Cough Syrup 4 Side Sealing Packing Machine: The Complete Buying Guide In 2024

Filling and packaging liquids can be a daunting task and it can be frustrating sometimes. Are you a pharmaceutical firm hoping to add cough syrups to your lineup of products? Are you trying to find a dependable and effective packaging solution to suit consumer demands? Or if you own a food or chemical manufacturing business and are facing difficulty in packaging liquid products.

There's nowhere else to look! The cough syrup (4-side sealing) packing machine is the best option available in 2024 for all of your packaging requirements.

The cough syrup (4-side sealing) packing machine is of the utmost importance in various industries, offering efficient, rapid, and accurate liquid filling and packaging. However, how can you make the best decision? How can you be certain that the equipment you buy will fulfill your production needs, adhere to standard practices, and provide the highest return on your investment?

Our comprehensive guide will cover all the information you want to make an informed decision regarding the cough syrup (4-side sealing) packing machine. So, let's dive in together!

1.Describe a cough syrup (4-side sealing) packing machine.

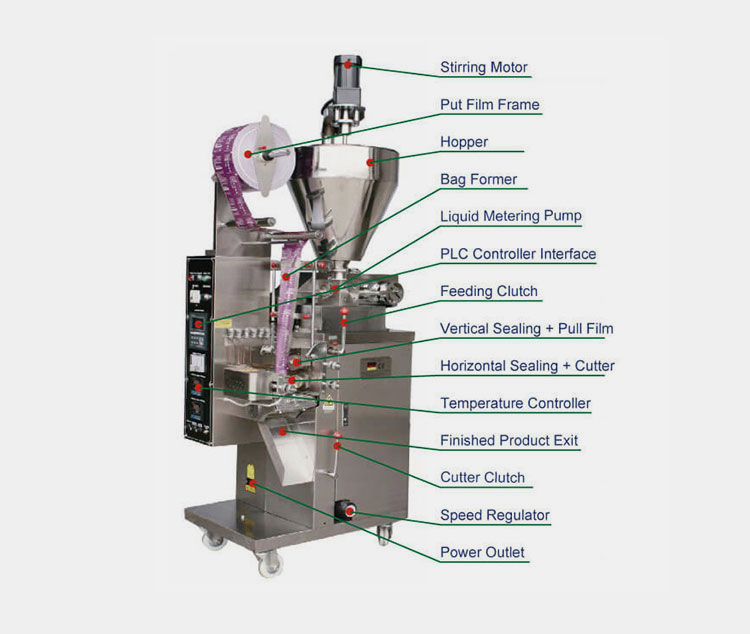

Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Jochamp

A cough syrup (4-side sealing) packing machine is specialized equipment designed for efficient and precise packaging of viscous and non-viscous liquids (such as cough syrups and other liquid items) into sachets and pouches, with an effective 4-sided sealing.

These devices are tailored with advanced technology to guarantee accuracy in filling and sealing processes, preserving the product’s quality and integrity. They are vital to various industries, whether pharmaceuticals, food, or chemicals, providing efficient and rapid production.

They are available in multiple models and can produce precisely weighed liquid packages at a rapid rate of 100 to 300 pouches per minute.

2.What are the applications of a cough syrup (4-side sealing) packing machine across industries?

The cough syrup (4-side sealing) packing machine is a tremendous piece of equipment employed in various industries, offering diverse applications.

Let’s discuss some common industries where the cough syrup (4-side sealing) packing machine plays a significant role.

Pharmaceutical Industry

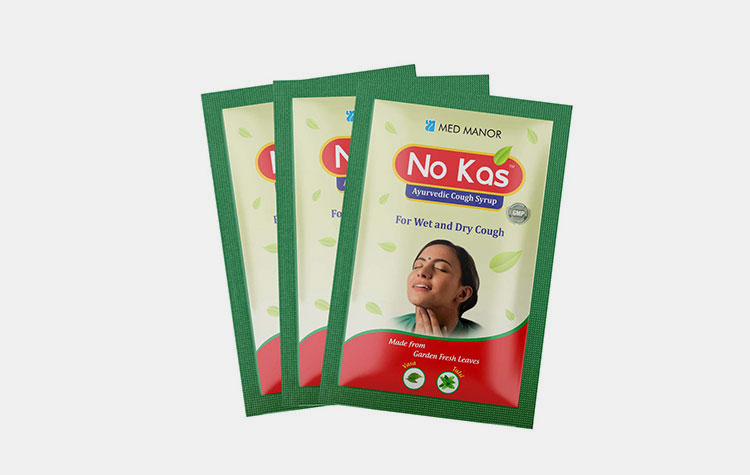

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Pharmaceuticals Industry

The cough syrup (4-side sealing) packing machine is gaining popularity in the medicine manufacturing industries. It is utilized for packaging liquid syrups, suspensions, elixirs, and other viscous products.

Food Industry

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Food Industry

You must have seen multiple small and large 4-sided sealed packages of various food items. Yes, they look elegant. A cough syrup (4-side sealing) packing machine is used in the food industry to package multiple food liquids into various pouches. The food items include ketchup, sauces, pastes, etc.

Beverage Industry

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Beverage Industry

The cough syrup (4-side sealing) packing machine is employed in the beverage industry to package various beverages, like preserved juices, energy drinks, coffee, etc, into all-sided sealed pouches.

Herbal Industry

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Herbal Industry

In the herbal industry, the cough syrup (4-side sealing) packing machine is employed to package plant extracts or liquid preparations into various package formats.

Chemicals Industry

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Chemical Industry

In the agricultural and chemical sector, the cough syrup (4-side sealing) packing machine is employed to dispense various liquid chemicals (which can be hazardous), such as sample paints, varnishes, detergents, adhesives, and others, into effectively 4-sided sealed packages.

Cosmetics Industry

Applications of Cough Syrup (4-Side Sealing) Packing Machine in the Cosmetics Industry

No wonder! The cough syrup (4-side sealing) packing machine has also gained entry into the cosmetic industry. It is utilized to package multiple beauty care products into elegant packages effectively.

3.What value a cough syrup (4-side sealing) packing machine can offer to your business?

You would be amazed to know that the cough syrup (4-side sealing) packing machine can benefit your production industry exceptionally and help you achieve rapid business growth.

Some of the key benefits of installing a cough syrup (4-side sealing) packing machine in your industry are;

Manufacturing Efficiency

Bulk Honey Sachets – Picture Courtesy: TenChat

The cough syrup (4-side sealing) packing machine provides tremendous efficiency in packaging liquids into sealed pouches. The laborious steps in the process can be automated without sacrificing the product’s quality.

Quality Enhancement

Consistent Quality Products – Picture Courtesy: Megawecare

The rapid production capability of the cough syrup (4-side sealing) packing machine doesn’t sacrifice the quality and hygiene of the product. Neglecting the human involvement to a larger extent and the automated controlled operation maintains the quality consistency of the product.

Increased Productivity

Increased Productivity

The cough syrup (4-side sealing) packing machine operates automatically, avoiding downtime, and resulting in increased productivity.

Easy to Operate

Operational Ease

A cough syrup (4-side sealing) packing machine has easy operational protocols and does not require lengthy instructions. The automatic variants only need adjustments to the processing parameters via the screen panel.

Reduced Spills/Wastage

Reduced Spills During Processing

Minimizing the human intervention in package production due to its automatic function, the cough syrup (4-side sealing) packing machine reduces spills and helps to conserve resources.

Versatility

Versatility of Cough Syrup (4-Side Sealing) Packing Machine

The cough syrup (4-side sealing) packing machine is a versatile device capable of processing various viscous and free-flowing liquids.

Cost Benefit

Cost Efficient – Picture Courtesy: K-flex

The cough syrup (4-side sealing) packing machine costs you big one time. The device is highly advantageous in the long-term consideration. The efficiency and accuracy of the device make it a better turn-on investment.

Additionally, the automation of the device aids in minimizing labor costs.

4.What do you know about the basic parts of a cough syrup (4-side sealing) packing machine?

A cough syrup (4-side sealing) packing machine consists of various mechanical and electrical components that work together for efficient and smooth operation.

The fundamental parts of a cough syrup (4-side sealing) packing machine are listed below;

Parts of Cough Syrup (4-Side Sealing) Packing Machine

| PARTS | FUNCTION |

| Stirring Motor | It is responsible for the agitation of the liquid material, which guarantees a uniform consistency. The liquid must be well mixed before packing to ensure the product’s quality. |

| Put Film Frame

|

The film frame is responsible for holding the packaging material (typically a film roll), utilized to make the individual liquid pouches. The film is dragged from the film frame and fed through the device for sealing. |

| Hopper

|

An enclosed vessel that contains the liquid product and maintains a steady feed into the machine. The feeding rate can be controlled by installing a valve to the hopper or other mechanism. The capacity of the hopper depends on its size which can be varied with different models. |

| Bag Former

|

This component is responsible for the liquid package formation. It determines the package dimensions and shape. The shaping and sealing of the film is done to form the individual bags. |

| Liquid Metering Pump

|

It regulates the precise filling of each bag. It guarantees precision and uniformity in filling every bag while upholding the designated volume for every package. |

| PLC Controller Interface

|

It is a touch screen employed to adjust and regulate the entire processing parameters. It helps in the close monitoring of the operation. It is a vital component and helps in operating the equipment with ease. |

| Feeding Clutch

|

It controls the flow rate of the liquid into each bag. It works synchronized with the liquid metering pump to regulate the liquid amount filled into each package. It guarantees that each package contains an accurate amount of liquid. |

| Vertical Sealing + Pull Film | The mechanism for vertical sealing seals the packaging material’s edges to form a tube, which will become the sides of the sachets. It also pulls down the film for further processing. |

| Horizontal Sealing + Cutter | The horizontal sealing mechanism closes the lower edge of the fabricated tube, creating a pouch. It also seals the top edge after liquid filling. The cutter cuts the finished sachet from the continuous film. |

| Temperature Controller | This component maintains a steady temperature of the sealing bars. It guarantees the correct sealing temperature for a particular film to ensure an effective seal. |

| Finished Product Exit | It allows the discharge of the finished liquid sachets from the cough syrup (4-side sealing) packing machine, to be collected for further processing. |

| Cutter Clutch | The cutter clutch controls the functioning of the cutter. It regulates the cutter's engagement and disengagement times, guaranteeing that the pouches are cut precisely and on schedule. |

| Speed Regulator | It regulates the operating speed of the device. It adjusts the device's speed to match the production needs and optimizes efficiency. |

| Power Outlet | It connects the machine to the power source for the device’s operation. |

5.What is the basic functional principle of cough syrup (4-side sealing) packing machine?

Working of a Cough Syrup (4-Side Sealed) Packing Machine

The cough syrup (4-side sealing) packing machine consists of various vital components that work together for an efficient and smooth operation.

Here we will discuss the fundamental operating protocols of a cough syrup (4-side sealing) packing machine.

Material Feeding: The liquid material is fed into the hopper manually or utilizing an automatic tool.

Film Unwinding:A large roll of film is put into the fill frame/holder that is pulled and unwound, once the machine gets started.

Formation of Pouch:The film is shaped with adjusted dimensions after reaching the forming tube. The vertical sealing mechanism seals the side edges while the horizontal sealing mechanism seals the bottom edge to form a pouch.

Filling: In this step, the precise amount of liquid material is poured into the formed sachet pouch. Each model has a unique filling mechanism installed (piston, pump, or volumetric cup).

Sealing:The horizontal sealing bars seal the top edge of the filled sachet. At the same time, it seals the bottom edge of the next sachet.

Cutting: The cutter is responsible for cutting the filled sachets from the film.

Product Exit:The finished liquid sachet exits through the device’s outlet for further processing.

6.Cough syrup (4-side sealing) packing machine: What types are available?

The cough syrup (4-side sealing) packing machine has evolved over the years and is designed with multiple structures and functions as per the customer’s needs and demands. There are different models available on the market.

Let’s discover the commonly employed varieties of cough syrup (4-side sealing) packing machines across industries, classified on multiple bases.

Classification Based on Package Configuration

Vertical Form Fill and Seal (VFFS) Cough Syrup (4-Side Sealing) Packing Machine

Vertical Form Fill and Seal (VFFS) Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Technopack Corporation

It is one of the most widely employed devices across industries. It is highly efficient and offers precise and rapid production. It is the most suitable device for large-scale manufacturing.

This machine forms, fills, and seals sachets in the vertical orientation. It is a versatile device and can handle a variety of packages and materials.

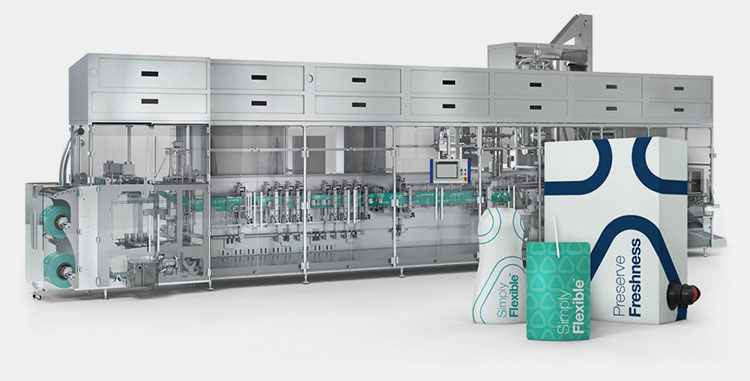

Horizontal Form Fill and Seal (HFFS) Cough Syrup (4-Side Sealing) Packing Machine

Horizontal Form Fill and Seal (HFFS) Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Bossar

This machine forms, fills, and seals sachets in the horizontal orientation. It is also an efficient device capable of handling multiple products and sealing the sachets through different effective sealing mechanisms.

It is a suitable device for large manufacturers that have a greater space.

Classification Based on Operating Mechanism

Piston Cough Syrup (4-Side Sealing) Packing Machine

Piston Cough Syrup (4-Side Sealing) Packing Machine

This machine ensures precise and efficient liquid filling into sachets using pistons as a filling mechanism. The piston precisely draws liquid from the hopper into the sachet.

Pump Cough Syrup (4-Side Sealing) Packing Machine

Pump Cough Syrup (4-Side Sealing) Packing Machine

This type of machine is utilized for accurately and consistently liquid filling into sachets. It is an ideal tool for pharmaceutical industries. It uses rotating pumps to direct the liquid from the hopper to the nozzle.

It is a versatile device, that handles viscous and non-viscous liquid materials.

Classification Based on Lanes

Single Lane Cough Syrup (4-Side Sealing) Packing Machine

Single Lane Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Jochamp

This type of machine is equipped with a single lane that processes the material. It is suitable for small enterprises as it has a lower production rate.

Multiple Lane Cough Syrup (4-Side Sealing) Packing Machine

Multiple Lane Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Samfull Packing

It is an advanced form of the machine consisting of multiple lanes working simultaneously to produce multiple sachets at a time. It is designed to enhance the production rate. It is adopted most often by large manufacturing industries. It is an expensive device due to its complicated design and efficient functioning.

7.Differentiate the cough syrup (4-side sealing) packing machine and the powder packing (4-side sealing) machine.

| FEATURES | COUGH SYRUP (4-SIDE SEALING) PACKING MACHINE | POWDER PACKING (4-SIDE SEALING) MACHINE |

| Image |  |

|

| Type of Material | The machine is designed to fill liquid products, such as syrups, oils, or viscous liquids. | The machine is designed to fill the powdered materials, such as powders and granules. |

| Filling Mechanism | It utilizes liquid-filling mechanisms, like pistons or pumps, to fill the liquids into sachets. | It utilizes auger screws or vibratory cups for packaging powders in sachets. |

| Machine Composition | It requires corrosion-resistant materials to prevent the device from damaging. | It requires materials capable of handling the powdered goods and avoiding device jamming. |

| Maintenance | It needs more frequent cleaning and maintenance for optimal functioning to avoid contamination. | It requires comparatively less frequent maintenance. |

8.What types of sealing mechanism a cough syrup (4-side sealing) packing machine can use for the sealing?

A cough syrup (4-side sealing) packing machine utilizes several mechanisms to seal the sachets or other packages to guarantee a leak-proof seal. The primary mechanisms include;

Heat-Sealing Mechanism

Heat Seal Sachet by Cough Syrup (4-Side Sealed) Packing Machine

It is the widely employed mechanism for sealing sachets in the cough syrup (4-side sealing) packing machine. In this method, a seal is created by melting the packaging material through heat. The heated sealing bars or clamps perform the sealing.

Pressure Sealing Mechanism

Pressure Seal Sachet by Cough Syrup (4-Side Sealed) Packing Machine

In this method, a high pressure is applied on the edges of the sachet to forge a tight seal. This mechanism is often employed along with the heat or ultrasonic sealing mechanism to ensure a quality seal.

Impulse Heat-Sealing Mechanism

Impulse-Heat Seal Sachet by Cough Syrup (4-Side Sealed) Packing Machine

This method is utilized for materials that are susceptible to high temperatures. Instead of constant heat, it only applies heat when sealing, providing a rapid process.

Ultrasonic Sealing Mechanism

Ultrasonic Seal Sachet by Cough Syrup (4-Side Sealed) Packing Machine

This mechanism utilizes ultrasonic vibrations for heat generation, that melts the packaging material and establishes a tight seal. It is an efficient method to create a high-quality seal.

Vacuum Sealing Mechanism

Vacuum Seal Sachet by Cough Syrup (4-Side Sealed) Packing Machine

This method involves the removal of air from the sachet packaging before sealing, resulting in a vacuum. It is an appropriate method of sealing cough syrups and other liquids to enhance the product’s shelf-life.

9.How do you check the sealing integrity of the liquid packs produced by the cough syrup (4-side sealing) packing machine?

Validation of the sealing integrity of the liquid sachets/pouches produced by the cough syrup (4-side sealing) packing machine is necessary to preserve the product’s safety and quality. The sealing integrity of the sachets can be checked in the following ways;

Visual Inspection

Visual Inspection – Picture Courtesy: Vitronic

A visual examination of sachets is conducted to observe for any conspicuous defects, such as:

- Incomplete seal.

- Wrinkled seal.

- Misaligned sealing edges or incorrect dimensions.

- Seal leakage.

Sealing Integrity Test

Vacuum Leak Tester – Picture Courtesy: Pacorr

This test is conducted to check the sealed sachet’s integrity to guarantee they are leak-free. It is a crucial quality control procedure to ensure the packed product’s reliability, and safety, and that it satisfies the necessary criteria.

There are many methods to identify the integrity of the sachets but the frequently employed method is utilizing the leak tester equipment, consisting of a vacuum chamber.

The two most popular techniques for sachet leak detection are;

Dry leak test

This approach utilizes a dry vacuum chamber. After placing the sample in the chamber, a vacuum is created. Examine the sachets' behavior under vacuum.

The sachets get inflated due to the vacuum. The leaked sachets will remain flattened and thus be identified.

Wet leak test

In this method, a water-filled vacuum chamber is used. The sample is put in the chamber. If a leak is present, bubbles will be generated, leading to leak detection.

10.What are the maintenance tips for a cough syrup (4-side sealing) packing machine?

Maintenance of Cough Syrup (4-Side Sealing) Packing Machine – Picture Courtesy: Viking Masek

Regular maintenance of a cough syrup (4-side sealing) packing machine is crucial for its optimal performance and reliability. Managers should conduct scheduled maintenance protocols to avoid machine downtime.

Here are some maintenance tips that can help keep the device in optimal working condition.

To avoid residue accumulation, which might impair the machine's function, thoroughly clean the machine regularly. Pay close attention to parts like the conveyor belt, sealing clamps, and filling nozzles.

Use suitable agents for cleaning and make sure all the cleaning techniques adhere to the standard hygienic guidelines.

Use appropriate lubricants to lubricate the mobile parts of the device to prevent abrasion and damage.

Examine the sealing station regularly. Sealing clamps and heating parts should be inspected to ensure the sealing integrity.

Conduct a scheduled inspection of all the components of the device to look for any damage or wear. Replace or repair the worn parts to ensure the machine’s efficiency.

Periodically test the safety elements of the device to verify they are working perfectly, to avoid any incident.

Remember to consult trained personnel for repairing and maintenance of the equipment.

11.How do you troubleshoot a cough syrup (4-side sealing) packing machine?

Yes, a cough syrup (4-side sealing) packing machine is a reliable piece of equipment that works efficiently. But just like any other industrial instrument, it can also encounter certain issues that need to be detected and rectified timely to avoid any huge problem or incident.

We will discuss some commonly encountered problems and their rectifications (Troubleshooting).

| PROBLEMS | POSSIBLE CAUSES | RECTIFICATIONS |

| Non-Uniform Filling

|

Damaged or clogged nozzles.

Non-calibrated nozzles. Trapped air in the filling system. Inconsistency in the liquid viscosity. Filling parameters are not correctly adjusted. |

Cleanse or replace the nozzles.

Calibrate the nozzle properly. Remove the air from the system. Adjust the liquid formulation to avoid inconsistent viscosity. Adjust the filling parameters. |

| Incorrect Sealing

|

Sealing temperature too high or low.

Inadequate pressure. Insufficient sealing time. Damaged sealing clamps. Dusty film or sealing surface. |

Adjust the sealing temperature, pressure, and time as per the packaging material.

Repair or replace the sealing clamps. Properly clean the film and sealing station. |

| Variations in Package Dimensions

|

Problems in the shaping tubes or misaligned tubes.

The film is not feeding properly or slipping. Cutting blades are dull or misaligned. |

Repair, replace, or adjust the shaping tubes.

Make sure the film feeding is appropriate. Replace the dull cutting blades. |

| Film Jamming or Creasing

|

Misaligned film rollers.

Misplaced film roll. Foreign materials are stuck in the machine. |

Make sure the film rollers and the arms are properly aligned.

Place the film roll in the center. Clear the obstructions in the machine. |

| Excessive Noise

|

Worn or loose parts.

Abrasion due to lack of lubrication. Misaligned components. |

Tighten the loose parts.

Replace the damaged parts. Lubricate the mobile components. Properly align the mechanical parts. |

12.What factors to consider while investing in the cough syrup (4-side sealing) packing machine?

It must be overwhelming looking at the heft of the models and variants available of the cough syrup (4-side sealing) packing machine on the market. Selecting the right equipment according to your needs is crucial to the growth and success of your business.

Here we will discuss some major factors you should consider before investing in a cough syrup (4-side sealing) packing machine.

Cost/Budget

Budget Assessment – Picture Courtesy: ET Money

It is an important factor to consider before shopping. Assess your budget and then select the suitable device that could satisfy your production needs efficiently. You need to determine not only the initial investment but the operation and maintenance costs as well.

Capacity

Production Capacity

The machine’s production capacity is what makes it unique. You should consider the device that meets your production requirements. Always keep in mind your current needs as well as your future objectives.

Filling System

Filling Mechanism Installed

Each variant may have a different filling mechanism installed in it. Opt for the equipment compatible with your products and process them efficiently.

Sealing Mechanism

Sealing Mechanism – Picture Courtesy: Multi-Pack Solutions

Sealing mechanisms could also be different in different models. Choose a machine that has suitable features for your products and desired packaging materials.

Versatility

Versatility

Look for a device that provides flexibility in packaging sizes and formats. The device should be able to handle various shapes and sizes packages.

Operational Ease

Operational Ease – Picture Courtesy: SteriPack

Select the device that does not have complex working procedures and has a user-friendly interface, so that the operators don’t face difficulty in operating the device.

Maintenance Needs

Maintenance Ease

Determine the structural design and maintenance requirements of the device and opt for one that can be maintained and cleaned easily.

Regulatory Compliance

Regulatory Compliance

The product’s safety is a crucial factor. So you should look for a device compliant with the relevant regulatory standards, such as GMP, CE, FDA, and ISO.

Customer Support

Customer Support & Warranty Policy

It is a fact that every manufacturer wants assurance in terms of warranty and customer support of the device. So opt for the brand and model that offers such policies.

CONCLUSION

Cough syrup (4-side sealing) packing machine is an advanced technological equipment popular, not only in the pharmaceuticals sector but also in other liquid manufacturing industries like food, chemicals, and cosmetics, for its rapid production and efficiency. Searching for a suitable device can be a lengthy process, therefore, it is important to have comprehensive knowledge that can help you procure the right machine for your business. So, if you are looking to invest in this amazing piece of equipment or want to have a better understanding of the device, instantly contact the Allpack Team. We will guide you in a better way!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide