Food Grade High Speed Vacuum Emulsifying Mixer

- High-quality Configurations

- High-speed Dispersion System

- Homogeneous Shearing Technology

Vacuum Emulsifying Mixer

Allpack vacuum emulsifying mixer is suitable for emulsification of pharmaceutical, cosmetic, and fine chemical products, especially materials having high matrix viscosity and solid content, such as cosmetics, cream, ointment, detergents, salads, sauces, lotion, shampoo, toothpaste and so on. The vacuum emulsifying mixer has a triple blender, hydraulic lift cover, high-speed homogeneity blender (Speed is 0-3500r/min, frequency speed regulation), and low-speed scraper blender (Speed is 10-70r/min, frequency speed regulation). Fast-cutting vortex emulsification blender is used in the homogeneity part, which can scrape at a low speed and automatically blend and snuggle up to the bottom and wall of the boiler. The machine draws powder material by way of a vacuum in order to prevent the power from flying.

Vacuum Emulsifying Mixer

APKYGJ Vaccum Toothpaste Making Machine Toothpaste Production

Allpack APKYGJ vacuum toothpaste making machine is the key process of toothpaste production. The working principle of the equipment is to put various raw materials into the paste making machine in turn according to a certain production process, and through strong stirring, dispersing and grinding, the various raw materials are fully dispersed and mixed evenly. Finally, it becomes a paste by vacuum degassing. AVE series paste making machine is based on the existing technology, our company has optimized the scraping paddle, high-speed dispersion system.

Variable frequency speed scraper mixing

High-speed homogenizer

Stainless steel platform ans stairs

APKZRJ Bottom Homogenizer Cosmetic Cream Ointment High Shear Vacuum Emulsifying Mixer

Allpack APKZRJ bottom homogenizer vacuum emulsifying mixer refers to the equipment professionally used for high-speed shearing, dispersion and mixing of materials. It can make the material fully emulsified and fine, mixed evenly, and remove air bubbles in the production process. Professionally used for cosmetic cream materials and pharmaceutical cream materials.You can choose PLC touch screen or push-button type vacuum emulsifiers.The main boiler lid adopts the lifting system, it is easy to clean.

Adopts imported electric appliances

Contacted parts are made of SS316L

The main tank can be heated and cooled

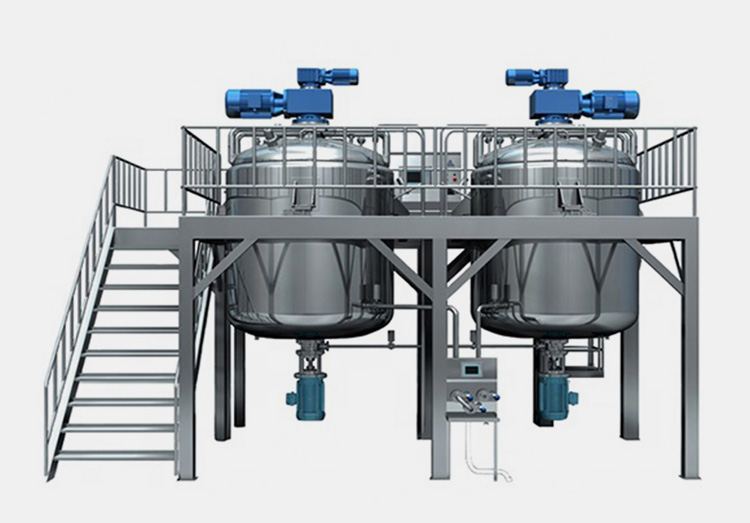

APKZRJ Fixed Type Vacuum Emulsifying Mixer

Allpack fixed type vacuum emulsifying mixer is made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are carried out mirror polishing, which is in complete accordance with GMP standard.The blending system adopts advanced triple blending and frequency conversion speed adjustment, so as to satisfy production of different technology requirement.The vacuum defoaming can make the materials meet the requirement of being sanitary and aseptic. The vacuum sucking material adopted can avoid dust, especially for the powder products.

High class appearance

High speed dispenser

Cosmetics making machine

APKZRJ Up Homogenizer Vacuum Emulsifying Mixer

Allpack up homogenizer vacuum emulsifying mixer means when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect.The machine is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc products through introducing advanced technology from abroad.

Adopts the imported frequency

Strictly according to GMP standard design and production

Excellent sealing quality and performance

The Buyer's Guide

Vacuum Emulsifying Mixer: The Complete Buying Guide in 2025

Mixing of high density and high viscosity materials for the purpose to prepare different kinds of medicines and other elements is quite a tough task.

But, vacuum emulsifying mixer or high shear mixer is a well known equipment that you can use for this purpose to boost your business and get quality production.

In this post, you will learn everything which is necessary to know when you want to purchase a vacuum emulsifying mixer for your production unit to fulfill your customers demand and market needs.

1.What is a vacuum emulsifying mixer?

A vacuum emulsifying mixer is a machine that helps to mix two or more substances together while creating an emulsion. The mixture of two liquids like oil and water that normally did not mix together is basically called emulsion.

The Vacuum Emulsifying Mixer is a versatile machine that can be used in a variety of industries. It is commonly used in the food industry to create emulsions, but it can also be used in the cosmetics and pharmaceutical industries.

2.Explain the different benefits of a vacuum emulsifying mixer?

A vacuum emulsifying mixer is a machine that is used to mix two or more substances together. An emulsion is created by doing this. This machine is basically used in the food industry to mix the products like different types of sauces and dressings.

There are many benefits to using a vacuum-emulsifying mixer. These benefits are as follows:

Prevents the Formation

The very first advantage of a vacuum emulsifying mixer is that it helps to prevent the formation of air bubbles in the mixture.

Evenly Distribute the Ingredients

Emulsifying Mixer Products

The second advantage of vacuum-emulsifying mixers is that it helps to evenly distribute the ingredients in the mixture. So, there is no extra distribution is done by using this machine.

Also, the great feature of machine is that it equally distributes the ingredients to all.

Keeps Mixture from Separating

The next and the important advantage of this machine is that it helps to keep the mixture from separating into its individual components.

Increases Shelf Life

The fourth one is that it helps to increase the shelf life of the product. By using the vacuum emulsifying mixer your product can be used for a longer period of time.

Consistent Product

The other advantage of a vacuum emulsifying mixer is that it helps to create a more consistent product.

Unique

The vacuum emulsifying mixer is unique. The machine also helps in improving the mixing performance. During the product handling you can get great mixing results by this machine.

Manufactured for Small and Medium-Scale Industries

The vacuum emulsifying mixer is mainly ideal for small and medium-scale industries. Basically, the working capacity of this machine is about 30L to almost 2000L.

Saves Time

The machine works very fast and saves time as compared to the manual technique of mixing. This machine is computerized which makes it faster in working.

Reduce Wastage

The vacuum emulsifying mixer reduces the wastage of mixing the ingredients. So, it is very beneficial for industries.

3.What is the working strategy of a vacuum emulsifying mixer?

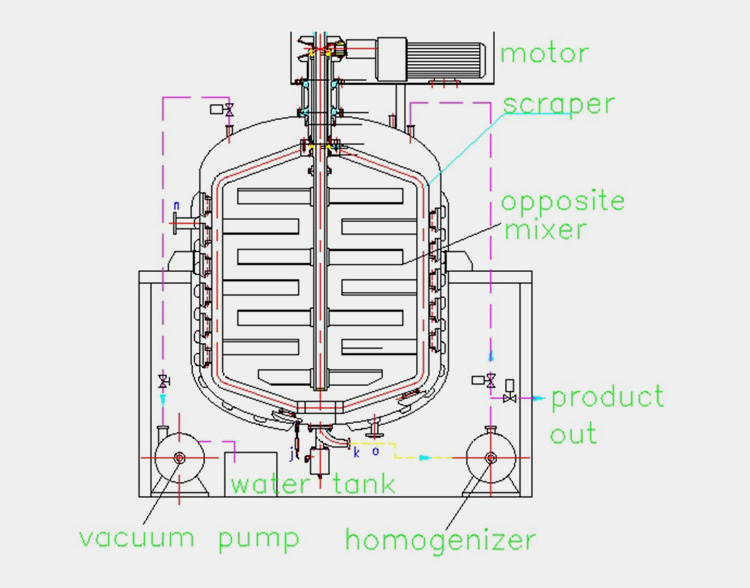

A top entry agitator is installed in the center of the vacuum chamber, and the material is drawn from the bottom by a vacuum pump. In terms of structure, it can be divided into the bottom entry and the top entry.

The homogenization head is installed on the top of the main pot body, and the material is introduced from the side-feed port.

The structure can be further divided into side entry and bottom entry according to the position of the homogenization head.

The working principle of a vacuum emulsifying mixer:

Working label diagram

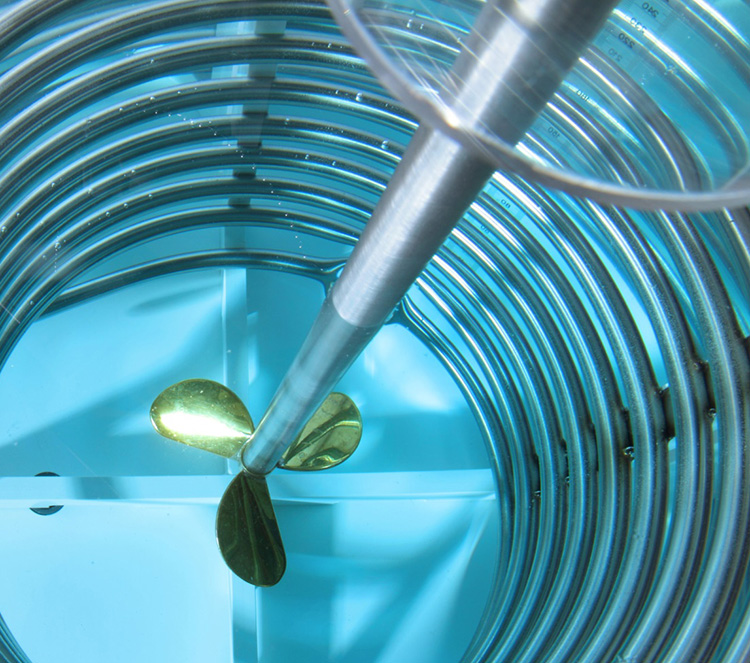

When materials are sucked into the mixing kettle by a vacuum pump, they are quickly dispersed and emulsified under the action of a high-speed rotating impeller.

At the same time, under vacuum conditions, air bubbles in materials are rapidly extracted, making materials fine and delicate.

After heating or cooling treatment in a water or oil bath, materials can be discharged through a discharge valve at the bottom of the kettle body to complete production.

4.Do you know about different types of vacuum emulsifying mixer?

A vacuum emulsifying mixer is a special type of mixer that is used to create emulsions during the mixing of products.

Two liquids mixed together by this machine and this mixing does not make bubbles. Vacuum-emulsifying mixers are often used to create lotions, creams, and other cosmetics.

There are different types of vacuum emulsifying mixers that are present in the market. All these machines work very smoothly and also give you uniform mixing.

The types of vacuum emulsifying mixers are as follows:

On The Basis Of Automation

Fully Automatic Vacuum Emulsifying Mixer

Fully automatic emulsifying mixer works continuously and is integrated with certain other supportive auxiliary devices to completely eliminate the human intervention. Its speed is up to the mark.

Components

Work frame, main frame, dual separate mixing tanks, one emulsifier, ladder, vacuum pump, mixing impellers and scrappers, control system, material conveying tubes and inlet/ outlet valves are the major components of automatic vacuum emulsifying mixer.

Working Process

Set the functioning specifications on control board including mixing speed, temperature level and processing time. Plug on the button, the operation will run smoothly by consistent rotation of impellers. Along with that, the sharp knifes clean out tank walls to ensure bubble free mixture. Just reaching up to desired level, device will automatically stop and convey the prepared solution through tube to receiving vessel.

Application

It can be used in every large scale industry like food, beverage, pharmaceutical, cosmetic, electronic and chemical industries etc.

Semi-Automatic Vacuum Emulsifying Mixer

Semi-automatic vacuum emulsifying mixer is employed for moderate level manufacturing thus need human interaction side by side with machine processing. Efficiency of this machine is also good, you can increase the capacity of material by using bowls of large sizes.

Components

It consists of mixing tank, control panel, emulsifying bowl with outer water pouring tube, agitator, sharp blades and temperature measuring gadget.

Working Process

Manually put the raw substances into mixing bowl. Make sure that required heat, speed and timing is well fixed. Start the machine, now the process will go on constantly until you shut down the power button after completion of each cycle. Here, you will manually pick the bowl having mixture and pour into other container.

Application

You can utilize it in low to medium scale industries or sectors confined to particular production like shampoo or lotion preparation and research labs where it is best suited.

On The Basis Of Structure

Vacuum Planetary Mixer

The vacuum Planetary Mixer is considered ideal for mixing material in the market because it has very high viscosity level.

The material that stuck while mixing is mainly removed by the knife-like scrapper that is present in the machine. It is basically designed to process intensive mixing and can be executed by triple methods like revolution, rotation and tilting. It is available in different sizes depending upon your capacity like 5 liter 10 or 20 liters etc.

Components

Major components of this machine includes stirring shaft, dual motors for rotating mixers, power switch, mixers, safety guard, main frame, stainless steel mixing bowl, temperature system and heat controller, bowl lift lever and high torque etc.

Working Process

First, you have to place the machine in even surface to ensure its stability. Then pour the raw materials into mixing tank and set temperature level for melting material in order for better mixture preparation. Now, turn on the switch button and centrifugal force will start moving material away from center to reduce material collection in middle of bowl. The constant rotation at good hearing ratio helps in making solution and also remove the air bubbles. Meanwhile, the tilting of flowing mixture finally results in providing the best fluid.

Application

You can better know the worth of this machine by its application such as solar panels, touch screen display, semiconductors or electrical appliances and for mixing ceramic slurry etc.

Laboratory Experiment

This laboratory experiment vacuum emulsifying mixer is available in the market in a smaller size. You can mix different types of chemicals in the laboratories by using this machine. You can mix the chemicals with some specific value. The mixing of chemical s should be uniform because some of the laboratory experiments are done on the basis of the mixing of different chemicals. This is done for making the experiment successful. So, this machine is very perfect for such type of experiment.

Components

This small compact equipment is made up of stainless steel frame, control system, upside stand, vacuum pump, mixing pot, impellers, scrappers, temperature meter, heating tube, water inlet and outlet valve.

Working Process

Working is quite easy as low volume is manually poured into mixing kettle and machine is started on the basis of predetermined specifications. Scrappers and impellers together completely break down the particulates and turn into pure uniform solution.

Application

This precise emulsifier is particularly used in laboratories and small scale industries for testing new solutions by mixing chemicals, natural ingredients and raw material.

Suppository Mixer

The next type is a suppository vacuum emulsifying mixer. The machine is used to give suppository medication. And also, you can get very high emulsification of oil which is solid like content. This machine is fully automatic with tri tanks, engaged in work simultaneously.

Components

It mainly composed of stainless steel work frame, main frame, water tank, oil tank, emulsify pot, homogenizer, agitator, heating system, scrapper, vacuum pump, hopper and control system.

Working Process

Operating method of this machine is easy enough. Firstly, raw material is separately put into water tank and oil tank. They are heated and well mixed. After completion of initial task, secondly the undissolved material is sucked into main emulsifying pot through vacuum pump, where collectively all the material is dissolved until reach its best form. During the process, agitator blow material for deforming, while at same time scrapper eliminate the stickiness of mixture on pot walls. Here, the source taken for heat is hot water, which is put into narrow hose located outside the mixing tanks.

Application

This emulsifier is mostly utilized by cosmetic and pharmaceutical Industries due to its stable and steady performance.

5.Compare and contrast between automatic vacuum emulsifying mixer and semi–automatic vacuum emulsifying mixer?

In below table you would be introduced with the dissimilarities between automatic and semi-automatic vacuum emulsifying mixer:

| No | Factors | Automatic Vacuum Emulsifying Mixer | Semi-Automatic Vacuum Emulsifying Mixer |

| 1 | Nature | It is fully automatic, consistent and fast in operation | It is semi automatic, inconsistent due to manual interference and slow in performance |

| 2 | Process | Process is simple but lengthy due to integrated machines | Process is simple but bit difficult because of human loading and unloading |

| 3 | Structure | Its structure is complex with so many parts | It is precise with few essential components |

| 4 | Application | Large scale firms such as food, cosmetic, pharmaceutical etc. | Medium scale firms, like laboratory, electronic and ceramic etc. |

| 5 | Machines |  |

|

6.How Would You Differentiate The High Shear Emulsifying Mixer And Low Shear Emulsifying Mixer?

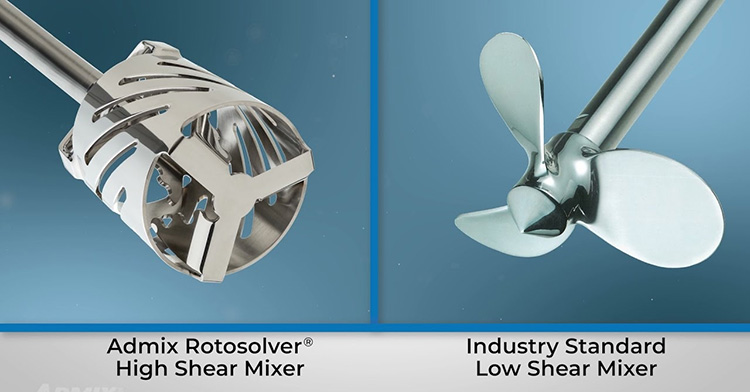

High shear emulsifying mixer and low shear emulsifying mixer are the two variant types of emulsion on the basis of functions they perform. The former is utilized for hard stuff while as later for sensitive material. Further details are expressed in below paragraphs:

High Shear Emulsifying Mixer

High shear emulsifying mixer is employed to deal the excessive production of hard and sturdy material. It uses extensive force for dispersion and make sure that particles are broken to their lowest level.

Low Shear Emulsifying Mixer

As the name display, low shear emulsifying mixer is made in such a way that it steadily mixes the raw materials in slow manner, so their sensitivity could not be damaged. Its purpose is only to mix the materials and maintain their little appearance in form of small particles.

Structure

The overall structure of both machines are almost similar, but the impellers or mixing agitators are different. High shear emulsifying mixer has multiple mixing impellers with sharp edges that can effectively dissolve every minor element to its best possible deformation. Contrary to this, the blades of low shear emulsifying mixer are simple and not so sharp. They do not damage the quality of material during operation.

Working Principles

High shear emulsifying works through full speed and remains fast in performance with goal of breaking down every smaller element in order to transform their shape into single uniform shape. It also requires high temperature for melting material. In contrast, the particles remain unbroken, but well mixed under moderate temperature and steady speed in low shear emulsifier.

Speed

High shear emulsifying has fast speed which eventually result in more output. On the other hand, low shear mixer is slow in performance, thus require much time for accomplishing task.

Application

High shear emulsifying is mostly suitable in plastic, electronic, chemical and liquid medical industries etc. Contrary to it, low emulsifying mixer is recommended for food industries, tablets processing and ceramic industry etc.

Price

High shear emulsifying mixer is expensive because of its structure, performance, high temperature and power consumption. While as, low shear emulsifying mixer is cost-effective due to simple construction, low power consumption and heat requirement.

7.What are the different industries in which vacuum emulsifying mixer is used?

Vacuum-emulsifying mixers are used in a variety of industries, including cosmetics, food, and pharmaceuticals.

Cosmetic Industry

The cosmetics industry uses vacuum-emulsifying mixers to create lotions, creams, and makeup. Vacuum emulsifying mixers help to evenly mix ingredients and prevent them from separating. This results in a smooth, consistent product.

Food Industry

The food industry also uses vacuum-emulsifying mixers to create sauces, dressings, and marinades. Vacuum emulsifying mixers help to evenly distribute spices and flavors in these products. This results in a more consistent flavor and texture.

Pharmaceutical Industry

Syrup Mixing

The pharmaceutical industry uses vacuum-emulsifying mixers to create medicines and supplements. Vacuum emulsifying mixers help to evenly distribute active ingredients in these products. This results in a more consistent dose of the active ingredient in each tablet or capsule.

8.How vacuum emulsifying mixer is different from other mixers?

Auto Vacuum Emulsifying Mixer

Vacuum emulsifying mixers are different from other mixers in several ways. These ways are as follows:

Vacuum Function

First, they have a vacuum function that helps to remove air bubbles from the mixture. This results in a more uniform mixture and prevents the formation of foam.

Heating Function

Second, vacuum emulsifying mixers have a heating function that helps to melt and mix ingredients more evenly. This is especially useful for mixing viscous or solid ingredients.

Cooling Function

Third, vacuum emulsifying mixers often have a cooling function that helps to cool the mixture after it has been heated. This is important for preventing the mixture from burning or overcooking.

Higher Speed than Others

High Speed logo

Fourth, vacuum emulsifying mixers usually have a higher speed than other mixers. This helps to reduce the mixing time and improve the quality of the final product.

More Efficient and Effective

Overall, vacuum-emulsifying mixers are more efficient and effective than other mixers. Their unique features make them ideal for mixing a variety of ingredients, including viscous or solid ingredients.

9.Which types of materials you can emulsify using a vacuum emulsifying mixer?

Vacuum emulsifying mixers can be used to emulsify a variety of materials, including water, oil, emulsifiers, and thickening agents.

Water

Vacuum Mixing

Water is the most common material that is emulsified using a vacuum emulsifying mixer. The water is added to the mixer along with the other ingredients. The mixer will then vacuum out the air from the mixture, creating an emulsion.

Oil

Oil is another common material that is emulsified using a vacuum emulsifying mixer. The oil is added to the mixer along with the other ingredients. The mixer will then vacuum out the air from the mixture, creating an emulsion.

Emulsifiers

Emulsifiers are a type of ingredient that helps to keep the mixture from separating. They are added to the mixer along with the other ingredients. The mixer will then vacuum out the air from the mixture, creating an emulsion.

Thickening Agents

Thickening agents are another type of ingredient that helps to keep the mixture from separating. They are added to the mixer along with the other ingredients. The mixer will then vacuum out the air from the mixture, creating an emulsion.

10.What are the necessary precautions for installation and operation of a vacuum emulsifying mixer?

We have pointed out the essential elements for your successful installation and using of vacuum emulsifying mixer. Make sure these are properly fulfilled:

- Always read the instructions before installation of machine.

- The location you fix for placing your machine should be permanent, as it is not movable and with heavy weight it may create difficulty for you.

- Examine the area is well ventilated as some chemical or hazardous substances may emit gases or smell which is not good for health.

- Try not to immerse the mixing tank in water and in case you have done this, completely dry it with soft cloth and ask a specialist if it is eligible for reusing.

- When you intend to increase or decrease the speed of machine, must power off the button, as it will help in long life of your emulsifier.

- Do not leave the mixer during operation because supervision is required in case of any mishap.

- Avoid using machine in absence of protective cover switch and completely remove the electric supply if you are not using it.

11.How to troubleshoot the problems caused when operating a vacuum emulsifying mixer?

To better understand the problems, their possible causes and troubleshooting of a vacuum emulsifying mixer, consider the table below:

| No | Problem | Possible Causes | Troubleshooting |

| 1 | Emulsifier cannot start | Either supply connection is poor or guards are incorrectly fitted | Check the connection and correctly fit guards |

| 2 | Temperature of emulsifier is not increasing | It may be due to incorrect power supply or the control system for heat may be damaged, so it is not displaying correct temperature | Make sure that power supply provided for temperature is enough and also ask any expert to correct or replace the temperature controller |

| 3 | Material get congregated in bottom of pot | This problem always occurs due to high viscous material | It can be solved by reducing material droplets and adding water so that the thickness of material might be reduced and its smooth flow could be retained |

| 4 | Emulsifier becomes too heated | It happens when machine is operated for too long with overload | Stop the operation for some time and restart it with low volume |

| 5 | Performance of mixer is low | It may be due to loose driving belts or they worn out have | Check and tight the chains, in case of damage belts replace them |

12.How to select a suitable vacuum emulsifying mixer?

In selecting of a suitable vacuum emulsifying mixer, you should consider the following factors:

Exact Information about Product

Firstly, you should know your products, including ingredients, texture, color, and other special requirements.

Production Capacity You Need

Then you need to know your production capacity. How many liters or how many batches do you want to produce per hour?

Based on the information above, we will recommend the most suitable model for you and provide a quotation.

Conclusion

A vacuum emulsifying mixer is a versatile machine that can be used in a variety of different settings. Whether you’re looking to create cosmetics, pharmaceuticals, or food products, the vacuum emulsifying mixer can help you achieve your desired results. If you’re interested in learning more about this machine and how it can benefit your business, be sure to check out our website for more information.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours