Hot Sale Bin Mixer For Your Granules

- Simple Structure

- High Mixing Efficiency

- Low Power Consumption

Bin Mixer

Allpack Bin Mixer is suitable for mixing dry granule materials for pharmaceutical, chemical, foodstuff, and other industries. Based on importing, absorbing, and digesting the new technology of foreign countries, all Allpack bin mixers feature simple structure, compact structure, high mixing efficiency, small occupation area, and lower power consumption. With high mixing speed and good mixing effect, the mixing uniformity rate can reach over 95%, inner of all Allpack bin mixers are of new type sealing structure, during mixing, it is free of pollution, with convenient operation and maintenance. The equipment can make the materials stir evenly under vacuum, make the products mix evenly, expand fully, have bright color, good elasticity, and extract protein to the greatest extent. Its scope of application is wide.

Bin Mixer

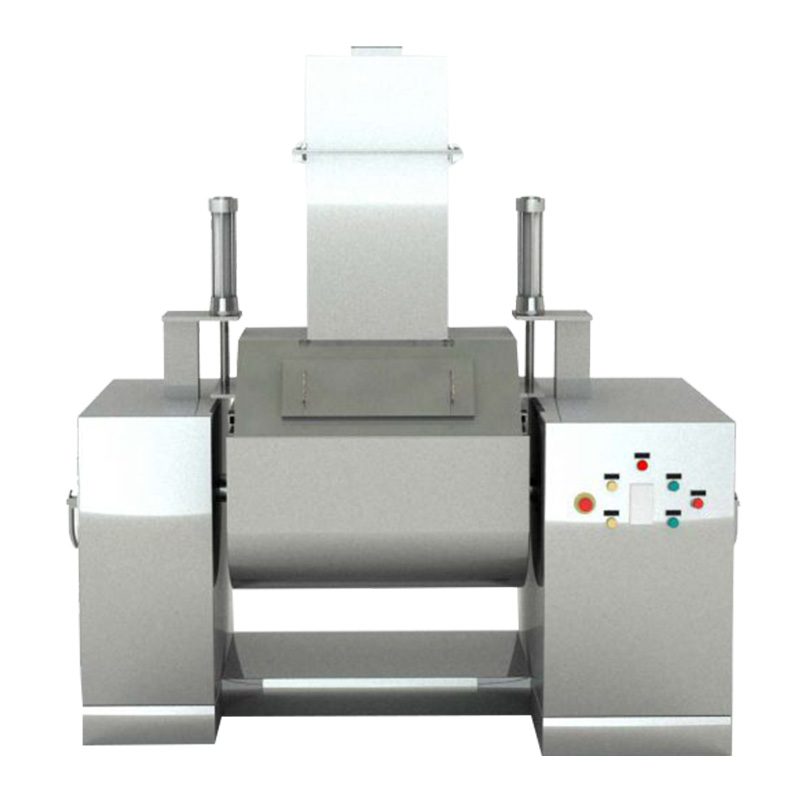

CH Series Horizontal Tanker Typed Bin Mixer

Allpack CH series horizontal tanker bin mixer is a necessary equipment for mixing. It has high efficiency and convenient operation. It is the preferred equipment for the production of dry sausage products, granular, mud mixed sausage products and pill products. It is also the optional equipment for the production of dumplings and wonton pasta products.The equipment can make the materials stir evenly under vacuum, make the products mix evenly, expand fully, have bright color, good elasticity, and extract protein to the greatest extent.

Easy cleaning &speed adjustable

Independent electrical control group

Safe and reliable

CW series stirring type Bin Mixer

Allpack CW series bin mixer is designed for mixing two or more dry powder or granule raw materials from the pharmaceutical industry, chemical industry, foodstuff industry, and so on. The structure of this bin mixer machine is unique. steel 304Its mixing efficiency is high and no dead corners. It is made of stainless steel 304 /316L. Its inner and outer walls are processed through polishing.Its appearance is beautiful. Its mixing is uniform. Its scope of application is wide.

Adjustable rotation speed

Safety device

Smooth operation&simple operation

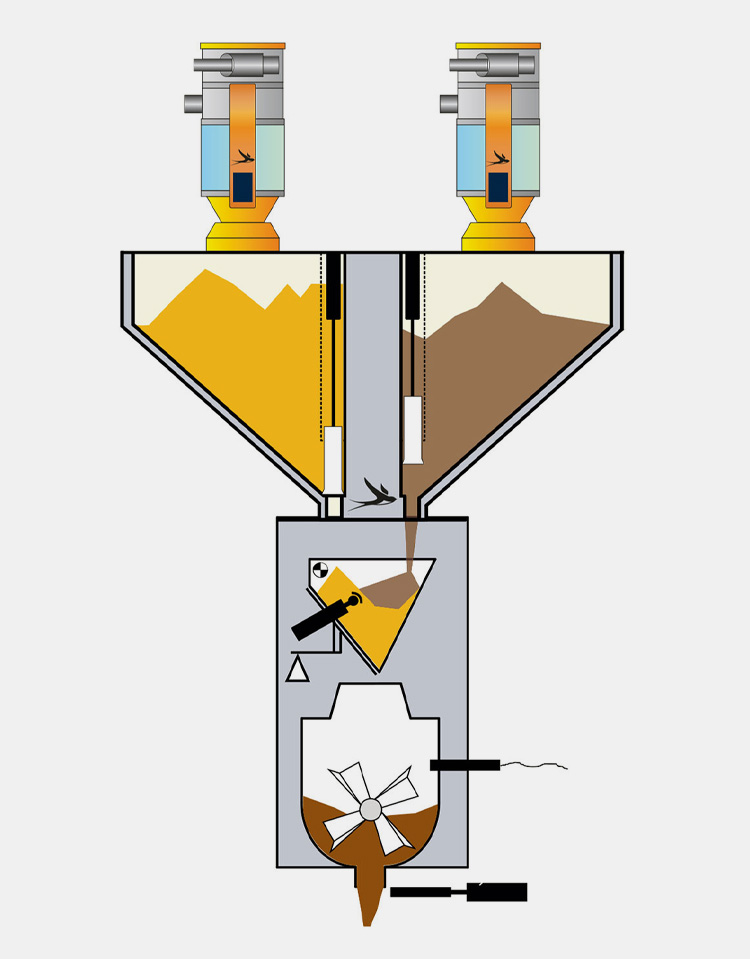

DLH Series Cone Bin Mixer

Allpack DLH series cone bin mixer is mainly applied in mixture and storage of plastic. Except for mixture and storage of plastic powder raw materials, food, chemicals, inflammable and explosive materials, volatile materials. Bulk specific weight needs to be considered when the size of raw materials are uneven or different shapes.This bin mixer is to use the spiral paddles to generate vortex for mixture purpose. The raw materials will be rotated into the central blending screw by the vortex.

Adopted with height-adjustable expansion brachet

With automatic stop device

Machine is comprised of easy-disassembly parts

GHS High Speed Bin Mixer

Allpack GHS high speed bin mixer is suits for mixing and potting various types of two components materials, that requires to use manually or potable mixing head. Able to apply material on electric (wire) road board industry, electronic components industry, electric light source industry, small home appliance industry, igniter industry, automotive supplies industry, vacuum cleaner industry, filter industry and many other fields.This is one of our best selling two components machines, for its accuracy mixing, dispensing, and flexibility for multi purposes potting.

Automatic valve cleaning

The operation is simple and user friendly

High efficiency&save material

Model CH-V Series High Efficiency Bin Mixer

Allpack CH-V series bin mixer is used for mixing the dry material grains in the medical, chemical, food, metallurgical and other industries. The mixing barrel structure is unique. The mixing efficiency is high. There is no corner that can not be reached. The barrel uses the stainless steel and its internal and external walls are polished. The outside appearance is beautiful. The mixing is uniform, with wide application. The bin mixer meets GMP standard.

Sterile,dust-free&lager loading capacity

Short mixing time&high efficiency

PLC control system

Model CH-VI Forced-Type BIn Mixer

Allpack CH-VI bin mixer adopts labor feeding and enclosed flapper valve for discharging. It will not produce powder dust, and it also will not produce mechanical compression and strong friction during mixing. So the material particles can remain intact. The mixing barrel is made of stainless steel, which won’t pollute the material. Besides, this machine has timing device, which can control the mixing time of materials.The machine is mainly used for the uniform mixing of powder, granular and other materials in various industries.

Wide range of applications

Various specifications

Evenly mixing

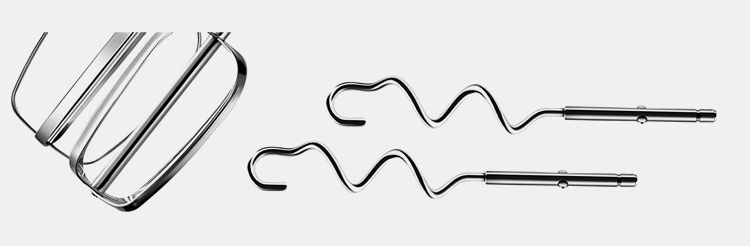

Model EYH Series 2D Movement Bin Mixer

Allpack EYH series 2D movement bin mixer is widely used in chemical, pharmaceuticals, food, and construction line.It can be used to mix powder with powder, powder with liquid, and powder with granule.Under the driven of motor, the double ribbon agitator mix the material quickly.The outer ribbon push the material from the two ends to the centre, inner ribbon push the material from center to the two ends.Thus to achieve material convention.The discharging port is set in the bottom centre, with the help of the outer ribbon,the material can be discharged completely, and no dead zone.

Flexible material selection

High efficiency mixing unit

Excellent discharging unit

CH Series Horizontal Tanker Typed BIn Mixer

Allpack CH series horizontal tabk type bin mixer is suitable for mixing powder and powder, particles and powder, powder and a small amount of liquid. It is widely used in chemical, pharmaceutical, food, feed, plastic and building materials industries, and can be made according to GMP standards. The machine has wide adaptability to mixture, can mix uniformly for viscous materials, can keep the integrity of particles as far as possible for granular materials, and can mix well for materials with a ratio difference of 1:1000~10000.

Flexible disassembly and assembly

High reliability and low noise

Adopts gear reducer plus belt drive

Model W Series Double Taper-shaped Bin Mixer

Allpack W-series doubee type bin mixer is a horizontal trough type mixer with single stirring arm. The stirring arm is removable so that is easy to clean. The part is surfaces which may touch the mixing materials are made of stainless steel, So they are good corrosion - resistant ,the mixing trough can automatically reverse for discharge an the missing time can be automatically controlled.It is made of high quality 304 stainless steel, with beautiful appearance, convenient maintenance and easy to clean.

High efficiency and non accumulation

Unique structure, uniform mixing

High mixing precision and high speed

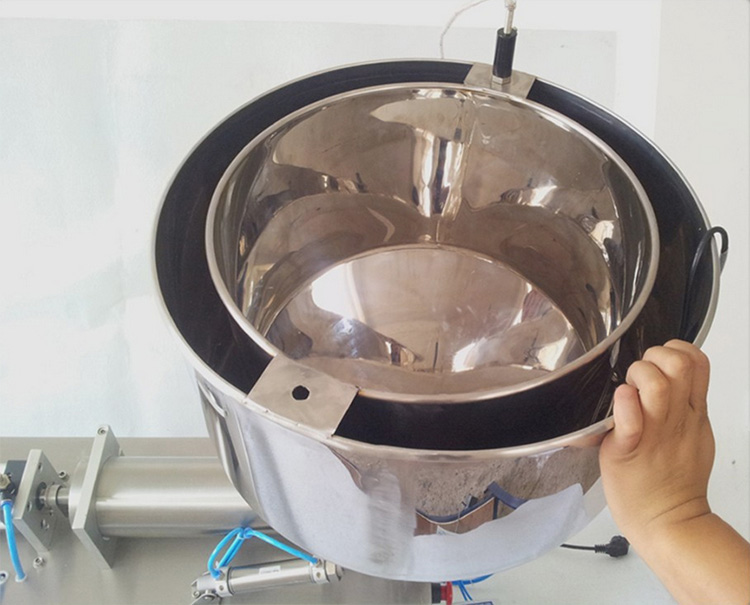

SWH Series 3D Motion Bin Mixer

Allpack 3D motion bin mixer can keep driving the mixer container into one three dimensional movement, then the materials inside will efficiently mix during this continuous process. it also has the features of smooth running, low noise, high loading volume, and short mixing time as well.It is widely used in food, pharmaceutical industry, additive industry and so on, the characteristics of the model is compared with the existing mixer on the market, it has great advantages, the mixing effect of powder to reach a new height.

Food Grade Surface Treatment GMP Standard

High-quality Stainless Steel CE and ISO certified

Adjustable Mixing Speed

WLDH Horizontal ribbon Bin Mixer

Allpack WLDH horizontal bin mixer is made of stainless steel, which is durable, easy to clean, and has no sanitary corners. The special mixer can stir and mix various raw meat with starch, auxiliary materials, water, etc. Excellent effect, fast speed, time-saving and labor-saving features.The stuffing mixer has good adaptability and mixing effect for granular, powder, mud, paste and slurry. Good shape retention for lumps, with forward and reverse function, automatic discharging function.

Stable operation, reliable quality

Low noise&long life

Easy installation and maintenance

WSH Series Double Paddle Tank Type Bin Mixer

Allpack double paddle tank type bin mixer is widely applied to medication, chemicals, fodder, ceramics, refractories, namely the mixture of powders and fluids; chemicals, compound fertilizer, dyes, pigments, rubber, building materials, refractories, tombarthite, resin glass,ie blend of solid-solid (powders and powders), solid-liquid (powders and fluids).The maximum workload of the 200 type machine is 200KG each time. If the moisture content of the raw materials mixed by the customer is different, the workload will also be different.

Materials can be mixed quickly and evenly in a short time

With stainless steel contact parts

Fast discharging, no residual

The Buyer's Guide

Bin Mixer: The Complete Buying Guide in 2025

When you are working with dry products such as powder, it will be a tough task for you to mix multiple dry ingredients.

To achieve this kind of tough task Bin Mixer is introduced into the industry and it became a worthy equipment to solve many mixing problems for different industries such as pharmaceutical etc.

You are going to learn many important aspects about the bin mixer in this article from basic to advance so, keep reading & stay with us to get handy knowledge about bin mixer.

1.What is Bin Mixer?

Bin Mixer

A bin mixer is an advanced and efficient machine that is used to ensure the uniform and thorough mixing of powders or granules.

This machine mixes the materials that needs to be mixed in two way; firstly the material gets mixed by tumbling within the bin and secondly it gets mixed due to rotation of the tilted bin.

2.Which kind of advantages you are going to get from Bin Mixer?

A bin mixer can prove to be very beneficial for your business. It can help your business in different ways. Some of the advantages of the bin mixer are described below.

Ensures Safety

The bin mixer ensures the safety of the operator. It is designed in such a way that there are almost no chances of accident.

Even after all the safety measures an accident occurs, the bin mixer has an emergency stop button which can be pressed to stop the working of the machine immediately.

Highly Productive

Highly Productive

The bin mixer is a very productive machine. It can do a lot of work in a very small time. You can mix a huge amount of powders or granules in it within a few moments.

In this way it increases the overall production of your industry leading to increased sales and an increased income.

Long Lasting

The bin mixer, if taken proper care of, can serve your business for a long time. This adds value to this machine because you only need to invest once and then you can use it for a really long time.

3.Explain different applications of Bin Mixer?

Pharmaceutical Granules

A bin mixer has a wide range of applications. Some of the important applications of the bin mixer are discussed below.

Used for Enhancing the Efficiency of Mixing

The bin mixer is used to ensure that all the ingredients that you want to mix are properly and accurately mixed together.

Used for Preventing the Chances of Cross-Contamination

The bin mixer is widely used for mixing the ingredients when the cross-contamination is an issue. You do not need to worry about cross-contamination while using the bin mixer.

Used for Mixing Powders and Lubricants

The bin mixer is a very versatile machine and so its use is not restricted to dry powders onle. It is widely used to mix powders into the lubricants.

This process is very important in industries such as the pharmaceutical industries where excipients and the active pharmaceutical ingredients are sometimes in different states.

4.Can you explain the working of a Bin Mixer?

The working of a bin mixer is not very complicated. It is a simple machine that is very easy to use and operate.

You need to follow a few simple steps to operate your bin mixer. These steps are described below.

Filling of the Accurate Amount of Ingredients

The first step includes the filling of the accurate amount of the ingredients to be mixes into the bin mixer.

You should take the capacity of your bin mixer into account before deciding the amount of ingredients that you are going to put in the bin mixer. Then, simply fill the exact amount of ingredients in to the bin mixer.

Setting the Mixing Time from the Control Panel

The next step after the filling stage is the setting of mixing time. In this step, you are required to set all the parameters carefully according to your needs.

These parameters include the mixing/blending speed and the time of mixing or blending.

Starting the Bin Mixer

After you have set the parameters of the bin mixer, you are required to start the machine. Upon starting, the bin mixer starts its functioning according to the parameters set in the control panel.

Stopping the Machine

After achieving uniform mixing, you have to stop the bin mixer.

Discharging the Product

Before the whole process is completed, the last step is discharging the final product of the mixing from the bin mixer.

These are the few simple steps that describe the simple yet efficient working of the bin mixer.

5.What are the main working components of a Bin Mixer?

A bin mixer is made up of many components which work together to ensure its smooth and efficient working.

Some of these components along with their brief explanation are described below.

The Rotation Counter

The rotation mixer is the most important part of the bin mixer because it performs the basic and the most important function of mixing in the bin mixer.

This is the part of the bin mixer that rotates the blending or mixing containers for thorough mixing.

The Light Guard

This part of the machine plays a very important role of increasing the speed and efficiency of the bin mixer.

The light guard ensures high quality mixing by using the infrared radiations. These infrared radiations are used for flash mounting on the walls of the container for ensuring the GMP finish.

The Operation Control

Bin Mixer Control System

PLC system is used in the bin mixer for making it an easy to use device. This system helps you control all the working of the bin mixer easily.

The control system has a touch screen interface that gives you access to all the operations of the bin mixer. You just need to get some basic knowledge about operating the PLC control panel.

The Laser Guard

As discussed earlier, the bin mixer ensures the safety of the operator as well as the ingredients or the materials in the blending container. This important function is done by the laser guard.

The laser guard is located just above the floor level. It is a very sensitive part of the bin mixer that can detect the entry of any person or the foreign/outside particles in to the bin mixer.

It must be noted that the machine stops working automatically when any person or the foreign/outside particles are detected. This prevents any damage to your product or the operator.

The Clamping Bars

A bin mixer machine, as we already know, works by rotating the blending container. The rotation also produces vibration in the machine that may cause damage to your bin mixer. Therefore, there is a need to keep your bin mixer during its operation.

This crucial task is done by the clamping bars or the clamping stands. These bars or stands keeps the bin mixer intact during the whole process so that it does not get damaged.

6.What are the different types of Bin Mixers?

Bin mixers are available in different sizes and shapes. Each type of the bin mixer has their own working capacity and specifications.

Some types of the bin mixers available in the market are described below.

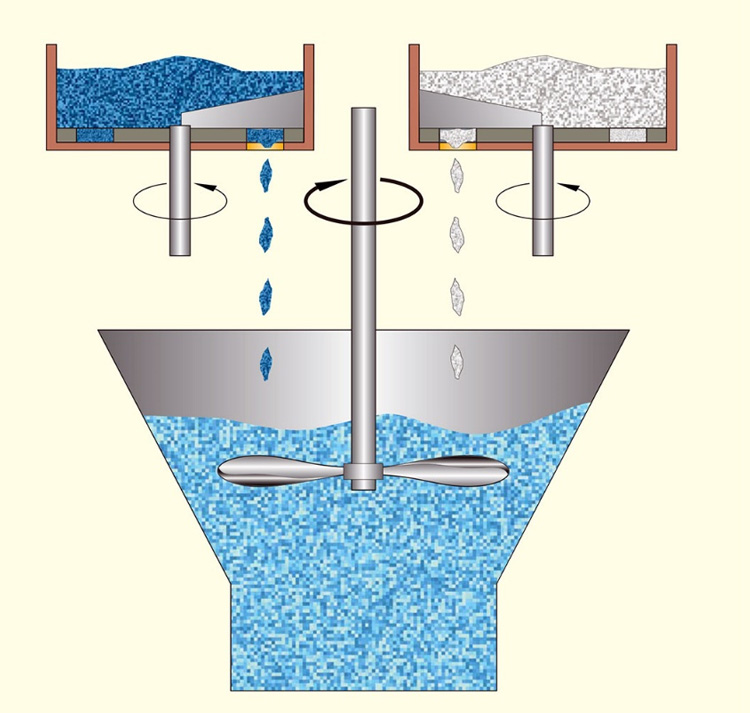

Tank Mixers

Tank mixers are machines that help to combine various types of liquids or gases into a uniform mixture. They can be used in a variety of industries, including the automotive and chemical manufacturing industries. Tank mixers are unique because they allow for precise control over the mixture.

Working

The working principle of Tank Mixer machine is based on the use of impellers and blades to mix the materials. The impeller rotates at a high speed, while the blade moves horizontally across it. This action results in a vortex that swiftly mixes the materials together.

Advantages

- They are versatile tools that can be used in a variety of different industries

- Tank mixers are reliable and efficient

- Tank mixers are affordable and easy to operate

Disadvantages

- Tank mixers can be quite loud

- They can become clogged quickly if not properly maintained

- Tank mixers can be slow and labor-intensive to use

Parts

The agitator

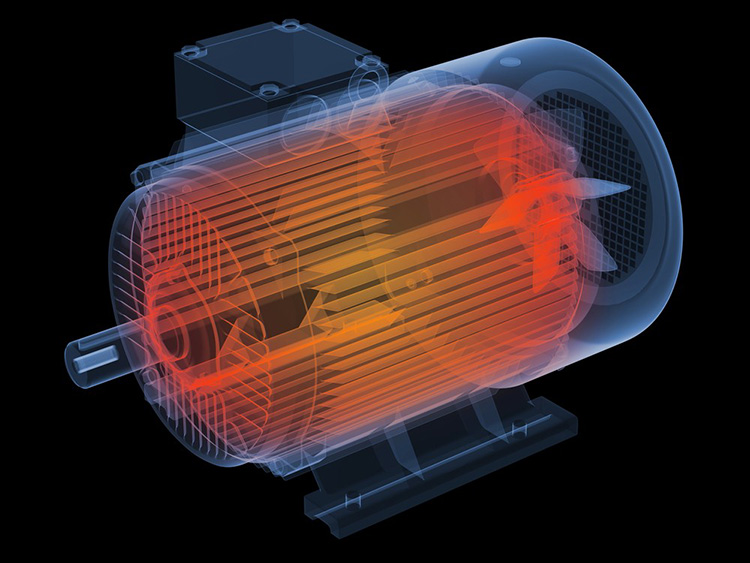

The agitator is responsible for stirring the contents of the tank and breaking down large particles into smaller ones. It is typically powered by an electric motor, though there are manual models as well.

The discharge pipe

The discharge pipe is used to send the resulting slurry or liquid mixture out of the tank and into another part of the machine.

Sanitary Mixers

Sanitary mixers are machines that help to create a sanitary environment for workers in factories, hospitals, and other places where people come into contact with dangerous or unclean substances.

Working

A sanitary mixer is a machine used for the purpose of mixing two liquids together. It consists of a series of blades that rotate around a central shaft, and it is used to create a homogeneous mixture by breaking up any clumps that may form. The rotating blades create turbulence, which helps to disperse the liquid evenly.

Advantages

- The sanitary mixers are very quick and saves time for you

- Using a sanitary mixer can help reduce the risk of cross contamination in your facility

- It is also less expensive than other types

Disadvantages

- They can be difficult to use

- They may not be effective at effectively cleaning surfaces

- The maintenance of this machine is expensive

Parts

The Motor

The motor is used to power the mixer’s rotating blades and helps to mix the ingredients together.

The Blade Assembly

The blade assembly consists of blades that spin around an axis, making contact with the ingredients being mixed in order to create turbulence.

Pail Mixers

If you’re looking for a unique way to get your gardening done, consider using a pail mixer. This tool makes it easy to combine different types of soil, mulch, and fertilizers into one mixture. Plus, it’s great for mixing up larger quantities of these materials than you would be able to mix with a shovel or spade.

Working

The working principle of a pail mixer is simple. The machine consists of two rotating blades that chop up the material being mixed. This chopped up material is then forced into a central funnel where it is forced into contact with the other ingredients.

As the mixture combines, the blades cause the liquid to spin around rapidly and produce a smooth, uniform mixture.

Advantages

- They are portable, which makes them convenient to use

- They have a variety of features, so you can customize them to your specific needs.

- They are fast and easy to use

Disadvantages

- They are considered very difficult to clean

- Pail mixers tend to be bulky and not easy to store

Parts

The Pump

The pump helps to move the water and mix it with the ingredients.

The Impeller

The impeller helps to mix the ingredients.

Lab Mixers

Lab mixers are a great way to keep your lab clean and organized. They are also a great way to create a unique atmosphere in your lab.

Working

The working principle of a lab mixer is relatively simple. It consists of a series of blades or paddles that rotate around an axis. This motion causes the liquids and gases to be mixed together.

Advantages

- The lab mixers are very convenient to use

- They can mix the substance more accurately

Disadvantages

- Lab mixers produce loud noise in labs

- They are difficult to use

Parts

The Auger

The auger is the important part of lab mixer. The auger is responsible for distributing the ingredients evenly throughout the mixer.

The Hopper

The hopper is the next part. It is responsible for moving the ingredients from one container to another. This allows the lab technician to mix the ingredients correctly and create a desired product.

Handheld Mixers

Handheld mixers are unique and engaging tools that can be used for a variety of applications. They are great for small businesses that want to create their own mixes, or for personal use when mixing music on the go.

Working

The basic working principle of a handheld mixer is simple. You connect the input of the mixer to the output of the mixer and use the controls to adjust the levels of sound coming from each speaker. This allows you to create a variety of sounds by blending together different volumes and frequencies.

Advantages

- They are easy to carry

- They have many different features that make them more advantageous

Disadvantages

- They are not suitable for large jobs

- They may not be able to handle high volumes

Parts

Batteries

The battery is the most essential part of handheld mixer. Without battery you cannot start working.

Switch & Beaters

A switch button enables you to switch the machine during runtime. Beaters are the front rode that will rotate to perform mixing.

7.What type of materials you can mix with Bin Mixer?

Bin mixer is a very versatile machine that has very wide range of applications. It can be used to mix different types of materials in different industries. Some of these are discussed below

The Pharmaceutical Industry

Capsule Powder

The bin mixer finds its most common application in the pharmaceutical industry. It is used to mix different granules and powders to be used for making tablets and granules.

It is also used for mixing ingredients of the liquid syrups and making suspensions and emulsions. The bin mixer allows uniform mixing of active pharmaceutical ingredients with the excipients.

The Food industry

The bin mixer is used in the food industry to mix different ingredients such as sugar grains, powders, liquids and other solids as well.

The Cosmetic Industry

Cosmetic Powders

In the cosmetic industry, the bin mixer s used to mix materials such as creams, lotions, face powders and nail polishes etc.

The Chemical Industry

The bin mixer is also extensively used in the chemical industry for mixing different types of chemicals in the form of powders, solids or liquids.

8.How can you select the best Bin Mixer for your business?

Selecting the right bin mixer is very important for your business because if you buy wrong machine, it will definitely cause financial loss.

Following the few points that you should consider while buying a bin mixer for your industry.

Compatibility

Always look for the bin mixer that has the speed and working capacity that matches the needs of your business. A compatible machine will give you optimal productivity according to your requirements.

Quality Compliance

cGMP Compliance

Make sure that the bin mixer you are going to buy has quality compliance approvals such as cGMP, CE and EN. These certifications are a guarantee that your machine is safe to use and has a good quality.

Never compromise on the quality and buy the best available bin mixer for your business. The bin mixer of high quality will give you better and efficient production that will increase your profit.

Beware of Scams

While buying the bin mixer, make sure that the seller of the machine is trustworthy and has a good reputation. Beware of the online scammers and always look for the reviews before buying the bin mixer.

9.How to troubleshoot the bin mixer?

If your bin mixer is not working properly, there are a few things you can do to troubleshoot the issue.

Power is Plug in or Not

First, check to see if the power cord is plugged in and that the outlet is working.

Checking of fuse box

Next, check the fuse box to see if there is a blown fuse. If there is, replace the fuse and try again. If the bin mixer still does not work, contact a professional for assistance.

10.What are the common problems of bin mixer?

There are several common problems that can occur when using a bin mixer. These include:

Blades become Bent or Damage

The mixer blades may become bent or damaged, which can cause the mixer to work less effectively or even break down completely.

The Machine can be Over Heated

The motor can overheat if the mixer is used for long periods of time or if it is overloaded. This can damage the motor and shorten its lifespan.

Causing Vibration on Mixer

The bearings in the mixer can wear out over time, causing the mixer to vibrate or make noise.

The Seal Can Leak

If the seals on the mixer are not properly maintained, they can leak, allowing moisture and dirt to enter the mixing chamber and contaminate the mix.

Above are the common problems that everyone face during the mixing of substances or materials.

Conclusion

ALLPACK bin mixer can benefit your business by cutting down your expenses, minimising the need for hiring labour, and ultimately increasing your profits. You should consider buying the ALLPACK bin mixer as it can prove to be a game changer for your business we are eager to assist you in any kind of help to achieve best quality Bin Mixer please do not hesitate & reach us Freely. Just make sure the machine is used properly and is taken good care of.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours