Juice 4 Side Sealing Packing Machine: The Complete Buying Guide In 2024

Juice 4 Side Sealing Packing Machine: The Complete Buying Guide In 2024

Starting from morning breakfast to afternoon snacks juices are an important part of the meals. Various types of juices refresh us throughout the day. Seems healthy. Customers are always looking for handy juice 4 side sealing packing. That is why manufacturers are striving to produce more and more juice products with cost-effectiveness.

For this, manufacturers always incorporate the juice 4 side sealing packing machine in the production line. This machine is designed with sophisticated technology that has revolutionized the field of packaging. Its automation level, precision, and versatility are desired in production lines.

If are you navigating the field of the juice 4 side sealing packing machine, then read carefully this buying guide to have a deep understanding of the fascinating world of the juice 4 side sealing packing machine.

1.What is Meant by Juice 4 Side Sealing Packing Machine?

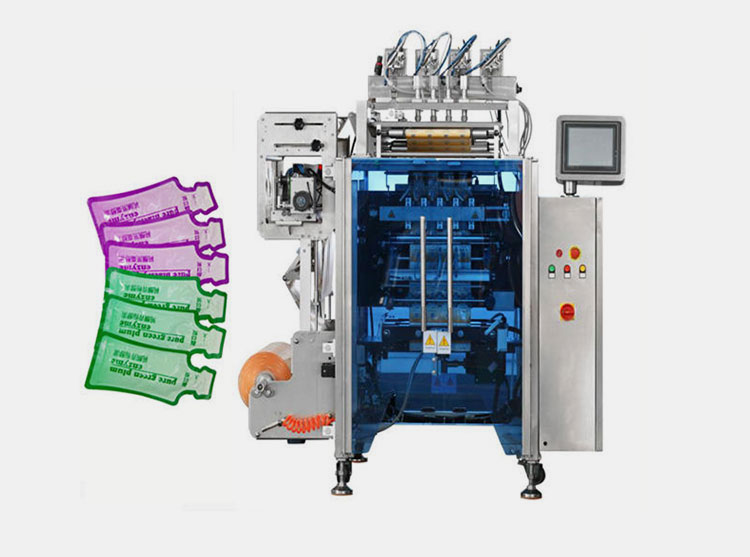

Allpack Juice 4 Side Sealing Packing Machine

Juices are available liquid form, so to pack them, an efficient and advanced machine is required which is known as juice 4 side sealing packing machine

It is equipped with the latest and sophisticated technology that aids in forming packs, filling them with juice products and then hermetically and permanently sealing them.

It seals sachet or stick packing on all four sides, providing a cheaper and simpler way to pack juices. It increases the shelf-life of the juice products by enclosing them properly. Juice 4 side sealing packing machine is versatile in carrying out its jobs and hence it can be changed to meet different production requirements.

2.Enumerate the Advantages of juice 4 side sealing packing machine

Manual packaging is a thing of the past. As with the juice 4 side sealing packing machine, you can create juice packing in a timely and affordable way. With its flexible and sophisticated technology, it is a means to pack juice cost-effectively. Here are the advantages of juice 4 side sealing packing machine:

Enhanced Production Efficiency

Enhanced Production Efficiency by Juice 4 Side Sealing Packing Machine- Picture Courtesy: Bucked Up

Juice 4 side sealing packing machine is an all-in-one machine, forming, filling, and continuously sealing packaging formats. This characteristic is essential in increasing production efficiency. With this machine, manufacturers can get more and more of their juice products in the market.

Consistency and Accuracy

Consistency by Juice 4 Side Sealing Packing Machine

Consistency in fill amount goes a long way in paving the way to customer trust, as users have confidence in manufacturers that deliver products without any error. Thus, manufacturers are increasingly using the juice 4 side sealing packing machine because it produces consistent results every time. It also creates a sachet or stick packs of the same length and shape in every batch.

Versatility

Versatility by Juice 4 Side Sealing Packing Machine

To compete with the manufacturers, it is necessary to customize and tailor design the products because customers are more attracted to unique products when they surf the market. Therefore, the juice 4 side sealing packing machine is important in this aspect because it is versatile and flexible, creating unique juice packing on parameters input.

Lower Material Waste

Low Material Wastage by Juice 4 Side Sealing Packing Machine

Manufacturers want lower material wastage every time because it is a cost-effective way to run a successful business. They prefer the juice 4 side sealing packing because it efficiently uses packing material every time. That is why, it produces less material wastage, saving valuable and expensive packaging film.

No Break in Packaging

No Breaks in Packaging by Juice 4 Side Sealing Packing Machine

Juice 4 side sealing packing machine has a robust and resistant design that will serve it for many years. Due to this robustness and durability, this machine can carry out its packaging jobs without taking any breaks or pauses in packaging. It can run every hour of every day, processing more and more batches.

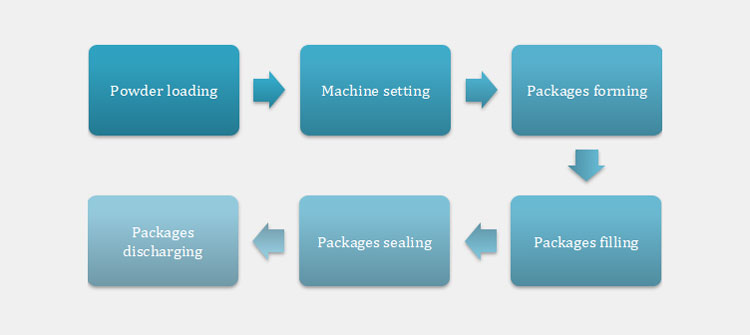

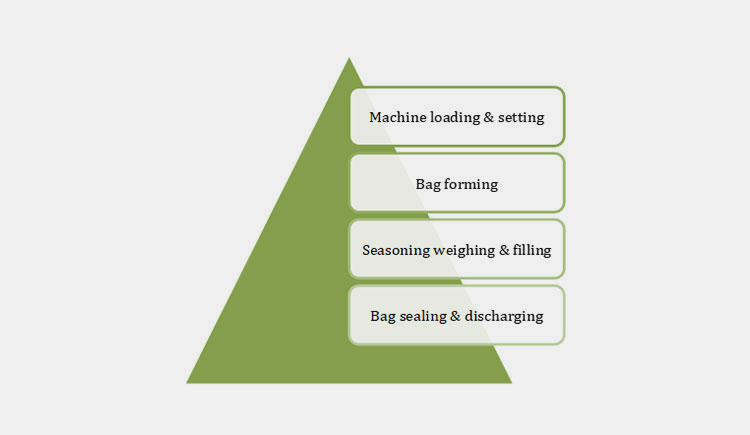

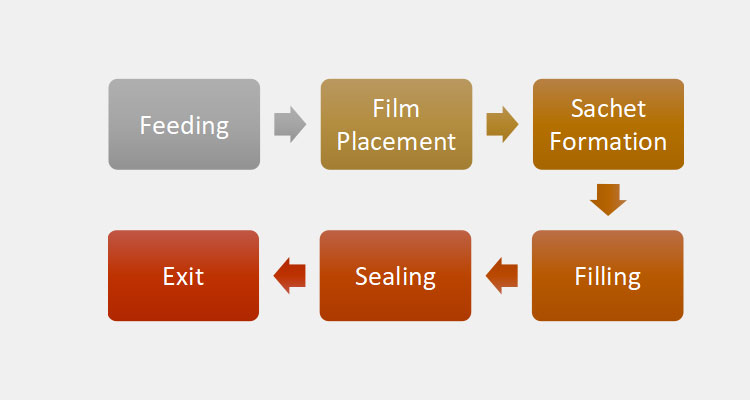

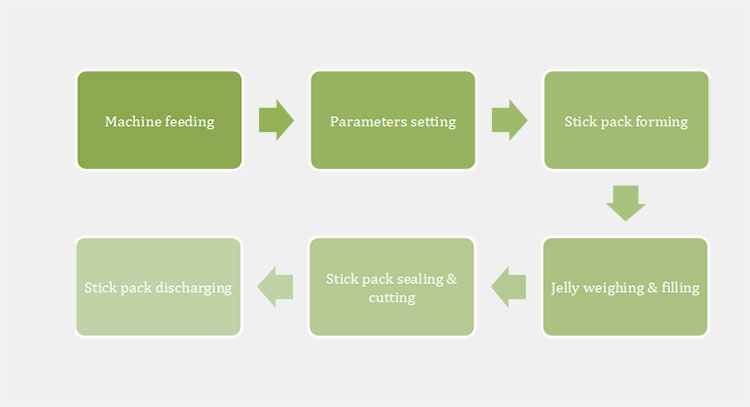

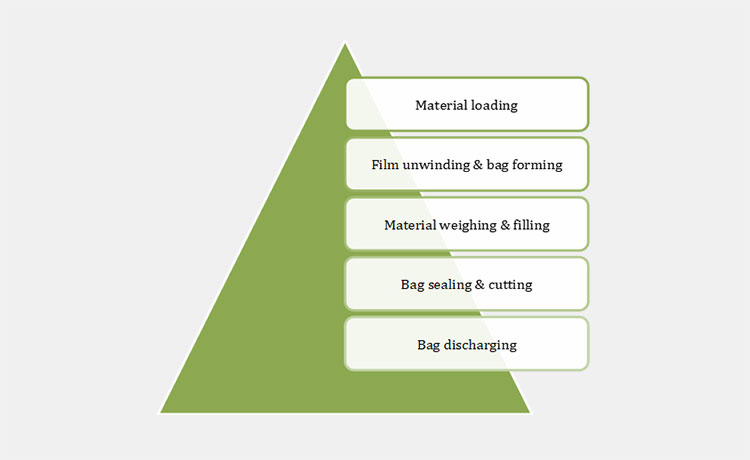

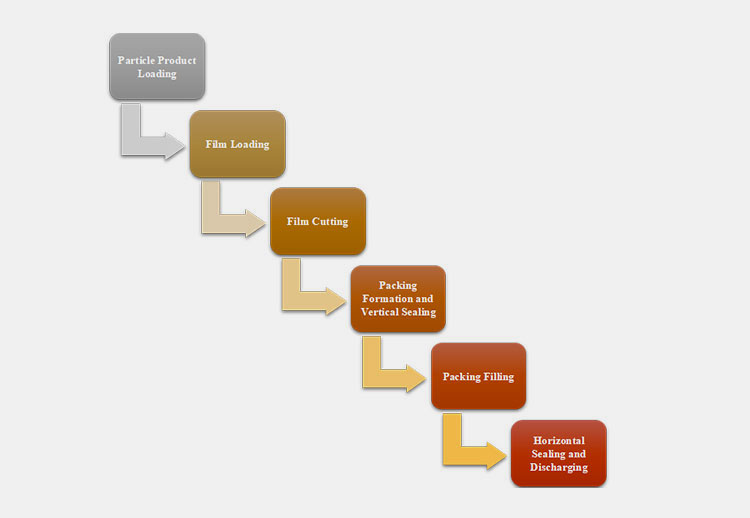

3.What are the Working Steps of the Juice 4 Side Sealing Packing Machine?

Juice 4 side sealing packing machine is an efficient machine, performing its working jobs flawlessly and neatly. The working steps of the juice 4 side sealing packing machine are as follows:

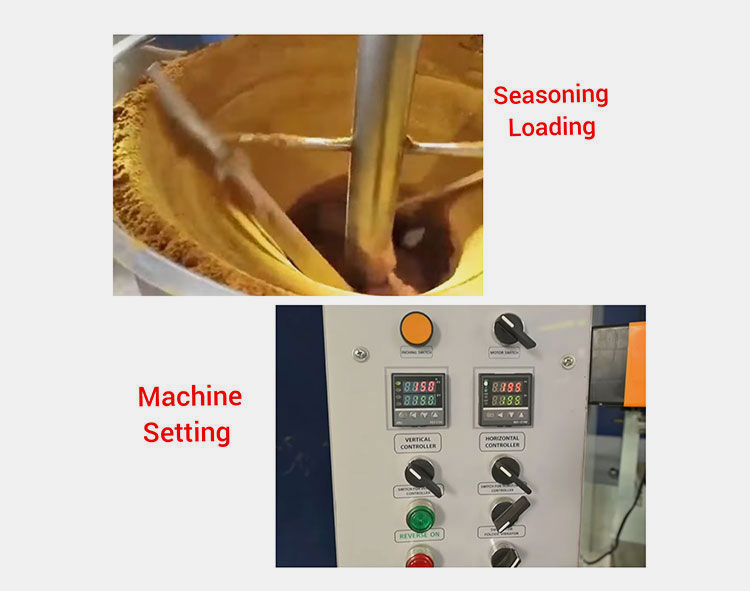

| Product Loading

Product Loading |

At first, the juice is loaded in the hopper found at the upper side of the machine. This hopper has a significant role in storing bulk amounts of juice products for nonstop operation. |

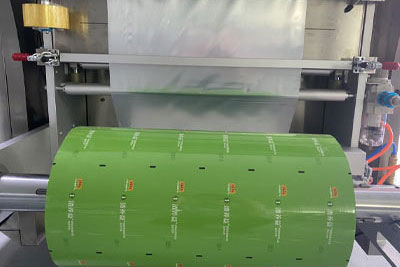

| Film loading

Film Loading- Picture Courtesy: samfull.net |

In the next step, the film is fixed on the cylindrical film holder. The operator passes the film over the rollers to maintain firm tension in the film. Afterward, the operator programs the necessary program parameters on the HMI. Once the machine starts, the film begins to unwind. With the constant and steady rotation of film rolls, the film unfurls and reaches the forming station. |

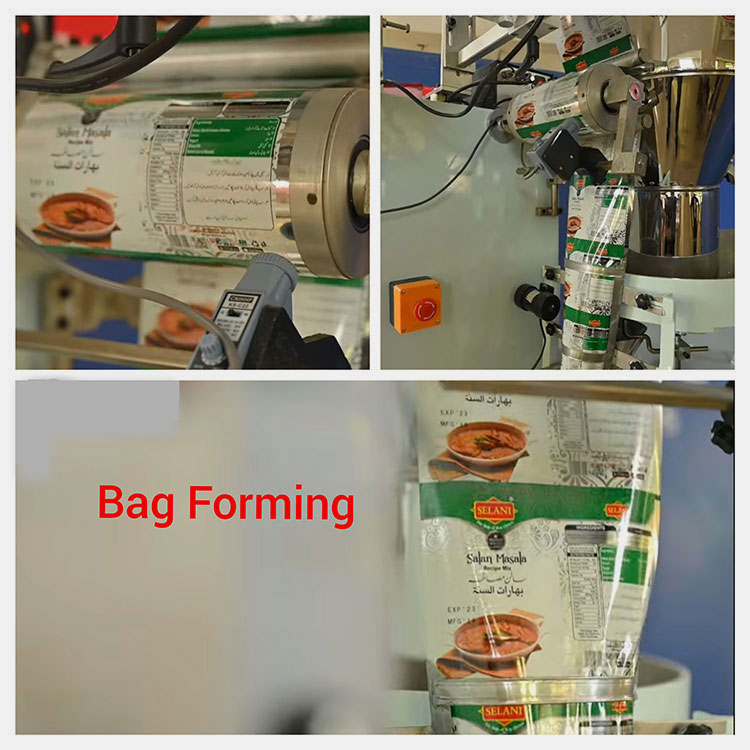

| Bag Forming

Bag forming and Filling- Picture Courtesy: landpack |

Upon reaching the forming station, here the film is doubled and folded. The longitudinal and lateral sealing jaws act on the film to seal its side and bottom edges. |

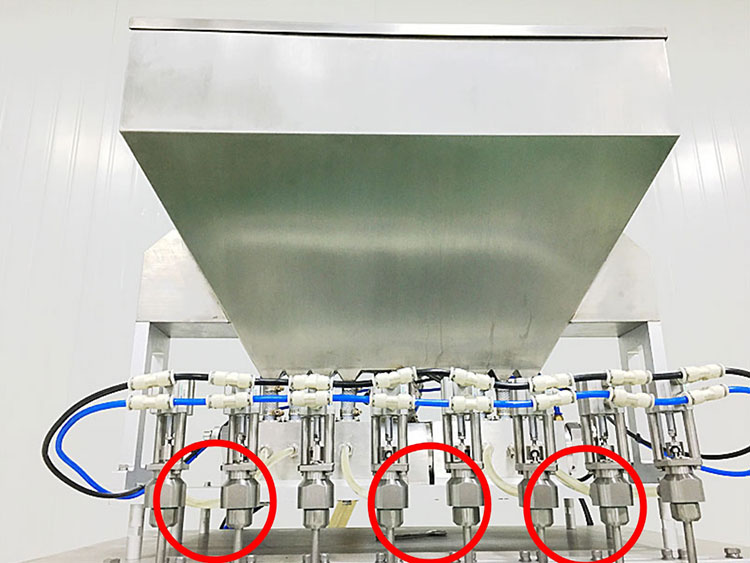

| Filling

Filling- Picture Courtesy: landpack |

At the same time, the filling devices move the juice from the hopper into the filling nozzles. These fill nozzles are essential in loading juice in the formed bag. |

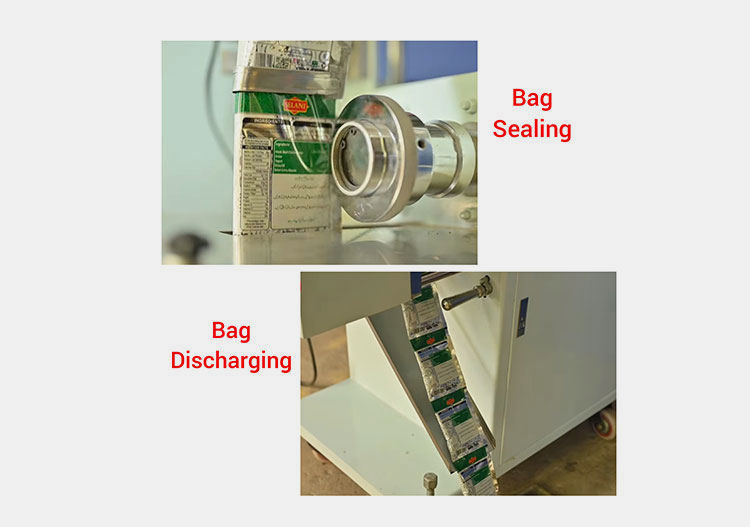

| Top Sealing and Cutting

Top Sealing and Cutting- Picture Courtesy: Landpack |

After filling, the top end of the juice-filled bag is hermetically sealed by the heated horizontal sealers. These sealers tightly close the top opening. The last step before juice bag discharge is cutting. In this step, the bag is cut from the film and moved to the discharge chute. After its separation from the other packaging, the finished bag drops down on the discharge chute or the product conveyor. From where it is transported to further packaging processes like cartoning. |

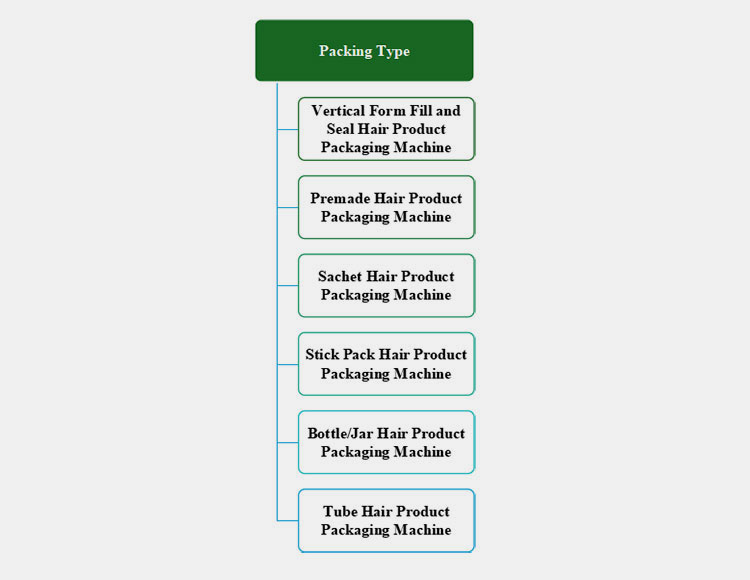

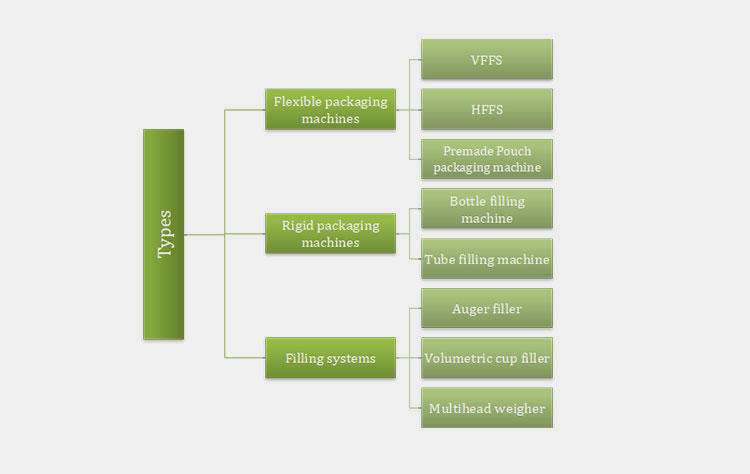

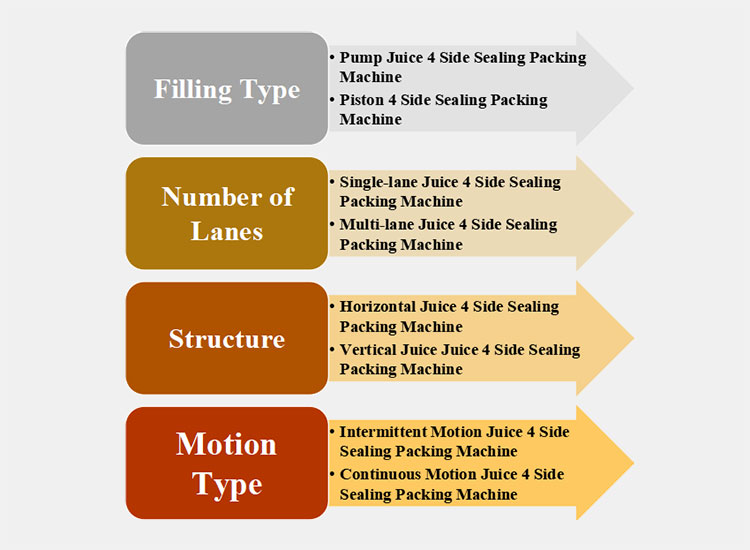

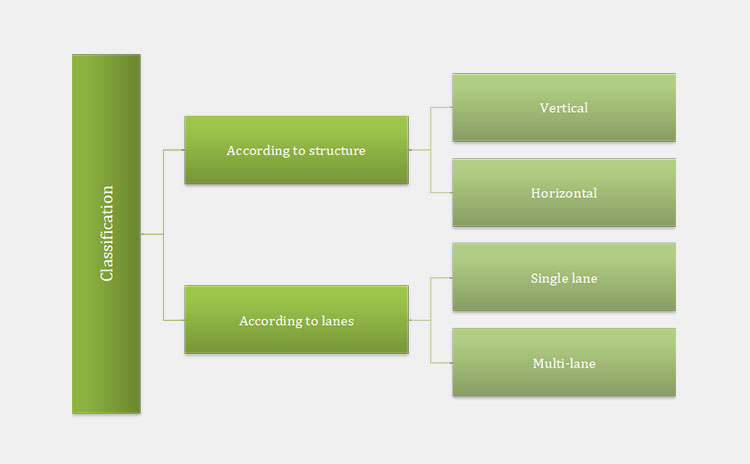

4.How to Classify Juice 4 Side Sealing Packing Machine?

The classification of juice 4 side sealing packing machine is described below:

According to the Filling Type

Pump Juice 4 Side Sealing Packing Machine

Pump Juice 4 Side Sealing Packing Machine

Small pumps are present in this type of machine. For precise loading, the quantities of juice are weighed. Then these quantities are loaded in the juice packs by the filling nozzles. There is accuracy and fill precision in every batch by this machine.

Piston Juice 4 Side Sealing Packing Machine

Piston Juice 4 Side Sealing Packing Machine

This type of juice 4 side sealing packing machine is equipped with a piston housed in a cylinder. To and fro motion of piston in cylinder aids in the accurate dispensing of the juice drink mix. This machine is best for rapid and contamination-free dispensing of juice products.

According to the Number of Lanes

Single-lane Juice 4 Side Sealing Packing Machine

Allpack Single-lane Juice 4 Side Sealing Packing Machine

It has a compact construction due to the presence of a single lane, therefore it produces juice packing at a time. It is usually found in small businesses and the home based industry.

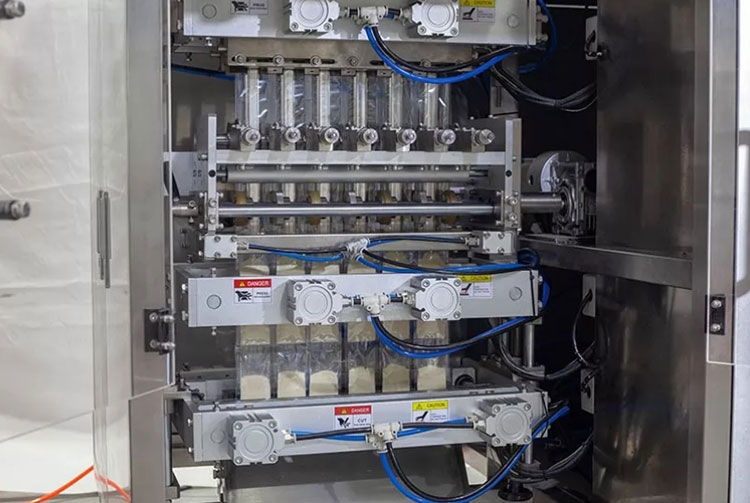

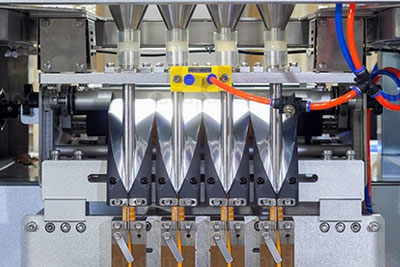

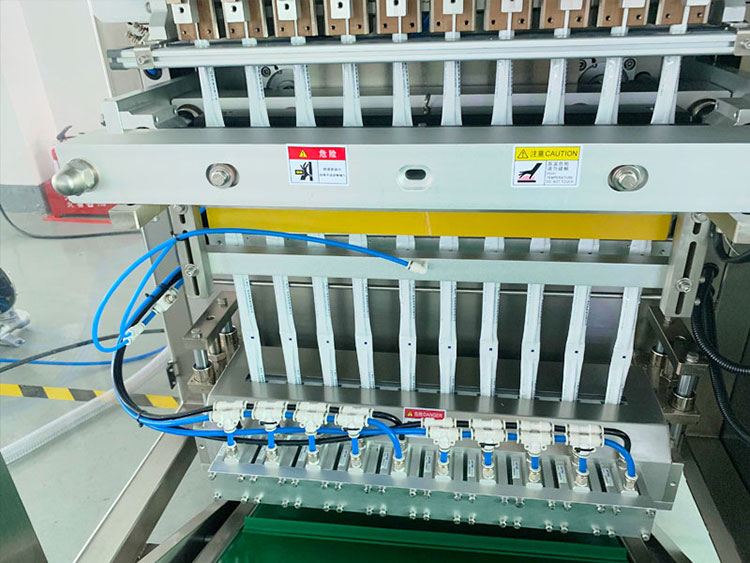

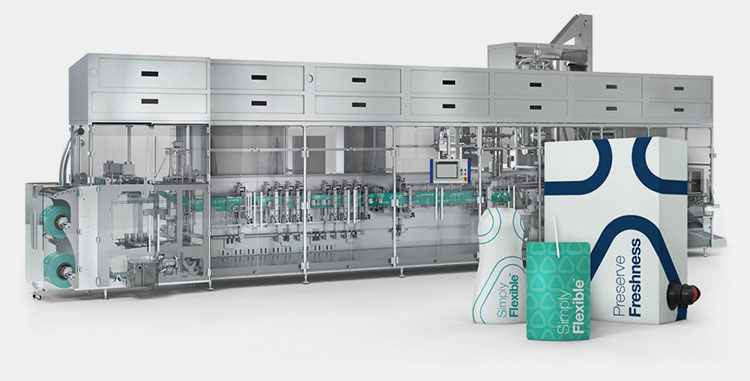

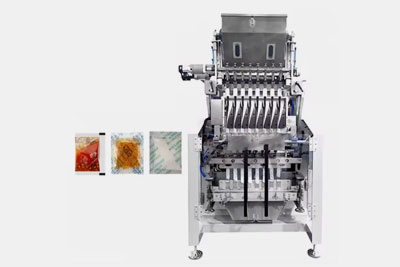

Multi-lane Juice 4 Side Sealing Packing Machine

Allpack Multi-lane Juice 4 Side Sealing Packing Machine

It is comprised of many lanes in the range of 4-20 lanes, as a result, it forms, fills, and seals more juice products than a single lane juice 4 side sealing packing machine It is needed in higher production plants, because it loads more quantities of juice, earning more profits for larger businesses.

According to the Structure

Horizontal Juice 4 Side Sealing Packing Machine

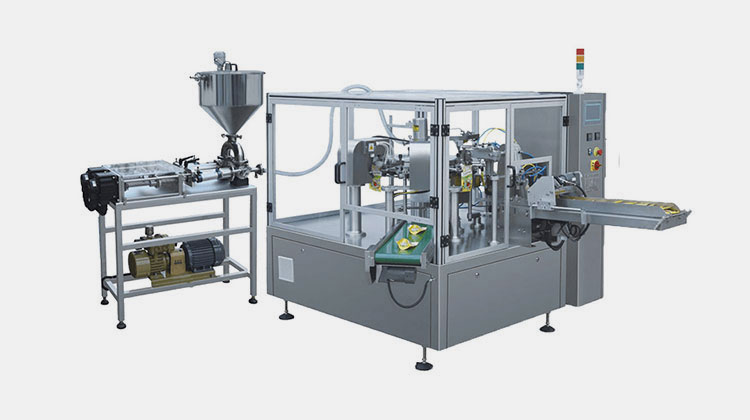

Allpack Horizontal Juice 4 Side Sealing Packing Machine

It is yet another brilliant type of juice 4 side sealing packing machine It is characterized by its horizontal body that occupies a larger space. It is a closed structure in which the working performance of the machine is monitored by a transparent window. The running steps like forming, filling, and sealing are executed in the horizontal direction.

Vertical Juice 4 Side Sealing Packing Machine

Allpack Juice 4 Side Sealing Packing Machine

This type of machine is defined by its vertical construction. It delivers optimized results, both in automatic and semi-automatic modes. It efficiently executes different steps of forming, filling, and sealing in a single run. Due to its vertical construction, this juice 4 side sealing packing machine functions in upside upside-down manner. It occupies a smaller space.

According to Motion Type

Intermittent Motion Juice 4 Side Sealing Packing Machine

Intermittent Motion Juice 4 Side Sealing Packing Machine- Picture Courtesy: IMA Group

The intermittent juice 4 side sealing packing machine is defined by its intermittent working performance, meaning it pauses after every step, thus having a slow processing rate. However, it is more versatile and flexible, producing numerous types of packing formats and can make different-sized formats.

Continuous Motion Juice 4 Side Sealing Packing Machine

Continuous Motion Juice 4 Side Sealing Packing Machine- Picture Courtesy: Samfull packing machine

This kind of juice 4 side sealing packing machine is defined by its continuous mode of operation. It does not stop between the cycles, hence can produce more sachet or stick pack due to its higher speed. It is equipped with advanced controls that aid in optimizing production efficiency.

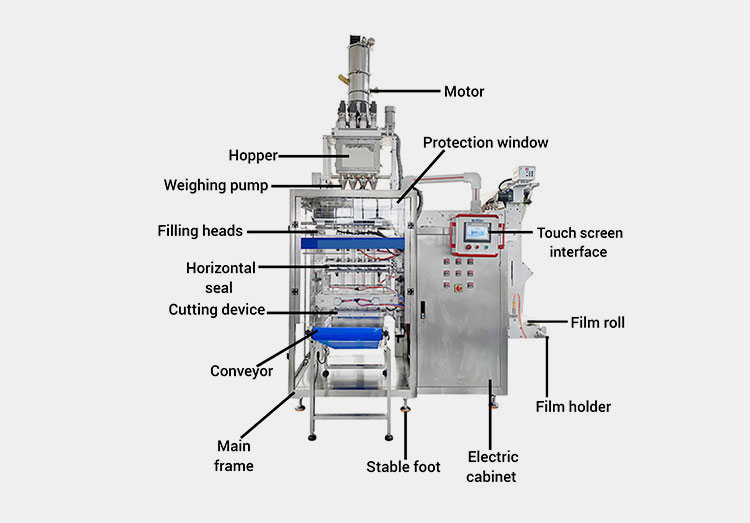

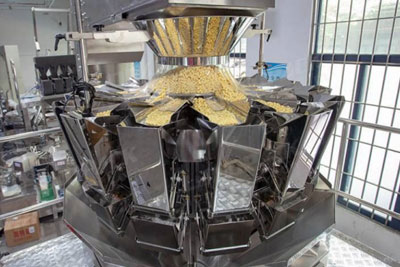

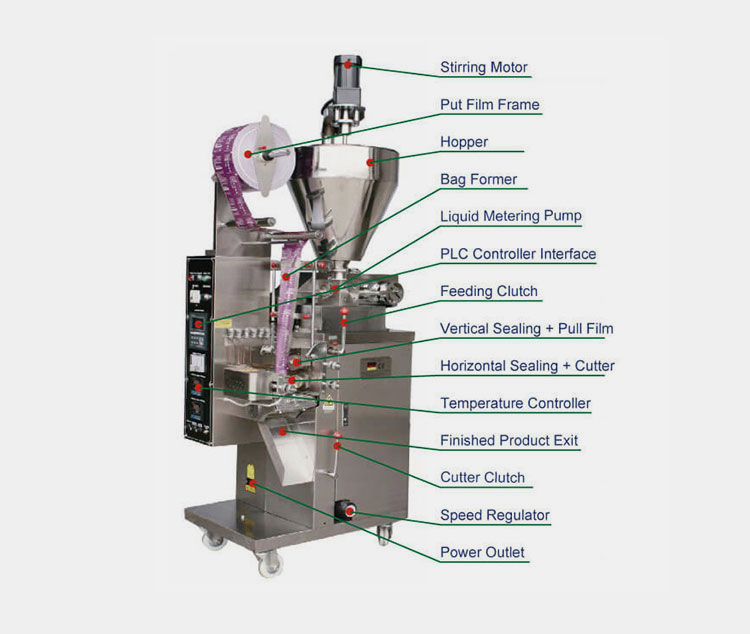

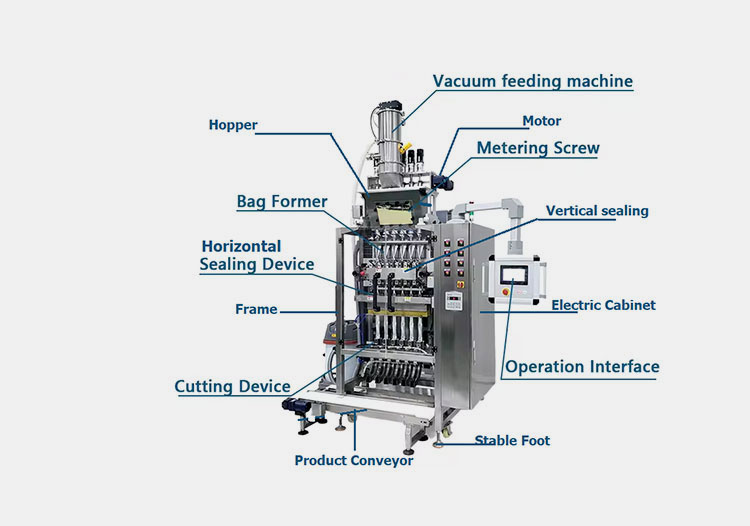

5.What is the Design of the Juice 4 Side Sealing Packing Machine?

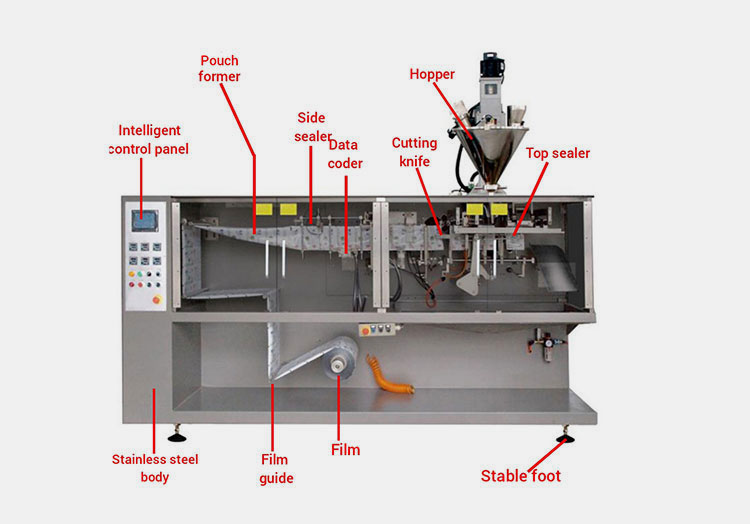

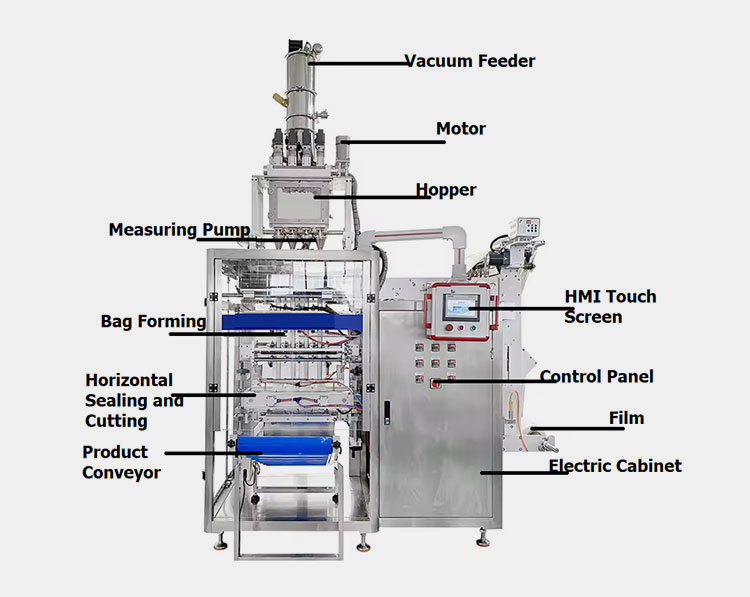

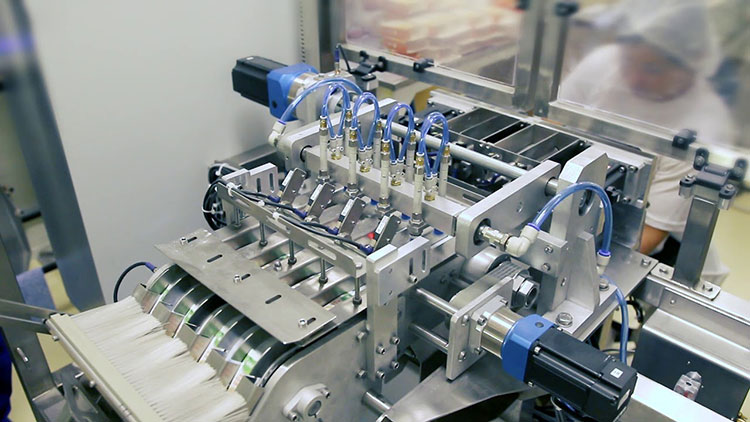

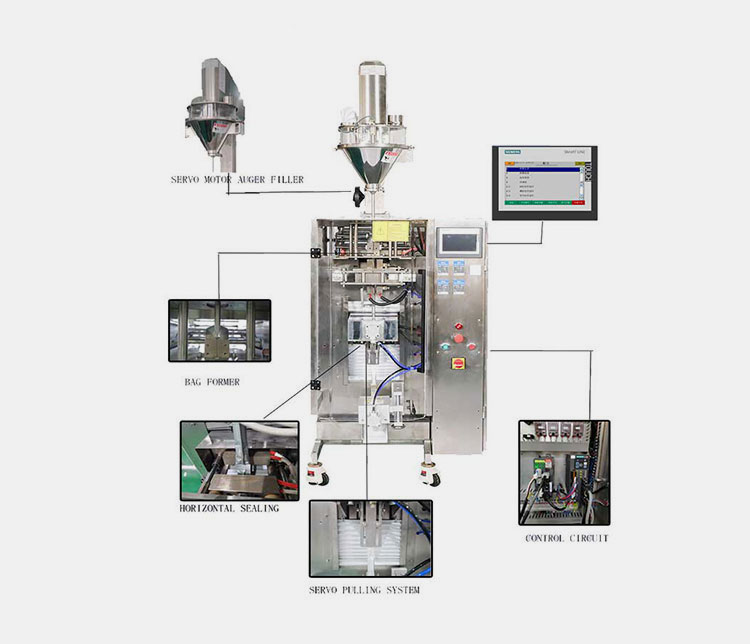

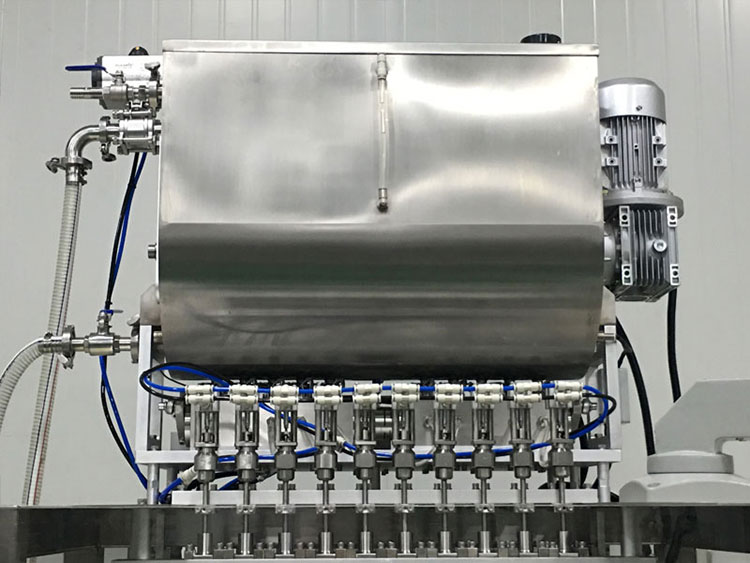

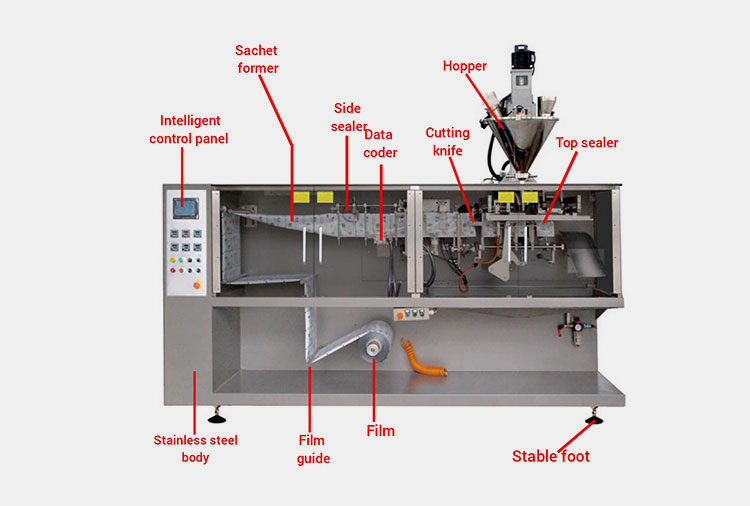

There is variation in the design of the juice 4 side sealing packing machine from one machine type to another. However, basic components are the same in every machine type. Here we are explaining the design structure of a multi-lane juice 4 side sealing packing machine

Design of the Juice 4 Side Sealing Packing Machine

Vacuum Feeder

It is located at the topmost side of the machine. Its function is to create a vacuum in the hopper part for a smooth supply of the juice to the weighing pumps and the filling devices.

Motor

It is present beside the vacuum feeder and is responsible for powering up different parts of the juice 4 side sealing packing machines. It provides energy to sealing jaws, cutting knives, and filling devices for their work.

Hopper

It is a bulk storage part of the machine. It is constructed with food-grade stainless steel material. It supplies bulk quantities of juice to the filling unit of the machine. Hopper has a significant role in the effortless performance of the machine.

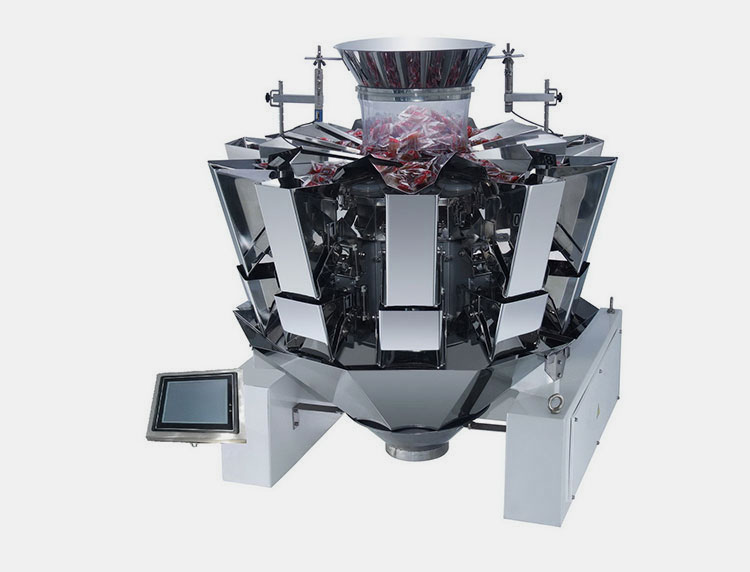

Measuring pump

There is a measuring pump present beneath the hopper. It acquires juice from the hopper, weighs them, and then supplies them to the filling unit.

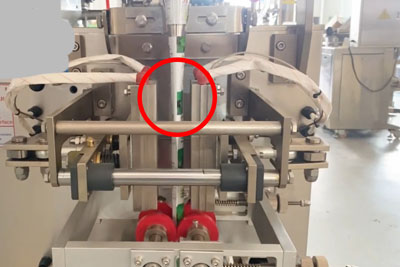

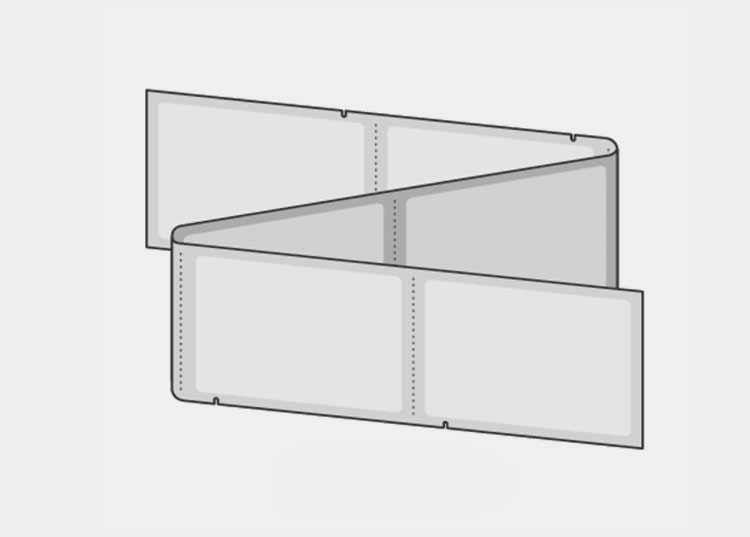

Bag forming

It is the core part of the juice 4 side sealing packing machine The bag-forming part transforms a thin layer of film into a one-fold for bag fashioning.

Horizontal sealing

As the juice 4 side sealing packing machine forms sachet and stick pack, the lateral or horizontal sealers present below the bag forming station are responsible for creating stringent bottom and top seals on the sachet or stick.

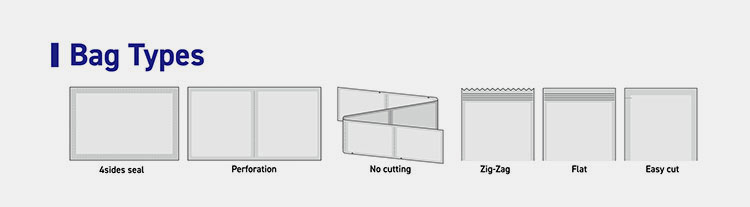

Cutting knives

It is another critical part of the machine. It is type of a cutting blade that trims away the finished juice bag from the film roll through the cutting process. The cutting knives are responsible for making different cuts like flat, zigzag, and other types of cuts on the bags.

Product conveyor

It is a conveyor on which juice packs are dropped down after sealing and cutting. These conveyors then carry these final form packing products to other units of the production line.

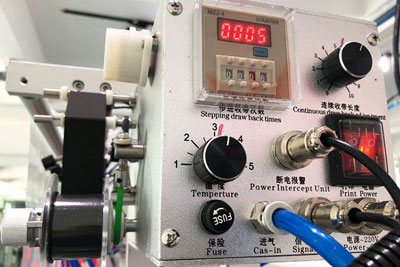

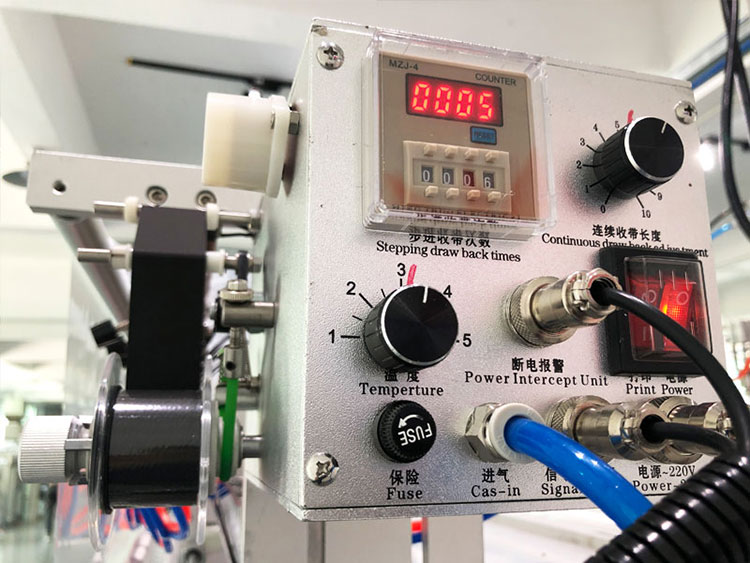

HMI Touch Screen

For programming different parameter inputs, the HMI touch screen is essential. The users interact with the colored display screen to set and supervise machine operation.

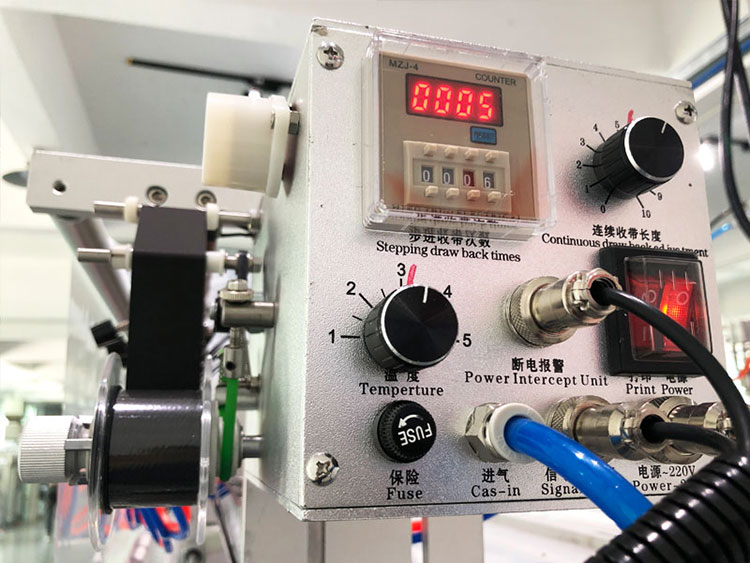

Control Panel

The control panel of the juice 4 side sealing packing machine has different knobs and switches for controlling the functioning of the machine.

Film

It is a thin robust layer of plastic, aluminum, and composite paper. It is important in the bag formation. Juice 4 side sealing packing machine has a film holder present in the frame of the machine. This roll stock and film holder is essential in a continuous supply of film.

Electric Cabinet

Different relays and switches are present in a robust electric box. It is also called the powerhouse of the machine as it provides electric energy to various parts for their working performance.

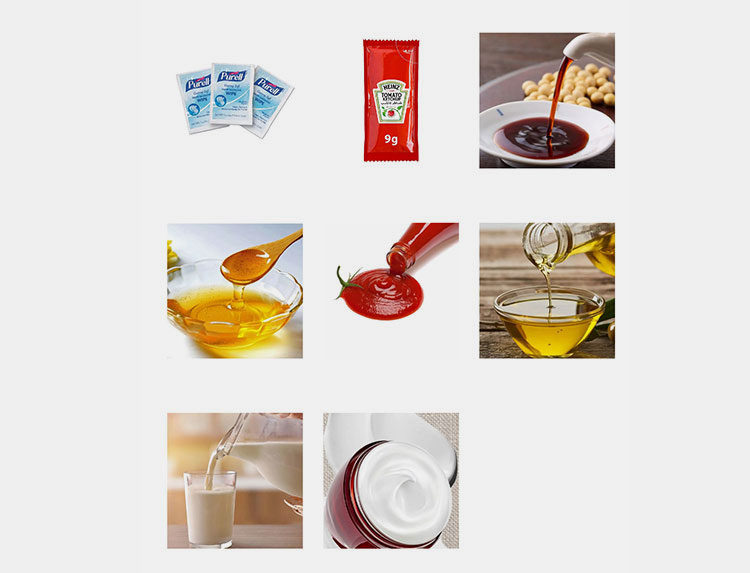

6.What are the Industrial Uses of the Juice 4 Side Sealing Packing Machine?

The juice 4 side sealing packing machine is found in almost every industry. This machine has diverse industrial uses because of its mechanization and efficiency. Here we are penning some important uses of this machine:

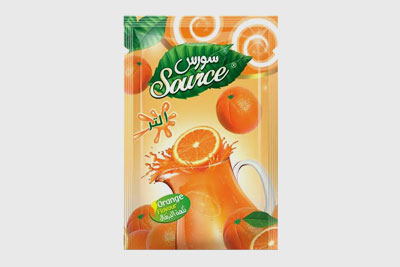

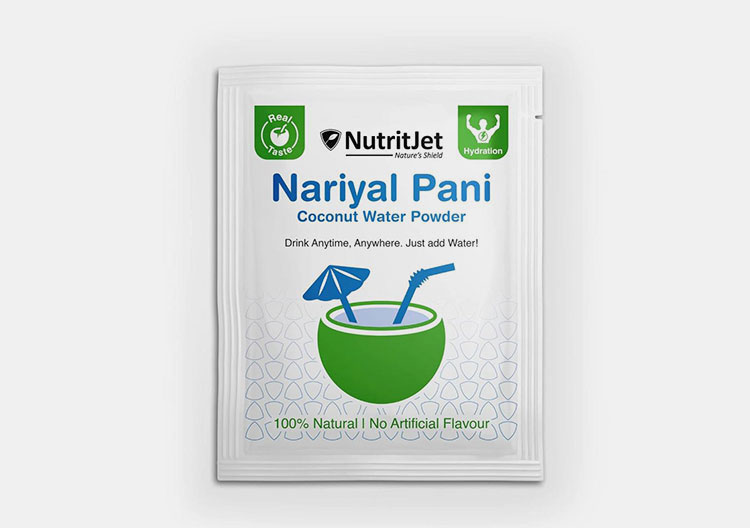

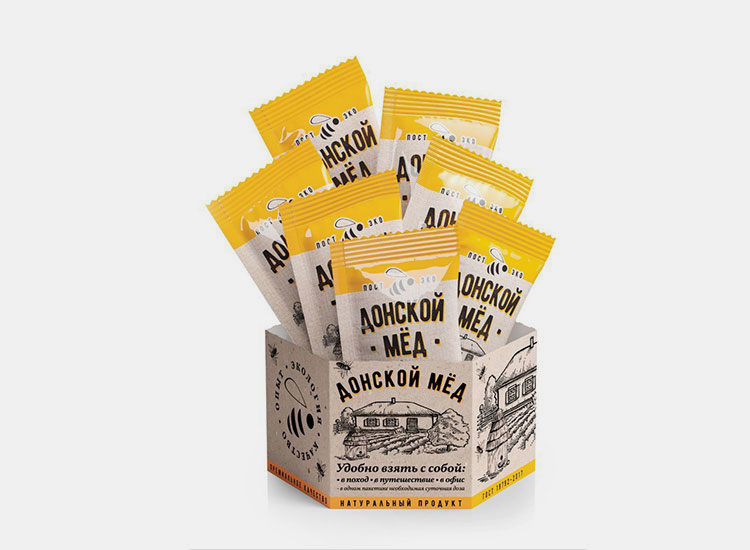

Juice Industry

Juices

The first and most important use of the juice 4 side sealing packing machine is indeed in the juice packing industry. Here juices are packed in flexible sachet or stick packaging. These drink and juices are important for the quick and instant preparation of juices both at home and at camping.

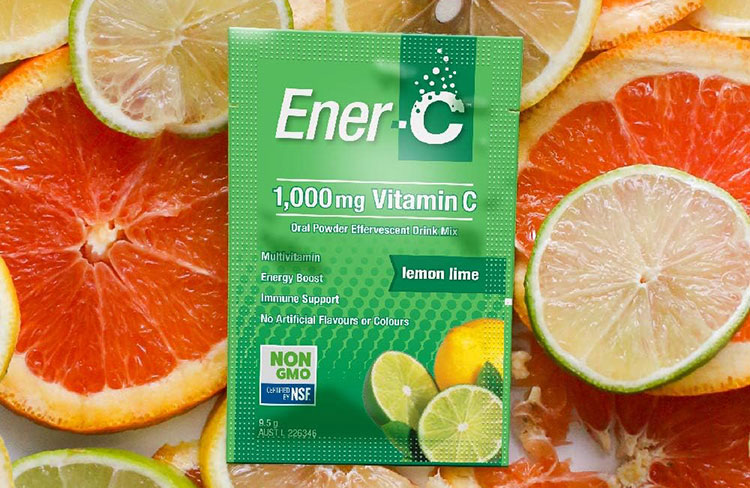

Beverage Industry

Beverages

Yes, different types of beverage like drink, liquid coffee and liquid teas are packed in small formats by the juice 4 side sealing machine. It is preferably applicable to all areas of beverage packing because of its higher processing speeds and excellent versatility.

Food Industry

Condiments

Juice 4 side sealing packing machine can liquid food products in sachet or stick pack. It dispenses different types of condiments like ketchup, mustard, mayonnaise, dressings, and spices like turmeric, chilli, salt, and pepper in portion-control packaging.

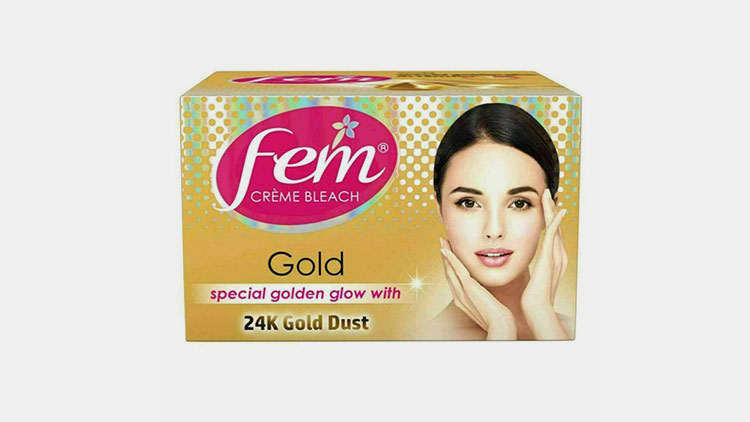

Chemical Industry

Paint Packs

Nowadays, the juice 4 side sealing packing machine is also seen in the chemical industry, as it loads different chemicals like oils, grease, paints, detergents, bleaches, disinfectants, etc in the convenient packs.

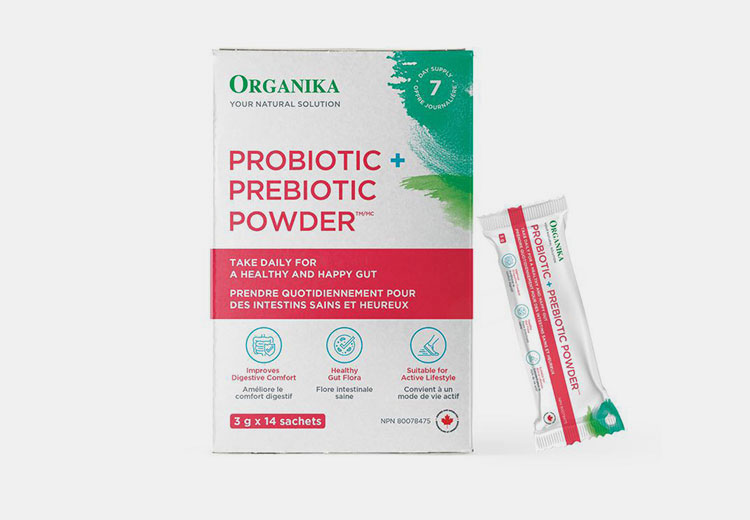

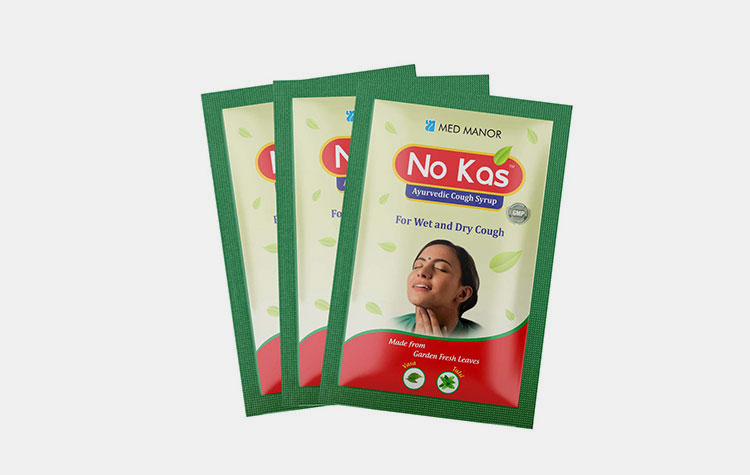

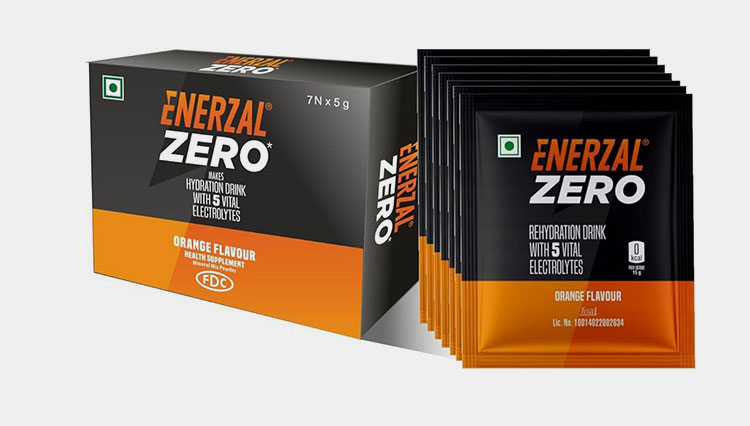

Medical Industry

Cough Syrup Packs

Due to its hygienic and closed processing, the juice 4 side sealing packing machine is also utilized in the pharmaceutical, nutraceutical, and herbal industries for packing different types of cough syrups, energy boosters, herbal, dietary supplements and many more products into compact packaging. This machine safely loads different pharmaceutical products without any contamination.

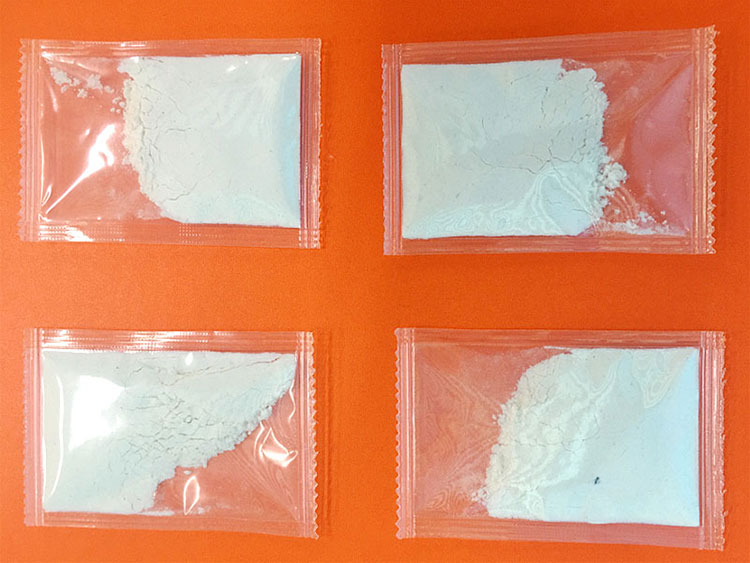

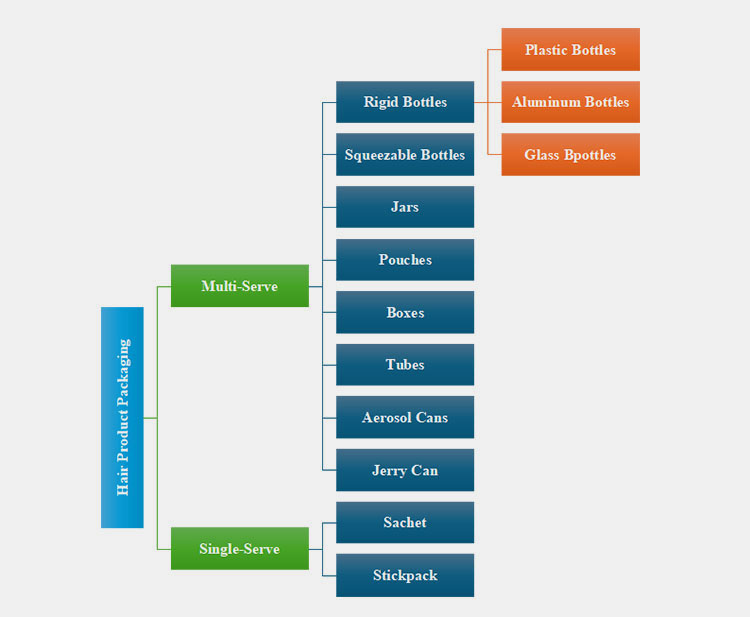

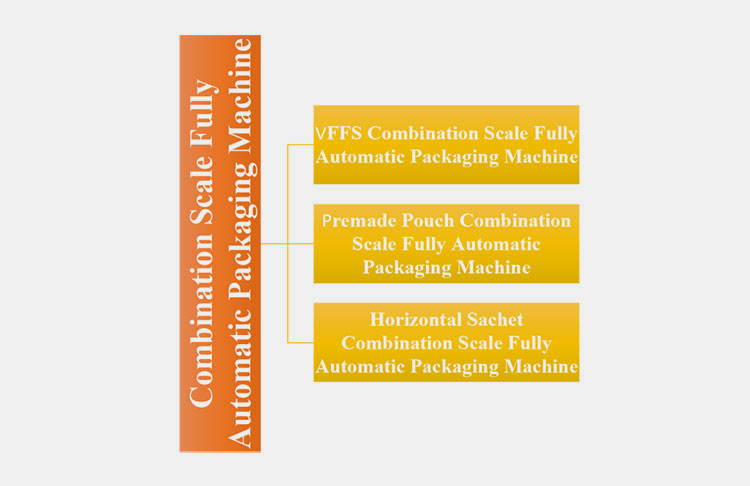

Beauty Care Industry

Beauty Products

This industry goes side by side with the other industries when it comes to the industrial use of the juice 4 side sealing packing machine Different shampoos, body wash, blushes, foundations, dye, and face masks are important examples of the use of this machine in the cosmetic and personal care industry.

7.What Materials are Processed by the Juice 4 Side Sealing Packing Machine?

Material fabrication has a significant role nowadays, and that’s why the juice 4 side sealing packing machine processes a wide range of materials to entice the juice end-users. Let’s have an insight into the different materials used by the juice 4 side sealing packing machine

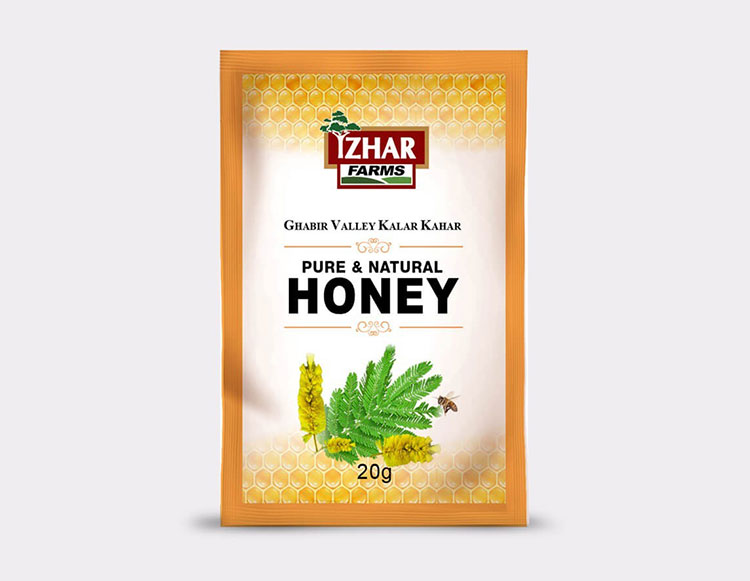

Plastic

Plastic Juice 4 Side Sealing Packing

Different types of plastic films like polyethylene, polypropylene, polyethylene terephthalate, and nylon are used for creating juice packing. These materials have strong resistance to gases and moisture. Moreover, they have chemical and heat resistance. They also offer strong seals and are robust.

Aluminium Foil

Aluminum Foil Juice 4 Side Sealing Packing- Picture Courtesy: Behance

It is another most widely utilized material by the juice 4 side sealing packing machine It prevents the entry of gases, light, and humidity inside the juice. Aluminium foil is good for boosting the shelf-life of products by protecting them from surrounding agents.

Metalized Films

Metallized Film Juice 4 Side Sealing Packing

These films are fabricated by depositing an aluminum layer over the plastics. These films have similar protective features to aluminum foil but they are lightweight, lustrous, and have lower purchase costs.

Composite Paper

Composite Paper Juice 4 Side Sealing Packing

They are formed by the multiple layers of plastic, aluminum foil and paper. It is used in juice 4 side sealing packing because of its excellent sturdy, barrier properties, strong seal, and light-blocking features.

Biodegradable Plastics

Biodegradable Plastics Juice 4 Side Sealing Packing

These are innovations in material science. Because of sustainability efforts, brands are now progressively using biodegradable plastics with their juice 4 side sealing packing machine These materials are decomposed and degraded easily and have reduced environmental impact.

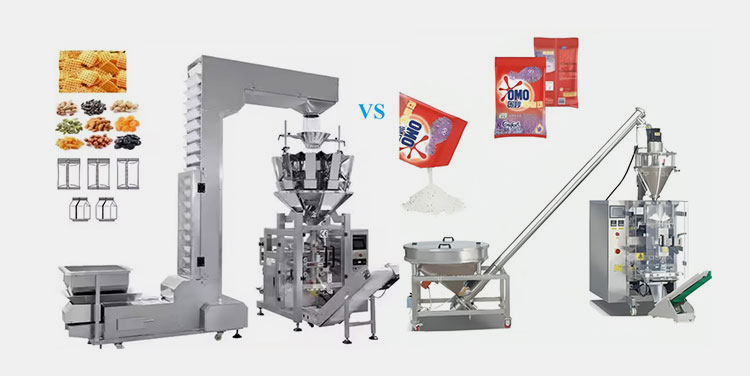

8.Differentiate between the Juice 4 Side Sealing Packing Machine and the Juice Bottling Machine.

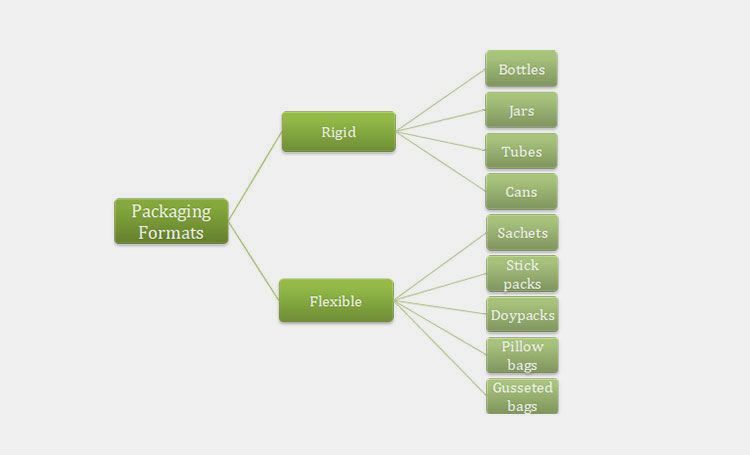

Both machines are used for packaging juices. However, they widely differ in their design, production speed and type of packaging. some of these differences are:

| Features | Juice 4 Side Sealing Packing Machine | Juice Bottling Machine |

| Picture |

Juice 4 Side Sealing Packing Machine |

Juice Bottling Machine |

| Packaging Format | This machine produces flexible packaging format. | The juice bottling machine creates rigid bottles. |

| Materials Used | This machine uses flexible plastic and aluminium foils to fabricate 4 side sealing packing. | It uses glass or rigid plastics to form bottles. |

| Packaging Size | It creates single-serve and small-serving packs. | It creates both single and large serving bottles. |

| Design | It has a simple design. | It has a more complex design. |

| Material Usage | Juice 4 side sealing packing machine requires less material per pack. | This machine uses more material per pack. |

| Sealing Method | It heats seals packs on all four sides. | The juice bottling machine uses caps and corks to seal the bottles. |

| Cost | The juice 4 side sealing packing machine generally costs less than the juice bottling machine. | It costs more than the juice 4 side sealing packing machine |

9.What is the Cleaning and Maintenance Schedule of the Juice 4 Side Sealing Packing Machine?

The long serviceable life of the juice 4 side sealing packing machine is dependent upon regular cleaning and maintenance. Hence, we are giving cleaning and maintenance schedule of this machine.

| Daily Maintenance | Visually inspect all the parts of the machine to ensure their proper working order. Wipe the surface of the machine with a damp cloth and cleaning agent to remove product buildup. Inspect the seal integrity to ascertain there is no leakage in the system. For smooth operation, lubricate all the moving parts.

|

| Weekly Maintenance | Perform a more deep cleaning of the machine, paying special attention to the hard-to-clean areas. Properly clean sensors present in the machine and ensure they are not defective. Check defects in the roller assembling, sealing jaws, and cutting system. Clean them deeply. |

| Monthly Maintenance | Perform an in-depth visual inspection of all the machine areas, particularly those under consistent frictional forces. Check the electrical connections like wires, cables, and switches for any wear and tear. Test the part functionalities to ensure they are effectively carrying out their jobs. |

| Yearly Maintenance | Replace any old part. Update machine HMI software if available. Check the functionalities of safety features. |

10.What are the Technical Faults and Their Solutions in the Juice 4 Side Sealing Packing Machine?

Technical faults might occur during normal working operations that can be easily troubleshooted by following these suggestions.

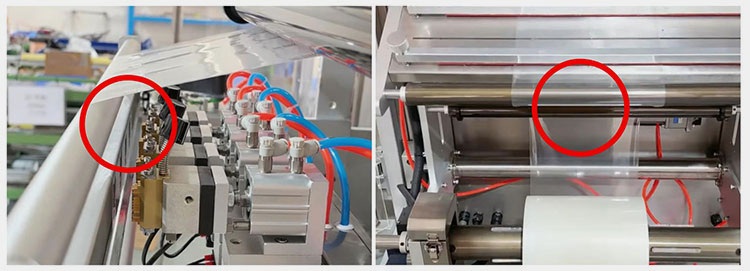

| Image | Cause | Solution |

| Incomplete or Infirm Sealing of Juice packs | ||

Incomplete or Infirm Sealing of Juice packs |

Weak sealing can occur due to low sealing temperature and pressure.

Low-quality materials can also cause infirm sealing. The sealing bars are dirty and worn out. |

Increase the sealing pressure and temperature.

Use superior quality packaging materials and change the sealing temperature according to the materials. Clean and replace old sealing bars. |

| Inconsistent Fill Quantity | ||

Inconsistent Fill Quantity |

Poor calibration of the fill devices.

There are blockages or leakage in the fill devices. There is no synchronicity between filling and sealing devices. |

Calibrate the filling devices to ascertain fill accuracy.

Clear the blockage and leakage in the fill devices. Sealing and filling systems should be in complete synchronization. |

| Issues in Film Feeding | ||

Issues in Film Feeding |

The fill roll is defective

Dirty film feeding system. Frictional buildup in film feed mechanism. Film guides and film tension are not properly adjusted. |

Ensure there is no defect in the film roll.

Clean the film feed systems. Properly lubricate the film feed mechanism. Fix the issues in the film guide and film tension. |

| Variation in the Cutt pattern | ||

Variation in Cut Pattern |

Dull cutting blades.

Improper settings of cutting speed. Inaccurate alignment of the cutting system. |

Sharpen the cutting blades and replace them if needed.

Properly adjust the settings of cut speed to ensure steady cutting. Properly align the cutting blades in the sealing jaws. |

| Forming Defects | ||

Forming Defects |

Dirty forming collars and forming tubes.

Improper settings of forming parameters like temperature, pressure, etc. Non-uniform distribution or overstretching of the film due to incorrect film tension. |

Clean the forming parts.

Fix the settings of forming parameters. Check the film tension and it should be proper that is not too high and not too low. |

11.What are the Buying Factors When Choosing Juice 4 Side Sealing Packing Machine?

There is a broad range of juice 4 side sealing packing machines and it is difficult to select your suitable type from this large collection in the market. Thus, to guide you in choosing the suitable machine, we are detailing some tips.

Choosing Your Business Type

Production Efficiency

First, choose your business type that is low level, medium scale, or large level. This allows you to inspect your production efficiency. So, from production efficiency, you can estimate the production speed of your desired machine.

Flexibility

The flexibility of Juice 4 Side Sealing Packing Machine- Picture Courtesy: eccosis.com.co

Juice 4 side sealing packing machine has different processing materials and packing styles, so first determine your desired packaging material, product type, and packing style and then choose the most compatible machine.

Machine Type

Machine Type- Picture Courtesy: BoJupack

There are quite a variety of juice 4 side sealing packing machines in the market which may overwhelm you. But do not lose your focus and check the size, features, production capacity, and automation level of the machine to select the machine that is best in every aspect.

Quality

Quality of Machine

Look for the machine having the best quality, but how to do so? The answer is simple, check their quality certification like GMP, ISO, CE, etc. These certifications tell us that the juice 4 side sealing packing machine is manufactured following the desired guidelines and protocols.

Conclusion

Now it's time to conclude this informative guide about the juice 4 side sealing packing machine We hope that this post added valued information about the machine. Juice 4 side sealing packing machine is very advantageous, especially in terms of accuracy and production efficiency. There are different types and models of this machine available in the market, so opt for your required machine by following the above-detailed guidelines. So, if you have more queries and are ready to purchase this machine, then without further ado contact Allpack and get an appropriate machine for your production. Happy Shopping!!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Juice 4 Side Sealing Packing Machine: The Complete Buying Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours