Your Versatile Paste Packaging Machine

- Thick Film Winding Device

- Stable Pouch Length Controlled

- Direct Sealing Temperature Detector

Paste Packaging Machine

Allpack Paste packaging machines are designed for filling and dispensing liquids, and we have these machines available for both low-viscosity and high-viscosity liquids. These high-performance machines speed up bottle-filling microcomputers operations. They’re made with stainless steel, are easy to clean and maintain, and all parts that come into contact with the product are certified food grade. The paste packaging machine adopts the pneumatic pump dosing unit which has the machine advantage of suit for viscous liquid items with highly efficient and reliable performance. Controlled by microcomputers and simple buttons, the paste packaging machine is easy to operate. All the sealing temperature, film pulling speed and interval time can all be adjusted as required. This type of machinery makes it easy to fill and seal containers with contents quickly and accurately.

Paste Packaging Machine

DXDG-20II Paste Packaging Machine

Allpack DXDG-20II paste packaging machine is equipped with one set of vertical sealing roller, one set of horizontal sealing roller and one set of sealing roller to strengthen. The vertical sealing roller is completed, continuous grain vein with leak-resistant line. The horizontal sealing roller is grain vein with leak-resistant line or plain sealing with leak-resistant line.The whole set of machine combines forming -vertical sealing--filling -horizontal sealing -horizontal strengthen sealing--notching-cutting together.

Equipped with safety door

Direct sealing temperature detector

Sa table pouch length controlled

DXDG-50II Paste Packaging Machine

Allpack DXDF-50II paste packaging machine is stainless steel material which comply to food safety grade and rust-proof, equip reliable performance electric & mechanism compoment.High packing capacity and speed, high efficient and lower your labour cost.The paster packaging machine is suit for automatic filling and packing liquid/paste/sauce/cream item, such as milk, juice honey, hair shampoo, tomato paste, salad dressing, jam ect. The machine adopt the pneumatic pump dosing unit which have the machine advantage of suit for viscous liquid item with high efficient and reliable performance.

Thick film winding device

Shaped sealing edge for marking

Simple operation&multi-language support

DXDG-100II Paste Packaging Machine

Allpack DXDF-100II paste packaging machine adopts piston type filling machine, and the logistics contact part is made of 304 stainless steel, which is food grade. It has stable performance and high precision.Filling volume: 5-25 ml,accuracy: ±1%.Most of the structure of the machine is a detachable buckle structure, which is easy to maintain. Controlled by microcomputer and simple buttons, the paste packaging machine is easy to operate. All the sealing temperature, film pulling speed and interval time can all be adjusted as required.

Controlled by a microcomputer and simple buttons

Durable and food grade

Back sealing, three-side sealing, four-side sealing

DXDG-500II Paste Packaging Machine

Allpack DXDF-500II paste packaging machine is suitable for automatic packing of lose nonstick, granular and thick powder production in the pharmarceeuical, the food, the plant germ, the chemical products such as instan drink,peiiet,monosodium glutamate,white sugar,soup coffee wheat groats etc.This machine has been adopted a PLC programmer control and provided whit a Chinese character displayer. Thus, this equipment is easy to poerate and convenient adjustment,with high automation.

Advanced digital photo electrical buymaking system

Synchronous bag pulling system

Steady and accurate

DXDG-1000II Paste Packaging Machine

Allpack DXDF-1000II paste packaging machine suitsfor automatic filling and packing liquid/paste/sauce/cream item, such as milk, honey, hair shampoo, tomato paste, salad dressing, jam, etc. The paste packaging machine adopts the pneumatic pump dosing unit which has the machine advantage of suit for viscous liquid item with highly efficient and reliable performance. The most important is the machine equip with small horizontal ribbon blender mixing machine, this will make the machine much suited for seasoning paste/sauce, such as chilli paste, for the mixing machine will have the paste evenly packaged with less deposite.

Automatic weighing

No plug&No Leak

Pneumatic sealing

The Buyer's Guide

Paste Packaging Machine: the Complete FAQ Guide in 2025

The process of packaging and sealing products is a challenging and labor-intensive task. However, today businesses are looking for cost-effective methods for quickly packaging products with minimal effort. And with the rise of modern automation technology, you can now find an array of paste packaging machines that can help streamline production.

Unfortunately, choosing a suitable machine can be challenging since many suppliers are in the market. So, if you’re looking for an in-depth guide to understanding these machines and finding one that fits your needs, you’ve come to the right place!

In this FAQ guide, we’ll break down everything you need to know about paste packaging machines in 2025 – from how they work to how they can help add value and reduce costs associated with your packaging operations. Read on to make an informed decision.

1.What Is A Paste Packaging machine?

A paste packaging machine is a highly efficient and versatile automated machine that helps to pack pastes, sauces, condiments, and other liquid-like items into containers. This type of machinery makes it easy to fill and seal containers with contents quickly and accurately. It also ensures that the contents remain safe from contaminants while in transit or storage.

With the help of a paste packaging machine, you can save time and effort while ensuring that your products are properly packaged. Furthermore, the machine helps to reduce waste and maintain product freshness. Therefore, it is essential for any business dealing with pastes, sauces, or condiments to have a paste packaging machine as part of their production process.

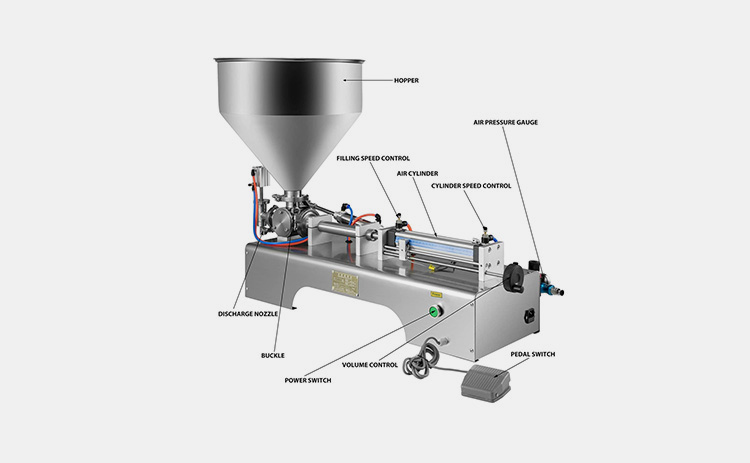

2.What Are The Components Of A Paste Packaging Machine?

Filling Tank

The filling tank holds the paste while it is being dispensed into the bags. It has a hopper where the paste can be poured and mixed before it is sent to the filling chamber, where it will be metered and fed into the packaging system.

Nozzle or Spout

The nozzle or spout is the tool used to dispense the paste into the bags. It can be manual or automated, with different settings for controlling the flow rate and size of the paste being dispensed.

Sealing Station

The sealing station is where the filled bags are sealed shut. It typically consists of several heating elements that apply pressure and heat to the package, ensuring a perfect seal every time. Furthermore, a station can be either manual or automated, depending on the requirements of the paste packaging machine.

Controlling and Monitoring System

The controlling and monitoring system allows operators to track and monitor the performance of the paste packaging machine in real-time and make adjustments as needed. It can also be used for troubleshooting any issues that may arise.

3.What Are The Advantages Of A Paste Packaging machine?

A paste packaging machine can be an invaluable asset when it comes to packaging paste-based products. This type of machine provides several advantages, such as:

Increased Efficiency

A paste packaging machine can help increase the efficiency of your production operations by providing automated processes for packaging products. This means you can produce more paste-based packages with less effort and time spent on manual labor.

Cost Savings

The cost savings associated with using paste packaging machines can be considerable for companies that must package large quantities of products. The devices can reduce labor costs, as fewer operators are required to package the product. Additionally, the time saved can lead to a reduction in energy consumption and other associated expenses.

Quality Control

Paste packaging machines help ensure that products are accurately packaged with consistent quality. They automate filling and sealing pouches accurately, ensuring that the right amount of product is included and that the seals are tight enough to prevent spills or leaks.

Improved Hygiene

Paste packaging machines help to improve hygiene in production plants by eliminating manual contact with products, ensuring a more sterile environment. The machines also provide no cross-contamination from one product to another, as they are programmed to package the items in their designated container.

Versatility

Paste packaging machines are highly versatile and can be adjusted to package different product types, from liquids and soft materials to solid items. This allows manufacturers to adapt their production line for new types of products quickly.

Additionally, the machines can be easily integrated into automated production lines, so they can easily be used to increase the speed and accuracy of production.

Scalability

Paste packaging machines are highly scalable, meaning they can be adjusted to meet the demands of an ever-growing production line. This makes them a great choice for small businesses looking to expand their product offerings without investing in additional machinery.

Additionally, the machines are easy to maintain and can be upgraded as production lines grow. This helps to ensure that the investment made in the device is well worth it.

4.What Are The Applications Of A Paste Packaging Machine?

Paste packaging machines are highly versatile and can be used for a range of applications. Some common uses of paste packaging machines include:

Food Processing

Paste packaging machines are used to fill and package a range of food products such as sauces, jams, jellies, honey, peanut butter, and syrups. The machine is designed to seal the product in plastic or aluminum bags without causing any damage to the paste.

Pharmaceuticals

Paste packaging machines are also used for pharmaceutical packaging products such as creams, ointments, and gels in various sizes and shapes. This helps ensure accurate dose delivery while ensuring contamination-free processing.

Personal Care Products

Many personal care items like shampoos, lotions, and creams are also packaged using paste packaging machines. This helps preserve the product’s integrity while ensuring accurate dosing for each use.

Chemical Processing

paste packaging machines are used to fill and package a range of chemical products, such as paints, lubricants, and adhesives. The device is designed to maintain the integrity of these materials by filling them into suitable packages without causing any damage.

5.How Does A Paste Packaging Machine work?

Paste packaging machines are systems used for packaging paste-like products. These machines can quickly fill various containers with different pastes, such as creams, lotions, sauces, jams, and preserves. The process starts by feeding the paste into the hopper at the top of the machine.

From there, the paste travels down through a series of funnels and tubes until it reaches the filling nozzle. The machine then dispenses exact amounts of the paste into containers below, usually small plastic or metal bags, jars, or bottles. Once filled, these containers travel along on a conveyor belt, where they are sealed and labeled before being packaged for shipment.

The process is fast and efficient, allowing manufacturers to produce large quantities of product quickly and with minimal effort. Furthermore, the machines are built with safety in mind, as they come with a built-in sensor system that will alert you if the sealer is not applied correctly or if the paste temperature is too high. This makes paste packaging machines an invaluable production tool for many industries.

6.What Are The Options For Controlling The Speed And Pressure Applied By A Paste Packaging Machine?

There are several options available when it comes to controlling the speed and pressure applied by a paste packaging machine. The most common approach is to use a motor controller that can be adjusted manually or automatically. In this case, a manual adjustment allows you to precisely control the speed and pressure, while an automatic adjustment will help ensure consistent results over multiple production runs.

Also, you can adjust the speed and pressure using a pressure relief valve, which can be set to release at different pressures. Finally, you can use a servo motor to control the speed of the machine for more precise adjustments. With any of these methods, it is essential to monitor the performance of your paste packaging machine to ensure consistent results. Doing so can provide the best quality product for your customers.

7.What Are The Different Types Of Paste Packaging Machines?

Various paste packaging machines are available, each suited to different types of products and specific needs. Here are some of the most common types:

Semi-automatic Filling Machines

These machines allow you to fill containers with semi-liquids such as pastes quickly. They can be used for small and large production runs and adjusted to suit different container sizes.

Vacuum-Filling Machines

Such equipment uses a vacuum to draw air out of the container before the paste is added, ensuring that all available space is filled evenly and accurately. They are perfect for high-volume production runs.

Form Fill Seal Machines

These machines are designed for high-speed production runs. They can be used to fill containers with a variety of liquids, including pastes, and seal them quickly and efficiently.

Piston Fillers

These machines use a piston to measure a precise amount of paste into each container accurately. This ensures that all containers are filled evenly and consistently.

8.What Types Of Products Can Be Sealed By A Paste Packaging Machine?

Paste packaging machines are an excellent option for businesses looking to package their products. Here’s a look at the different types of items that a paste packaging machine can seal:

Shampoo

Shampoo is an everyday item that can be sealed with a paste packaging machine. It’s important to ensure the lid of the container is properly sealed to ensure it contains no spills or leaks.

Sauces

Sauces can also be sealed with a paste packaging machine. This is especially useful for products that need to be stored for long periods, as the lid will be securely fastened.

Jams & Jellies

These products require an airtight seal to maintain their flavor and texture. A paste packaging machine is ideal for sealing these products, as it provides a water-resistant barrier that keeps the product safe from contamination.

Chocolate

Chocolate can quickly melt and spoil if not properly sealed. Therefore, a paste packaging machine is often used to seal chocolate products to keep them fresher for longer.

Pharmaceutical creams

Another product that often requires sealing is pharmaceutical creams. These products must be stored in a hermetically sealed container to ensure they remain safe and uncontaminated. A paste packaging machine can provide this level of protection for these items.

Honey

Honey is an incredibly sticky product and needs to be sealed using a particular method. So, you may need to use a paste packaging machine to ensure that your honey stays fresh.

Paints

Paint is a liquid product that needs to be appropriately sealed. A paste packaging machine is perfect for this task, providing an airtight seal and ensuring the paint stays fresh until use.

Industrial Lubricants

Industrial lubricants are often sold in large containers and require a secure seal. Therefore, a paste packaging machine can be used to securely seal these products, ensuring their integrity during transportation.

9.What Are The Different Types Of Packaging Materials That Can Be Used With A Paste Packaging Machine?

There are many different types to choose from when it comes to packaging materials for a paste-packaging machine. Here is a breakdown of the most common materials used:

Paperboard

This type of material is mainly made from recycled paper products and typically features a laminated coating that helps protect against leaks. It’s widely used for packaging food products and other liquids because of its strength, ease of printing, and cost-effectiveness.

Polyethylene (PE)

PE is a versatile plastic that can be used in various forms for many different applications. It’s often used as a primary layer to protect against leakage, making it ideal for packaging liquids like paint, sauces, and other food products.

Polypropylene (PP)

PP is a strong plastic that’s often used as the second layer for paste packaging machines. It helps to provide extra strength and rigidity, making it ideal for heavier items or liquids that require additional protection.

Aluminum

This type of material is lightweight, durable, and resistant to corrosion. It’s often used as an extra layer of protection for liquids that require a longer shelf life.

Polyvinyl Chloride (PVC)

PVC is a strong plastic that’s also highly resistant to moisture, making it an ideal choice for packaging products like spices and dry ingredients. PVC is also incredibly durable and can be printed on to create attractive packaging designs.

10.How Is A Paste Packaging Machine Different From Standard Packaging Machines?

A paste packaging machine is a specialized type of packaging machine that differs from standard ones in several ways. First, it is designed to handle products that have a more liquid or semi-liquid form, such as pastes and gels. Standard machines cannot accurately take these materials without leaving behind residue or inaccurate measurements.

Additionally, paste packaging machines are equipped with special features to ensure they are not damaged while in operation. For example, many are equipped with a soft material such as rubber which helps prevent damage due to the extra force needed when packaging paste-like materials. They also often include additional safety features like overfill protection and double seals to increase the accuracy and reliability of the packaging process.

Finally, paste packaging machines offer much more customization than standard packaging machines. This allows for greater control over the size, shape, and weight of the product being packaged, as well as how much of it can be filled into each bag or container. This added level of control sets paste packaging machines apart from their standard counterparts.

11.What Are The Common Problems and Solutions Associated With A Paste packaging Machine?

While paste packaging machines are designed to make the filling process more accessible, they can also be prone to problems. Here are the common issues with paste packaging machines and their solutions:

Leaking Pouches

This is one of the most common issues with paste packaging machines. The problem can be caused by faulty seals, worn or broken parts in the machine, incorrect setup, and even improper pouch loading.

Solution: To solve this issue, it is essential to check all parts of the machine and replace any worn or broken components. Additionally, proper loading of the pouches should be ensured, and correct setup must be followed with each new pouch.

Clogging and Jamming

Several different factors, including incorrect temperature settings, inadequate lubrication, or improper setup, can cause this problem.

Solution: To prevent this, regularly clean the machine and use a filter on the hose that delivers the paste to eliminate any large particles before they enter the machine. Additionally, making sure you’re using fresh products can also help reduce the chances of clogging.

Misfeeding

Misfeeding is often caused by incorrect pouch loading, worn or broken parts in the machine, and improper setup.

Solution: To ensure your paste packaging machine is working to its full potential, check all settings and adjust accordingly. Also, double-check that you are using the right material for the job and that all machine parts are in good working order.

12.What Safety Measures Should Be Taken When Operating A Paste Packaging Machine?

Safety is of utmost importance when operating a paste packaging machine. Therefore, it is essential to follow the safety measures below.

Read and Understand the Operator Manual

Before using a paste packaging machine, it is essential to read and understand the operator manual to know how to use the device safely and correctly.

Use Safety Equipment

Protective safety equipment such as goggles, gloves, and face shields must be worn while operating a paste packaging machine.

Wear Appropriate Clothing

Long sleeves and loose-fitting clothes should be avoided when operating a paste packaging machine as they can get caught in the machine’s moving parts. Always wear tight-fitting clothing and close-toed shoes for protection.

Keep Machine Clean

Regular maintenance and cleaning are essential to keep the machine in good working order and prevent malfunctions or injuries.

Use Caution When Working with Electricity

Always check that all electrical connections are properly secured, and never touch exposed wires. In addition, always unplug the machine when cleaning or performing maintenance.

Be Aware of Your Surroundings

Be aware of all personnel and objects in the vicinity and anything that could pose a hazard to you or the machine. Also, always look for any signs of wear and tear on the machine. If anything appears damaged, only use it once it has been inspected and repaired by a qualified technician.

13.How Often Does A Paste Packaging Machine Need To Be Maintained?

To ensure the optimal performance of your paste packaging machine, it needs to be maintained and serviced regularly. The frequency of maintenance depends on how often the machine is used and what kind of environment it operates in.

In fact, a well-maintained paste packaging machine should receive regular maintenance every six months. However, if it is operating in extreme conditions or used frequently, it may be necessary to service the machine more often.

If you are still determining how often your paste packaging machine should be serviced, consult a qualified technician for advice. They will be able to assess its condition and advise as to what maintenance and servicing schedule would best suit your needs.

Remember that regular maintenance keeps your machine running smoothly and efficiently. Neglecting your machine’s maintenance schedule could lead to costly repairs or even a complete breakdown. So, follow the recommended maintenance schedule and keep your paste packaging machine running like clockwork.

14.Are There Special Requirements For Using A Paste Packaging Machine?

Depending on the model and size of your paste packaging machine, you may need additional training or certifications to operate it safely and properly. Additionally, you should be familiar with local food safety regulations, as they may apply to the use of paste packaging equipment in your area.

Ensure you read the operating instructions carefully and follow all safety protocols when using the machine. If you are still getting familiar with the operation of this type of equipment, it’s best to contact a professional for assistance. This is because improper use can result in severe injury or damage to the equipment.

So, know what you’re doing before operating your paste packaging machine.

15.What Factors Should Be Considered Before Purchasing A Paste Packaging Machine?

Cost

Price is an essential factor to consider when purchasing a paste packaging machine, as it may determine the machine’s capabilities and how often it can be serviced in the future. Consider researching machines within your budget and opting for one that meets your needs without breaking the bank.

Speed

Depending on how quickly you need the paste packaging machine to operate, speed should be considered when making your purchase. Look for machines specifically designed for high-speed production and automation, if needed.

Accuracy

For precise packaging, accuracy is essential. When selecting a paste packaging machine, check the specs to ensure it can handle any quantity of product accurately and precisely.

Quality

Make sure the machine you purchase is high quality and built to last. In addition, select a machine with reliable components, so it will not experience frequent breakdowns or need constant maintenance.

Durability

When selecting a paste packaging machine, ensure it is designed with durable materials and components that can withstand long-term use. This will ensure the machine continues to function correctly and reduces repair costs in the future.

Versatility

Depending on your business needs, you may want a paste packaging machine compatible with many different packaging supplies, such as bags, pouches, or containers. Look for versatile machines that can be easily configured to work with other products.

Maintenance

Before making a purchase, inquire about the maintenance requirements of the machine you’re considering. Ask what parts may need to be replaced or serviced to keep them running smoothly and efficiently. Understanding these requirements will help you properly budget for future repairs.

Conclusion

Paste packaging machines are vital equipment for anyone in the food industry. They provide an easy and efficient way to package paste products. In this guide, we’ve answered some of the most common questions about paste packaging machines. We hope you found it helpful. If you have any other questions or would like to purchase a machine, please don’t hesitate to contact us at Allpack.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours