablet press. If these are encountered, tablet pressing operations should be stopped immediately and the machine checked by an experienced technician.

- Set tablet pressing force according to tablet specifications: Tablet pressing forces should always be set according to the tablet’s specifications in order to ensure that tablet weight and tablet size are consistent for each tablet pressed. Applying too much force may cause tablet press components to malfunction and damage tablet quality.

11.What Are The Maintenance Procedures For A Tablet Press Machine?

Lubrication

It is important to lubricate the tablet press machine often to ensure it runs smoothly without any problems. Lubricate all moving parts, including tableting punches, tableting dies, and tableting punch holders. This can be done using a lubricant specifically designed for tablet press machines.

Cleaning

The tablet press machine should be regularly cleaned with a clean cloth and warm soapy water to remove any dust or debris that may have accumulated on the surface.

Adjustments

It is important to regularly check the tablet press machine for any adjustments that need to be made. Ensure the tablet size, height and weight are adjusted to the correct settings.

Inspections

The tablet press machine should be inspected regularly for any wear or damage that may have occurred. Check the tableting dies and tableting punches for any signs of wear and other parts, such as tablet chutes, tablet feeders, and tablet ejectors. Any repairs or replacements should be made as soon as possible.

Maintenance

Regular maintenance should be performed on tablet press machines to ensure they are properly working and running at peak performance. This includes regularly cleaning, lubricating, adjusting, and regularly inspecting the tablet press machine.

12.What Are The Common Challenges Associated With Using A Tablet Press Machine And Their Possible Solution?

Clogging of tablet press machine

This is a common problem that arises due to tablet ingredients not being properly distributed in the tablet die.

Solution

Ensure proper distribution of tablet ingredients and also clean the tablet press regularly.

Jamming of tablet press machine

Jamming occurs when tablet particles become stuck in the tablet die and prevents tablets from being produced.

Solution

Ensure that tablet components are properly mixed and distributed, as well as making sure that the tablet press is maintained regularly.

Overheating of tablet press

Overheating of tablet presses can be caused by a variety of problems such as excessive use, incorrect settings, or lack of lubrication.

Solution

Ensure proper setting of tablet press temperature, as well as regularly lubricating the tablet press machine in order to avoid any potential overheating issues.

Uneven tablet coating

Uneven tablet coating can be caused by a variety of problems such as incorrect settings or too much moisture.

solution

Ensure proper setting of tablet coating parameters, as well as making sure that tablet ingredients are properly mixed and distributed.

13.What Factors Should Be Considered Before Investing In A Tablet Press Machine?

Size of Tablet Press Machine

The size of the tablet press machine is an important factor to consider before investing in one, as you need to ensure it can effectively produce tablets with the desired specifications and characteristics.

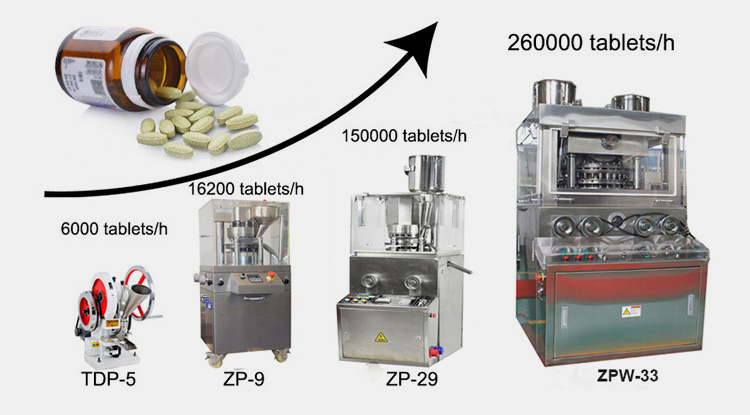

Production Capacity

It is also necessary to consider the tablet press machine’s production capacity to ensure that it can produce enough tablets in a timely fashion.

Maintenance and Safety Features

It is also important to consider the maintenance requirements of the tablet press machine, as well as any safety features that are included with the machine.

Cost

The cost of the tablet press machine is another key factor to consider before investing in one, as it will greatly impact your overall budget.

Quality

The quality of the tablet press machine is also important, as it should be able to produce tablets with consistent and accurate specifications.

Availability of spare parts

Finally, the availability of spare parts for the tablet press machine should also be considered before investing in one, as these parts may be needed to maintain the machine and keep it running smoothly.

CONCLUSION

A tablet press machine is a device that compresses powder into tablets of uniform size and weight. A tablet press can be used to manufacture tablets for a wide variety of industries, including the pharmaceutical, nutraceutical, and food industries. If you’re interested in purchasing a tablet press machine for your business, be sure to contact Allpack. They offer high-quality tablet press machines at competitive prices, and their team of experts are ready to answer any questions you may have about choosing the right machine for your needs.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours