Perfect Tablet Counting Line For Your Needs

Tablet Counting Line

Allpack tablet counting line is a capsule & tablet counting line, which consists of a bottle unscrambler, an automatic electronic counting machine, an induction sealing machine, a capping machine, and a labeling machine. The whole counting and filling line conforms to the GMP standard, and the number of grains can be set arbitrarily, from 0 to 9999. This tablet counting line adopts vibration feeding and rotary cutting design, and the feeding speed can be adjusted steplessly, which is suitable for manual bottle placement. By using photoelectric sensing technology, the particle accuracy is over 99.7%. Tablets and capsules can be adjusted at will without changing the mold. Wide applicability, this counting line adopts original anti-dust technology, that can be used for counting and filling tablets( including abnormal tablets), capsules, and gels(including abnormal gels.

Bottling Line

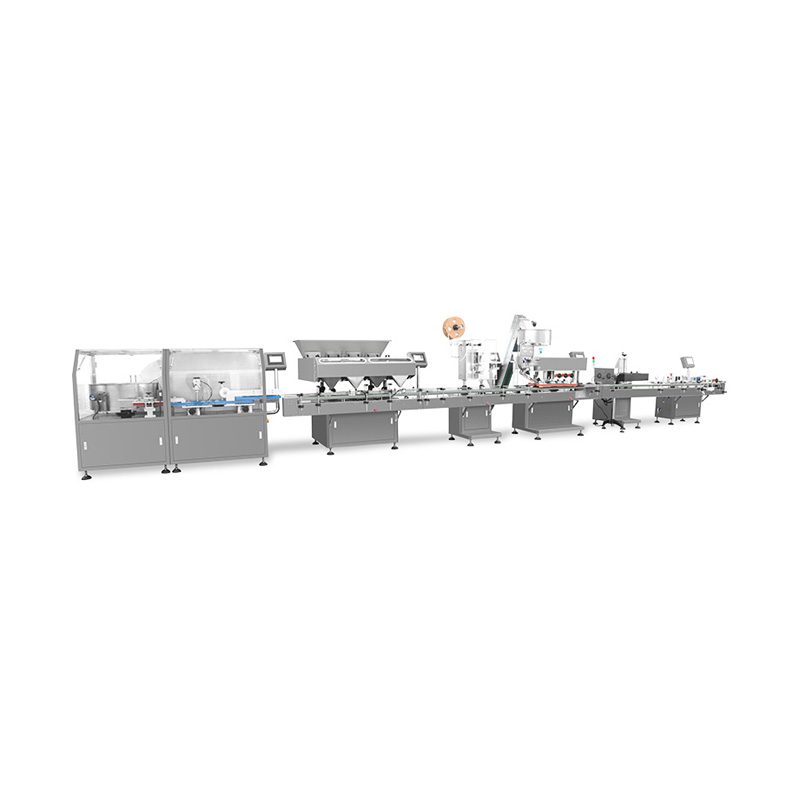

JF-A100-12 Low Speed Automatic Grain Capsule Tablet Pill Counting Line

The JF-A100-12 low-speed automatic grain capsule & tablet and pill counting line is composed of JF-A100 round bottle unscrambler, JF-12 electronic counting machine, JF-C120 automatic drying tank (inserting cotton machine or paper machine), JF-D901 automatic capping machine, JF-2 induction sealing machine, JF-201 round bottle side sealing machine (coding machine). With wide application, this counting line applies original dust-proof technology.

Wide Application

High Intelligence

Original Dust-proof Technology

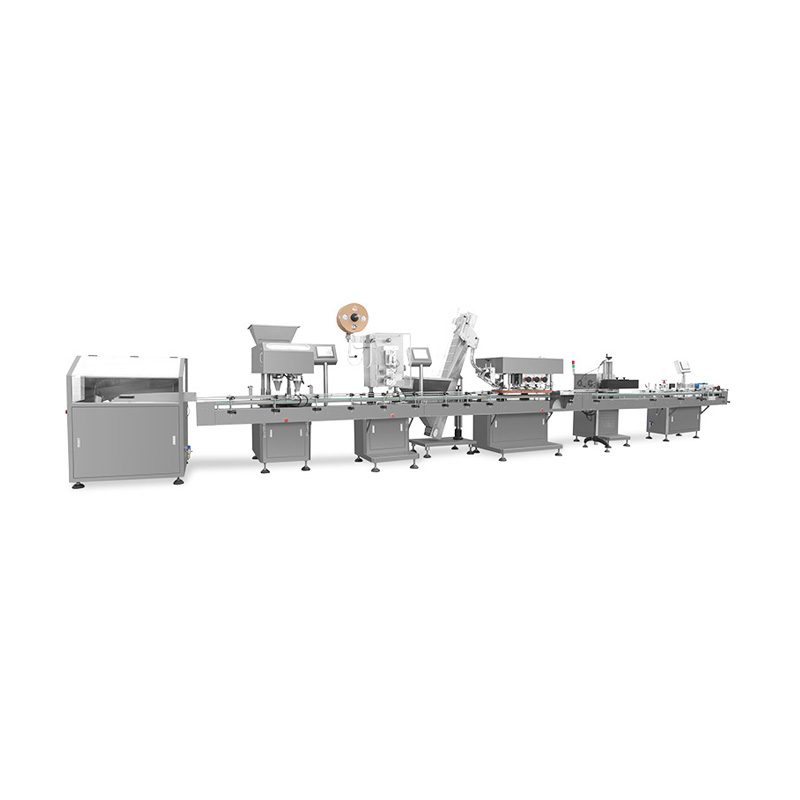

JF-A160-16 Medium Speed Automatic Multifunction Capsule Tablet Pill Counting Line

JF-A160-16 medium speed automatic multifunction capsule & tablet and pill counting line is composed of JF-A160 bottle unscrambler, JF16 electronic counting machine, JF-C120 automatic bag inserting machine (inserting cotton machine or paper inserting machine), JF-D902 capping machine, JF-2 induction sealing machine, JF-201 round bottle side coding machine (coding machine).

High Efficiency

Wide Applicability

Original Anti-dust Technology

JF-2000-32 High Speed Automatic Multifunction Capsule Tablet Pill Counting Line

JF-2000-32 high-speed automatic multifunction capsule & tablet and pill counting line is composed of a JF-2000 bottle unscrambler, JF32 electronic counting machine, JF-C120 automatic bag inserting machine (inserting cotton machine or paper inserting machine), JF-D903 high-speed capping machine, JF-3 water-cooled induction sealing machine, JF-201 high-speed round bottle side coder (coder).

Good Cooperation

Intelligently Designed

Multi-language Interactive Operation Panel

The Buyer's Guide

Tablet Counting Line: The Complete Buying Guide In 2025

Are you tired of putting your constant efforts for tablets counting despite being the runner of different machines? Probably yes! Well, it's a good sign and you might be wondering how any hardship could be your well wisher. It is because this discomfort has paved your way to lookup for a more astonished, sophisticated, and comprehensive but compact solution which is indeed a tablet counting line.

Tablet counting line is a united assembly of several machines which perfectly fulfill your diverse needs regarding tablets counting and their further processing. You can employ it for many other things and make your production more excellent. But for this you need to delve deep in tablet counting line and explore the different aspects associated with it. So, let's start discovering these all one by one!

1.What Is Tablet Counting Line?

Allpack High Speed Automatic Multifunction Capsule Tablet Pill Counting Line

Tablet counting involves not only the counting, but it needs proper mechanism where they are safely packed into bottles in a protected way for the sake of retaining quality and essence throughout their shelf life. Similarly, an assembly of several automatic machines is introduced to facilitate the entire process of tablets counting along with its bottling, sealing, and labeling.

This integration of multiple equipment is termed as tablet counting line, which is composed of a bottle unscrambler, electronic counter, desiccant inserter, bottle capping machine, induction sealer, and an automatic labeler. Together these devices enable you to have precise, efficient, and convenient tablets counting in a consistent manner.

2.Describe The Features Of Tablet Counting Line?

A tablet counting line come up with excellent characteristics which distinguishes it from individual machines. Some of the prominent attributes are discussed below:

Consistency

Tablets accuracy presentation- Picture Courtesy: freepik.com

The interconnected machines of tablet counting line support uninterrupted and smooth processing of tablets from its counting till packaging. It depicts the strong consistency of tablet counting line which ultimately reduce the downtime and adds to the production efficiency.

Durability

Tablet counting line is built with corrosion resistant and quality stainless steel. The integration of small to large tools through advance technology enhance its stability during operation and it can be easily adjustable.

Accuracy

Multiple scattered tablets with spoon- Picture Courtesy: freepik.com

Tablet counting line has automatic system for the counting of tablets. Hence, with the help of vibratory channel, detection system, and rejection mechanism, it ensures up to the mark tablets counting precision.

Resilience

Different shapes of tablets and capsules- Picture Courtesy: freedesignfile.com

Another attribute of a tablet counting line is that it is capable to process various sizes and shapes of tablets. Not only that, but you can employ it to count objects other than tablets including capsules, candies, and gummies etc.

User-friendly

User-friendly presentation idea- Picture Courtesy: 10bestdesign.com

Tablet counting line has an intuitive Human Machine Interface that is extremely convenient to use. Along with that, the line support multiple languages through which you can easily communicate your demands to it.

3.What Type Of Containers Can Be Processed By A Tablet Counting Line?

As we have explained earlier that a tablet counting line is not only meant for counting tablets but also their filling into respective bottles and containers. So, here the types of bottles which a tablet counting line can process will be enlisted:

Plastic Bottles

Plastic bottle with cap- Picture Courtesy: dhgate.com

Most of the bottles which are used for filling counted tablets are made up of plastic. Hence, a tablet counting line is best suitable to process these plastic bottles for the filling of tablets and undergoing them through capping and labeling process.

Glass Bottles

Glass capsule bottle- Picture Courtesy: yellowimages.com

Glass bottles provide safe and hygienic environment for the sensitive nature of tablets. This is the reason, why most of the sterile tablets, capsules, and candies are packed in glass bottles and jars. Similarly, they are eligible for packaging by a tablet counting line.

4.Can A Tablet Counting Line Be Used For Products Other Than Tablets?

Various candies & jellies- Picture Courtesy: candyclub.com

The answer to your question is definitely yes! A tablet counting line can be easily employed for counting products other than tablets. Infact, tablet counting line is popular for its product versatility and has presence in different industries. These materials include:

- Capsules

- Candies

- Gummies

- Chocolate beans

- Jellies

- Grains

- Shooting balls

- Detergent pods

- Seeds

- Bubble gum

5.What Sizes And Shapes Of Tablets Are Suitable For Tablet Counting Line?

Different sizes of round tablets- Picture Courtesy: Aipak Pharmaceutical Equipment

Tablets are virtually made in different shapes, but the most common shapes include round, oval, triangle, oblong and square. The shape of tablets depends upon two factors: the first is its dosage because high dosage tablets come in big size so desirable shape is adopted for the convenience of patients in swallowing tablets while as, the second reason is to enhance the tablets charm especially for kids in confectionery industry.

Similarly, pharmaceutical tablets have fixed sizes according to which they are compressed and delivered to consumers. The popular size of pharmaceutical tablets ranges from 1mm to 22mm. Apart from this, the standard size for tablets is >5 mm in diameter.

It is pertinent here to mention that all the above-mentioned shapes and sizes of tablets can be easily counted by a tablet counting line. Not only that, but you can also use irregular shapes and sizes of tablets and capsules to ensure precision in counting.

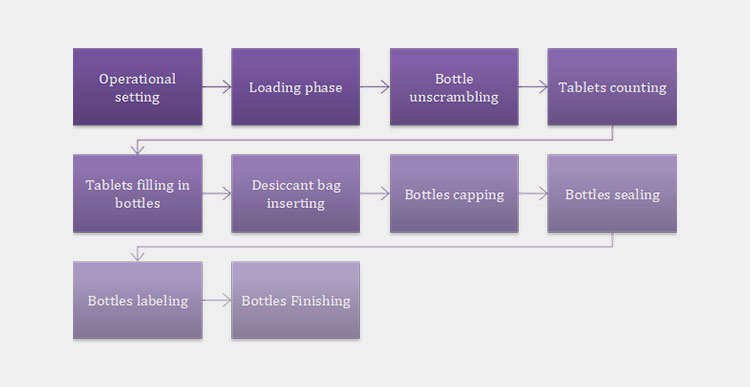

6.Explain The General Working Mechanism Of A Tablet Counting Line?

A tablet counting line follows non-stop consistent operation that ultimately leads to the perfect counting as well as the accurate bottling of tablets. Below steps will clearly show how actually a tablet counting line functions. These include:

Operational Setting

Before starting your tablet counting line, you need to pick the suitable setting for it. This setting will simply include the fixation of parameters in machine through Human Machine Interface such as the quantity of tablets to be filled in each bottle, the speed of conveyor belt, power of induction sealer, and the point of desiccant bag cutting.

Along with that, you have to adjust the external parts like the height of filling heads, induction coil, and capping head in accordance with bottles size.

Loading Phase

Bottle and capsules loading onto tablet counting line: Picture Courtesy: altrimex.nl

At this point, the loading of different machines will take place. For instance, the stock of empty bottles will be loaded into bottle unscrambler, bulk of tablets will be stored in the tablet counter hopper and the placement of caps in feeding station. Similarly, the respective film and labeling rolls will be supplied to labeling machine and desiccant inserting machine.

Bottle Unscrambling

Bottle unscrambling- Picture Courtesy: altrimex.nl

Ultimately, the tablet counting line will be turned on with the very first unit initiating its functioning, a bottle unscrambler. It will process the randomly positioned bottles through a rotary disc and align them in a correct way. Proceeding further, the bottles, standing on their base and having opening on the outer side, will be supplied to the tablet counting machine through drive mechanism.

Tablets Counting

Tablets counting on vibratory channel- Picture Courtesy: Aipak Pharmaceutical Equipment

In this step, the second machine on tablet counting line, a tablet counting machine, will detect the presence of bottles on one hand while as start counting the tablets on the other. In addition, the tablets will be dropped from hopper onto vibratory trays, scattered there, will took hold on different compartments, and will be mobilized forward through constant vibration. Simultaneously, the tablets on front line will be counted through detector and will be dispensed to the filling head.

Tablets Filling into Bottles

Tablets filling into bottles- Picture Courtesy: altrimex.com

Once the counted tablets are pushed towards the filling head, the sensors will detect the presence of bottles after which the tablets will be filled into bottles precisely.

Desiccant Bag Inserting

Desiccant bag inserting process- Picture Courtesy: altrinex.nl

Moving ahead, the desiccant inserting machine will get energized and begin forming a bag from film. After the formation of bag, fixed amount of transparent granulated silica gels will be filled into the bag and bag will be sealed from the top. When the formation of desiccant bag get completed, it will be cutted and single bag will be dropped into single tablets bottle.

Bottles Capping

Bottle capping- Picture Courtesy: altrimex.nl

When the tablets counting, filling, and desiccant bag insertion is achieved, the bottles will undergo sealing process. For this, the caps will be automatically provided to the chute. Then these caps are fitted over the bottles opening and torque is applied to realize airtight sealing.

Induction Sealing

Induction sealing of bottles- Picture Courtesy: altrimex.nl

Moving forward, the most crucial step will be accomplished here through the induction sealing head which produces an electromagnetic field that ultimately warm up the foil liner inside the cap. This heated foil then get melted on the inner-seal and causes a strong inner seal bond to the lip of the container. Hence, a hermetical sealing of tablets bottles will taken place.

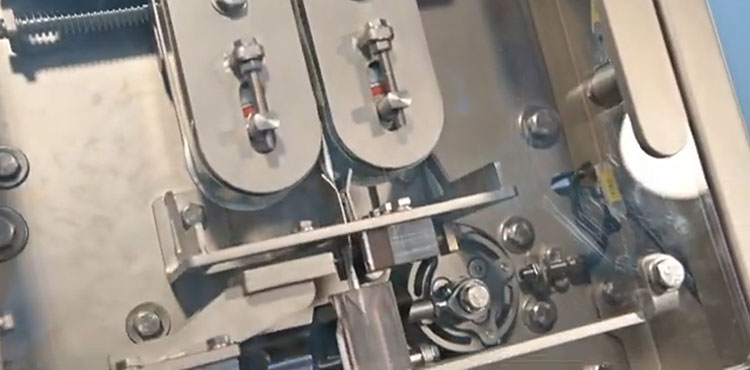

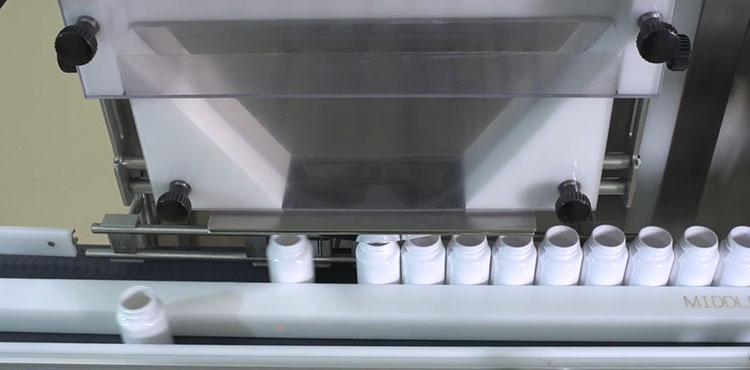

Bottles Labeling

Bottle labeling- Picture Courtesy: altrimex.nl

This step of labeling is carried out in the final phase through the last machine of a tablet counting line which is a labeling machine. It starts pulling adhesive label from the roll on a label plate with the help of pulleys. Afterwards, the labels are applied around the bottles and a force is applied through a sponge to ensure smooth, flat, and bubble free labeling.

Bottles Finishing

Bottles collection- Picture Courtesy: altrimex.nl

Finally, the labelled bottles are collected either manually or attaching an additional device for efficient and safe assembling.

7.Elaborate The Various Equipment Which Make The Body Of A Tablet Counting Line?

As a tablet counting line is made up of different machines, it is important for you to have proper knowledge regarding each machine as well as the important aspects associated with them including their structure and their role. Therefore, the table below will greatly help you in this way:

| No | Machine | Description | Structure | Operation |

| 1 | Bottle Unscrambler

Allpack APC-A100 Automatic bottle unscrambler |

Bottle unscrambler is an automatic machine used to align the scrambled bottles onto tablet counting line. | It is made up of stainless-steel body, stable four feet, control system, rotating disc, and a bottle barrel etc. | It functions by taking the wrongly positioned bottles from barrel, rightly positioning them via rotating disc, and finally supplying these unscrambled bottles to tablets counting line through conveyor. |

| 2 | Tablet Counting Machine

Allpack APC-16 High speed tablet capsule counting machine |

Tablet counting machine is the core part of tablet counting line integrated for the purpose of precisely counting tablets and filling them into bottles. | It is an assembly of a hopper, vibratory channel, counting compartment, human machine interface, main frame, conveying system, filling heads, and rejection system. | The operation of tablet counting machine is simple enough which starts from tablets serialization through vibratory trays and, pass through counting phase, and end up in their filling into bottles. |

| 3 | Desiccant Inserting Machine

Allpack APC-C120 Automatic desiccant inserting machine |

Desiccant inserting machine is an excellent machine attached to the tablet counting line. Its function is to canister silica gel into tablets filled bottles in order to keep the tablets dry and stable. | Its structure is comparably compact and stable comprising a film roll, silica gel hopper, bag forming mechanism, sealing system, bag cutting device, main body and detection system etc. | It follows a sequential order to form bags from film, fill it with precise silica gel quantity, seal the desiccant bag and insert it into the bottle. |

| 4 | Bottle Capping Machine

Allpack APC-D903 High Speed Capping machine |

Bottle capping machine is another machine in line to cap the different types of tablets filled with different types of caps and make them airtight. | The machine consists of a chucks, inserters, clutches, motor and gear boxes, gripper disc, sorters, feeders, pulleys, shafts, sprockets and other common components such as conveyor and stainless steel body. | It works on the principle of torque and air pressure where caps are first applied over bottles and then screwed tightly to ensure protected closure. |

| 5 | Induction Sealing Machine

Allpack APC-M1 Induction Sealer |

Another crucial equipment of tablet counting line is undoubtedly the induction sealing machine which is used to provide stringent sealing to capped tablets bottles. | It is made up of a durable stainless steel body having stable structure. The overall components count for induction sealing machine include the induction coil, time regulator, sensor, electric system, and induction sealing head station. | It uses an electromagnetic field which in turn results in melting the polymer of bottle cap foil. Ultimately, a strong sealing of bottles is realized by the foil sticking to bottle neck. |

| 6 | Labeling Machine

Allpack APC-T1 Round Bottle Side Face Labeler |

The final machine placed at the end of tablet counting line is a labeling machine. It is integrated to achieve the astonishing labeling of tablet bottles efficiently. | It consists of a label plate, label pulling shafts, label application wheel, sponge wheel, label cylinder, electric eye, drive mechanism, and a control system. | The operation of labeling machine follows certain principles encompassing the feeding of label on plate and its processing. The label is pulled via shafts, applied around bottles, and stick to the bottles through sponge. |

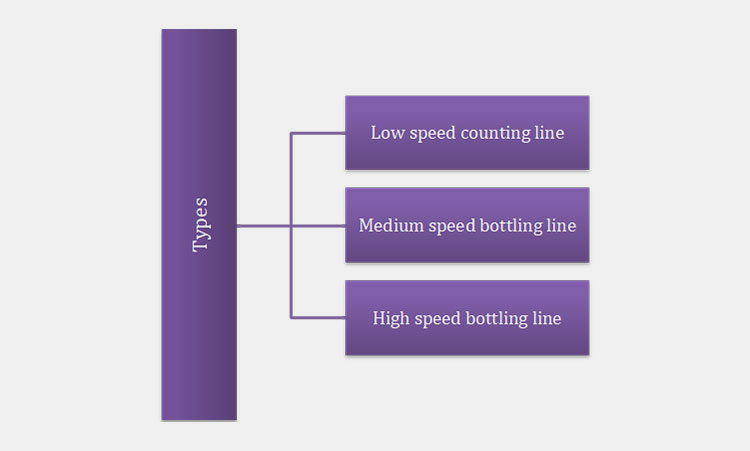

8.What Are The Different Types Of Tablet Counting Line?

Keeping in mind the production of small to medium and large facilities, Allpack has designed different types of tablets counting lines to aid you in your respective fields. These are described below:

Low Speed Automatic Bottling Line For Capsule/Tablet

Allpack Low Speed Automatic Bottling Line For Capsule/Tablet

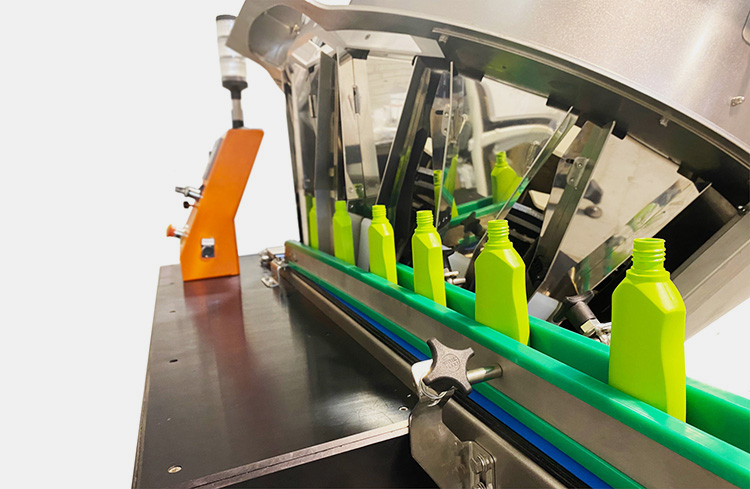

Low speed automatic bottling line by Allpack is the first type of tablet counting line you can employ for your tablets counting. The line follows a simple functioning and process single bottle at a time.

Structure

Its structure is precise and small compared to other types of tablet counting lines and include a rotary bottle unscrambler, automatic tablet counting machine, desiccant inserting machine, capping machine, induction sealer, and a labeling machine

Speed

This tablet counting line follows a consistent manner in tablets counting as well as packaging. Its overall growth rate is somehow low with speed rate of finishing up to 50 bottles in a minute.

Application

It is best suitable for junior to middle scale pharmaceutical, chemical, and food industries.

Medium Speed Automatic Bottling Line

Allpack Medium Speed Automatic Multifunction Capsule & Tablet and Pill Counting Line

Medium speed automatic bottling line is the second type of tablet counting line meant for intensifying the productivity gains by providing facilities for processing two or more bottles simultaneously.

Structure

It has a medium sized body comprising bottle unscrambler, electronic counting machine, automatic desiccant inserter, capping screwing machine, induction sealer, and round bottle side face labeler.

Speed

The speed of medium speed tablet counting line is efficient with its capacity to finish over 80 bottles per minute.

Application

This model of tablets counting line will indeed be a best choice for the medium to large level facilities working on healthcare, pet care or beauty care tablets and capsules.

High Speed Automatic Bottling Line

Allpack High Speed Automatic Multifunction Capsule Tablet Pill Counting Line

This is the third and the most efficient tablet counting line that processes your tablets with ultrafast speed and support multiple bottles at the same time.

Structure

The structure of high-speed automatic bottling line is comprehensive enough due to the integration of a high speed bottle unscrambler, 32 channel tablets counting machine, automatic desiccant iserter, high speed capping screwing machine, water-cooled induction sealer, and high speed round bottle side face labler

Speed

By using this innovative and intelligent tablets counting line you can get the wonderful output of 90 bottles in a single minute.

Application

High speed automatic bottling line is the one and only perfect choice for undertaking your highest possible production targets in every sector whether food, medical, or agriculture industry.

9.Highlight The Areas Where Tablet Counting Line Can Be Used?

A tablet counting line can be used in various industries where manufacturing of products resembling tablets and capsules are produced. Some of the notable sectors where a tablet counting line can be employed are as follows:

Healthcare Industry

Presenting technology in healthcare industry- Picture Courtesy: forbesindia.com

Healthcare industry is the broadest field where you will find the inevitability of a tablet counting line. It is because the abundantly produced capsules and tablets in pharmaceutical and nutraceucal sectors need proper counting of medicines to ensure accuracy of dosage while packaging.

Beauty Care Industry

Beauty softgels in bottles- Picture Courtesy: jasminetalksbeauty.com

The importance of a tablet counting line can be better understand in a beauty care industry by looking towards its ever rapid growth. Now, people rely more on taking beauty supplements in form of gummies, softgels, and pills to beat the issues like hair fall, dark circles, and acne. So, these all components can be better counted by a tablet counting line.

Pet Care Industry

Doctor treating a cat

Pet care is becoming a concerning topic in modern day world. Therefore, you will find industries associated with the manufacturing of various types of medication in form of tablets and capsules to treat animals. In such facilities the help of tablet counting line is taken to deliver precise medication.

Food Industry

Colorful candy wafers- Picture Courtesy: sprinklebakes.com

Food industry is indeed a comprehensive realm where various food is delivered in form of tablets, capsules, and small balls. For instance, candies, gummies, and jellies would be the perfect examples of such food for which a tablet counting line can be used for counting.

Agriculture Industry

Seed growth in soil- Picture Courtesy: freepik.com

Well, agricultural industry encompasses the processing of multifarious seeds for whose counting a tablet counting line is always needed. Hence, its application is found here too.

10.Enlist The Quality Standards A Tablet Counting Line Should Comply?

ISO quality standards aspects- Picture Courtesy: freepik.com

As tablets counting line is meant to be used for the most responsible task of counting and processing sterile nature of tablets it must comply certain quality standards. These quality standards ensure that the tablet counting line is fully free from any sort of dangers that is associated with the line's material which is in contact with tablets and other aspects.

Therefore, few most important and crucial quality standards are four which are internationally recognized for the safe manufacturing and processing of food products as well as their manufacturing equipment. These include:

- Good Manufacturing Practices (GMP)

- International Organization for Standardization (ISO)

- Food and Drug Administration ( FDA)

- CE Quality Specifications (for recognition in European Union)

11.What Is The Preventive Maintenance For A Tablet Counting Line?

Preventive Maintenance display- Picture Courtesy: llumin.com

It is clear that you will need a tablet counting line for a longer period of time to serve your requirements. It implies that the efficient and stable functioning of tablet counting line is important which can be only possible when you take care of its regular maintenance. Therefore, we have explained for you the preventive maintenance of a tablet counting line in an easy way. Have a look towards it!

Before Operation Maintenance

Firstly, you have to make sure that the installation place is free from all sorts of contamination, heat, and moisture. Secondly, it is eminent to adjust the external parts of tablet counting line like the height of filling heads, capping heads, and induction sealing head, and the adjustment of conveyor etc. Thirdly, the correct setting of machine parameters is important each time when you are about to start the operation.

After Operation Maintenance

The after-operation maintenance will include the examining of different components to check the abnormalities. It will involve the lubrication of moving parts especially the disc of bottle unscrambler, conveyor motor, and the labeling pulleys etc. Along with that cleaning is the must task you should carry to disinfect the machine, sensors, and other parts. Apart from this, when you find any part damaged or worn out make sure to replace it timely and avoid further damage caused by using faulty components.

12.How Can You Solve The Common Problems Of Tablet Counting Line?

It is significant to remind you that a tablet counting line may malfunction when you operate it. But it does not mean to worry about it rather you simply need to find the causes of errors and taking measures accordingly to solve them. So, we have explained some of the common problems which you might face along with their solutions. Make sure to understand these all:

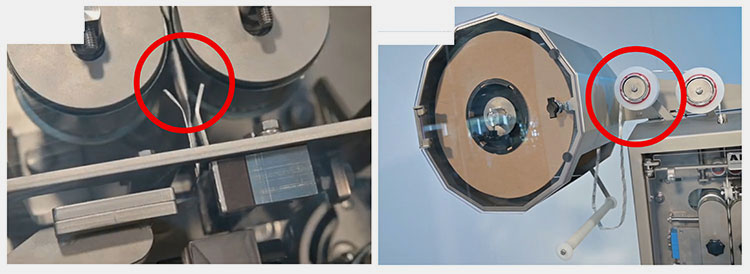

Bottle Unscrambler

Bottle unscrambling- Picture Courtesy: directindustry.com

Jamming of bottles

The operational error sometimes cause bottles jamming which badly affect the tablet counting line function.

You can solve it by resetting the machine parameters and look for external adjustments of conveyor.

Stagnancy of rotary disc

It happens when the disc has a friction problem due to low lubrication or any bottle struck in a bottle unscrambler hose causing it to stop moving.

Solve it by lubricating the rotary disc and adjust the space of

Bottle damaging

It occurs when the sensor does not stop detecting bottles even when one step get completed. This result in bottles overlapping which lead to their damage.

It can be solved by first setting the sensors, in case of damage install new effective sensor.

Tablet Counting Machine

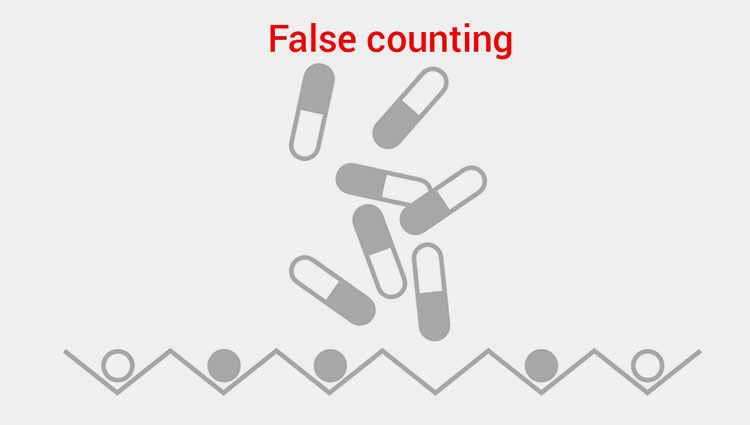

False counting of capsules- Picture Courtesy: altrimex.nl

Erroneous Counting

Most probably, it is caused by the wrong counting time duration and wrong placement of vibratory channels.

Make sure to adjust the photoelectric time in milliseconds and reset the vibratory channels.

Tablets Jamming

Most of the time tablets get struck during counting because of the excessive counting speed.

Here, you need to control the counting speed so that tablets will be processed gently.

Unusual Alarming

It occurs when the sensors get contaminated due to the tablets residues and start alarming.

So, you have to clean the sensors and make sure the attached dust collector device is working accurately.

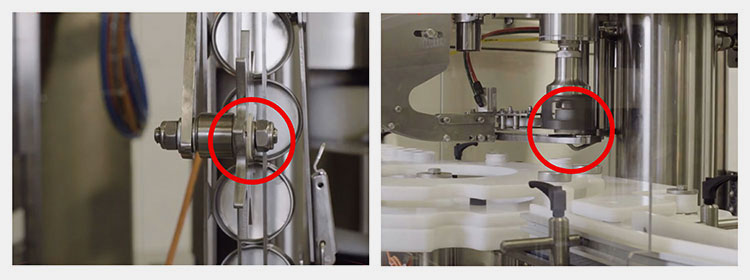

Desiccant Inserting Machine

Highlighting induction sealer errors- Picture Courtesy: altrimex.nl

False cutting of desiccant bags

When there is problem in machine setting, it get displayed in the form of inaccurate pulling, bag forming, filling, and ultimately cutting. Thus, the false cutting results in the spillage of silica gel.

To resolve this issue, you need to reset the entire parameters of machine, so that, it will be able to perform accurately.

Over & understanding of desiccant bag

Sometimes, instead of filling one desiccant bag into one bottle the machine fill two desiccant bags in one bottle and leave few bottles with no desiccant bag. This is because the sensor is abnormal.

Hence, you have to clean the sensor first, and then set the speed of film regulator for functioning in accordance with the speed of bottles passing under station.

Capping Machine

Indicating capping errors- Picture Courtesy: altrimex.nl

Missing caps

It is one of the main issues caused by the misplaced caps in spindle which leads your tablets filled bottles uncapped during process.

You can solve it by properly examining the spindle and chuck and make sure that they are in good working position to hold the caps ready for delivery over bottles.

Bottle breakage

The bottles get damaged during operation because the disc holders are not settled in accordance with bottle size.

Hence, setting machine according to the size and shape of bottles will help you overcome this serious problem which can otherwise ruin your entire packaging process.

Induction Sealing Machine

Indicating errors of induction sealing machine- Picture Courtesy: packagingstrategies.com

Partial, weak, or no seal

There are multiple reasons responsible for these errors. First is the insufficient power of induction coil. Second is the disparity between conveyor speed and that of the power. Third is the improper height of coil.

The solution is simple: adjust the induction sealing power, create balance between conveyor speed and power, and set the coil height.

Too strong sealing create difficulty in removing

The reason is excessive electromagnetic power or too low speed of conveyor.

Ergo, increase the speed of conveyor and reduce the sealing power to suitable level.

Torque problem

Bottles which are incorrectly torqued make the induction sealing machine unable to seal foils.

Therefore, before moving the bottles towards induction sealing machine you need to make sure that all the bottles are well capped and accurate torque application has been taken place.

Labeling Machine

Labeling machine with marked problematic areas- Picture Courtesy: altrimex.nl

Labels Removing Back From Bottles

It occurs due to the poor compression of a sponge around bottle and sometimes the label has insufficient adhesion.

The possible solutions are revising the force of a sponge or fur brush for strong compression of labels and using a tackier product for your labels stickiness.

Blistery Labeling

The contaminated surface of bottles leave them with bubble like spots because label become unable to access every part of bottle surface.

In such case, it is important to operate your tablet counting line in a hygienic environment and another thing is that your bottles must be free from debris and any sort of other particulates.

Labels Tearing During Pulling

There are two possible reasons for the concerned issue: weak label and the dry pulleys.

So, first you need to use strong labeling roll and secondly, keep your labeling pulleys always lubricated so, they will not pull the label in a harsh manner.

13.What Are The Considerations For A Tablet Counting Line?

Whenever you intend to incorporate a tablet counting line into your industry always avoid rushing towards it because it will leave you with more regrets and less benefits. Let's explore what are some vital considerations:

Throughput

Multiple bottles filing with tablets simultaneously- Picture Courtesy: altrimex.nl

It is imperative to have a look towards the speed ratio of a tablet counting line as it is the only reason which compel you to opt for a tablet counting line. You can find it simply by looking towards the line production capacity per minute or per hour.

Cost

Calculating budget- Picture Courtesy: runsystem.id

The second point is to take your current state of budget in your mind and avoid finance related issues. For instance, low speed tablet counting line will be suitable for limited budget, however, in case of being experienced in the field and having an extensive business portfolio then opting for a high speed tablet counting line will undoubtedly multiply your gains.

Brand Reputation & Quality

Brand reputation icon- Picture Courtesy: getseoinfo.com

Taking care for the factors like brand reputation of supplier, its experience, customer service, quality warranty, and compliance to quality standards are also important to be noted.

14.Why Is It Worth It To Be A Customer Of Allpack For A Tablet Counting Line?

Allpack logo

Becoming a customer of Allpack will bring you immeasurable advantages. You might be thinking how. Then follow the underlying facts:

- Allpack provide you one year of warranty.

- The company has over 11 years of experience in manufacturing and supplying pharmaceutical and packaging related machines.

- All of its equipment, especially tablet counting lines, are certified by GMP, FDA, CE, and ISO.

- Here, you can avail the opportunity of getting professional support regarding your purchased machine.

- Last but not least, you have wide range of options to choose between them the best compatible tablet counting line.

Conclusion

To sum up this buying guide about a tablet counting line, it is paramount to highlight its significance and relevance in modern day tablets counting and packaging. Tablet counting line is a resilient solution that perfectly match your vary needs in a single run. Its efficiency and performance is unmatchable. So, if you are interested in exploring or buying a tablet counting line do not forget to consider Allpack where you will find the solution if your choice. Stay tuned and connected with us!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586