Your Best Powder 3 Side Sealing Machine Supplier

- High speed adaptable

- Require less materials and storage

- Suitable for liquids&powders&creams&grainy products

Allpack Powder 3 Side Sealing Machine

Allpack high-speed powder 3 side sealing machine is mainly used for making 3 side sealing pouches that for small serving applications.The kind of pouch made by this high-speed powder packing machine is suitable for packaging of products with small weight which is usually lower than 50 g. It is mainly used for the food packaging industry for products such as flavorings, coffee, and some spices.The pouch made this powder 3 side sealing machine also has easy product access with tear notch feature.If you have request high productivity,this powder 3 side sealing machine will be your best choice!

Powder 3 Side Sealing Machine

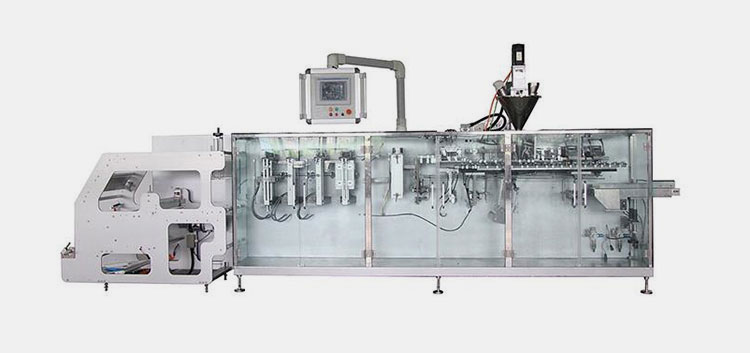

APK-889 Ultra-high speed automatic powder&granule 3 side sealing machine

Allpack ultra-high speed automatic powder&granule 3 sided sealingmachine adopts a rotary system,that will automatically make bag forming, filling, edge sealing, and counting in the horizontal direction, with machine speed up to 400-1200 packs per minute.The 3 side sealing pouches made by this powder packing machine have aesthetically pleasing and tightly sealed edges. And this high-speed powder 3 side sealing machine is also equipped with an automatic film connection device, it reduces film changing time and improves production efficiency.

Fully automatic horizontal 3 side sealing mach machine

All servo drives

Volumetric product feeder with rotary cup conveyor system

The Buyer's Guide

Powder 3 Side Sealing Machine: The Complete Faq Guide In 2025

Are you a manufacturer looking to improve the efficiency of your manufacturing operations in the sectors dealing with powders? Are you facing difficulty in packaging powdered substances effectively while maintaining their quality? If so, you are not alone.

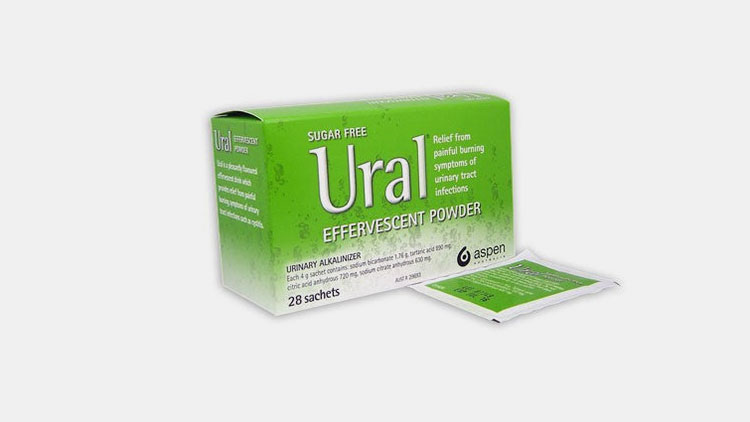

Picture Courtesy: Everyday Health

A powder 3 side sealing machine, with the incredible ability to solve the challenges associated with packing powdered materials, has become an essential instrument in multiple sectors, including the pharmaceutical industry. Investing in a powder 3 side sealing machine will ease your production processes effectively and will eventually help your business grow.

But before you opt for a device, you must know that there are multiple varieties of the machine available on the market. You should have basic knowledge of the machine to choose the right one according to your needs.

In this “Powder 3 Side Sealing Machine: The Complete Faq Guide In 2024’, we will explore the detailed description and the most asked questions about the powder-packing machine. So, join us in this guide;

1.What is a powder 3 side sealing machine?

Powder 3 side sealing machine

An industrial device made especially for the effective filling, packaging, and sealing of powdered materials is called a powder 3 side sealing machine. It can be utilized by various industrial manufacturers, including pharmaceuticals, chemicals, and food.

A range of powders may be effectively packaged by the powder 3 side sealing machine in several packaging (bags, sachets, or containers) in quick succession over time. The machine's efficient and simplified workflow has made it an essential component of many different businesses.

The equipment is in charge of filling the sachet with powder according to a set recipe and sealing it for delivery. It has evolved over the years, available in a range of variants.

2.What are the industrial applications of a powder 3 side sealing machine?

The powder 3 side sealing machine is versatile and remarkably adaptable in various industries. Some variants might be designed to handle a particular powdered substance while the modern ones might have the built-in features of handling different kinds of powders.

Here we are mentioning some major sectors that can utilize a powder 3 side sealing machine to boost their manufacturing efficiency.

Pharmaceutical Industry

Applications in the Pharmaceutical Industry – Picture Courtesy: Health Chemist

In the health sector, the device is employed for the wrapping of powdered drugs with correct measured dosages in various packages, particularly sachet production.

Food and Beverage Industry

Applications in Food & Beverage Industry- Picture Courtesy: Custome Pouches

In the food and beverage industry, the powder 3 side sealing machine is utilized for efficient packaging of powdered food goods, such as powdered milk, coffee, tea, salt, spices, flour, etc.

Chemical Industry

Applications in the Chemical Industry – Picture Courtesy: Pakona Engineer

In the chemical and agricultural industry, the powder 3 side sealing machine is utilized to package and dispense powdered chemicals, such as pesticides, rodenticides, detergents, fertilizers, veterinary chemicals, etc.

Cosmetic Industry

Applications in the Cosmetic Industry – Picture Courtesy: Ellana Cosmetics

Baby powders and cosmetic chemicals are the most popular cosmetic agents that can be package-wrapped with a powder 3 side sealing machine.

3.How the powder 3 side sealing machine can benefit you?

Purchasing a powder 3 side sealing machine can yield substantial advantages for your company. These devices, which can be used in the food, pharmaceutical, or cosmetic industries, are made to increase output, cut down on waste, and guarantee constant quality.

A powder 3 side sealing machine can help your company in the following ways:

Efficiency

Efficient Processing – Picture Courtesy: Technopack Corporation

Many of the laborious and time-consuming processes involved in packaging goods into sachets, such as metering and loading bags with the appropriate amount of product, may be automated using an automatic powder 3 side sealing machine.

In addition to time leverage and labor expenses, this helps in maintaining product quality by guaranteeing the right quantity of powder in each sachet.

Quality Consistency

Improved Quality of Products – Picture Courtesy: Custome Pouches

The powder 3 side sealing machine enables the packaging process under a strictly controlled environment, producing a high-quality and consistent finished product.

Increased Shelf-Life

Improved Product Shelf-Life

The powder 3 side sealing machine regulates the processes in a strictly controlled environment, avoiding cross-contamination, resulting in an increased shelf-life of the packaged products.

Waste Reduction

Reduced Product Spills – Picture Courtesy: Ocean Property

The automated functionality and reduced human intervention of the powder 3 side sealing machine aid in maintaining the product quality and consistent production of sachets with uniform and accurate dosing.

This helps in the reduction of wastes and spills, resulting in resources and cost preservation.

Increased Productivity

Enhanced Production – Picture Courtesy: Aphena Pharma Solutions

The automated mechanism and neglect the human involvement to a greater extent results in enhanced productivity.

Operational Ease

Easy to Operate – Picture Courtesy: BD Rowa

The powder 3 side sealing machine is easy to operate without requiring much training. The automatic variants are even simpler in operation, as they only need to switch ON and adjust the parameters from the control screen, the rest of the operation is done automatically.

Versatility

Versatility to Deal with Various Powders

The adaptability and versatility of certain variants of the powder 3 side sealing machine make it an incredible industrial tool, benefitting the manufacturer in various product processing.

Cost-effectiveness

Cost-effectiveness in the Long Run

Although the initial expense of a powder 3 side sealing machine is high, they are beneficial in terms of cost in the long run. The effectiveness and quality of production aid in the business growth, leading to a better turn on investment.

4.What is the basic functional protocol of a powder 3 side sealing machine?

Working of Ultrahigh Speed Automatic Powder 3 side sealing machine

Each variant of the powder 3 side sealing machine operates in a unique mechanism. Here we will discuss the working principle of the ultrahigh-speed automatic (3-side sealing) powder 3 side sealing machine.

Set up the operating parameters, including filling amount, sealing temperature, and trimming length as per the particular product that needs to be packaged.

The device feeds the packing film, which is then formed to take on the appropriate sachet shape.

In this device, the sachet is made in the sachet-forming station, by folding and sealing from three side edges, and one side is kept open.

The device adopts a rotary filling mechanism. The powdered ingredient, which is bulk-fed, is precisely measured and dispensed into the fabricated bags. The process in this specific device is optimized for fast and accurate filling.

Following the filling step, the sachet is sealed in the sealing station via heat and ultrasonic device to guarantee an airtight seal.

The sealed sachets are then trimmed and segregated from the film.

The device can process single or multiple sachets in a row.

The ultrahigh-speed automatic (3-side sealing) powder 3 side sealing machine is an ideal machine operating automatically at an incredible speed and offering diverse applications across industries.

5.How many bags/sachets can the powder 3 side sealing machine make per minute?

Picture Courtesy: Design Plus

Different variants of the powder 3 side sealing machine are rated based on the number of sachets it can make per minute. Typically, an automatic powder 3 side sealing machine can produce/seal even over than 400-1200sachets/min.

However, the actual speed of production is based on several factors, such as product characteristics, sizes of containers/bags, machine type, and operator skills.

The speed of the machine can be estimated by conducting a test trial.

6.How do you classify a powder 3 side sealing machine?

The availability of a heft of models of a powder 3 side sealing machine can be overwhelming. There are a variety of variants categorized on multiple criteria. Here we are discussing the major categories of the powder 3 side sealing machine.

PACKAGING-FORMAT-BASED CLASSIFICATION

Ultrahigh Speed Automatic (3-side sealing) Powder 3 side sealing machine

Ultrahigh Speed (3-side sealing) Powder 3 side sealing machine

The ultra-high-speed automatic powder 3 side sealing machine is equipped with a rotating mechanism that can produce packages at a rate of 400-1200 sachets/min. It automatically forms sachets, fills, edge-seals (3-sided), and counts horizontally.

The device also has an automatic film connection tool that minimizes the film replacement time and enhances operational efficiency. The 3-sided sealed sachets are elegant-looking.

Single as well as multiple sachets can be produced using this device. It has diverse applications in several industries.

Vertical Form Fill Seal (VFFS) Powder 3 side sealing machine

Vertical Form Fill & Seal (VFFS) Powder 3 side sealing machine

It is the most widely employed device. The vertical form fill and seal powder 3 side sealing machine is an efficient and fast production tool. It is an ideal equipment for processing free-flowing powders.

The device is popular for its rapid function and usually utilized in the food sector for the wrapping of condiments, coffee, and other powdered items.

It creates the wrapping bags from packing films using a shaping tube and sealing clamps. The powders are then poured into the sachets and then top-sealed via horizontal sealers.

Horizontal Form Fill Seal (HFFS) Powder 3 side sealing machine

Horizontal Form Fill & Seal (HFFS) Powder 3 side sealing machine

The HFFS machine contains several stations, in the horizontal direction, for the fabrication of sachets, loading of powders, and then sealing the sachets. It is an automated device that works efficiently.

The device starts working by unwinding of film rolls, which are directed toward the bag production area. The formed bags are then directed to the filling station and the packet is firmly closed via sealing clamps. The device can also process pre-formed bags.

Stick Pack Powder 3 side sealing machine

Stick Pack Powder 3 side sealing machine – Picture Courtesy: VKPAK

The stick pack powder 3 side sealing machine utilizes numerous lanes to pour powders into sticks/sachets. It can be employed to package food, nutritional, or cosmetic items.

The device is typically utilized to manufacture one-time-serve materials and is a favorite among contemporary consumers due to its mobility and ease. The stick-like sachets are made and sealed at both ends by the machine.

Pre-made Pouch Powder 3 side sealing machine

Pre-Made Pouch Powder 3 side sealing machine – Picture Courtesy: kenhigh

It processes and fills prefabricated pouches. The device consists of a rotating table with several stations for distention, loading, and sealing.

The pre-made bags are fed inside the magazine which are directed to the distention area. After that, the ingredients are loaded within the distended bags and then ultimate top-edge sealing is done via horizontal sealers.

AUTOMATION BASED CLASSIFICATION

Semi-Automatic Powder 3 side sealing machine

Semi-Automatic Powder 3 side sealing machine

In the semi-automatic powder 3 side sealing machine, a part of the operation is done by the device automatically but the presence of the worker is required for most of the steps, such as material feeding, bag insertion, and removal of filled sachets.

Automatic 3 side sealing machine

Automatic 3 Side Sealing Machine

Continuous human involvement is not necessary for a fully automatic powder 3 side sealing machine. The worker only has to set the working parameters and the rest of the operation is done by the device.

These devices consist of sensors that assist in the coordination of various components during the process. Such as a filling sensor detects the calculated quantity of powder and sends the signal to the device to cease the filling action.

The sensors facilitate to reduce the human errors and ensure functional accuracy.

OPERATING PRINCIPLE-BASED CLASSIFICATION

Auger Filler Powder 3 side sealing machine

Auger Filler Powder 3 side sealing machine – Picture Courtesy: Jawla Engineering

This type of powder 3 side sealing machine is utilized for filling precise and uniform quantities of dry granules or powders into a package. The device makes use of an auger screw which rotates and drives the powder to the auger plate.

From the plates, the powder is poured into the container. The auger blades also rotate in the opposing direction to prevent air entrapment.

Volumetric Cup Filler Powder 3 side sealing machine

Volumetric Cup Filler Powder 3 side sealing machine – Picture Courtesy: CoreTamp

This device is employed to load free-flowing powdered goods in sachets/jars. The volumetric cup powder 3 side sealing machine is composed of loading cups, hoppers, retention plates, and driving motors.

The device is tailored with various cups that transmit a specific quantity of powders to the sachets.

7.What is the importance of bulk density in the powder 3 side sealing machine?

Picture Courtesy: Eminence Organics

The bulk density of a powder indicates how much it will compact under pressure and how easily it flows. It is the product of mass and volume plus the contribution of inter-particulate voids.

The dry powders with free flowability, like granulated sugar, will not bunch much and have a lesser bulk density. In contrast, brown sugar with its non-free-flowing characteristics, has a greater bulk density, due to its tenacious nature. The more you exert pressure, the greater its bulk density becomes.

Numerous elements influence the bulk density of powdered goods, such as the amount of entrapped air, the cumulative density of particles, and the size and shape of particles.

Now if a powder 3 side sealing machine is handling two different kinds of powders, one is freely flowable while the other is non-freely flowing, the dimensions of the packages needed will vary. This is due to the varying bulk densities of the ingredients and the room around the particles.

The freely flowing powder will not be compacted easily due to greater space around it, hence will require a large pack.

That’s why the bulk density is important in the powder 3 side sealing machine as it has a significant impact on the package attributes. Additionally, the bulk density also regulates the kind of filler needed for the operation as well as the packaging speed that can be achieved.

8.What is the difference between a semi-automatic and fully automatic powder 3 side sealing machine?

| Fully Automatic Powder 3 side sealing machine | Semi-Automatic Powder 3 side sealing machine |

A fully automatic powder 3 side sealing machine is designed to operate at a faster rate with the least amount of human intervention. Businesses with a large number of products and little variance should use such machines. The fully automatic powder 3 side sealing machine could include automatic mechanisms for various steps of operation, such as feeding, measuring, filling, packaging, and discharging. It offers a higher degree of precision, quality, consistency, and efficiency in the operation, but requires a greater investment. |

A semi-automatic powder 3 side sealing machine requires a significant amount of human involvement. For instance, a company could use a packaging system with automated scaling and packing, but a person would still need to feed and discharge the product. If complete automation seems too much at this point, semi-automatic packing lines are an excellent place to start. Often, parts of a semi-automated line can be combined with other pieces of machinery at a later time to form a completely automated system. The semi-automatic powder 3 side sealing machine provides less control over the process and is less efficient and productive comparatively, but has a much lower cost and is affordable. |

9.Can a single powder 3 side sealing machine handle different-sized packages?

Different-Sized Powder Pouches- Picture Courtesy: Dachuan

“Generally, yes” is the succinct response. Modification in the device to accept various bags is called changeover, which might take minutes or hours, depending on several factors.

A universal machine isn't always the best choice. It can make more sense to invest in various systems or to automate just specific steps of the process if your demands are more diverse.

The rationale is that the powder 3 side sealing machine is designed to function best under specific constraints. If you have different demands, it may be difficult, expensive, and inefficient to adjust the machine parameters to suit those variances.

A machine that does one task excellently might occasionally be preferable to a computer that performs several tasks "just okay."

10.What are the maintenance protocols of a powder 3 side sealing machine?

Powder 3 side sealing machine Preventive Maintenance

The continuous operation of a powder 3 side sealing machine can result in the decline of its efficiency. To keep the device in an optimal operating condition, you have to develop and follow the proper maintenance protocols.

Some of the maintenance guidelines are;

- After every production batch or as per the predetermined timetable, disassemble the equipment and perform a deep cleaning of all the machine parts, particularly the components that come in direct contact with the powdered substances.

- Sanitize the contact elements for food powders or drug powders.

- Lubricate the moving components of the device, such as bearings, chains, and others, to maintain the proper motion and prevent friction.

- Perform a regular examination check of the entire equipment to check for any wear or tear. Consider timely repair or replacement of the damaged parts to ensure the optimal performance of the machine.

- Following the reassembly or repair, test the device using vacant bags to make sure it is operating as intended.

- For the sake of quality assurance and to assist in the identification of areas that require improvements or upgrades, maintain documentation of every service call, fix, calibration, and other tasks.

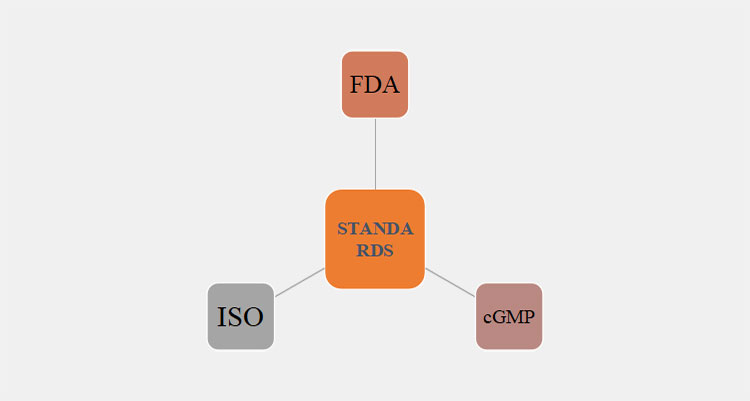

11.Are there any standards that a powder 3 side sealing machine should comply with?

For industrial devices to guarantee safe and efficacious product manufacturing while maintaining their quality and consistency, they must comply with the standard specifications.

The primary quality requirements that a powder 3 side sealing machine must satisfy are;

cGMP:the current good manufacturing practices are the regulatory requirements for the proper designing and other operations of the product.

CE:the certification of the European Conformity (CE) implies that the device satisfies the standard guidelines related to safety and environment.

ISO:the ISO-9001 affirmation signifies the device’s safety and quality as per the standardized regulations.

12.What common problems you might face while using a powder 3 side sealing machine and how can you tackle them?

Human mistakes or mechanical failures account for the bulk of problems with the powder 3 side sealing machine.

Here are some common issues and their remedies in a powder 3 side sealing machine.

Track Hotness

Hot Tack Issues – Picture Courtesy: Greener Corporation

The condition of the packaging material not being able to sustain the powder’s weight during the operations, such as heating or sealing.

Solution: make a stronger seal by elevating the sealing zone’s temperature.

Cold-air blasts can strengthen the hot track.

Extended Length of the Bag

Undesired Pouch Length

Regulate or reset the length variable of the bag to the desired length.

Imperfect Sealing

Defective Sealing

The condition of loose sealings.

Solution: adjust the sealing clamps. Always set the clamps aligned while a constant temperature is maintained.

Variations in Bag Size

Variations in Bag Sizes

Clean the film belts or regulate the film loading belt tension. Make sure the availability of the film rolls.

Frequent Clogs/Leaks

Package Leakage or Clogging

Adjust the device components properly, such as augers, hoppers, and seals. Consider a suitable device for your ingredients. Conduct regular maintenance.

Non-Uniform Filling

Non-Uniform Filling- Picture Courtesy: Insightbio

Check the volumetric adjustments to validate the calibration. Consider trained personnel for processing or adoption of automatic variants.

13.What factors should you consider while shopping for a powder 3 side sealing machine?

A powder 3 side sealing machine takes a significant amount of investment, therefore a wise choice is essential for the long-term success of your company.

Some of the important factors to consider while shopping for a powder 3 side sealing machine are;

Budget

Cost Factor – Picture Courtesy: Business Today

Before opting for a powder 3 side sealing machine, you must first clearly define your budget. Take into account the machine's original cost of purchase as well as continuing operating expenses.

Dealing Products

Your Product Nature and Composition – Picture Courtesy: Kerala Spices

You should know about the products you are dealing with and want to package. Consider the machine variant that is suitable for your products and capable of handling them effectively.

Production Capacity

Production Capacity of Machine – Picture Courtesy: Webpackaging

By evaluating your present and future production requirements, you can determine the necessary production capacity. This will assist you in choosing a machine that will meet your production requirements.

Adaptability

Customization in Powder 3 side sealing machine to Deal with Multiple Products

Considering a powder 3 side sealing machine that is customizable and has the flexibility to deal with a variety of products is essential. A device that can handle multiple products is the ideal one to opt for.

Regulatory Compliance

Regulatory Compliance – Picture Courtesy: Intellect QMS

Consumer health is a primary priority of any company. Therefore, a machine variant should be selected which is compliant with regulatory standards to ensure the safety and efficacy of the products. A hygienic packaging and product will also build the public’s confidence in the company.

Maintenance Ease

Easy Maintenance – Picture Courtesy: Levapack

There are a variety of machine variants available on the market, from simply designed to complex structured. Opt for a device that is easy to maintain to ensure its optimal performance and does not cost much.

CONCLUSION

Powders are instant products to use and have an increased demand across multiple sectors, including drug powders, cosmetic powders, chemical powders, and edible powders. A powder 3 side sealing machine is an indispensable device for all industries, offering robust, efficient, and quality packaging of powdered goods in a variety of different packages. Investment in a powder 3 side sealing machine can boost your business growth. If you are looking to buy the device then feel free to contact the AllPack Team for further assistance.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586