Combination Scale Fully Automatic Packaging Machine: The Complete Buying Guide In 2025

Do you like snacks? Are you impressed by snack packaging? For packaging cereals, snacks, and pulses, a robust machine combination scale fully automatic packaging machine is utilized in a wide range of industries.

The market of snacks and other granular items witnessed a huge surge due to customers’ demand for packaged goods. Hence, the use of a combination scale fully automatic packaging machine has become necessary. The profitability of businesses is increased using a combination scale fully automatic packaging machine.

Now are you looking for this commendable solution? Then do not worry and first enjoy this informative blog post. In this blog, we will discuss tips and tricks to acquire maximum benefits from a combination scale fully automatic packaging machine.

1.What is the Combination Scale Fully Automatic Packaging Machine?

Combination Scale Fully Automatic Packaging Machine

A combination scale fully automatic packaging machine consists of a multi-head weigher system that is a fundamental part of the machine. This machine combines two technologies- multi-head weigher and automatic packaging equipment to assemble a smart, advanced, and efficient packaging system.

A combination scale weighing system has multiple heads. These heads have their load cells with which this machine accurately and precisely loads different kinds of snacks and granular items in bags or other packaging containers.

Moreover, the combination scale fully automatic packaging machine has completely automated systems that can quickly form, fill, and seal multiple kinds of bags depending upon the needs.

2.Why Combination Scale Fully Automatic Packaging Machine is Popular?

The combination scale fully automatic packaging machine is popular because it comes with great profits. Some of the benefits are discussed below:

Increased Productivity

Increased Productivity by Combination Scale Fully Automatic Machine- Picture Courtesy: Dieline

First and foremost, a combination scale fully automatic packaging machine is a sophisticated piece of technology and it is completely automatic. It produces multiple ranges of bags in one cycle. It acquires increased efficiency with its automation. Increased efficiency translates into more revenue for businesses.

Filling Precision

Filling Precision by Combination Scale Fully Automatic Machine- Picture Courtesy: Dieline

Due to its high-tech gadgets, efficient multi-head weigher, and sensitive load cells, the combination scale fully automatic packaging machine achieves up-to-par filling precision and accuracy. Sensitive load cells precisely measure and fill accurate quantities of the products. Moreover, it also has forming and sealing accuracy due to its refined forming and sealing components.

Flexibility and Versatility

Versatility by Combination Scale Fully Automatic Machine- Picture Courtesy: Packaging of the World

This machine is fully capable of meeting the evolving needs of the industries due to its flexibility and versatility. It can cater to the ever-changing requirements of the industries by packaging a wide range of bags. Furthermore, it is capable of filling diverse products with simple changes of parts.

Cost-Reducing

Cost Reduction by Combination Scale Fully Automatic Machine

A combination scale fully automatic packaging machine is cost-reducing equipment that can reduce labor pay by lowering the need for human interventions. It lowers packaging waste and inaccuracies by lowering the need for manual processing.

Ease to Use

Ease of Use- Picture Courtesy: Crank Software

A combination scale fully packaging machine is an ideal equipment for filling both food and non-food items. It has high-tech and advanced technologies like a PLC system and an intuitive touch screen, which makes it easier to program, control, and monitor this machine. Due to convenient use, this machine is less labor-intensive.

3.Where Combination Scale Fully Automatic Packaging Machine is Used?

A combination scale fully automatic packaging machine is found in all major industries of the world because of its automated functioning and speed. Below is the list of different industries where this machine is seen.

Food Industry

Use of Combination Scale Fully Automatic Machine in Food Industry- Picture Courtesy: Dieline

In the food industry, a wide range of food products like grains, nuts, dried fruits, pulses, sugar, salts, coffee beans, and frozen items are packed by the combination scale fully automated packaging machine. This packaging machine for food items is a necessary piece of equipment for the food industry as it efficiently and effectively carries out its packaging jobs.

Confectionery and Snack Industry

Use of Combination Scale Fully Automatic Machine in Confectionery Industry- Picture Courtesy: Dieline

It is another major industry in which combination scale fully automated machine is utilized. Whether candies, toffees, chips, chocolate, biscuits or gummies, this machine is highly recommended for packaging. It is a highly demanded solution because it packs different confectionery items without wasting them.

Plastic Industry

Use of Combination Scale Fully Automatic Machine in Plastic Industry

It is also utilized in the plastic industry to pack small plastic granules for down-the-line packaging in large bags. It also packs plastic parts in large robust and tough packaging containers for easy and speedy transportation.

Agriculture Industry

Use of Combination Scale Fully Automatic Machine in Agriculture Industry- Picture Courtesy: Packaging of the World

It is another demanding industry where combination scale fully automatic packaging machine plays a significant role. In the agriculture industry, this machine packs granular fertilizers, pesticides, herbicides, plant growth promotors, etc quickly and easily.

Pet Industry

Use of Combination Scale Fully Automatic Machine in Pet Industry- Picture Courtesy: Dieline

Yes, the pet industry also utilizes the combination scale fully automatic packaging machine for packaging different kinds of pet snacks, treats, biscuits, kibbles, pet dry foods, and many more in pouches or other bags. This machine has equal importance in the pet industry and human food industry.

Hardware Industry

Use of Combination Scale Fully Automatic Machine in Hardware Industry

Not only this machine is utilized for packing food items, but it is also seen in the hardware sector and it packs smaller hardware parts, nuts, bolts, screws, and others in packaging pouches. These hardware items are safely loaded inside the pouches without harming the machine and hardware components.

4.What are the Fundamental Components of a Combination Scale Fully Automatic Packaging Machine?

The combination scale fully automatic packaging machine is equipped with different mechanical and technological parts that perform their specific part for swift and flawless packaging of different products. These parts are discussed one by one below:

Parts of Combination Scale Fully Automatic Machine

| Multi-head Weigher | This part is the central part of the machine and consists of a radial feeder, weighing buckets, and load cells. The radial feeders are the channels that transfer the products from the elevators to the individual weighing buckets.

They move the products by vibration, transferring the controlled amount of product. The weighing buckets are the containers in which products are temporarily stored for weight measurement. Load cells are present below each weighing bucket and calculate the weight of products in each weighing bucket. |

| Elevator | The elevator is divided into small sections. The products from the product hopper are dispensed into sections of the elevator that carry the products upward towards the multi-head weigher. |

| HMI Touch Screen | It is the interactive interface of the machine, where different settings of packaging parameters are input. Using this control panel, operators can view the progress of operation and get notified about malfunctioning in the machine. |

| Product Hopper | The packaging operation begins at the product hopper where bulk quantities of the products are loaded. It is present at the bottom of the machine and usually is a square-type container. |

| Product Chute | The finished packaging is unloaded from the equipment and is moved to the product chute or product conveyor for collection and further packaging. |

| Forming Tube | The forming tube is a chief part that shapes the film into a tubular pouch. It is essential in forming pouches of consistent dimensions. |

| Support Platform | It is a cage-like structure and is a safety feature fitted in most of the combination scale fully automatic packaging machines. It supports the entire weight of the machine and prevents operators from interacting with the machine while it is operational. |

| Safety Glass | It is made of organic glass and allows the operators to safely inspect the performance and packaging operation of the machine without going near it. |

| Sealing Jaws | There are two types of sealing jaws-horizontal and vertical. Vertical sealers form longitudinal seals that run along two vertical sides of pouches while horizontal sealers fabricate lateral seals to air-tightly seal pouches. |

| Cutting Knife | A sharp cutting blade is present in the center of horizontal sealers and it is used for cutting and trimming the edges of pouches. |

5.How Does the Combination Scale Fully Automatic Packaging Machine Work?

Different steps in combination scale fully automatic packaging machine occur in synchronization for smooth packaging. Here is the list of steps occurring in the combination scale fully automatic machine.

| Product Loading

First, the products like granules are loaded in the product hopper present in the lower part of the machine. These granular feeds move to the upper hopper by the product elevator. |

Product Loading- Picture Courtesy: Landpack.com |

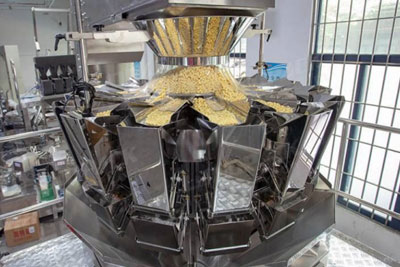

| Feeding into Weighing Bucket

The vibratory plates disperse the materials from the upper hopper to the combination scale. These combination scale multi-weighing heads then distribute materials to weighing buckets from which materials are dispensed to the electric scale or load cells. These load cells determine the weight of the materials. These load cells perform accurate filling without going over or under the set limit. |

Feeding into Weighing Bucket

|

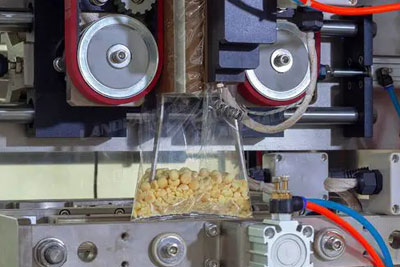

| Forming and Filling

The packaging film loaded on the film holder, reaches the forming station. Here human collar and vertical sealers work in synchronization to carry out the forming of the pouch. The forming tube folds and wraps the packaging while vertical sealing jaws seal the edges of the film. Finally, the filling of materials is performed with the help of a filling nozzle. |

Forming and Filling |

| Sealing and Cutting

After filling, hot sealing elements seal the top edges of the bag by heat or pressure. After sealing, the next step is cutting which is carried out by the integrated cutting knives that trim the edges of two joined pouches. |

Sealing and Cutting |

| Discharging

The product conveyors collect and remove the finished pouches from the machine. |

Discharging |

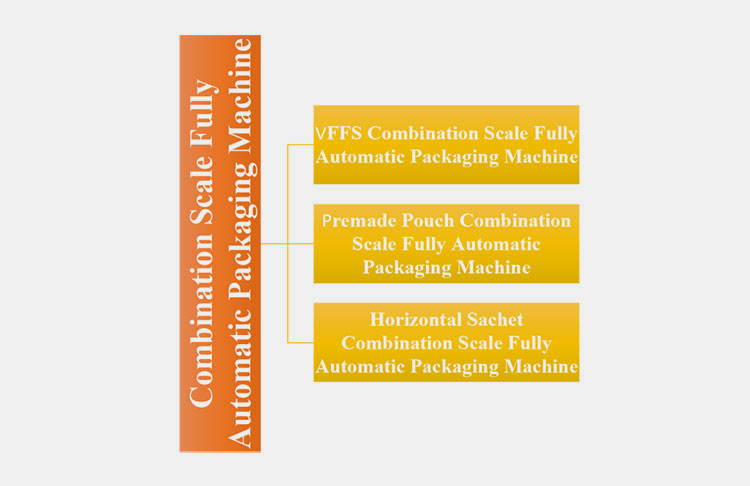

6.What is the Classification of the Combination Scale Fully Automatic Packaging Machine?

The classification of combination scale fully automatic packaging machine is penned below:

VFFS Combination Scale Fully Automatic Packaging Machine

VFFS Combination Scale Fully Automatic Packaging Machine

One of the most commonly used combination scale fully automatic packaging machines is the vertical, form, and seal (VFFS) machine. It is a small footprint and cost-effective machine. Because it uses efficient uses packaging material, producing less amount of waste. It produces versatile pouches by transforming packaging film.

Premade Pouch Combination Scale Fully Automatic Packaging Machine

Premade Pouch Combination Scale Fully Automatic Packaging Machine

As the mane refers, this machine does not use packaging film instead uses already-made pouches to package different granules and other feed. It has a larger footprint than the VFFS combination scale fully automatic packaging film. It has more production capacity than its VFFS counterpart because it skips the forming step. There are two main steps in its working- filling and sealing.

Horizontal Sachet Combination Scale Fully Automatic Packaging Machine

Horizontal Sachet Combination Scale Fully Automatic Packaging Machine

This type of combination scale fully automatic packaging machine has a horizontal mode of packaging. Due to its horizontal design, it has a much larger footprint. It is a type of machine that fills sachets by using packaging film that travels in a horizontal direction. It fills precise quantities of materials and creates stringent sealing using sealing jaws.

7.What Packaging Formats Does Combination Scale Fully Automatic Packaging Machine Process?

There are different product pouches are seen on the market aisles. So, a combination scale fully automatic packaging machine can easily process myriads of pouch types such as:

Stand-up Pouch

Stand-up Pouch- Picture Courtesy: Packaging of the World

As the name suggests, these pouches have flat bases with which they can sit upright on the display selves. With its bottom gusset, they can easily stacked on the display shelves. This feature helps in space utilization.

Quad Seal Pouch

Quad Seal Bags- Picture Courtesy: Packaging of the World

This bag features four corners that offer more strength and stability to these pouches. It has a flat base and squared top seal, due to this, it resembles a block. Hence it is also called a block bottom pouch. It can house more products due to its flattened physical structure.

Zipper Pouch

Zipper Pouch- Picture Courtesy: Dieline

This pouch has resealable zipper closures below the top seal that help users close the pouch after use. This zipper pouch bottles up the freshness of products for a longer time.

Gusset Pouch

Gusset Pouch- Picture Courtesy: Packaging of the World

These pouches have side and bottom folding. Due to its bottom folding, this pouch can stand upright. It expands upon loading the product and, therefore can store more products.

Vacuum Sealed Pouches

Vacuum Sealed Pouches- Picture Courtesy: Du clos des renards

These pouches are an innovation in the packaging field. These are made of tough and protective barriers. The air is completely removed after the product is fed into the vacuum pouch.

Shaped Pouch

Shaped Pouch- Picture Courtesy: TedPack

To increase product appeal, brands have introduced shape pouches in the market. They have unique shapes like a bottle, fruit, star, etc, unlike the traditional rectangular pouch shapes.

Pillow Pouch

Pillow Pouch- Picture Courtesy: Packaging of the World

This pouch has three seals, top, bottom, and central seal. It has bulging in the centre which offers it a pillow shape. It is also called T-seal pouches because of its middle seal.

Sachets

Sachets- Picture Courtesy: Wellness Warehouse

These are tiny rectangular, square, or triangular-shaped sachets, packing one serve of the granular items.

8.What are the Sealing Types Formed by Combination Scale Fully Automatic Packaging Machine?

There are different types of seals formed by the combination scale fully automatic packaging machine like:

| Lap Seal

This type of seal is formed by joining the outer edges of the film to its inner film side. It is also called an overlap seal because both inner and outer layers overlap to create a seal. |

Lap Seal- Picture Courtesy: Dieline |

| Fin Seal

This seal is formed by the joining of two inner layers. Then one edge of the seal is doubled to form a fin. Hence, it is also called a fold-over seal. |

Fin Seal- Picture Courtesy: Dieline |

| Tear Notch Seal

It is a tiny pre-cut section found on the top seal for ease of opening the pouch. |

Tear Notch Seal- Picture Courtesy: Packaging of the World |

| Flat Seal

It is a simple and elegant seal that has straight lines. This seal type is routinely found on various pouches. |

Flat Seal |

| Patterned Seal

This seal has decorative designs like triangles, diamonds or zigzags to boost the physical appeal of the product pouches. |

Patterned Seal- Picture Courtesy: Dieline |

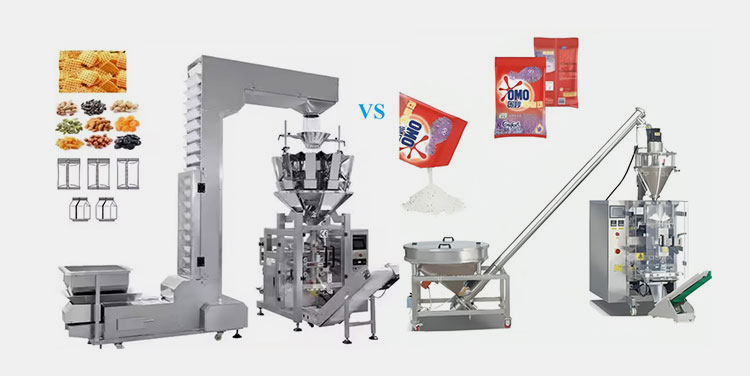

9.Is There a Difference between a Combination Scale Fully Automatic Packaging Machine and a Powder Packaging Machine?

Combination Scale Fully Automatic Packaging Machine and Powder Packaging Machine

Both these machines are used for packaging the product, they vastly diverge from each other depending upon their design, product type, and more. The key differences in combination scale fully automatic machine and powder packaging machine are detailed below for your understanding:

| Features | Combination Scale Fully Automatic Packaging Machine | Powder Packaging Machine |

| Filling System | This machine employs a combination scale also called a multi-head weigher for filling different products. These scales simultaneously load the product, boosting speed and efficiency. | This machine employs auger and volumetric cup fillers for dispensing powder products. |

| Application | It is well-suited to fill a diverse range of powders, granules, confectionery, snacks, cereals, and other free-flowing goods. | It specifically fills the powders including both food and non-food items. It is not suited to filling chunky and sticky items. |

| Packaging Types | It can process bags, pouches, and boxes. | It can process different types of pouches like stand-up, gusset, quad seal, etc. |

| Automation | As the name indicates, this machine is completely automatic, needing little to less assistance from human operators. | Its automation may vary. Some types of powder packaging machines are semi-automatic and manual. Others are fully automatic. |

10.Does the Combination Scale Fully Automatic Packaging Machine have Built-in Components that Reduce Cleaning Time?

Yes, a combination scale fully automatic packaging machine comes with different built-in components that reduce the cleaning time and decrease cross-contamination risk. These components and features are discussed below:

Stainless Steel Design

Stainless Steel Design

The frame and contact parts of this machine are constructed using stainless steel material that is anti-corrosive and convenient for cleaning. This machine does not degrade upon filling with harsh chemicals and other cleaning agents.

Quick Release Parts

Quick Release Parts

Combination scale fully automatic machine comes with quick release systems with which different components of the machine are easily disassembled without needing the tools. This decreases the maintenance and cleaning time.

Clean-in-Place Systems

Clean-in-Place Systems- Picture Courtesy: Central States Industrial

Some types of combination scale fully automatic packaging machines have clean-in-place systems that allow complete and thorough internal cleaning without dismantling the parts of the machine. CIP system uses different kinds of cleaning agents, detergents, and water sprays to clean the machine.

11.What are Frequent Problems and Their Solutions for the Combination Scale Fully Automatic Packaging Machine?

Although this machine is an advanced and sensitive packaging unit, still unanticipated problems can arise unexpectedly in this machine that impact production capacity and quality. But there are some tips and tricks to solve these problems such as:

| Causes | Solution | Images |

| Product Wastage or Overfilling | ||

| Error in the programming of fill settings.

Differences in the densities and granule flow rate. Defects in the filling or weighing devices. |

Accurately program the fill settings on the HMI.

Reduces the differences in densities and flow rate and re-calibrate the machine. Replace or repair the defective filling and weighing systems. |

Product Wastage or Overfilling |

| Contamination in Fill Product | ||

| Poor cleaning of the machine.

Lack of cleaning after batch results in cross-contamination. Bad-quality packaging film. |

Properly clean the machine.

Use CIP cleaning systems for cleaning the machine between batches. Use superior-quality food-grade film materials. |

Contamination in Fill Product |

| Jamming or Tearing of Packaging Film | ||

| Sealing jaws are not aligned accurately.

Defective sealing jaws. High or low tension in the packaging film. The packaging film is not aligned properly. Packaging films are of low quality. |

Realign the sealing jaws

Replace or repair sealing jaws. Adjust the tension settings of the film. Properly align the packaging film. Use high-quality film materials. |

Jamming or Tearing of Packaging Film- Picture Courtesy: Landpack.com |

| Bad Sealing | ||

| Defective or old sealing jaws

Dirty sealing jaws Insufficient temperature and pressure during the sealing process. |

Replace old sealing jaws.

Properly clean the sealing jaws. Maintain adequate temperature and pressure while sealing. |

Bad Sealing |

| Poor Weighing | ||

| Defective load cells.

Product accumulation in the weighing systems affects weighing precision. The poor setting of the weighing system. Out-of-calibration weighing system |

Repair worn-out load cells.

Properly clean the weighing system. Adjust weighing settings on HMI. Recalibrate weighing systems |

Poor Weighing |

12.How to Choose an Ideal Combination Scale Fully Automatic Packaging Machine?

It is necessary to choose an ideal combination scale fully automatic packaging machine that is well-matched with your production demand to acquire maximum advantage of your investment. We are giving some tips that will be helpful in your decision process.

Production Volume

Production Volume- Picture Courtesy: World Brand Design Society

How much number of pouches will you package per hour? The answer to this question will give you an estimate of your production volume. Estimating your production capacity will aid you in choosing a machine that will exceed your production needs.

Product Type

Product Type

Granules are available as free-flowing grains and chips and non-free-flowing like brown sugar and instant coffee granules. These stick together which causes hindrances in their flow. Understanding these physical characteristics of granules is a must for considering the best machine type.

Type of Pouches

Type of Pouches- Picture Courtesy: Trend Hunter

There is a variety of pouches like pillow pouches, stand-up pouches, and gusset pouches. Furthermore, these pouches have myriads of sealing and cutting patterns. Combination scale fully automatic machine usually forms a particular type of pouch. So select your required pouch type and design and then choose the machine accordingly.

Quality Certification

Quality Certification

Quality certification of the machine tells about the optimal quality and working condition of the machine. There are various quality standards like ISO, GMP, FDA, CE, etc. The quality of combination scale fully automatic packaging machine is assured through these certifications.

Conclusion

In a nutshell, a combination scale fully automatic machine is an amazing machine, customized to speed up the packaging of granules and non-granular items in various types of pouches. It uses a multi-head weigher for accurately dispensing products and is fully automatic. Yet, there are some variations of this machine, depending upon packaging operators. This blog discusses some tips and tricks especially just for you. So, if you are convinced to buy the combination scale fully automatic machine, consider Allpack, as we will provide excellent-quality machines suited to your production needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide