Honey Manufacturing: The Complete FAQ Guide In 2025

Honey Manufacturing: The Complete FAQ Guide In 2025

Have you ever thought about how the shiny golden honey in your jar is manufactured? Behind this, there is honey manufacturing process. It is the step-by-step process of extraction, cleaning, processing, and packaging. One of the important things that is strictly followed is the safety of food regulations. Because of this, demand of clean honey is at the peak.

Honey can be stored for years; providing a long shelf-time. In honey manufacturing process, not only modern technology of food processing is used, but a mixture of both traditional and modern technology is used. People prefer a hygienic and chemical-free sweetener; honey.

If you are beekeeper or want to start business and searching for a guide about honey manufacturing, you are on the right spot. This FAQ guide will shower you with information about honey manufacturing. However, let’s explore it.

1.What do you know about honey manufacturing?

Honey manufacturing-Picture courtesy: apicoladanangie.com

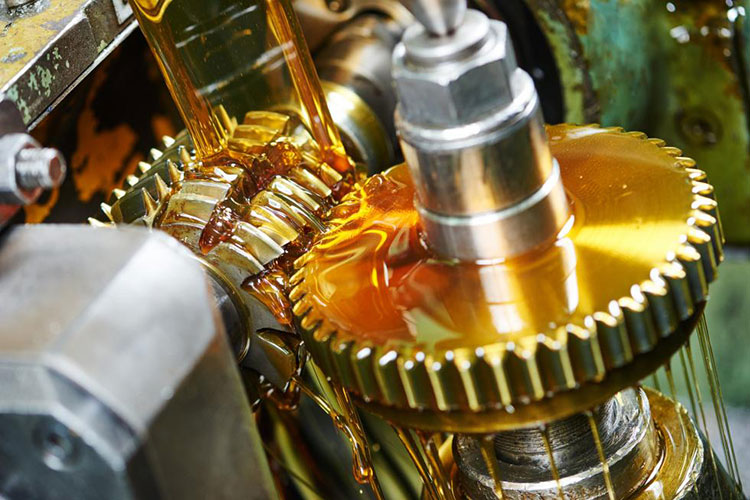

Honey manufacturing is a process of extract the raw honey and transformed the golden honey in a clean and moisture-controlled bottles. This process is using advanced technology using sensors, sterile packaging and eco-friendly machines that make the honey standing on your shelf. The manufacturing begins with collecting the delicious bee nectar from flowers and stores in honeycombs.

When these combs are loaded with honey, the beekeeper take these combs to the industry where equipments are used to extract, purified, clean and packaged. The nature sweet treasure is gone through several careful steps to make it possible for you to enjoy your breakfast.

2.Enlist the benefits of honey manufacturing process?

One might think that the honey is extracted from the beehives and directly poured into the jars but this is not the case. It has to go through various steps. From this one can get numerous benefits. Below are the benefits you can get from honey manufacturing process.

Shelf line

Shelf line-Picture courtesy: difford’sguide.com

One of the benefits you can get from the honey manufacturing is the longer shelf line of honey. You can store honey for months or even to years, with out getting rinsed and remain fresh as it is extracted lately. This is because the manufacturers during honey manufacturing check the moisture level and controlled it to keep it stable. A clean and air tight sealing also control the moisture level. If moisture of raw honey from beehives are not controlled, it gets fermented.

Good taste and texture

Good taste and texture

Are the taste of honey get change? No, it’s sweet taste remains the same. The honey manufacturing process uses the methods to purify the honey that maintain the good taste of honey. Have you seen the balanced viscosity and smooth textured honey? This process uses the heat and removes waxes to give a honey smooth texture. You can use the honey over the bread or in a tea without getting afraid of lumpy and runny honey.

Clean honey

Clean honey

You may have seen the raw honey contains wax and honeycombs pieces and you can not gather strength to serve it to the guests. But don’t worry, you don’t have to be ashamed now. Because by honey manufacturing, all these debris are removed by filtration. You get a clean, free of impurities and contamination honey.

Hygienic packaging

Hygienic packaging-Picture courtesy: paramountglobal.com

You can get proper sealed honey from the markets. This is done by honey manufacturing process. Honey comes in various outstanding packaging options such as squeeze bottles, pouches and safe jars. These are air tight, tamper proof, and germs free sealed. Due to their attractive packaging, they can be exported.

Waste utilization

Waste utilization-Picture courtesy: mielimperial.com

Sometimes, the waste produced or remain after the whole process can be use in one way or other. Same, the wastes such as wax, pieces of bee comb and propolis that are collected by filtration of honey are, often, reused. But, how to reuse? The manufacturer uses the modern methods to form different products such as lip balms, candles, product wraps etc.

Product variety

Product variety-Picture courtesy: beeculture.com

You might have seen different colored and flavored honey on the market shelves. Behind variety of honey, there is honey manufacturing process. You can get a flavored honey, cream honey, and honey blended with fruits. Therefore, you can buy honey according to your taste, diet, and recipe need. A flavored honey can be made by infuse the natural ingredients with honey, best suitable for recipe.

Open business opportunities

Open business opportunity-picture courtesy: heritagebeefarm.com

Another benefits you can get is open business opportunities by using honey in various ways, beyond honey production. Honey is used to make candies, soaps (cosmetic products) and other products that uses honey. It can also use in honey-based beverages and medicinal supplements.

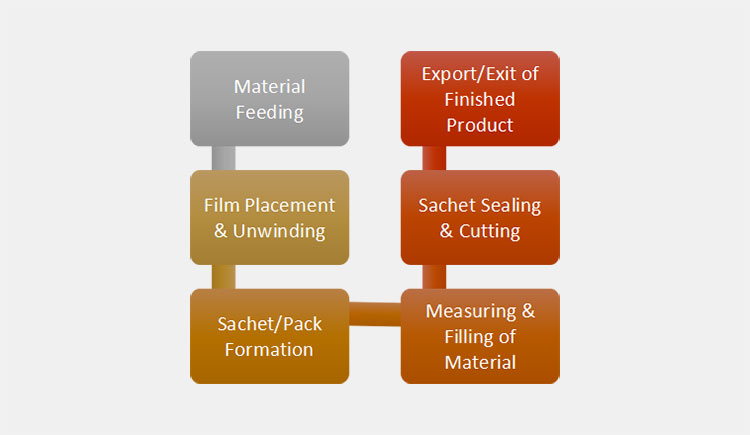

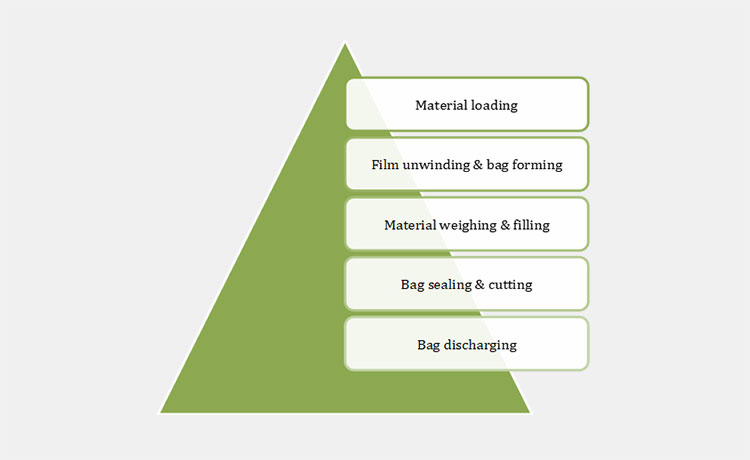

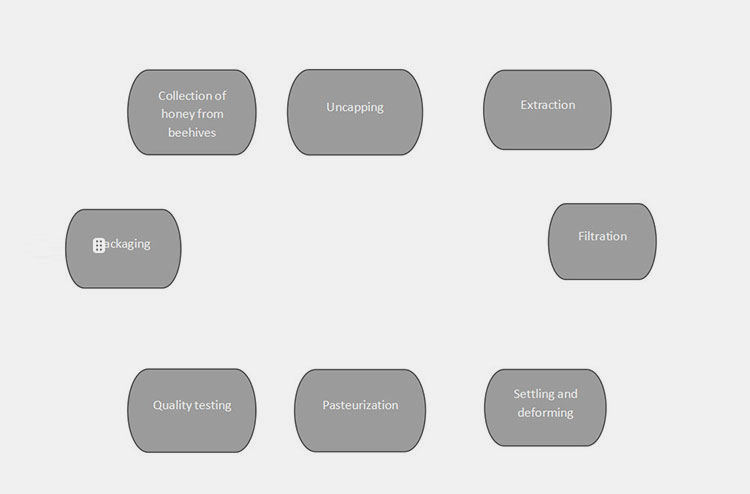

3.What are the necessary steps involved in honey manufacturing?

There are several steps involved in honey manufacturing. Here are the important steps below.

Collection of honey from beehives

Collection of honey from beehives-Picture courtesy: beespartners.com

The first step begins with harvesting honey from hives. This is done when cells are 80% capped with honey. Beekeepers remove the frames from beehives. These frames have cells that are filled with honey with sealing over the top. Without harming bees, frames are transferred to the processing plant.

Uncapping

In uncapping process, the sealed cells are uncapped or removed in order to make honey flow for the onwards process. What’s next? An automated uncapping machine is used to remove the wax seal from the comb. This machine contains blades and knives that are heated to 35 centigrade to efficiently cut the capping.

Extraction

Extraction-Picture courtesy: bee professor

For extraction honey from the combs, an automated extractor is used. An uncapped frames are loaded in a stainless-steel tank of extractor that spin them by using a centrifugal force to extract honey from comb.

These machines can handle large quantity of frames. In colder places, heated extractors are used to heat the frames to easily extract honey from combs. Honey is drained into tank for further process.

Filtration

Honey is passed through filters to remove the pollen, was and if any remaining bee parts. Filters like diatomaceous earth filters are used to get a clean and clear honey.

Settling and deforming

The already filtered honey is allowed to settle in large tank. This is left for 3 to 4 days in which fine particles and air bubbles come to the top surface and form foam, which is removed.

This is done either manually or mechanically.

Pasteurization

Pasteurization-Picture courtesy: mydadshoney.com

This step is optional and use for commercial products. Pasteurization is done for at least 30 minutes and 145 Fahrenheit to kill any microbes that can cause fermentation. This step is performed with care because overheating can degrade the enzymes and nutrients in honey.

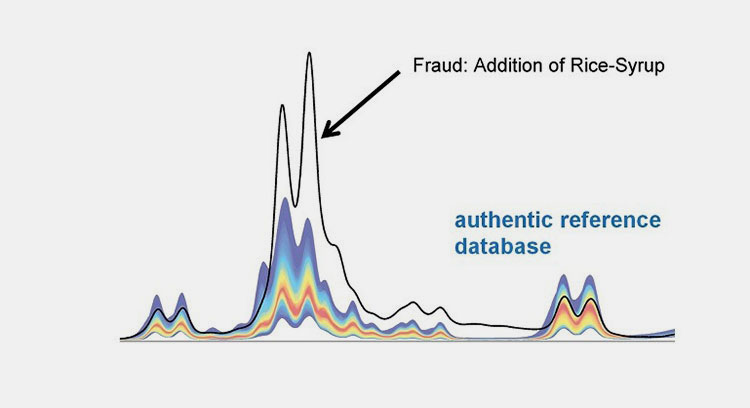

Quality testing

During the process, quality tests are done.

- Firstly, to check the contamination or moisture level, refractometer is used for this purpose.

- The color, viscosity, and HMF level are checked.

- Adulteration is checked via NMR spectroscopy.

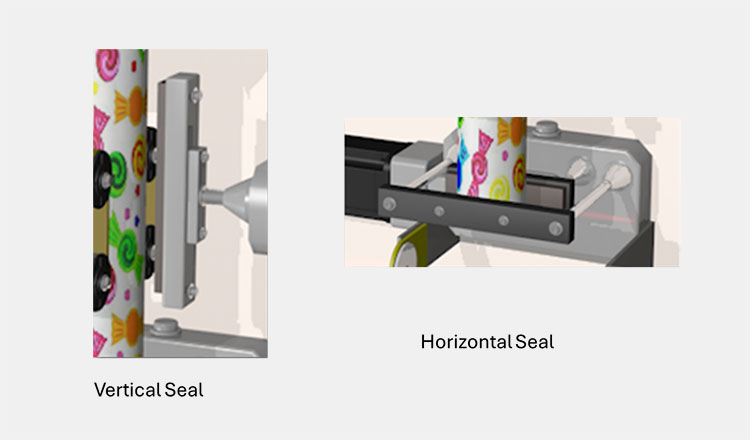

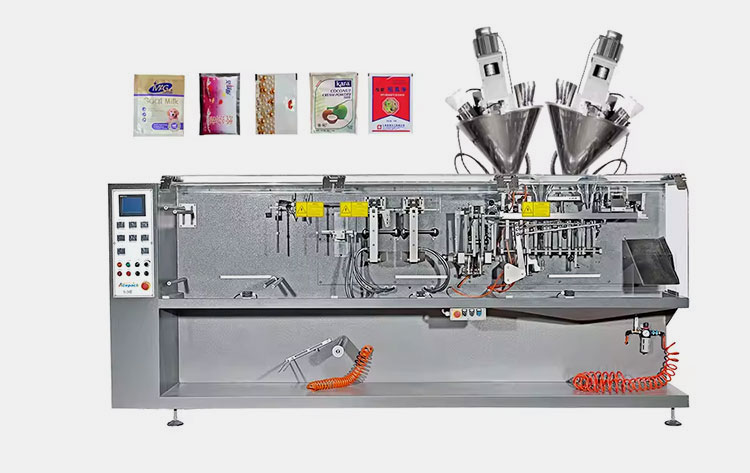

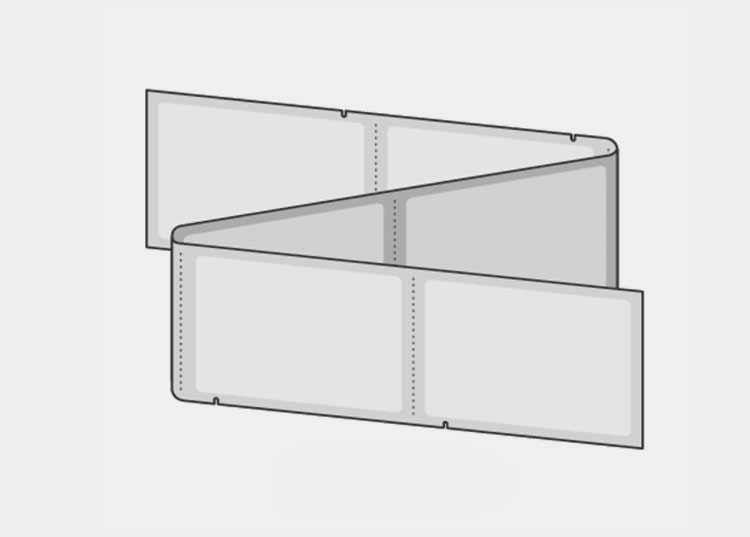

Packaging

Packaging

The final step is here where honey is precisely and accurate dispense into the desired packaging materials and styles. By using capping machine, jars are sealed. Labelling is done automatically where required information like batch number, honey origin, floral source etc. are applied.

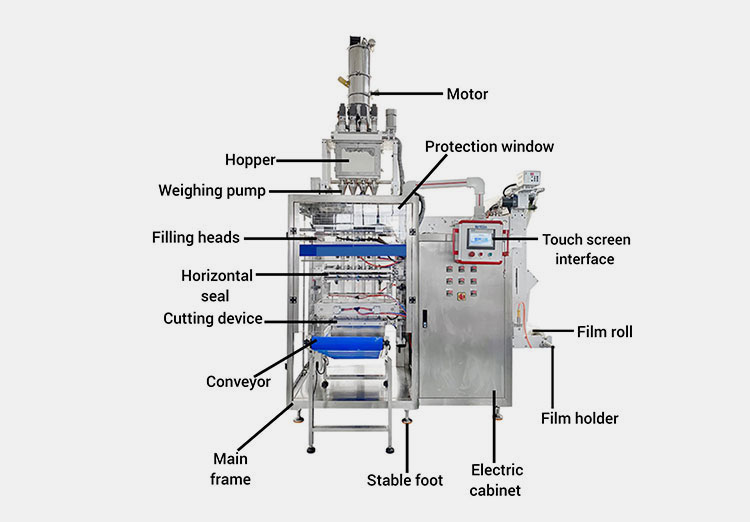

4.Describe the equipment’s involved in honey manufacturing?

Followings are the equipments involved in honey manufacturing.

Uncapping machine

Uncapping machine

There is layer on beehive that seals the honey comb. Uncapping machine is designed to remove the bee wax that seals the honey inside the comb cells. This uses the heat knives or roller to slice off the wax caps.

Different models of this machine can handle different size and shapes of frame.

Extractor

Extractor

As you can assume from its name, it extracts the honey from the honeycombs. Extractor uses a centrifugal force to spin the frames to extract the honey. It can hold various frames. Honey stores at the bottom of extractor, from here honey flows to the collection tank.

This process is carefully done, to prevent the comb structure, which you can reuse for bees.

Dehumidifier

Dehumidifier-Picture courtesy: foodtechprocess.com

High moisture level in honey can spoil or ferment it. So, a specialized machine known as dehumidifier is used. This is designed to remove the water content from the honey to 18%. most of the dehumidifier uses the vacuum evaporator to remove the moisture without heating the honey.

This is effective as the enzymes, antioxidants or nutrients remain preserved.

Pasteurizer

Honey pasteurizer-Picture courtesy: directindustry.com

Some of the honey is pasteurize depends on what is it using for. Heat is provided to honey to kill germs or microbes to prevent honey from any future fermentation and crystallization.

Plate heat exchanger and immersion heater is used for heating honey, for 15 to 30 minutes with 140-149 Fahrenheit. What about overheating? There are thermometer and digital control system that manages the overheating.

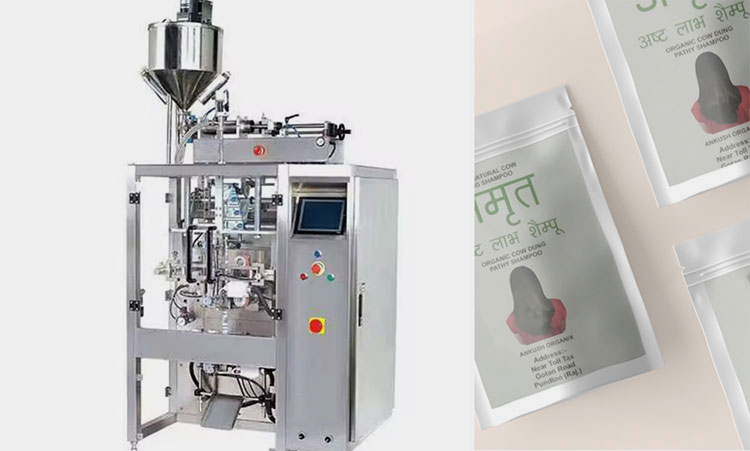

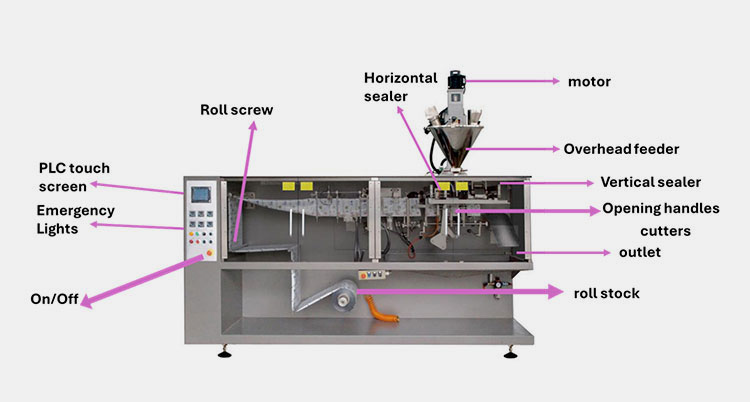

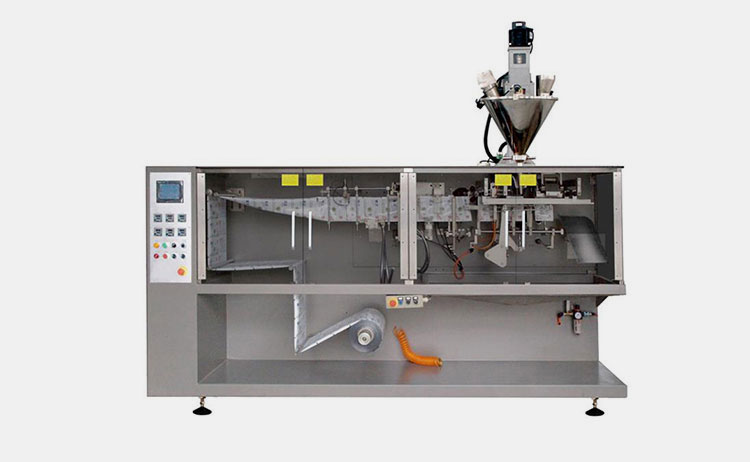

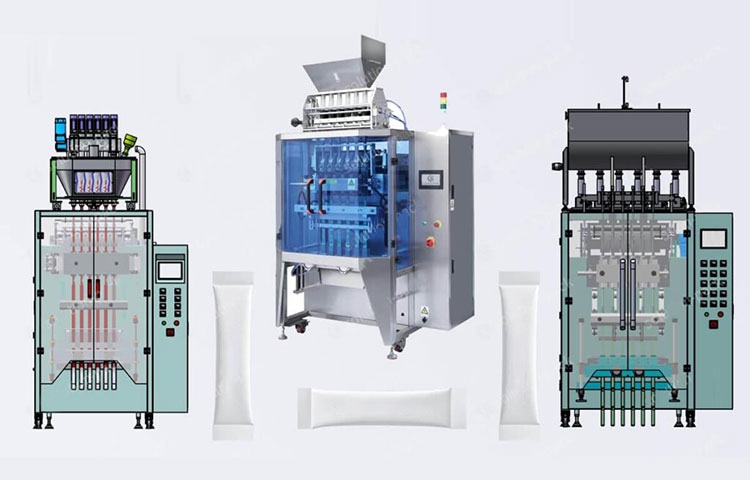

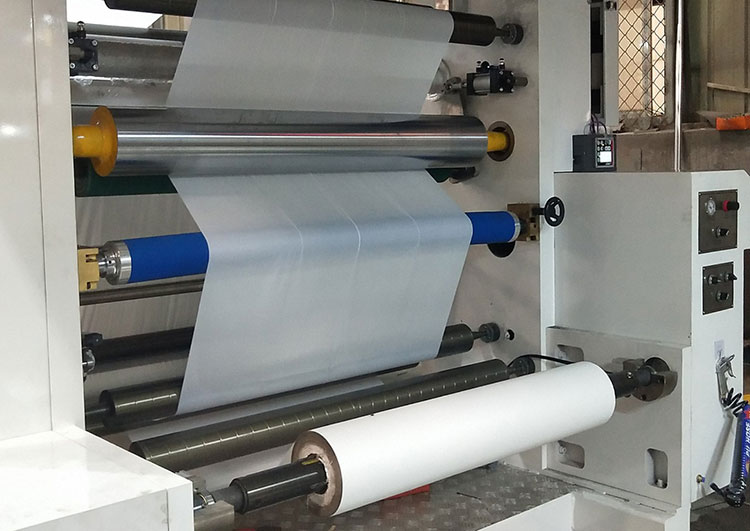

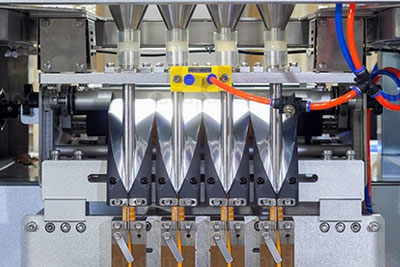

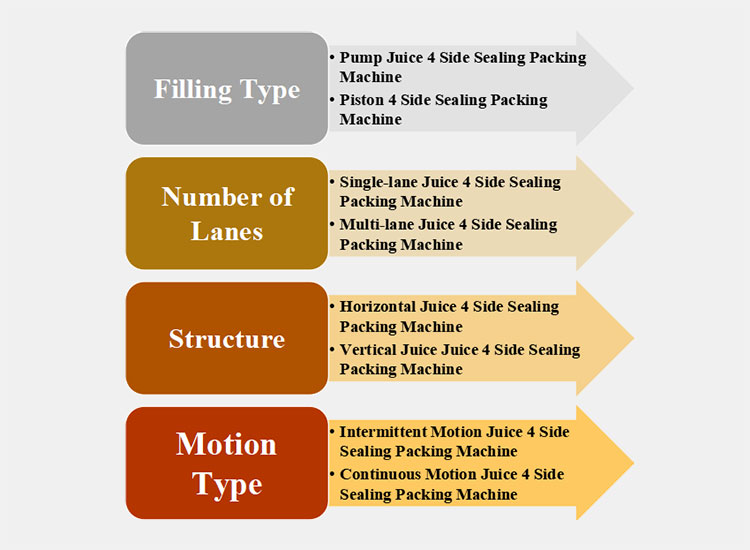

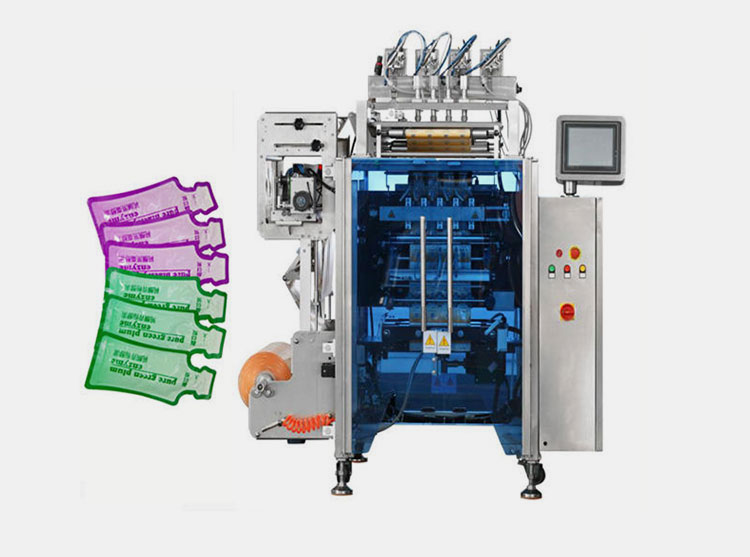

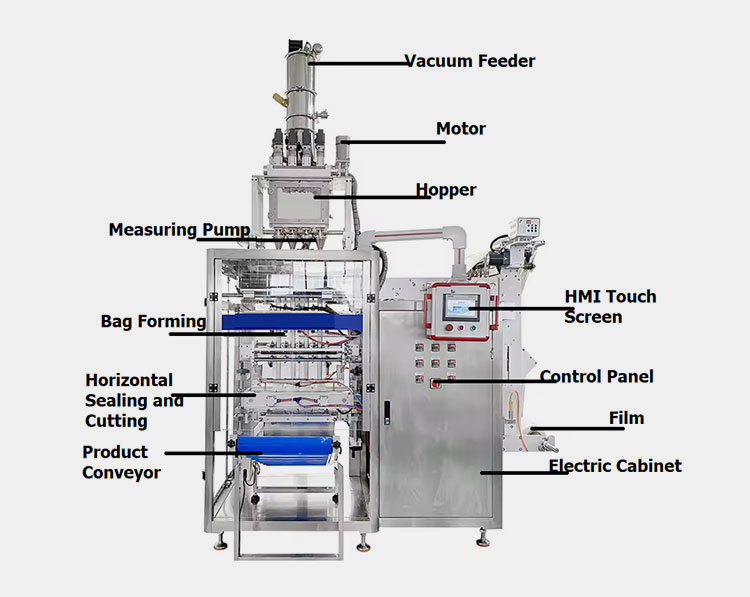

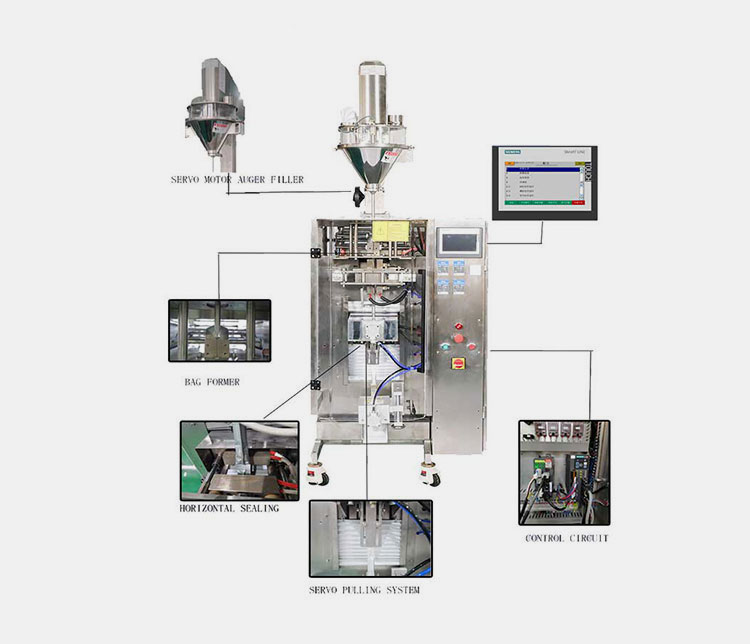

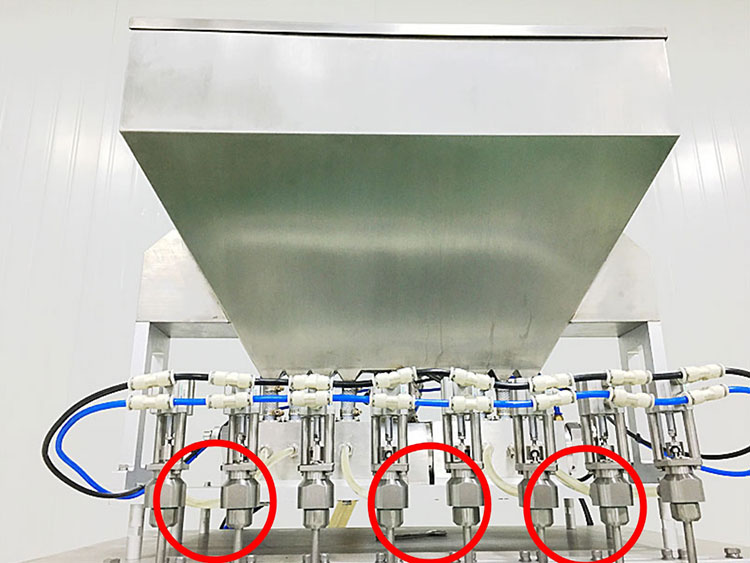

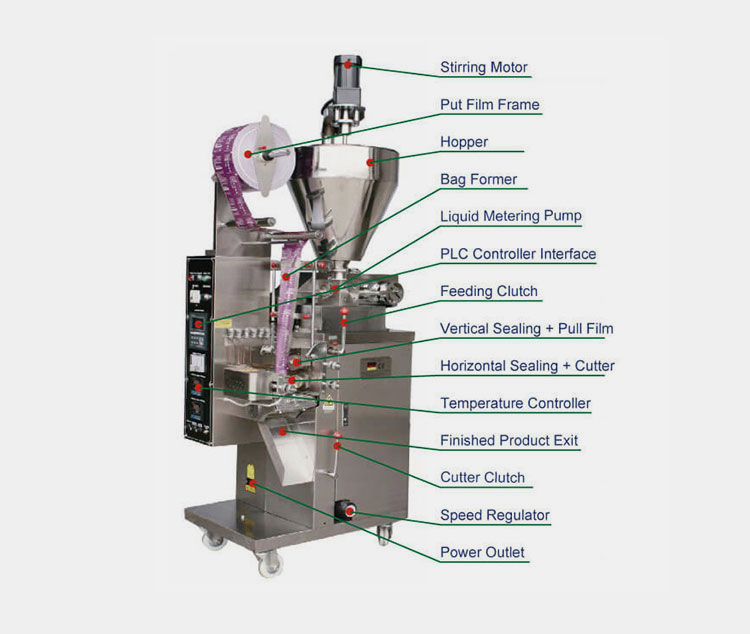

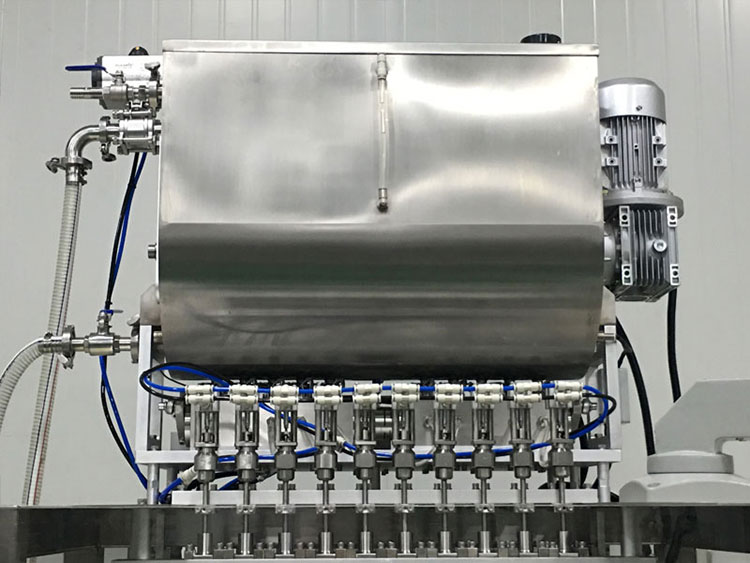

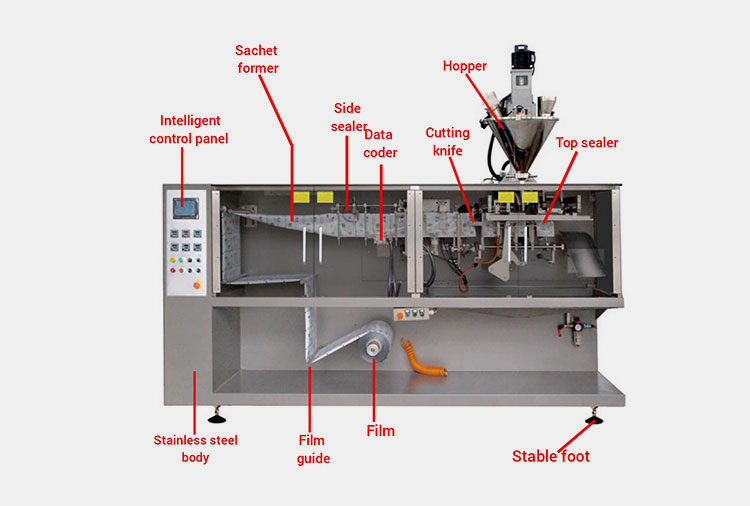

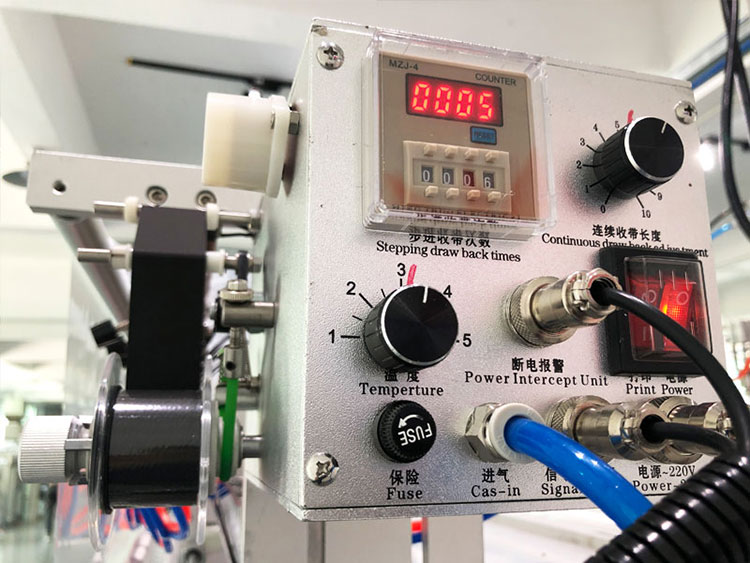

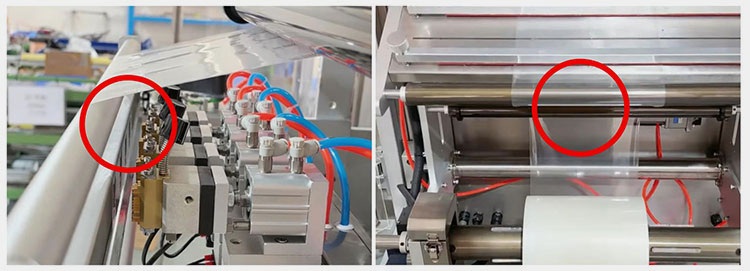

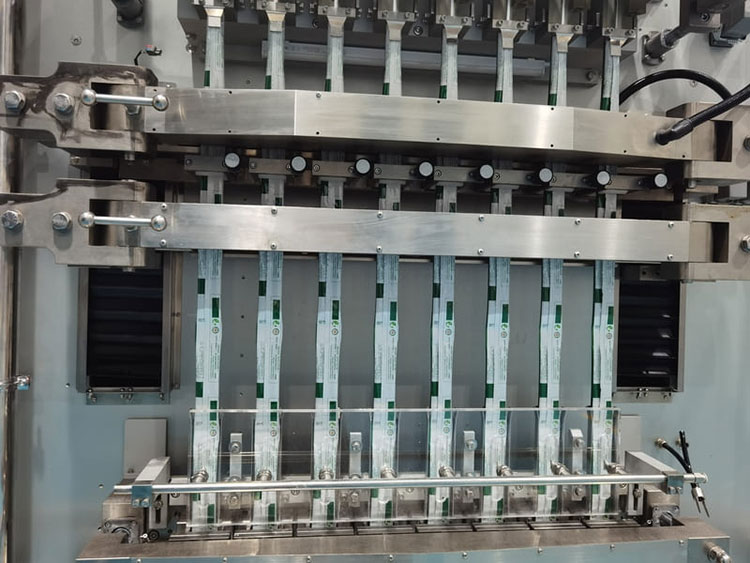

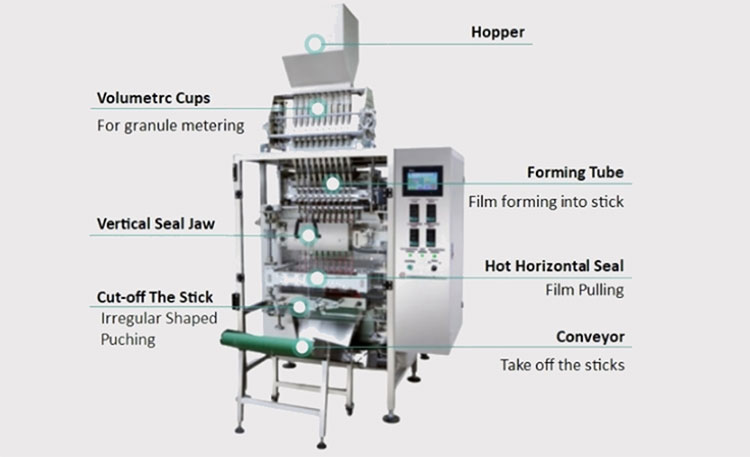

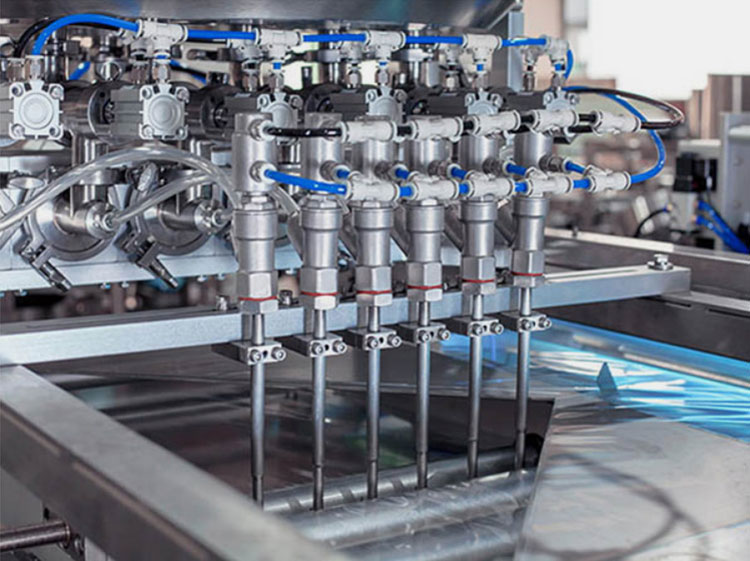

Filling machine

Filling machine is used to dispense honey in different packaging materials. It accurately fills without overfilling or underfilling the jars, ensures the consistent and efficient handling. Here are the following types of filling machine.

Gravity filling machine

Gravity filling machine-Picture courtesy: makwell.com

In this type of filling machine, gravity is used to fill honey from tank into bottles or jars. These machines are highly accurate and precise, and it makes sure that honey flows in direction of gravity.

What about its working? A hopper is filled with honey, then, it is passed to the filling nozzle. Jars are placed beneath the nozzle and filled by using gravity.

Piston filling machine

Piston filling machine-Picture courtesy: beesequipment.com

As the name indicates, piston is used to fill containers from honey. It is ideal for thick substance. Piston pulls the honey into chamber. It, then, push the honey from nozzle into the jars.

This machine is ideal for thick honey and best for both small- and large-scale industries.

Vacuum filling machine

Vacuum filling machine

Here, to reduce the internal pressure, vacuum is created. The, honey is put in the container until reaches the pre-designed level. This ensures the consistent filling.

Pump filling machine

Piston filling machine

This machine offers high accuracy and speed. It uses pump to push honey into the container.

Capping machine

Capping machine-Picture courtesy: ceclemachine.com

To maintain freshness and prevent honey contamination is prerequisite. For this purpose, a machine know as capping machine is used. It is designed to place caps on the jars or bottles to give them air-tight closure. This ensures good quality of products.

But a question may pop in your mind that how it capped the bottles? So, the filled bottles or jars are moved to the capping station. By using capping feeder, caps are placed over the bottles and torque system is applied to secure air tight capping.

Labelling machine

Labelling machine

Labelling machine is used to label containers. You may read the labeling of honey jars or bottles to check its origin or other information. Therefore, labeling is done to make sure that customers know the basic information about the product.

Here, by conveyor system, containers are loaded in machine. Labels are used from the rolls and stick to the containers using a roller arms.

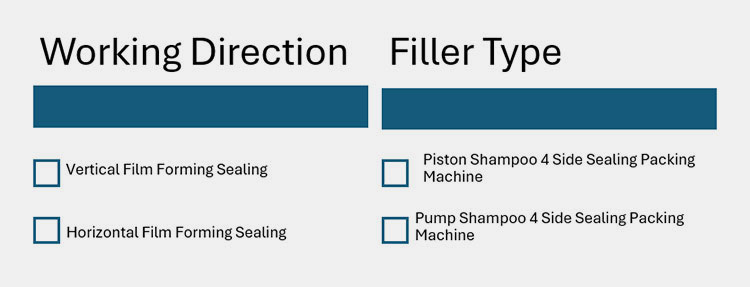

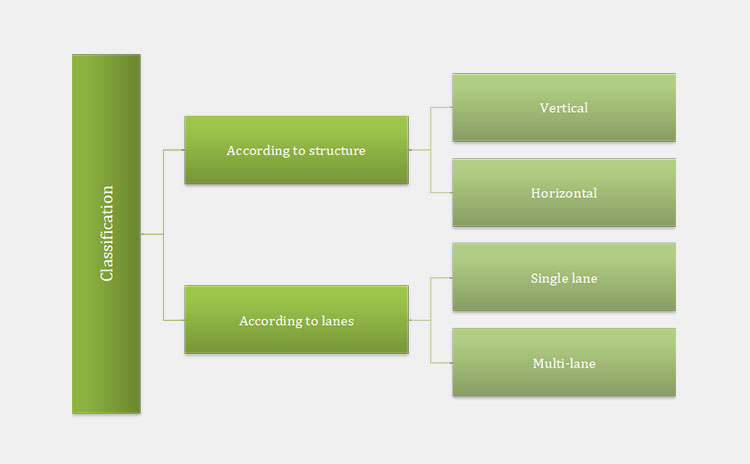

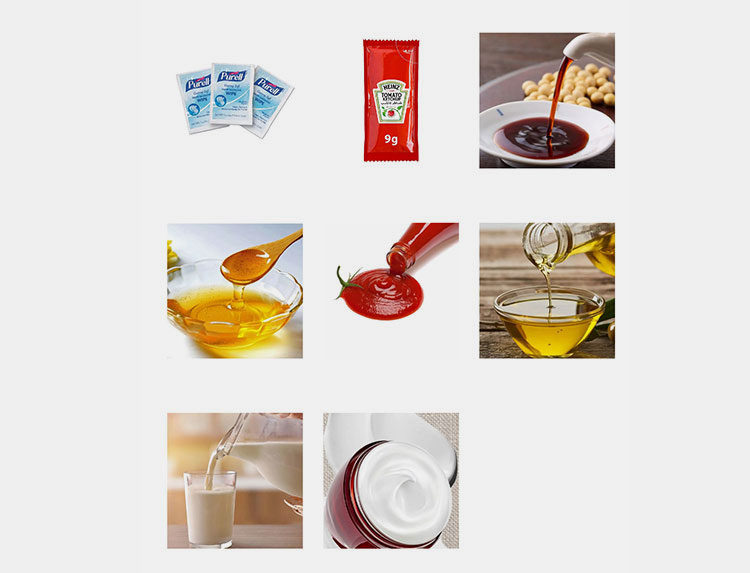

5.What kinds of packaging material are handled to package honey in honey manufacturing?

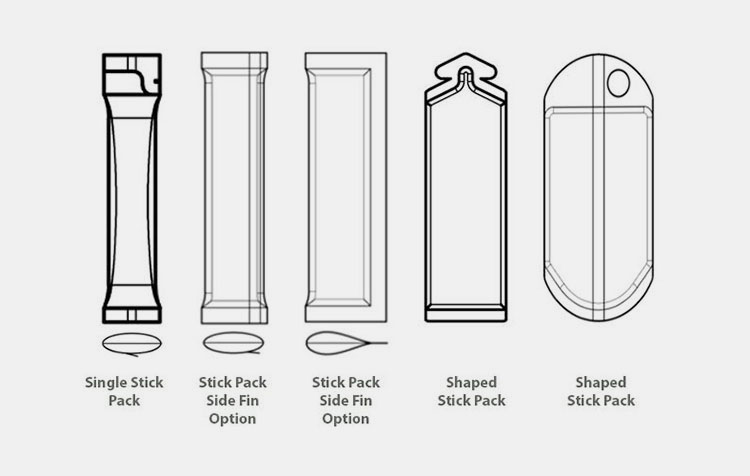

Packaging is important to safe honey, along with this, it adds attraction to the already golden honey. It is packed in different packaging materials to keep it fresh and easy for use. Here are the following packaging materials that are handled during honey manufacturing.

Plastic bottles

Plastic bottles

One of the packaging materials to pack honey is plastic bottles. They are made of PET that are cost effective, and easy to use and light weighted bottles. These often come in squeezable bottles which make it easy for you to dispense the required amount of honey. In some cases, a person is in hurry and pouring honey from the jars creates mess. In this situation, a squeezable plastic bottle comes handy.

Metal tins

Metal tins-Picture courtesy: ebay.com

These are often used to store bulk honey. These are durable and best for shipping or export. Provides long term storage and preserve honey from air and moisture. You can give a tin of honey as gift because it has a fancy and stylish.

Glass jars

Glass jars

Are you looking for something that can’t affect honey taste and color? Then, glass jars are best option for you. Glass jars are used to package honey. These are non-reactive, chemical free, and durable that can not affect any change in taste, freshness and color. A customer can see the honey from outside due to its transparent appearance. Although they are heavier but it adds elegancy to your shelves.

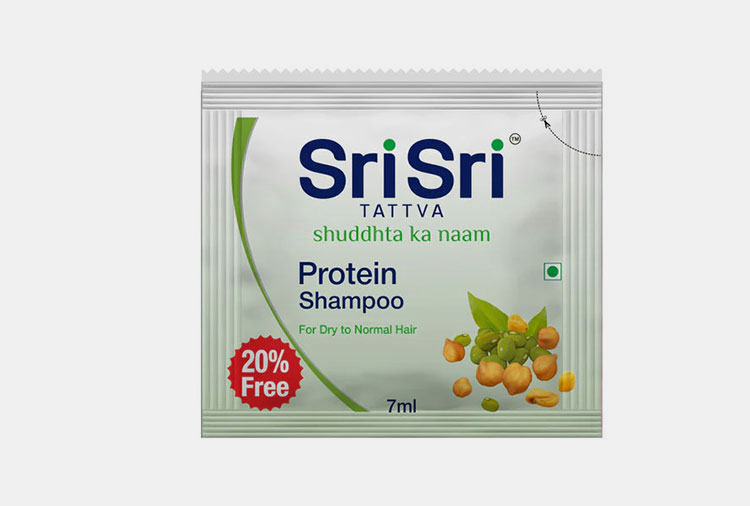

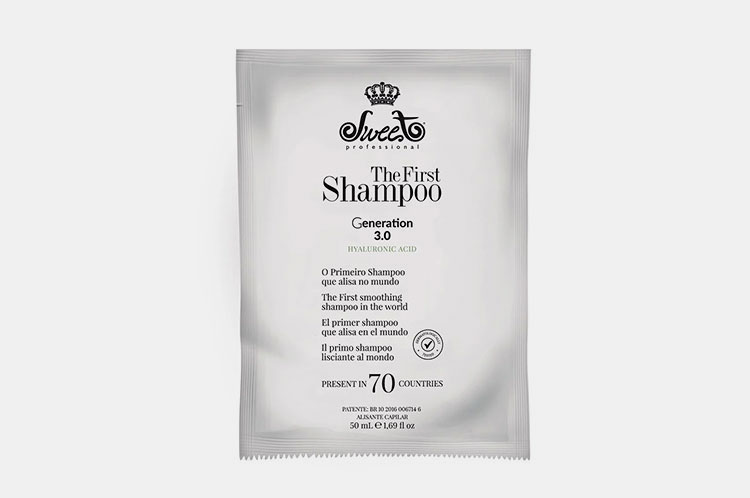

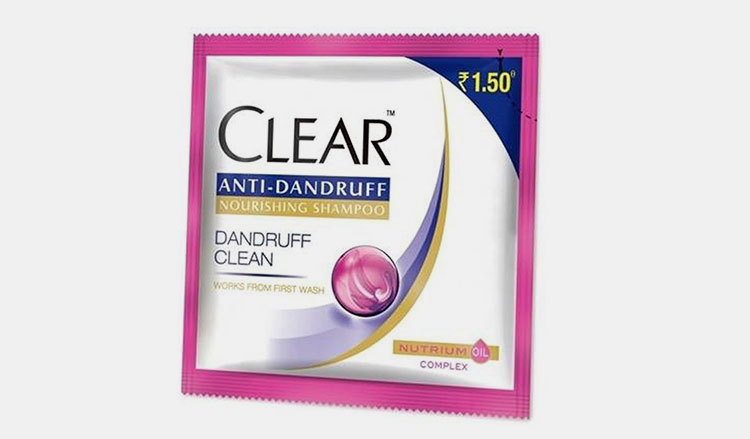

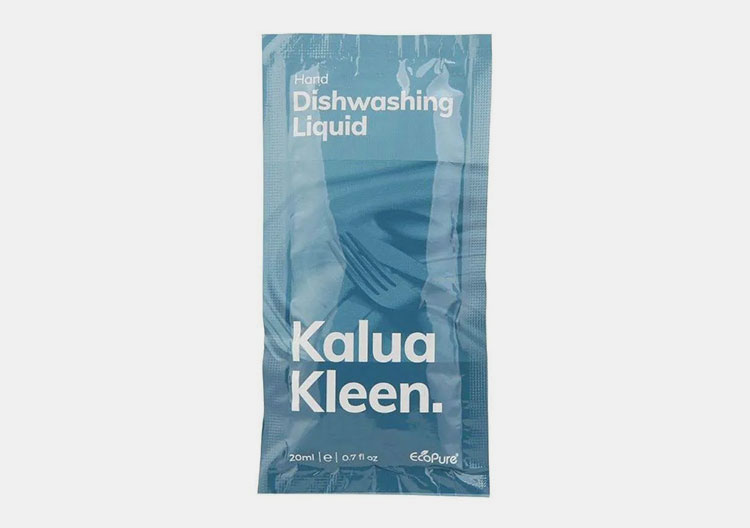

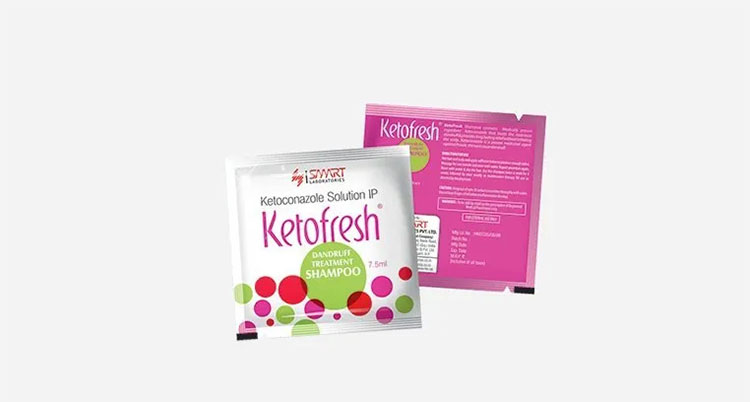

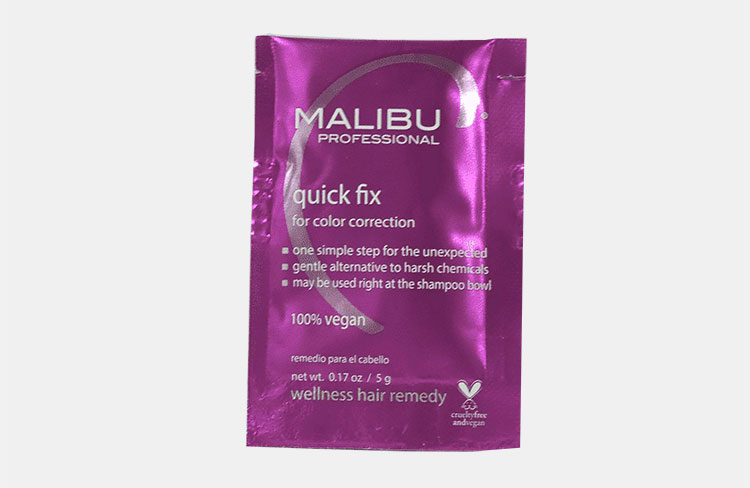

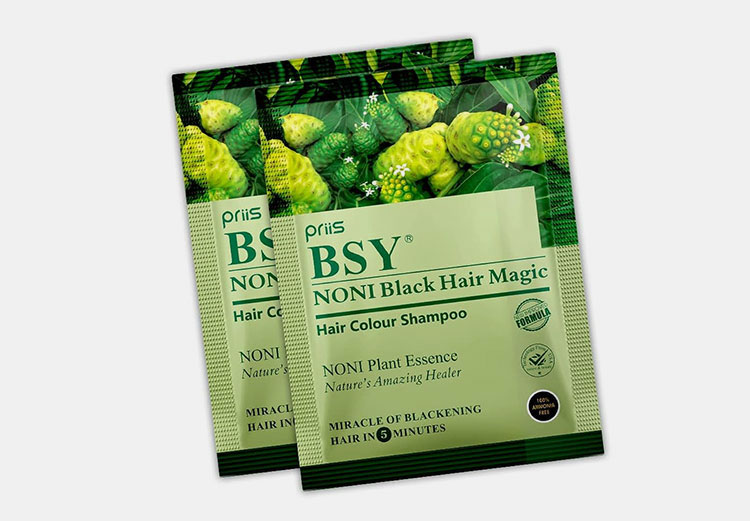

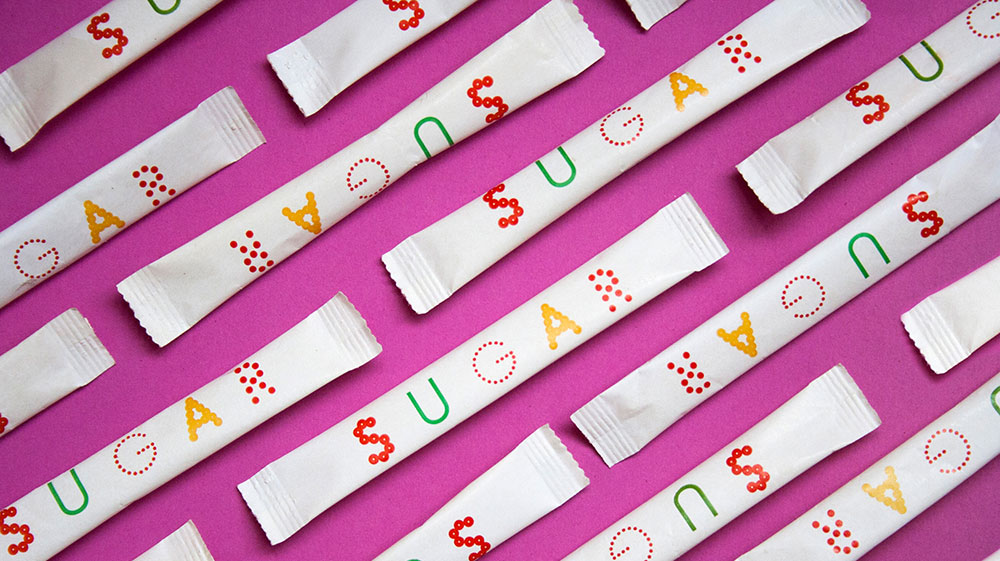

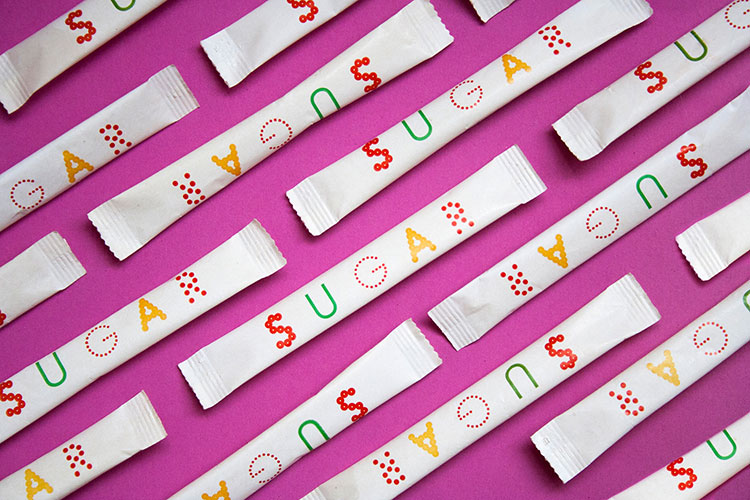

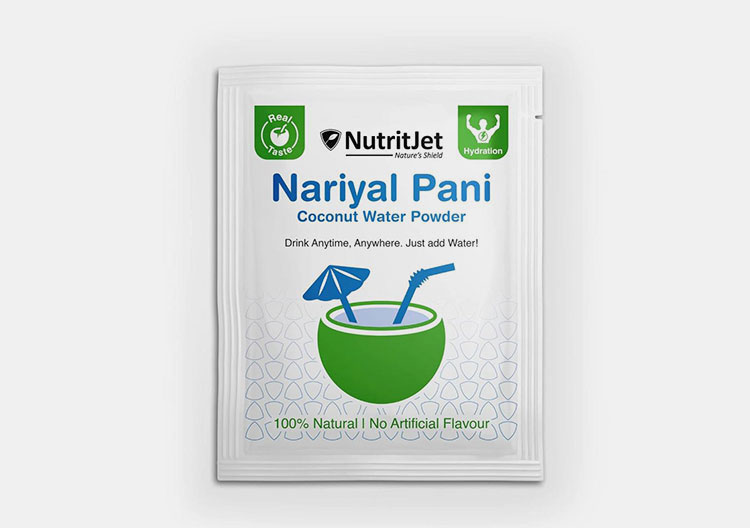

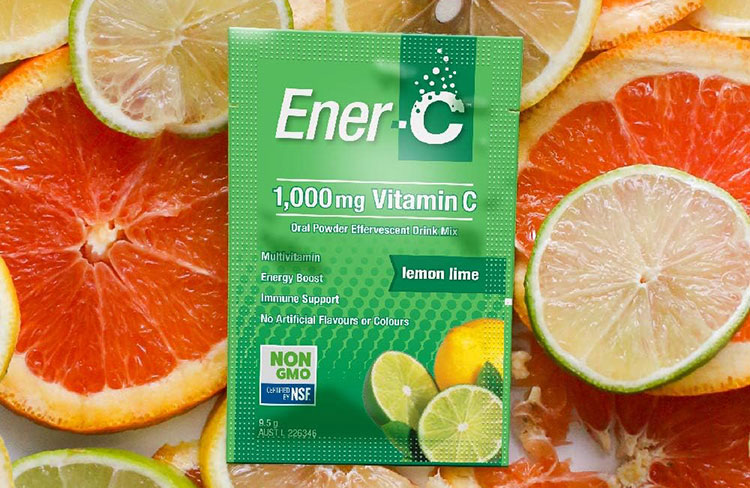

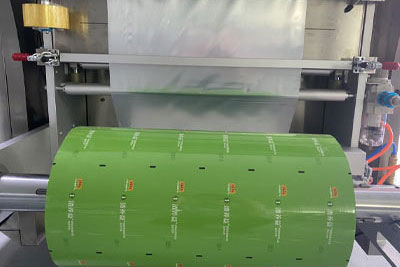

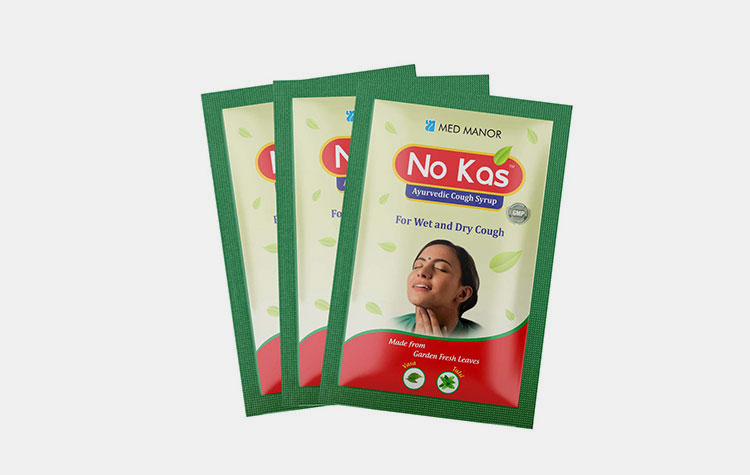

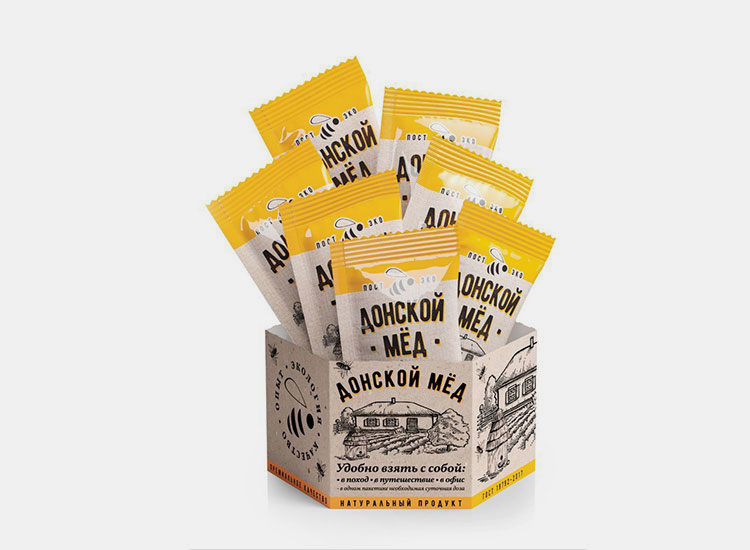

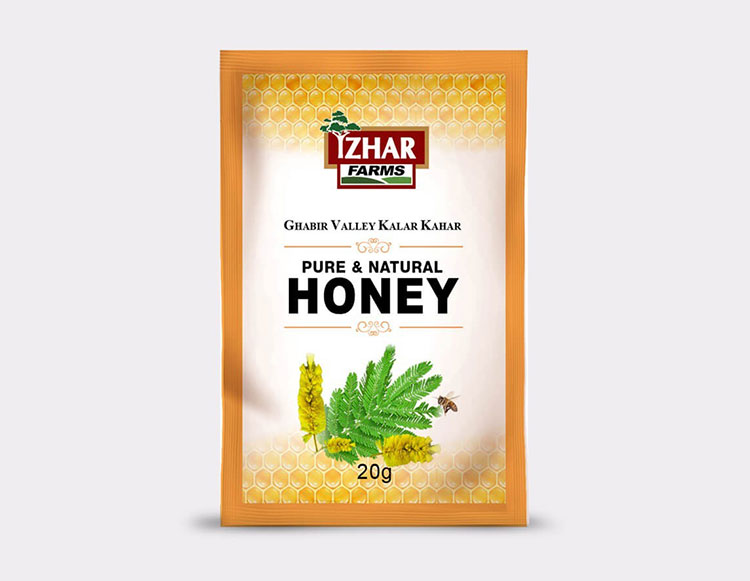

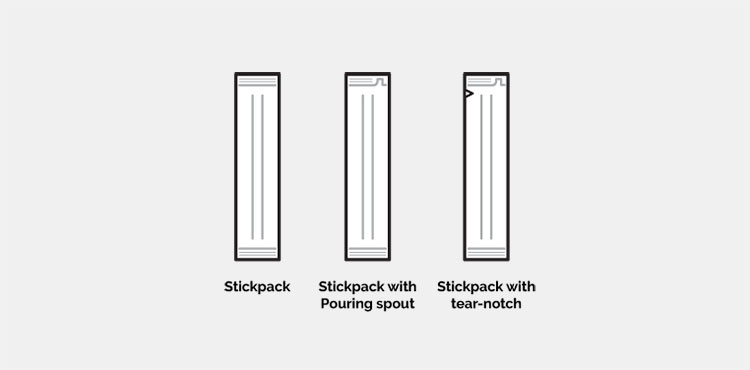

Sachets and pouches

Sachets and pouches

Honey is packed in sachets and pouches. These are travel-friendly and single-use. If you don’t want to carry jar or bottle then these flexible and light-weighted sachets are the best option. Coffee, hotels, in bags etc. have these honey pouches or sachets.

6.What kinds of honey are made in honey manufacturing?

Kinds of honey

You might think there is only one kind of honey but this is not correct. Do you know there are different kinds of honey? Depending on the process, harvesting method and floral source, there are different types of honey with their unique texture, benefits, and color. What are you waiting for? Let’s get started.

Organic honey

Organic honey

Organic means chemical free. Are you worried about your health? Then this organic honey is best suited. It is made from the organically grown plant nectar and the chemicals, pesticides, and any other additives are not used by beekeeper. The most important thing is that bees are not given any antibiotics and beehives are made of natural materials.

Do any chemicals use in packaging of organic honey? No, to maintain its freshness and stability, no chemical and heat is used.

Raw honey

Raw honey-Picture courtesy: pocketcityfarms.com

Another honey that are handled in a honey manufacturing is the raw honey. You get all the enzymes, nutrients and antioxidant. To make raw honey, honeycombs frames are taken from the beehives. By using a centrifugal extractor, honey is extracted. No heat is used to preserve the enzymes, nutrients and their antibacterial qualities. Debris are removed by straining the honey.

The whole process is done with great care and under controlled environment to preserve its flavor and nature.

Creamed honey

Creamed honey

Honey is processes in honey manufacturing to get creamed honey. Most of the people get cranky by the stick nature of honey. But you don’t have to worry. Creamed honey is not sticky but is like butter.

Crystallization process is used to crystal honey to give a spreadable texture to it. To make a creamed honey, raw honey is taken, then a small amount of finely crystalized honey, a seed, is taken as a template and added in a raw honey. Both are mixed uniformly and stored in a cooled environment. This gives a honey a crystalized nature. When all the process is done, it is ready for packaging.

Infused honey

Infused honey

Infused honey is made with infusion of different ingredients such as herbs, spices, fruits etc. These are actually infused with raw honey. The ingredients in raw honey are left for days to blend its flavor. They are filtered to remove any solid particles from the mixture.

Multifloral honey

Multifloral honey-Picture courtesy: daaliearthfoods.com

This kind of honey is made by nectar of different types of flowers. If you talk about the taste, it varies depends on the region climate, vegetation and other factors. It has an amazing taste with affordable price. As it is made from nectar of different flowers so it contains mixture of enzymes, antioxidants and nutrients.

Multifloral honey had many benefits for health.

7.What is the difference between regular and organic honey manufacturing?

Regular honey and organic honey

As you might think that both are honey. So, there will be no difference. But this is not the case. There are differences between both. However, let’s get started to know.

|

Difference |

Regular honey |

Organic honey |

| Beekeeping | Beehives are rearing near the place where there is contamination, pesticides, fertilizers, no organic place. | Beehives are located in organic, free of any pesticides, and other chemical areas. |

|

Extraction method

|

This type of honey is finely processed and heated at high temperature. So, the enzymes and nutrients get degraded. | It is gently heated and not filtered to retain its natural pollen, nutrients and enzymes. |

| Floral source

|

Bees are forged in a place where the bees collect nectar from plants that are treated with pesticides and other chemicals. | Here, bees are forges in a place where there is no use of chemical for plants. Hence, bees collect nectar from pesticides free plants. |

| Wax material | Wax made of chemicals may use. This includes chemicals in the honey. | In organic honey, no chemical wax is used for hives. A natural and organic wax is used for hives. |

8.What are the challenges that can be confronted in honey manufacturing?

Challenges-Picture courtesy: rexben. medium

There are many challenges that can be face in honey manufacturing. These affects the efficiency and quality of honey. Followings are the challenges that are confronted in a honey manufacturing.

|

Challenges

|

|

| Quality assurance

|

Some of the industries use the liquid sugar to increase the weight of honey. There is the risk of adulteration. Sometimes, the honey is contaminated from microbes, pesticides and other contaminated materials, if bees are bearded in the polluted areas. |

| Degradation | There are enzymes, antioxidants and nutrients in honey. But by excess heat, these may get degraded. Therefore, its quality gets crap. |

| Fermentation risk | There are some levels of moisture in honey but if moisture increase from the required moisture, there is high risk of getting it fermented. It causes the honey bad in taste, smell and can leads a packaging material leak. |

| Crystallization | It is normal that in cooler place, honey may become crystal. But in industries, it becomes a big deal when gets crystalized. Clogging pipes, rejected batches, or delayed bottling are all due to honey crystallization (at large tanks, premature crystallization occurs) |

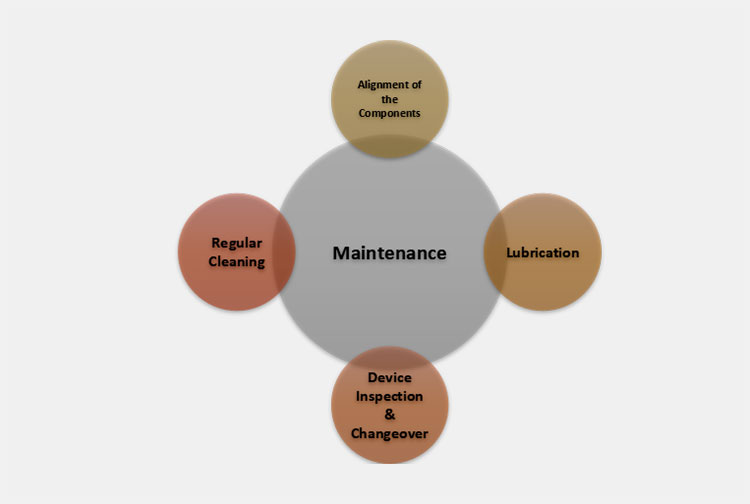

| Cross-contamination risks | Honey has a sticky nature. After every batch, its cleaning maintenance is necessary. However, not cleaning is the challenge that is faced during honey manufacturing.

The remaining honey on the machineries attract insects, promotes cross-contamination and promote microbial growth. |

| Waste management | During honey manufacturing, wastes like wax, foam, extra water and leftover honey are produced. These wastes can create cleanliness or sanitation issues if not managed properly. |

9.Do you know the innovations in honey manufacturing in 2025?

In 2025, numerous technological advancements are done to ensure the effective, sustainable and productive honey processing. This technology can empower beekeepers to comply with demand. Are you curious what these innovations are? Let’s explore them.

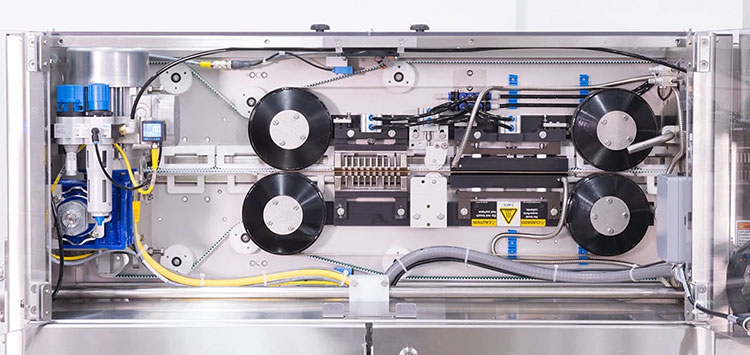

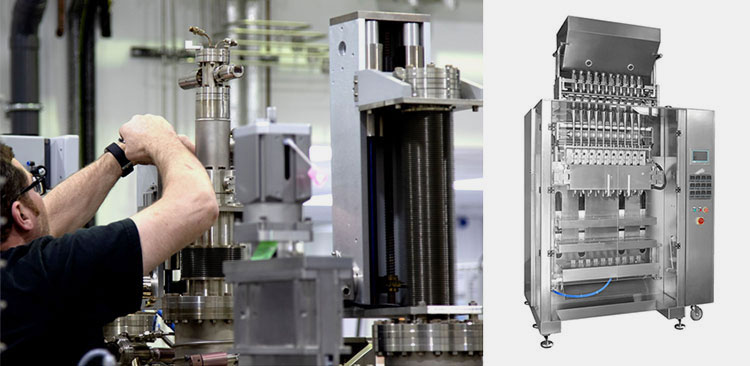

Automated honey processing

Automated honey processing-Picture courtesy: foodtechprocess.com

One of the important innovations regarding this is the automated honey processing. Honey is extracted from the combs by automated extractor systems. This efficiently extract honey without damaging the hive structure.

To uncapping the hive and to handle the honey the process, there are robotic arms and laser uncapping system. This not only ensures hygienic management but also reduce the labor costs and less chances of human intervention.

AI-based adulteration detection

AI-based adulteration detection-Picture courtesy: phys.org.com

Honey purity is very necessary. A small percentage of impurity can result in many problems in honey such as fermentation. Manufacturers are turning to the AI-based detectors that detect the impurities, chemicals, and adulterants with accuracy by creating their thermal images. This ensures the quality of honey and customer’s trust.

Smart beekeeping

Smart beekeeping-Picture courtesy: planetbee.org.com

In rearing bees, there are chances of their colony death, increase or decrease in moisture or temperature. But technological innovation has minimized these problems. The automated monitoring system checks the temperature, bees’ activity, hive weight, moisture and other factors. This precise beekeeping increases the honey production.

Sustainable practices

Sustainable practices-Picture courtesy: milkwood.net.com

Sustainability is the key to the honey production innovations. Biodegradable hive materials, minimal use of non-biodegradable materials, and also making honey in farms that encourage a green and balanced ecosystem. Manufacturers are also investing in solar based programs to make honey production more eco-friendly.

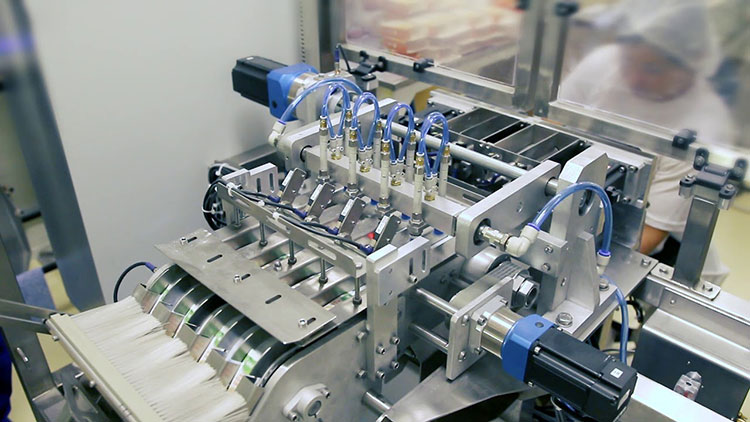

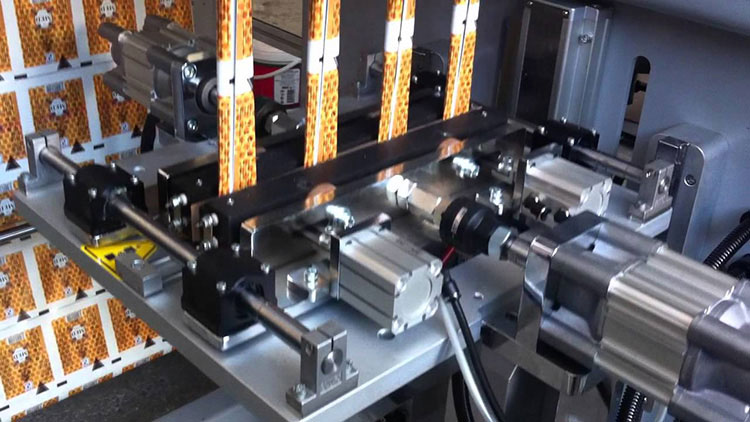

Robotic packaging

A clean and germs free packaging is the key requirement in producing a high-quality product. An innovation of robotic handling of bottling and sealing of honey in different size and shapes of packaging materials is done that ensures no material wastage, precise dosing and batch consistency.

10.What are the quality control measures in honey manufacturing?

Quality control measures is necessary to make your product standard high by providing safety and compliance with food regulatory authority. Followings are the quality control measures in honey manufacturing.

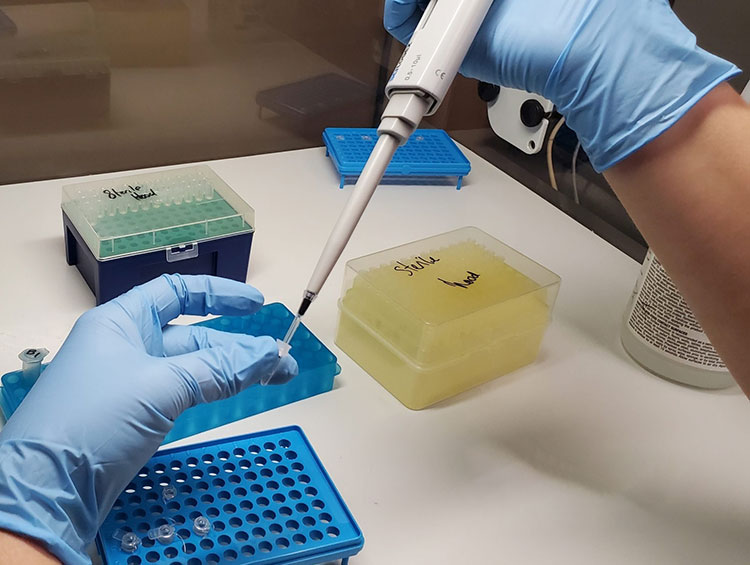

Contamination test

Contamination test-Picture courtesy: bootlegbiology.com

Honey testing from contamination is important as you may have to export it, and if rinsed, the brand image can deteriorate globally. However, honey must be tested for the microbes, any heavy metals, pesticides and other antibiotics by conducting residue analysis and lab culture.

Moisture testing

Moisture testing

To maintain moisture content is necessary because moisture can ferment or spoil the honey if its level is high; more than 18% water content. So, refractometer must be used to regularly check honey and prevent it from fermentation.

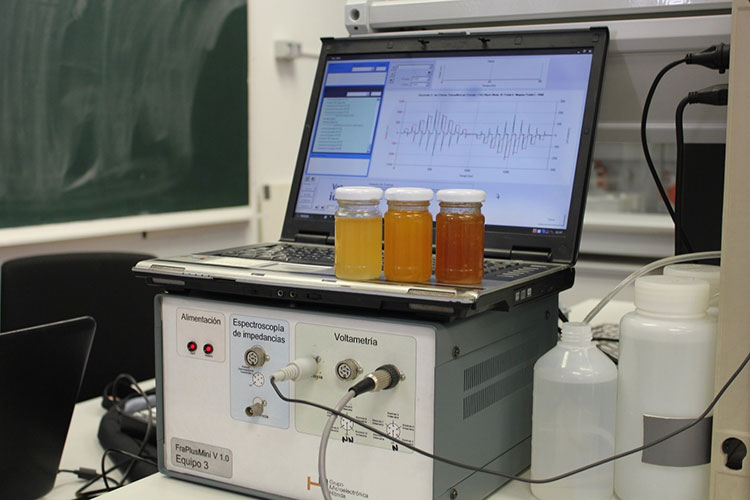

Adulteration test

Adulteration test-Picture courtesy: news-medical.net

To test purity of the honey, adulteration test is conducted. Some of the manufacturers add water, sugar syrup to increase weight of honey. Therefore, tests like HMF and NMR is done to ensure no foreign materials are added.

Batch record

Keeping records can help you to solve the problems arise during or later in the process and also can build a trust connection with the customers. So, keeping the harvesting date, floral origin, lab results and other information is important.

Origin verification

Pollen test-Picture courtesy: fifebeekeepers.com

To label the information on the containers, origin of honey is necessary, that is the basic information customers looking for. Therefore, the pollen tests are conducted by which you can know its origin both botanical and geographical.

Conclusion

To conclude this FAQ guide, you came to know that world has come to the brink of technological innovation even in honey manufacturing, technology is used; from traditional beekeeping to the packaging. Every step is chained with clean, safe, innovative equipments, and careful testing. If you are dealing with any kind of honey, no step or testing can be ignored, a little negligence can waste your entire batch and will not comply with food safety. If you are looking for any kind of machinery, then you are welcome to this website where you can contact and buy a high-quality machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Honey Manufacturing: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours